Page 4

WARNING!

NO MODIFICATIONS OR ADDITIONS MAY BE MADE TO THE SMARTFOAM PORPORTIONING SYSTEM

WITHOUT

PRIOR WRITTEN PERMISSION FROM:

HALE PRODUCTS, INC

607 NW 27th Avenue

Ocala, Florida 34475 USA

Telephone: 352-629-5020

FAX: 800-533-3569

❑All electrical systems have the potential to

cause sparks during service. Take care to

eliminate explosive or hazardous

environments during service and/or repair.

❑Toprevent electrical shock always disconnect the primary power source before attempting to service any part of the Hale

Foam system.

❑Toprevent system damage or electrical shock the main power supply wire is the last connection made to the Hale

Foam motor controller.

❑Release all pressure then drain all concentrate and water from the system before servicing any of its component parts.

❑Do not operate system at pressures higher than the maximum rated pressure.

❑Use only pipe, hose, and fittings from the foam pump outlet to the injector fitting, which are rated at or above the

maximum pressure rating at

which the water pump system operates.

❑Hale Foam proportioning systems are designed for use on negative ground direct current electrical systems only.

❑Do not mount radio transmitter or transmitter cables in direct or close contact with the SmartFOAM control unit.

❑Before connecting the cord sets and wiring harnesses, inspect the seal washer in the female connector. If the seal washer

is missing or damaged, water can enter the connector causing corrosion of the pins and terminals. This could result in

possible system failure.

❑Always disconnect the power cable, ground straps, electrical wires and control cables from the control unit or other

Hale Foam system

equipment before electric arc welding at any point on the apparatus Failure to do so could result in

a power surge through the unit that

could cause irreparable damage.

❑DO NOT connect the main power lead to small leads that are supplying some other device, such as a light bar or siren.

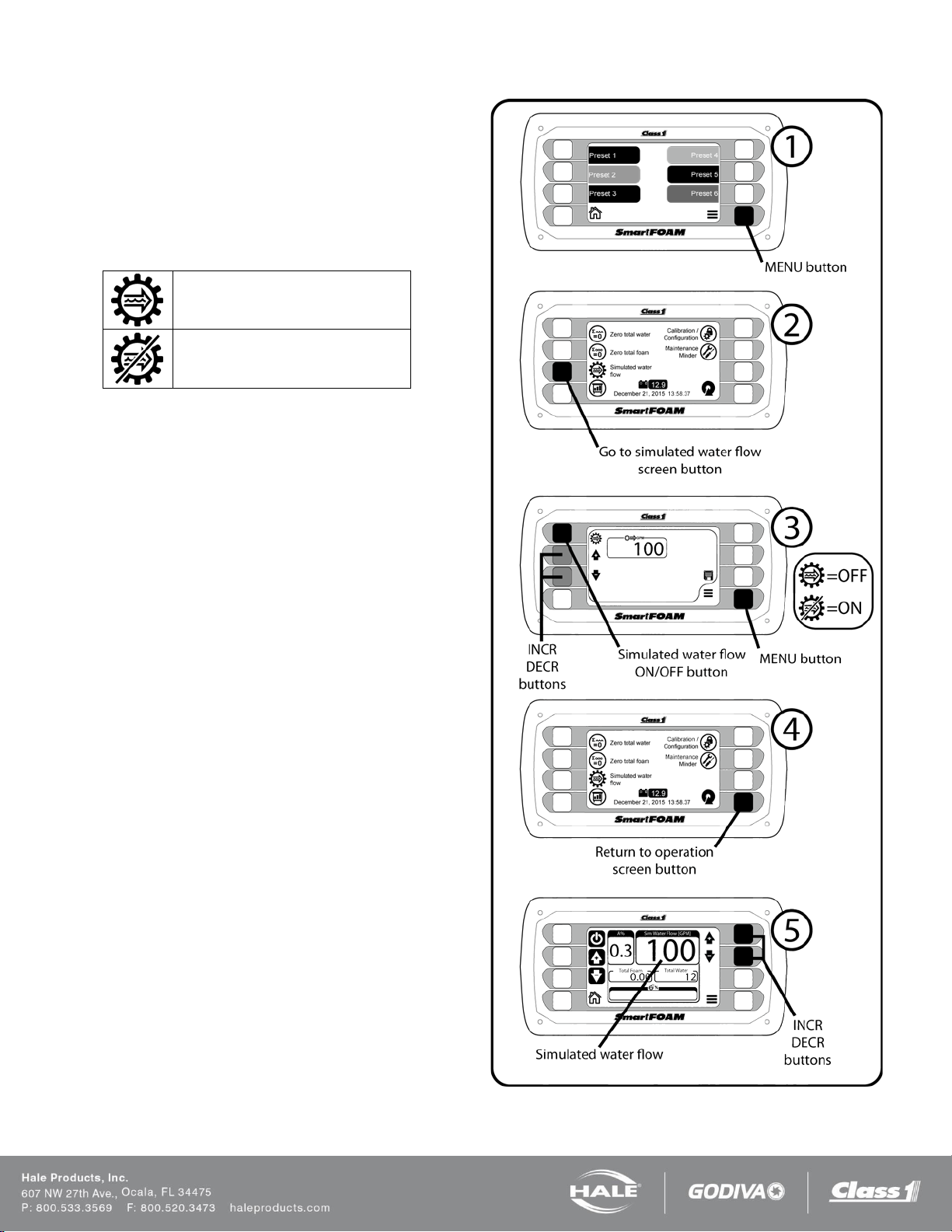

❑When operating the Hale SmartFOAM in Simulated Flow mode, an outlet for the foam concentrate must be provided to

prevent excessive pressure build up in the discharge piping or hoses.

❑Make sure the foam tank and foam concentrate suction hoses are clean before making final connection to foam pump.

If necessary, flush tank and hoses prior to making connection.

❑Check all hoses for weak or worn conditions after each use. Ensure that all connections and fittings are tight and

secure.

❑Ensure that the electrical source of power for

the unit is a negative (–) ground DC system, of

correct input voltage,

with a reserve minimum current available to drive the system.

❑The in-line strainer/valve assembly is a low pressure device and WILL NOT withstand flushing water pressure in

excess of 45 PSI (3 BAR).

❑When determining the location of Hale Foam system components keep in mind piping runs, cable routing and other

interferences that

could hinder or interfere with proper system

performance.

❑Always position the check valve/injector fitting at a horizontal or higher angle to allow water to drain away from the

fitting. This avoids the possibility of sediment deposits or the formation of an ice plug.