Carbon Film

Installation Instructions

Page 8

1. Electric underfloor heating is designed to run at low temperatures and can have a slightly slower warm-up time than

conventional heating. This can be countered by using the features of the programmable thermostat instead of

switching the system on or off.

2. If installed in new buildings and especially conservatories, the heating period may be affected by the moisture con-

tent within the building. All new floor constructions and new buildings should be fully dried out before fitting wood,

engineered wood or laminate flooring.

3. The carbon film heating system is primarily designed to heat wood, engineered wood or laminate flooring. With such

materials it is important to control the temperature to which they are heated. The industry standard for most wood

flooring products is 27°C. Be aware that the carbon film heating system is capable of heating above this tempera-

ture and is only limited by the thermostat and the temperatures that it is set to operate to.

Notes

Electrical Notes

To satisfy the requirements of an acceptable British Standard a double sheathed single core cable to BS.6004 must be

used under floors. All our cold cables comply to this standard.

Each individual heating element is designed to accommodate a current carrying capacity of up to 10Amps and should be

connected in parallel at the junction box.

Consideration must be given by the electrical contractor in respect of the individual heating circuit ratings relative to the

thermostat rating, circuit breakers, interconnecting cable sizing and switched contactors where the load of the heating

system exceeds the rating of a single thermostat. Good wiring practice must be observed and the wiring must comply

with the IEE 16th edition regulations.

The electrical installation must incorporate a 30mA RCD Protection

Trouble shooting and FAQ’s

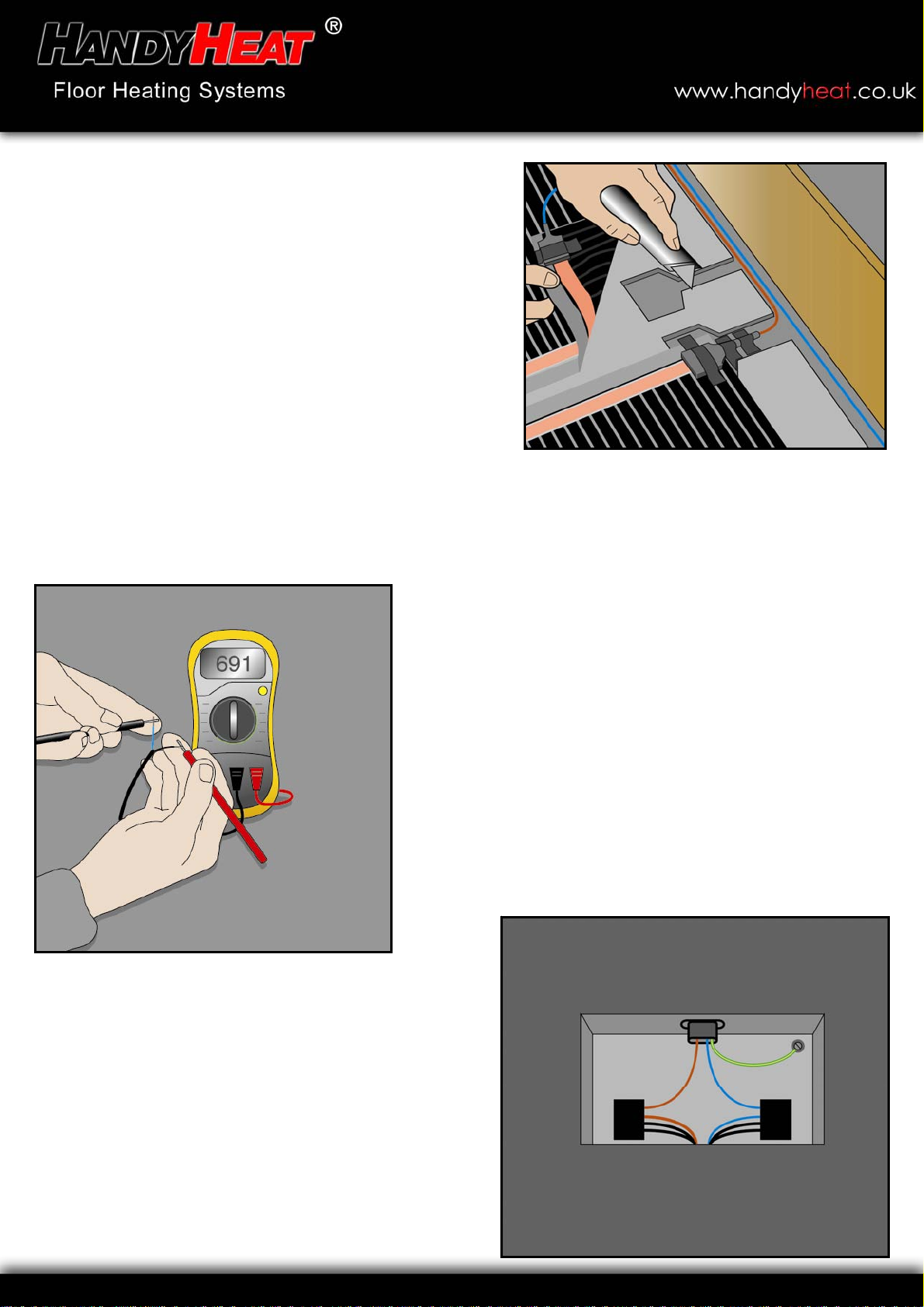

Q. When I perform the resistance test on the heating element I cannot get a reading.

A. Check that the test equipment you are using is set to read Ωand that both the inner and outer cable insulation

sheaths have been removed.

Q. What size cable should be used to connect the thermostat to the junction box?

A. The size of the cable will vary depending upon the electrical load required for the heating system. Therefore this ca-

ble needs to be correctly sized by the electrician.

Q. The heating elements are slightly too long, can they be cut?

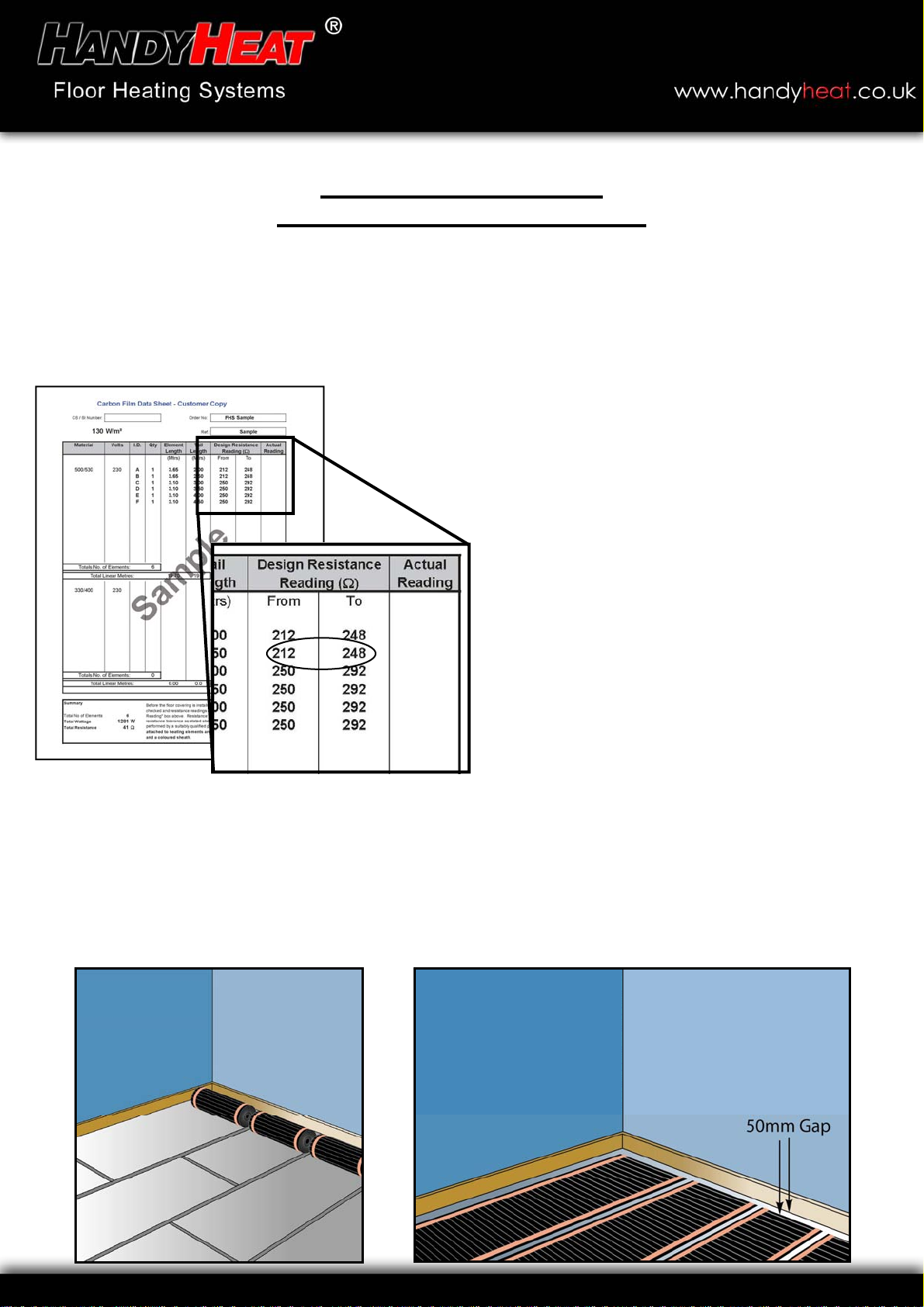

A. Yes. The element should be cut across it’s width, along a clear section, in line with the cutting marks on either edge

of the element. Once cut, the ends of the copper conductors need to be sealed either re-using the green stickers

from the end of the off-cut or use electrical insulation tape.

Q. Can the elements be overlapped?

A. Under no circumstances should the heated areas of the elements be overlapped. Only the clear spoils at the edge

of the element can be over lapped

For help and advice regarding this product, please contact the Floor Heating Helpline: 0870 199 7842

These instructions are correct at time of writing