1-3-6 Safety Check after Repairment

- 04 -

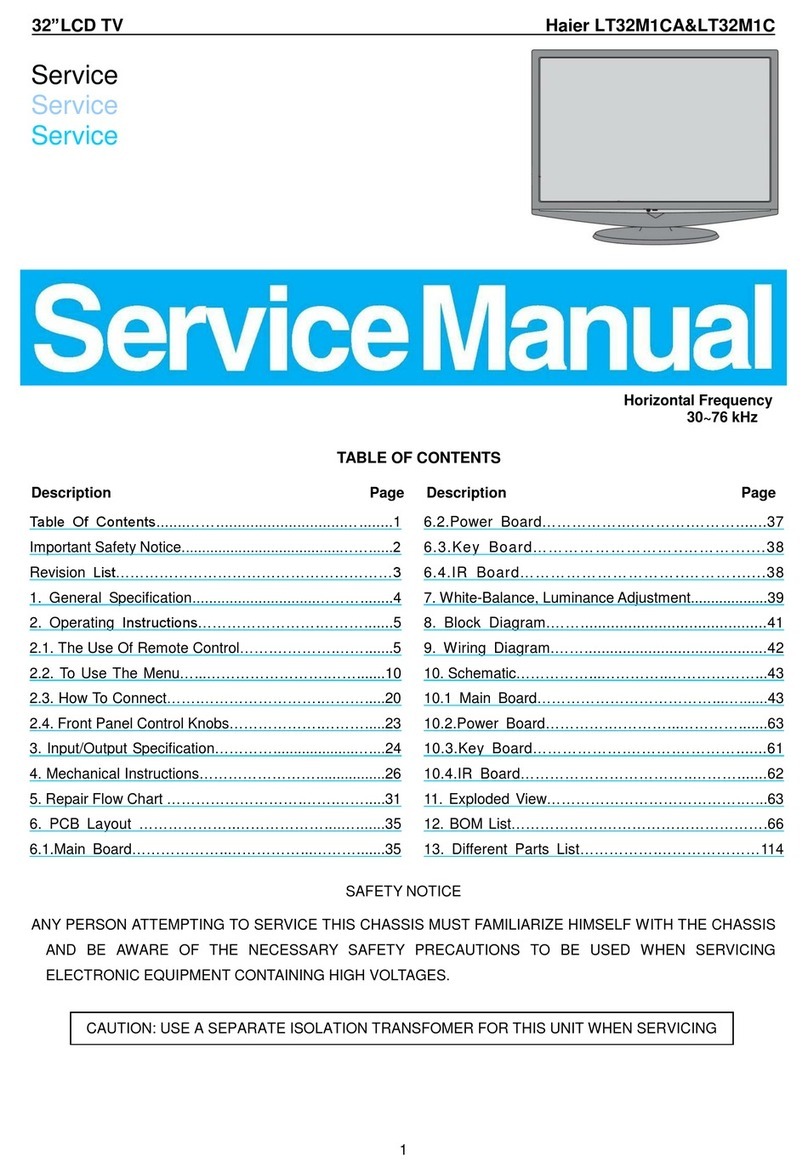

Service Manual

Model No.:

&RQ¿UPWKDWWKHVFUHZVSDUWVDQGZLULQJZKLFKZHUHUHPRYHGLQRUGHUWRVHUYLFHDUHSXW

in the original positions, or whether there are the positions which are deteriorated around

the serviced places serviced or not. Check the insulation between the antenna terminal or

external metal and the AC cord plug blades. And be sure the safety of that.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power source before;

a. Removing or reinstalling any component, circuit board module or any other receiver

assembly.

b. Disconnecting or reconnecting any receiver electrical plug or other electrical

connection.

c. Connecting a test substitute in parallel with an electrolytic capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity installation of electrolytic

capacitors may result in an explosion hazard.

2. Test high voltage only by measuring it with an appropriate high voltage meter or other

voltage measuring device (DVM, FETVOM, etc) equipped with a suitable high voltage

probe.

Do not test high voltage by "drawing an arc".

5. Do not defeat any plug/socket B+ voltage interlocks with which receivers covered by this

service manual might be equipped.

8VHZLWKWKLVUHFHLYHURQO\WKHWHVW¿[WXUHVVSHFL¿HGLQWKLVVHUYLFHPDQXDO

CAUTION: 'RQRWFRQQHFWWKHWHVW¿[WXUHJURXQGVWUDSWRDQ\KHDWVLQNLQWKLVUHFeiver.

3. Do not spray chemicals on or near this receiver or any of its assemblies.

4. Unless specified otherwise in this service manual, clean electrical contacts only by

applying the following mixture to the contacts with a pipe cleaner, cotton-tipped stick or

comparable non-abrasive applicator; 10% (by volume) Acetone and 90% (by volume)

isopropyl alcohol (90%-99% strength).

CAUTION:7KLVLVDÀDPPDEOHPL[WXUH

8QOHVVVSHFL¿HGRWKHUZLVHLQWKLVVHUYLFHPDQXDOOXEULFDWLRQRIFRQWDFWVLVQRWUHTXLUHG

Capacitors may result in an explosion hazard.

6. Do not apply AC power to this instrument and/or any of its electrical assemblies unless

all solid-state device heat sinks are correctly installed.

7. Always connect the test receiver ground lead to the receiver chassis ground before

connecting the test receiver positive lead.

Always remove the test receiver ground lead last. Capacitors may result in an explosion

hazard.

9. Remove the antenna terminal on TV and turn on the TV.

10. Insulation resistance between the cord plug terminals and the eternal exposure metal

should be more than Mohm by using the 500V insulation resistance meter.

11. If the insulation resistance is less than M ohm, the inspection repair should be required.

If you have not the 500V insulation resistance meter, use a Tester. External exposure

metal: Antenna terminal Headphone jack