Chapter 4: safety precondition

Please insert the power cord into

special receptacle with rated vol-

tage. Be sure to use single-phase

three pins receptacle. The earthing

terminal of the receptacle must be

earthed reliably. If possible, please

adopt electric leakage protector.

When the machine is normally

using, please put the power plug

at the location easily to be insert-

ed and extracted by hand. Be sure

to pull the plug off when there's

power failure, or the machine is

being moved, cleaned or when it

is idle.

If the power cord is bad, to avoid risk it is required to replace it by the

technicians of our special shop or the after-sale service department.

Keep the pin of the power plug clean.

4

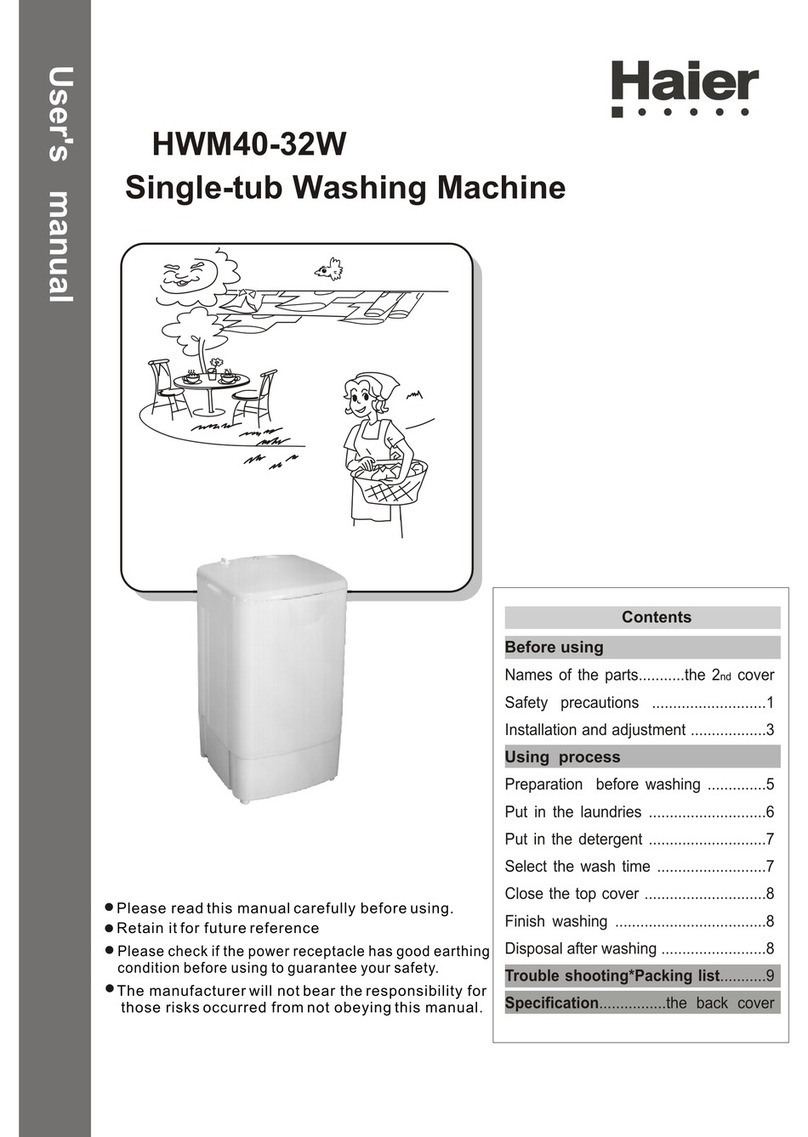

Do not put the machine at damp

place like the bathroom . Never

wash it with water. Do not place

wet laundries on the control panel.

Do not use water hotter than 50

In case the washing machine is installed

on ground with carpet , do not block the

ventilation hole with carpet.

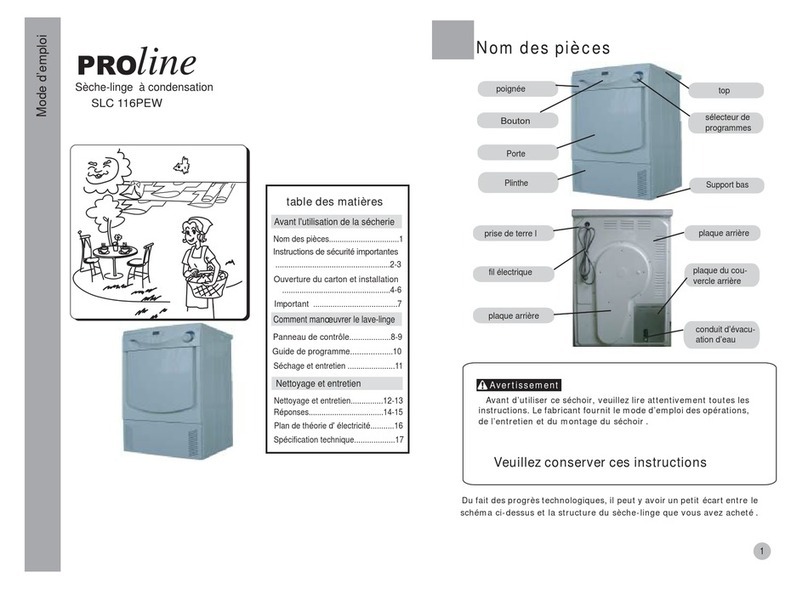

Ventilation hole at

the bottom of the

washing machine

Do not wash water-proof laundries like

the raincoat, bike covers etc. to avoid

abnormal vibrations in spinning.

Do not let the machine share one receptacle

with other electric appliances. If the power

plug is damaged, or the plugging into the

receptacle is loose, do not use the plug any

more.

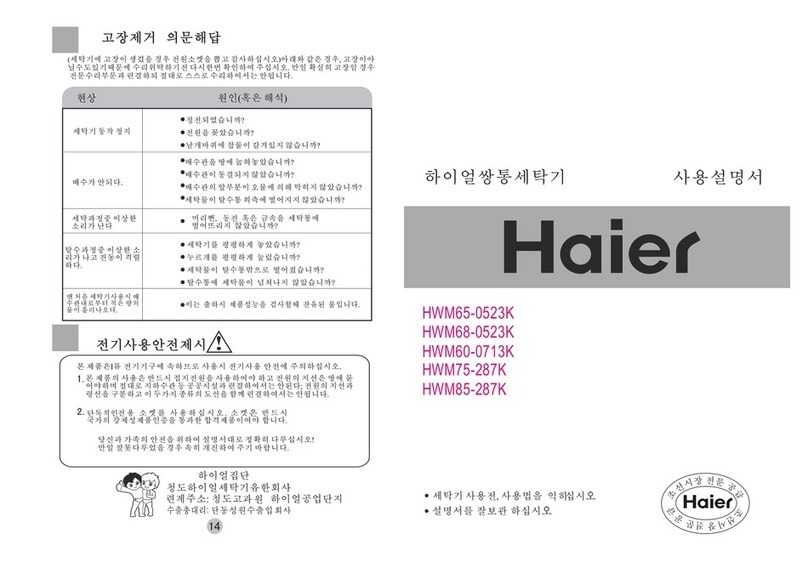

Warning sign

Forbidding sign

Contents marked with that symbol are actions forbidden to perform.

Performing of those actions may result in damage of the machine

or injure the personal safety of the user.

Contents marked with that symbol are related to the safety of the

product and the users.Please operate in strict conformity to the contents.

Service Manual Issue

Rev.

Model NO:LMDR8124/0224PBAB0