Safety precautions

7100.006204 PS17 Instruction manual 408.04.19

1 Safety precautions

1.1 Appropriate use

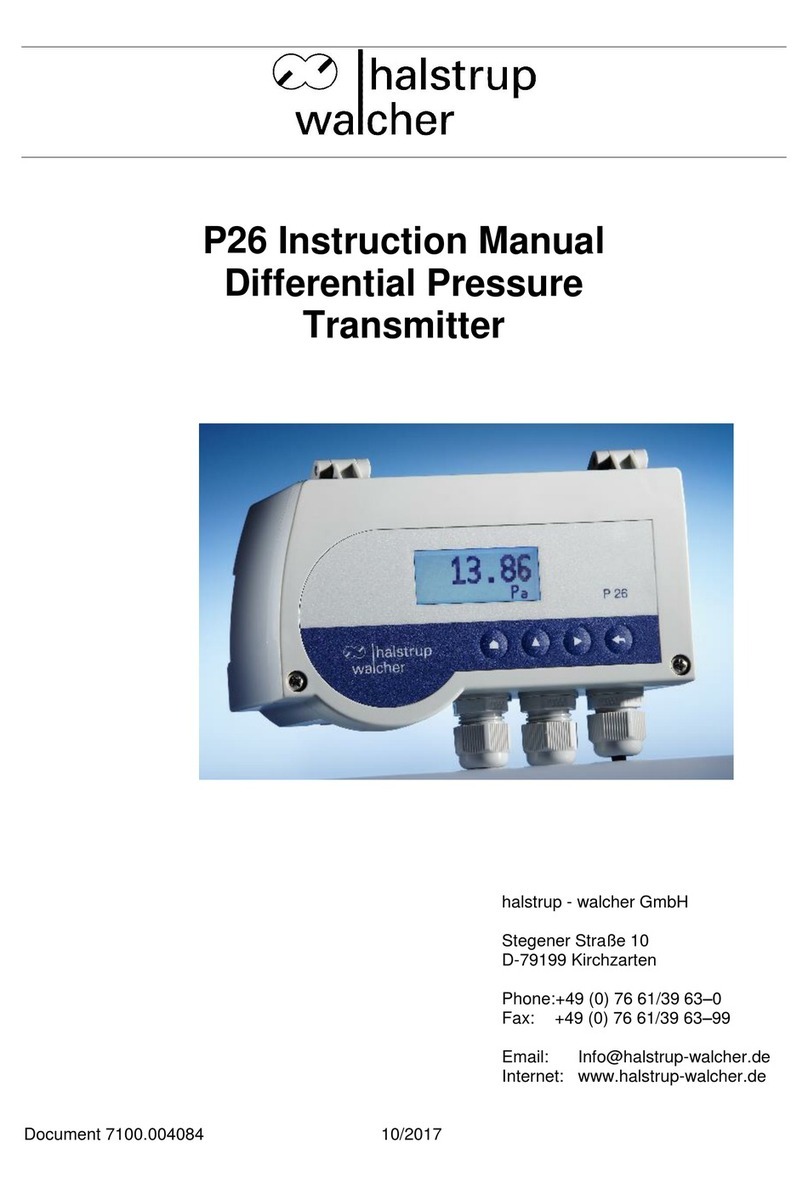

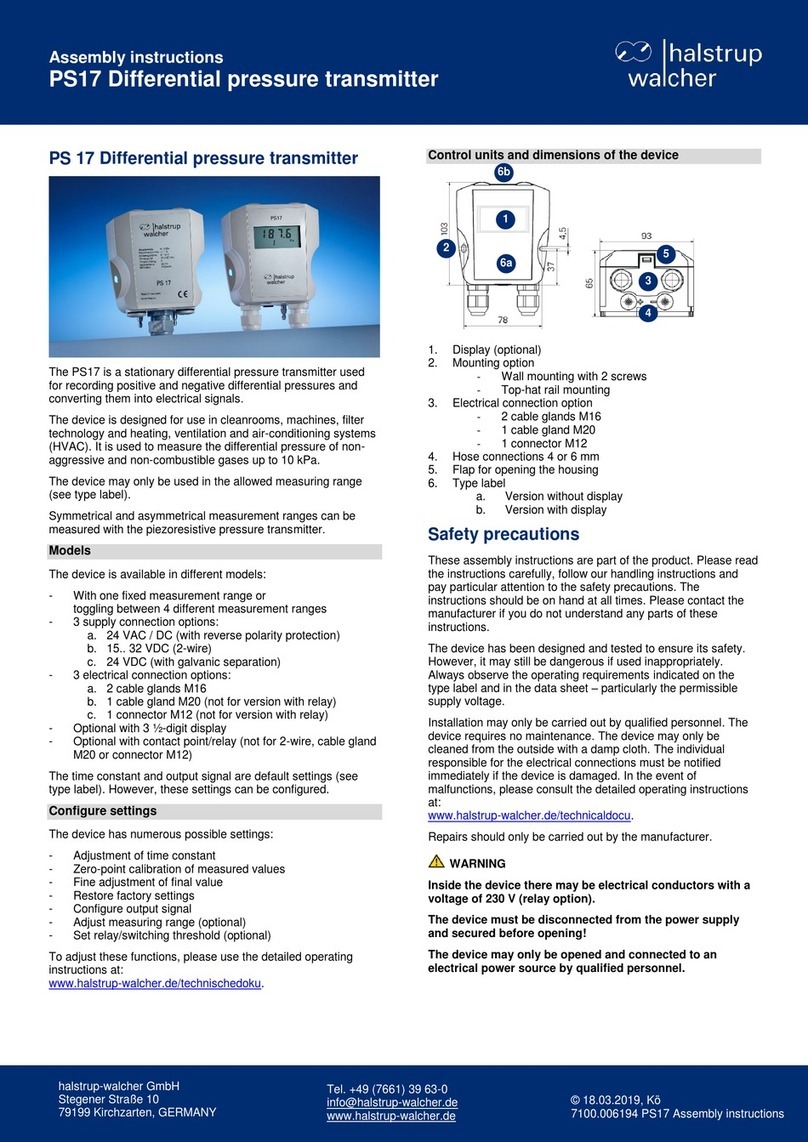

The PS17 differential pressure transmitter is designed to measure differential pressure in

cleanrooms, machines, filter technology and heating, ventilation and air-conditioning

systems (HVAC). It is used to measure the differential pressure of non-aggressive, non-

combustible gases up to a pressure of 10 kPa in non-explosive environments.

Always observe the operating requirements indicated on the type label and the data sheet –

particularly the permissible supply voltage.

The device may only be handled as indicated in this manual. Modifications to the device are

prohibited. The manufacturer is not liable for damages caused by improper use or failure to

follow these instructions. Violations of this type render all warranty claims null and void.

Repairs should only be carried out by the manufacturer. The device may only be cleaned

from the outside with a damp cloth.

1.2 Warning symbols

The device has been designed and tested to ensure its safety. However, it may still be

dangerous if used inappropriately. Precautions must be taken to prevent the device being

used incorrectly by mistake. This device requires no maintenance. The device must be

installed by trained technical personnel.

The following warnings are used in this instruction manual:

WARNING

This warns you of a potential hazard that could lead to serious bodily injury up to and

including death if the corresponding instructions are not followed.

2 Storage and transportation

Do not close the pressure inlets during shipping. Changes in barometric pressure may

damage devices with low measurement ranges.

In addition, ensure that the device is stored at the correct temperature (see data sheet).

3 Disposal

The electronic components of the device contain environmentally hazardous materials and

materials that can be reused. The device must therefore be sent to a recycling plant when

you no longer wish to use it. Compliance with the environmental codes of your country is

essential.