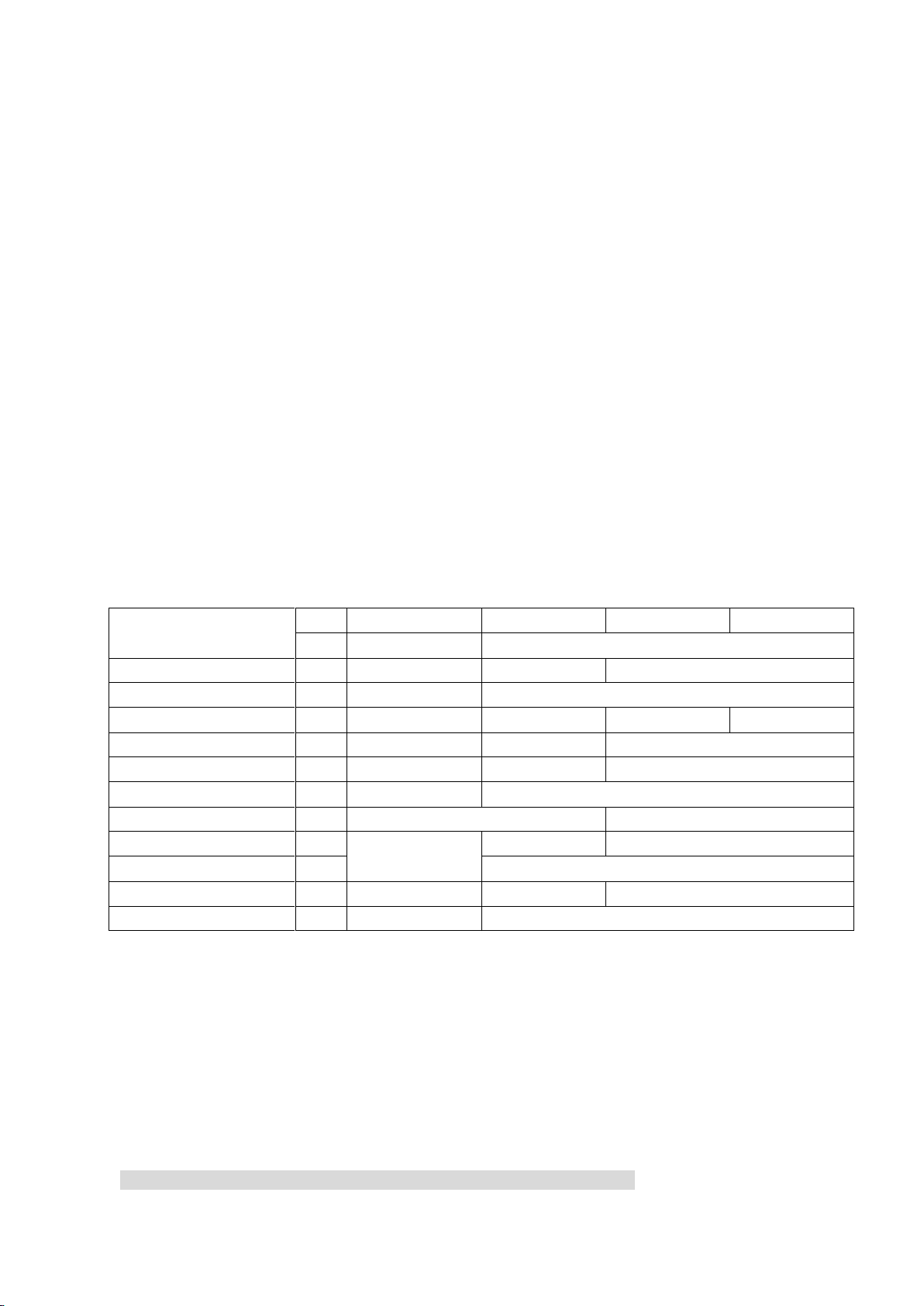

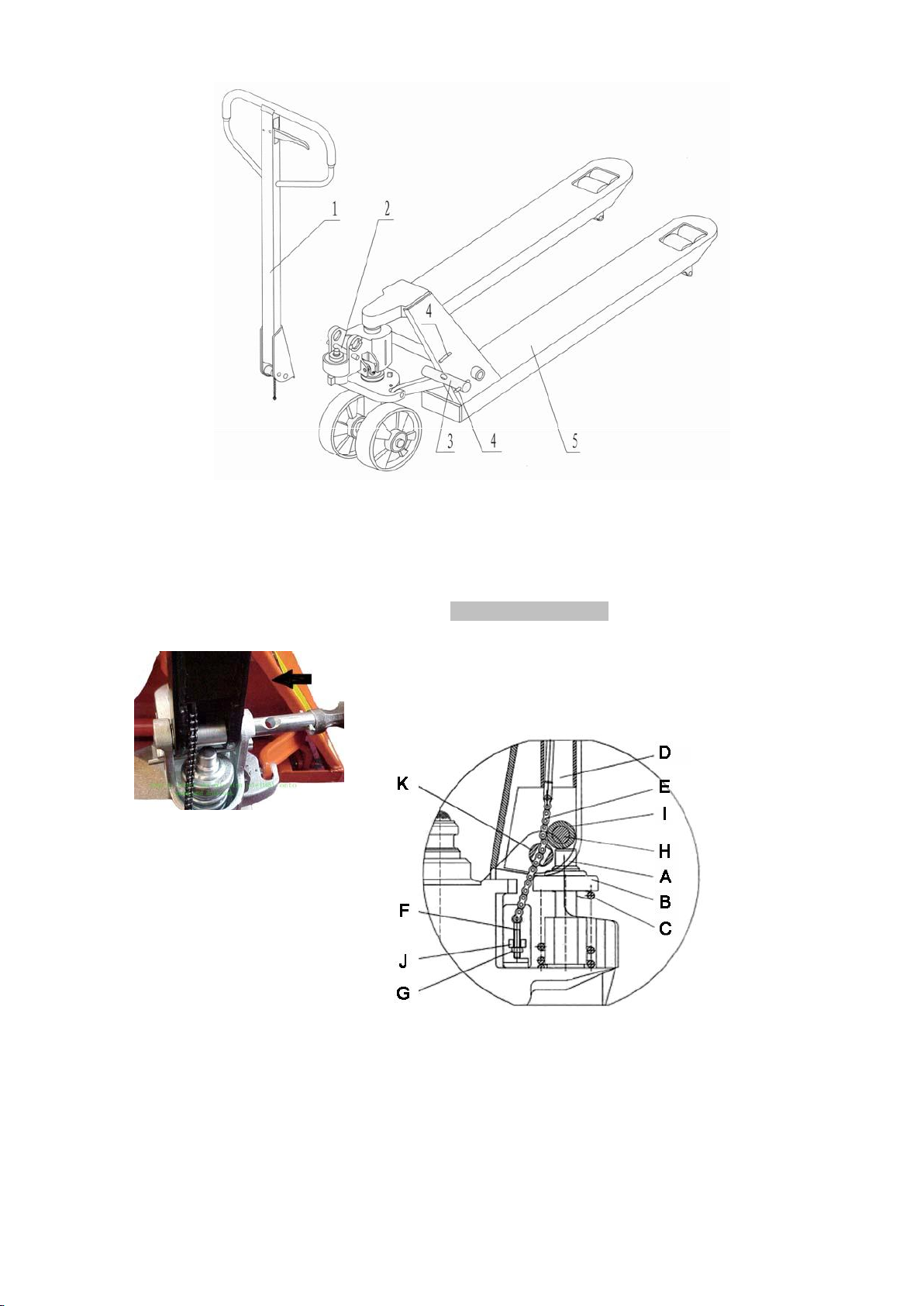

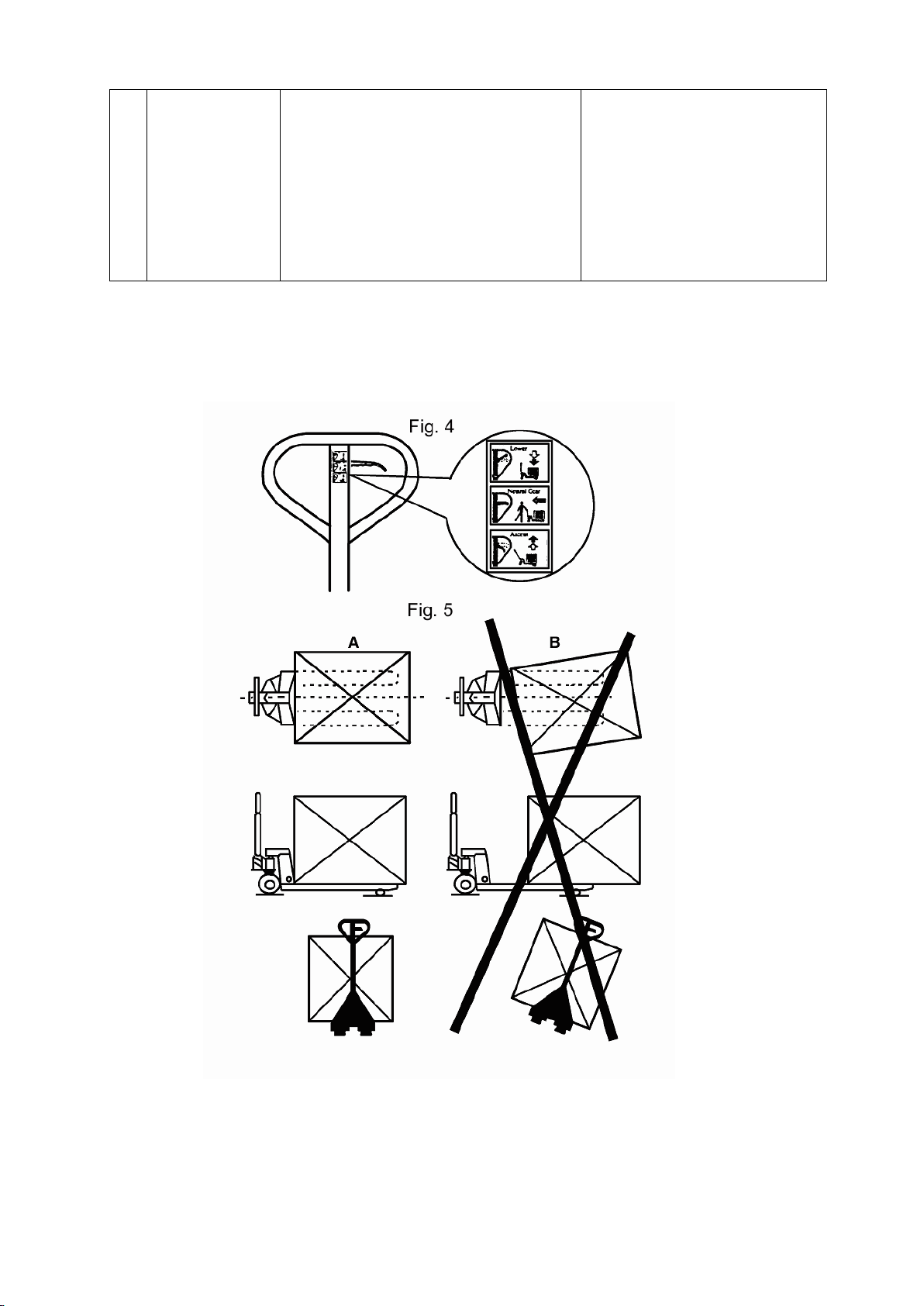

3. TO ADJUST RELEASE DEVICE

On the draw-bar of this pallet truck, you can find the control handle which can be regulated in three

positions :

Raise - handle down

Drive position - handle in center position

Lower - handle up, the lever moves back the drive position when released.

If however they have been changed, you can adjust according to following step:

3.1 If the forks elevate while pumping in the DRIVE position, turn the adjusting nut on the adjusting

bolt or adjusting screw clockwise until pumping action does not raise the forks and the DRIVE

position functions properly.

3.2 If the forks descend while pumping in the DRIVE position, turn the nut or adjusting screw

counter-clockwise until the forks do not lower.

3.3 If the forks do not descent when the control handle is in the LOWER position, turn the nut or

adjusting screw clockwise until raising the control handle lowers the forks. Then check the DRIVE

position according to item 3.1 and 3.2 to be sure the nut or adjusting screw is inthe proper position.

3.4 If the forks do not elevate while pumping in the RAISE position, turn the nut or adjusting screw

counter-clockwise until the forks elevate while pumping in the RAISE position. Then check the

LOWER and DRIVE position according to item 3.1, 3.2 and 3.3.

4. MAINTENANCE

Your pallet truck is largely maintenance-free.

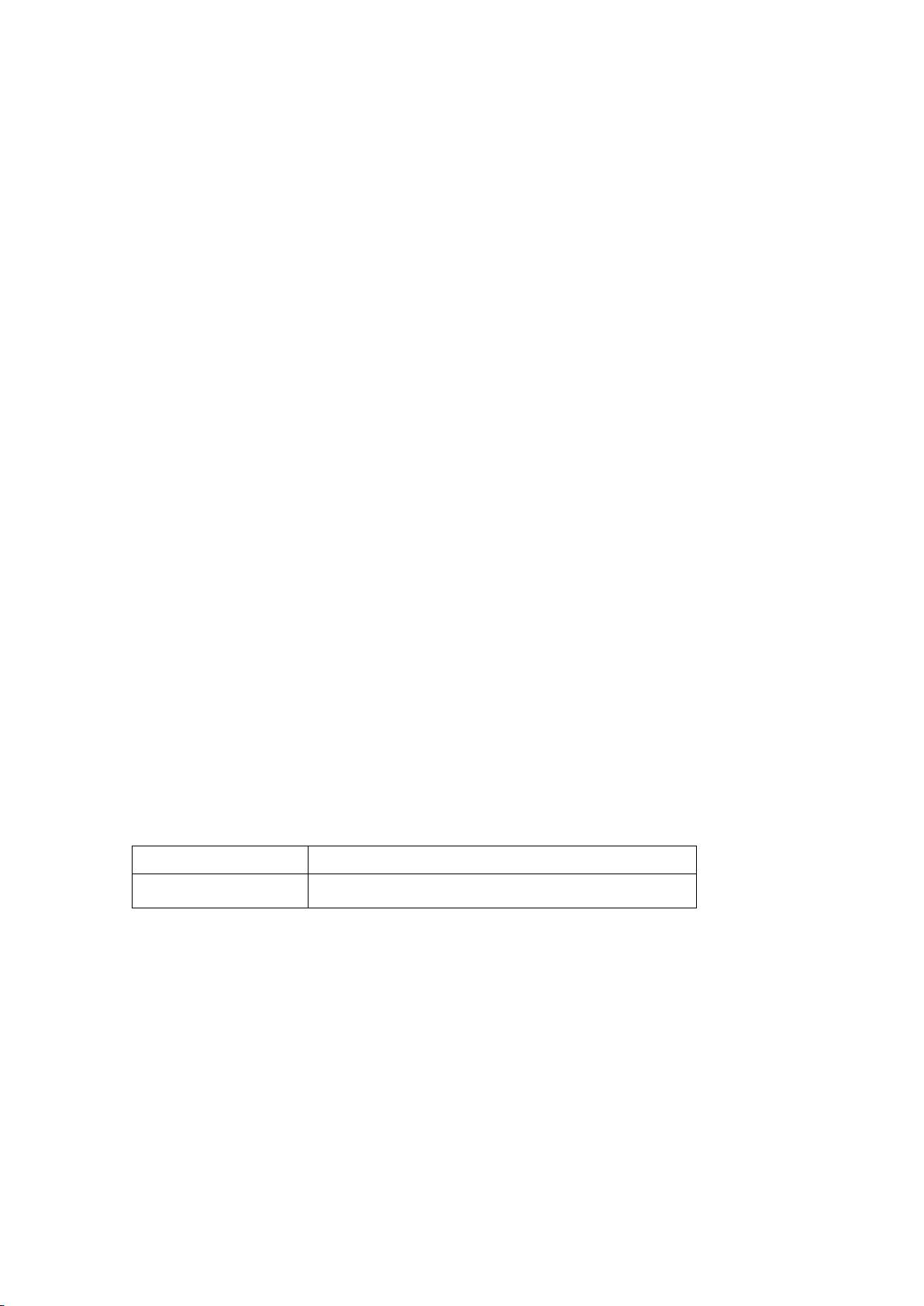

4.1 Hydraulic Oil

Please check the oil level every six months. The oil capacity is about 0.3lt. Use the hydraulic type

oil according to temperature scale below.

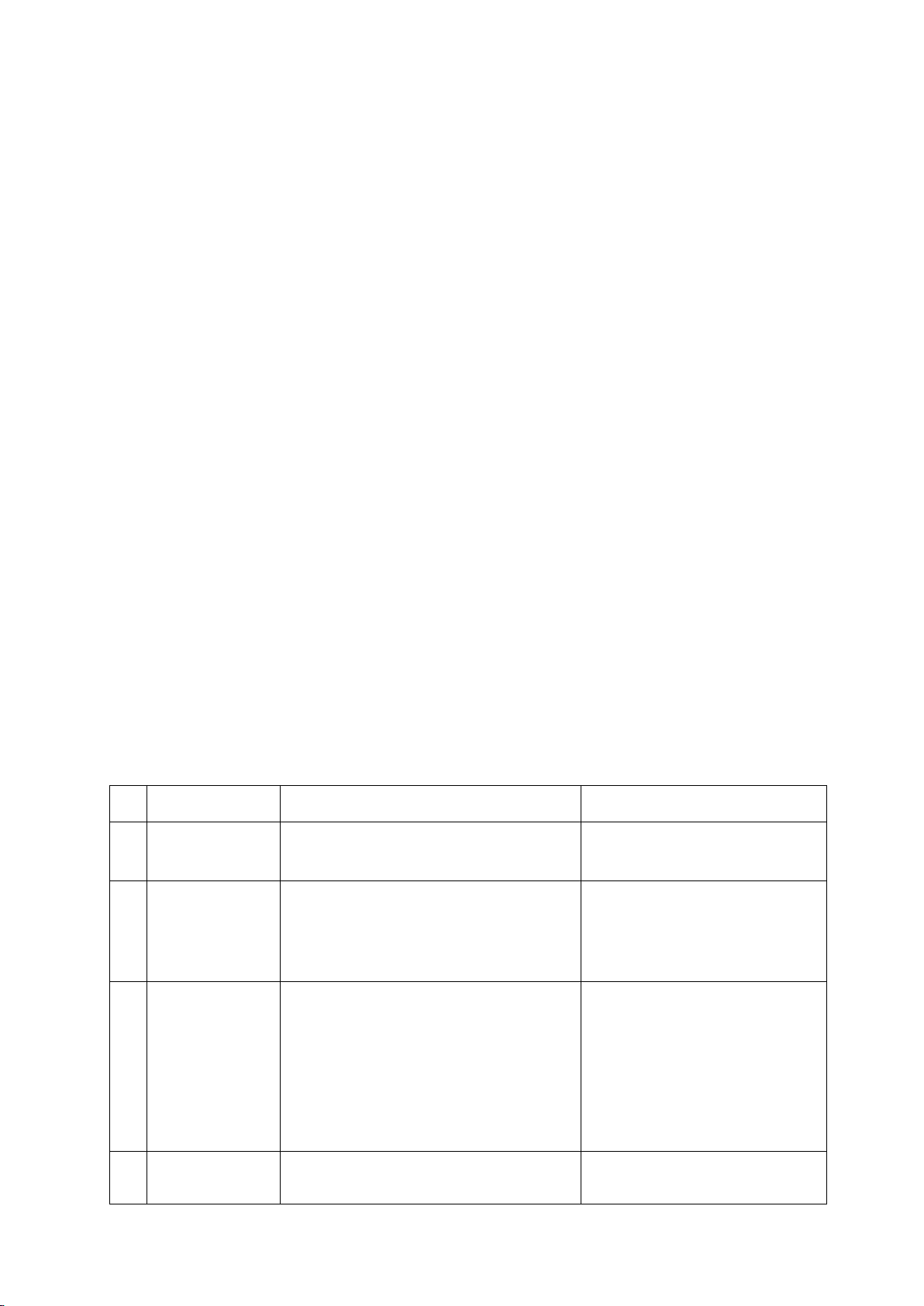

4.2 HOW TO EXPELAIR FROM THE PUMP UNIT

The air may come into the hydraulic oil because of transportation or pump in upset position. It can

cause that the forksdo not elevate while pumping in the RAISE position. The air can been banished

in the following way: let the control handle on the LOWER position, then move the handle up and

down for several times.

4.3 DAILY CHECK AND MAINTENANCE

Daily check of the pallet truck can limit wear as much as possible. Special attention should be paid

to the wheels, the axles, as thread, rags, etc. It may block the wheels. The forks should be

unloaded and lowered in the lowest position when the job is over.