SENSITRON

A Halma Company

MT2276E

GALILEO 32

Manual (EN)

P. 9/14

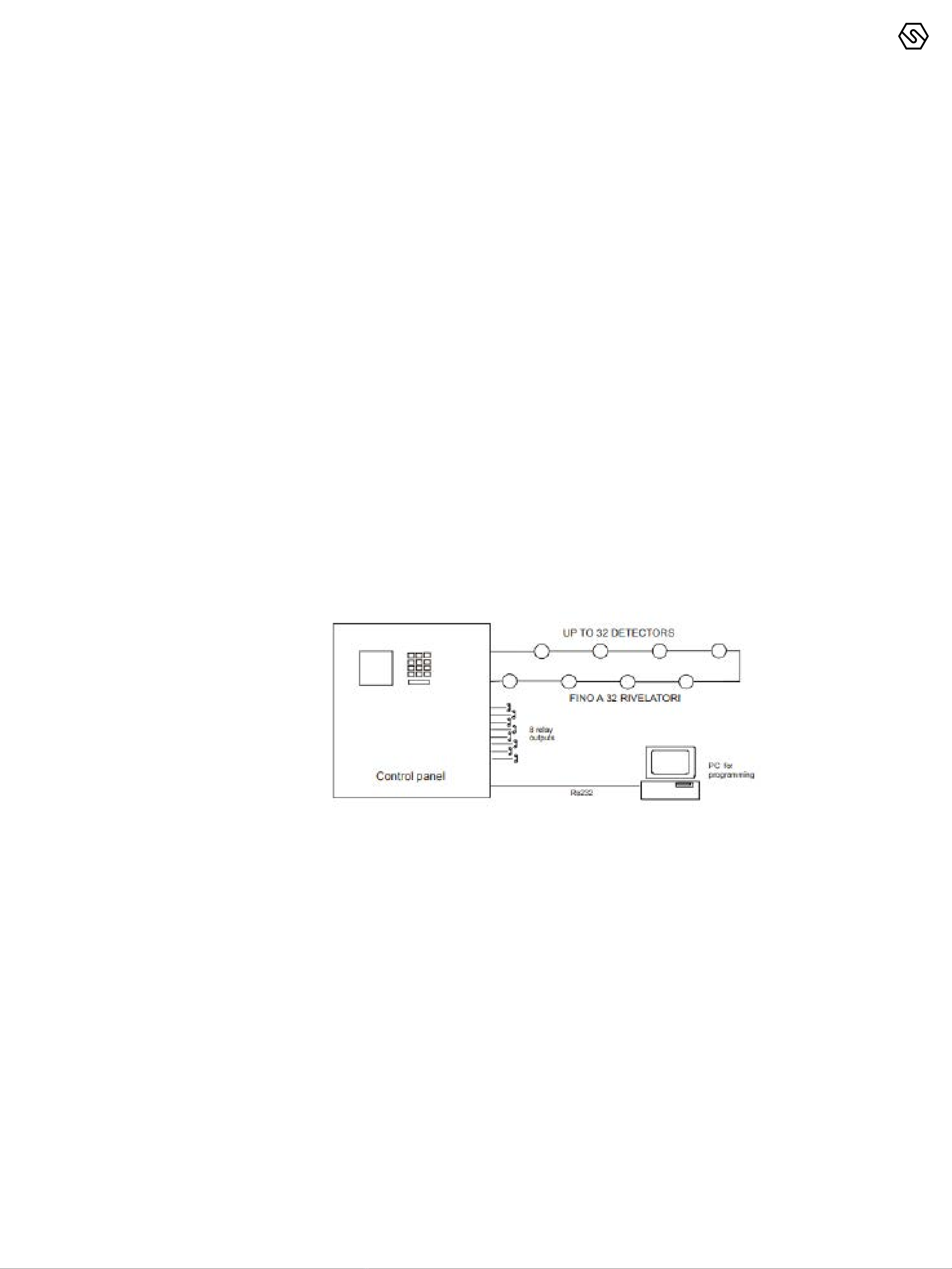

. SERIAL CONNECTION TO A PERSONAL COMPUTER

The control panel can be connected to a Personal Computer using the RS485

serial port, to permit initial programming.

Below the connection to the Personal Computer.

Figure 2.7

Personal computer connection

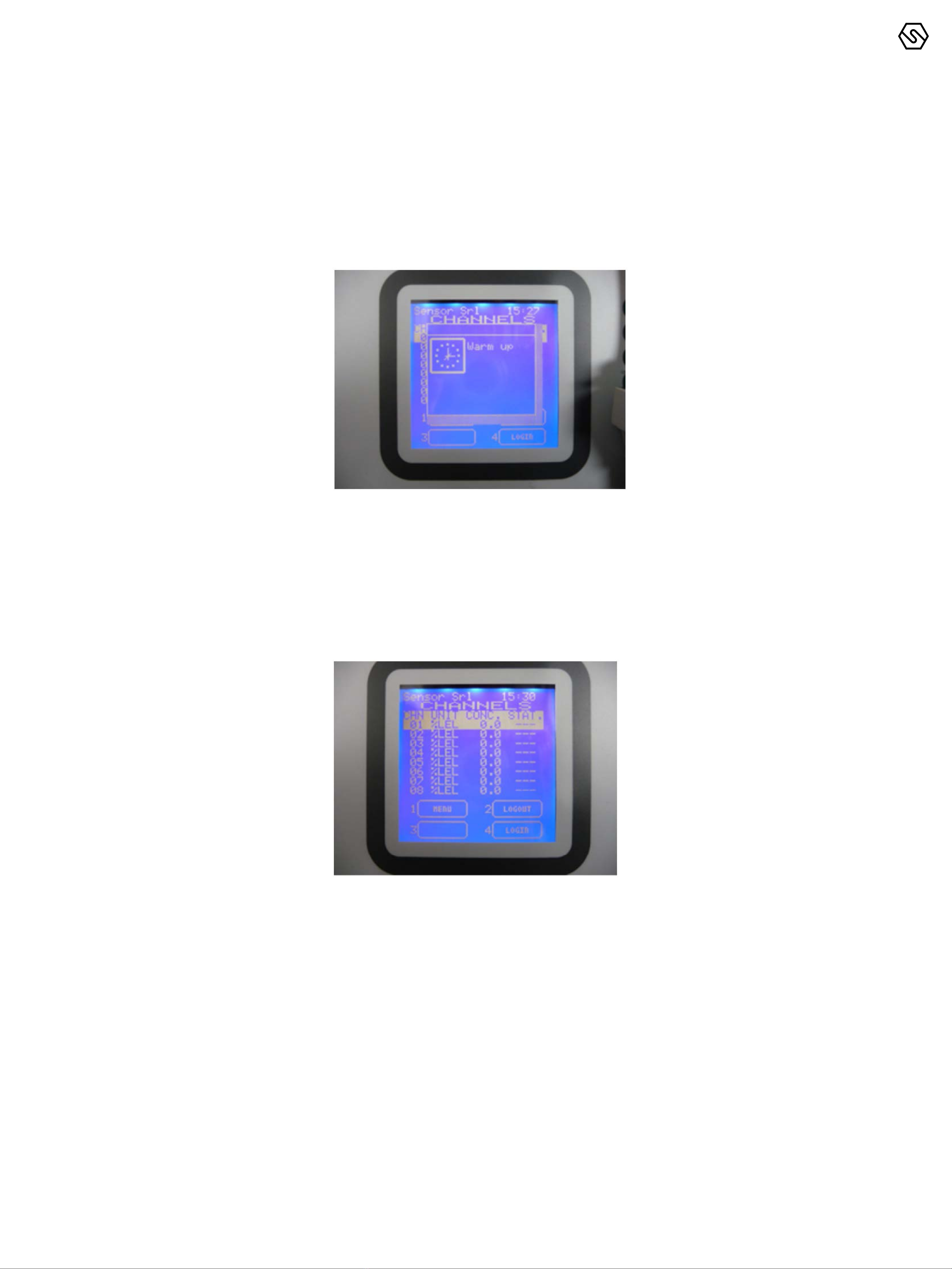

3. System power up

and operation

The chapter explains the procedures for the operation, the commissioning and

the maintenance of the control unit Galileo 32.

For the programming of the Galileo 32 control panel the PC software is required.

The communication between the user and the central unit is done by means of

an LCD display. In the various system states, various screens will be shown on

display. A few general rules apply at any level as follows:

- Should there is a list displayed, scrolling through may be done using

the UP/DOWN and LEFT/RIGHT arrow keys. Once a selection has been

made, in some menus, pressing ENTER key will switch to a more

detailed view of that particular selection.

All the arrow keys, UP/DOWN, LEFT/RIGHT are being used also to

move through the parameter under change fields.

At any display level, pressing the ESCAPE key instead will switch back

to the previous view. Pressing twice the ESCAPE key will take back to

the main screen.

The same, at any display level, should the keys are not pressed for

more that 3 minutes, the view will automatically switch back to the

main window of the Normal mode.