9 of 32 © 2015 Watts Water Technologies

Phase 2 - Electrical Rough-in

To prevent the risk of personal injury and/or death, make sure power is not

applied to the product until it is fully installed and ready for final testing. All

work must be done with power turned off to the circuit being worked on.

STEP 2.1:

Circuit Breaker (Overcurrent Protection)

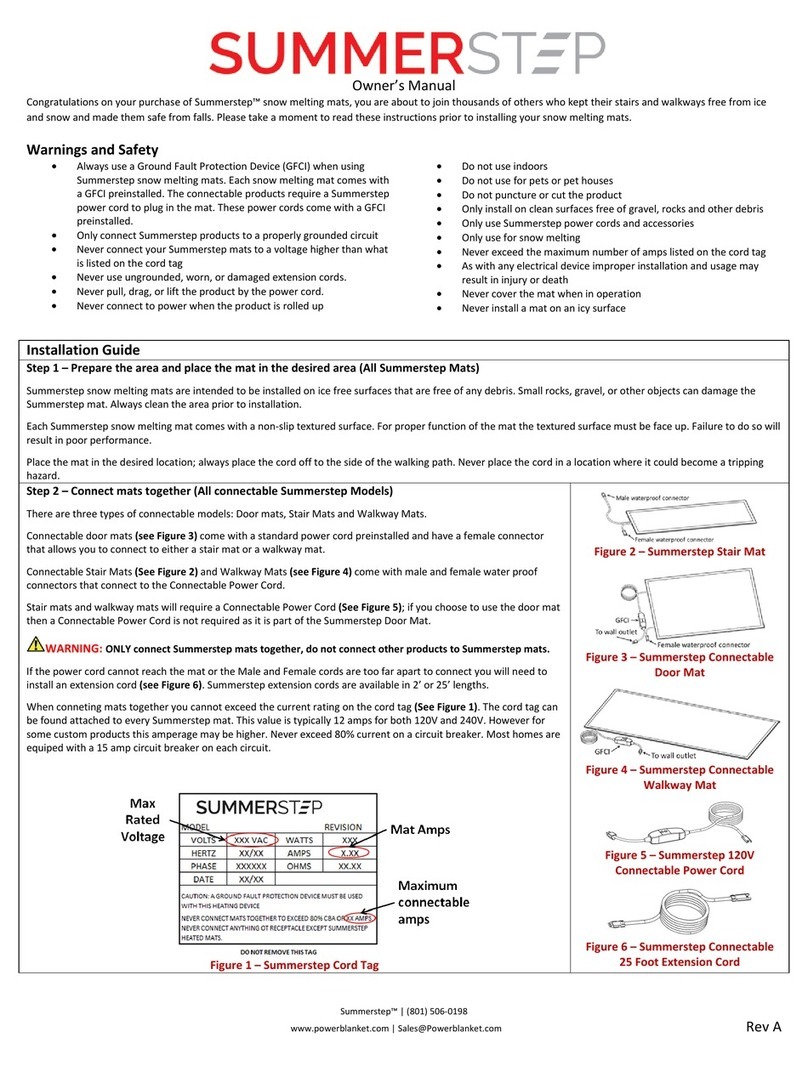

TapeMat(s) must be protected against overload by a circuit breaker. GFCI type (ground fault

circuit interrupter) or AFCI type (arc-fault circuit interrupter) breakers may be used if desired,

but are not necessary when using SunStat controls with integral GFCI

The rating of the breaker (see Table 5) is determined by the amp draw of the heating mats.

Add the amp ratings of all mats to be connected to the SunStat control (see Table 2 or the

Nameplate Label on the mat). If the total is less than 12 amps, use a 15 or 20 A breaker

(preference is 15 A). If the total is between 12 and 15 amps, use a 20 A breaker. If the total

is over 15 A, another circuit will be required with its own breaker and SunStat control.

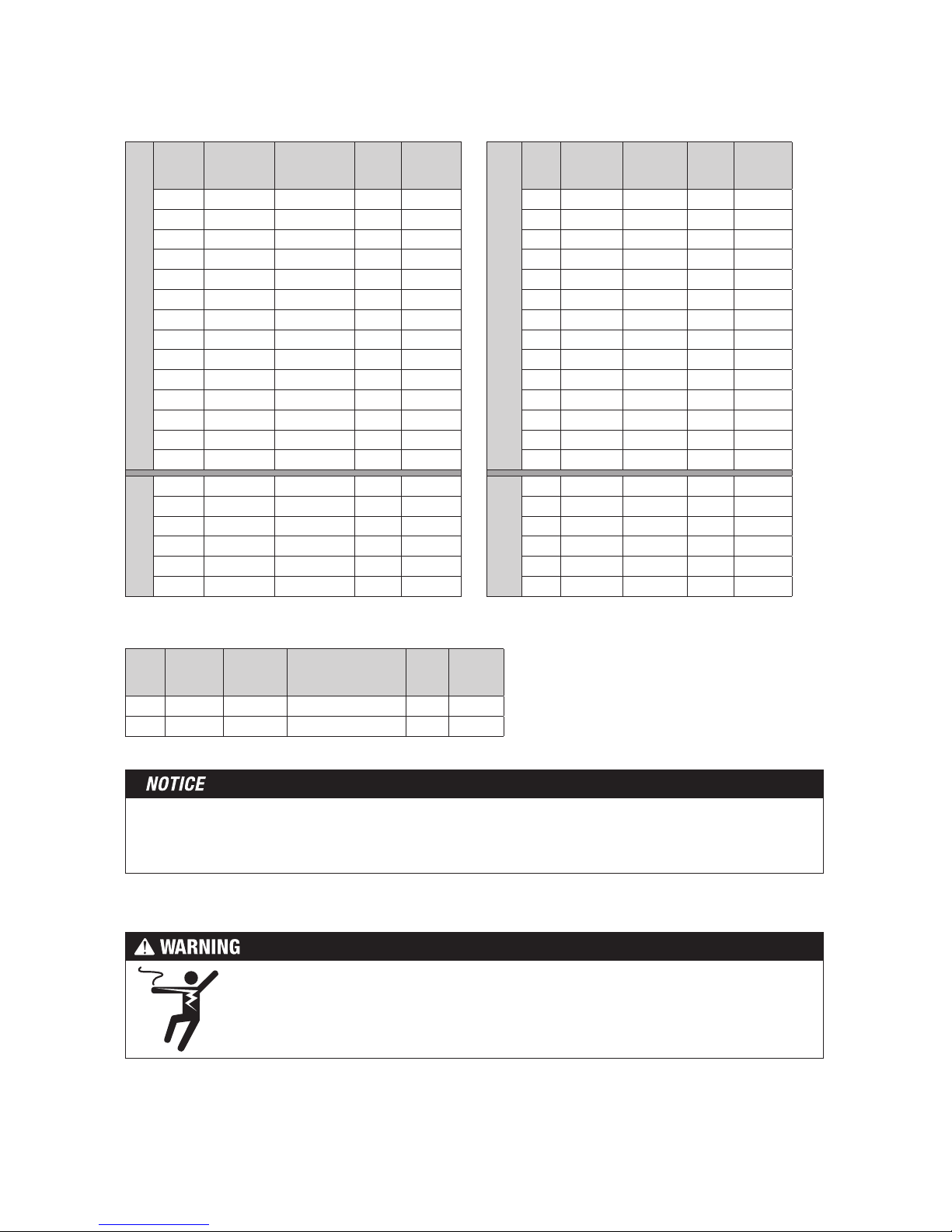

Circuit Breakers and Supply Wire

Mat(s) Supply Wire Breaker

VAC total amps (AWG)* qty type** rating

120 up to 12 amps 14 1SP 15 or 20 A

120 up to 15 amps 12 1SP 20 A

240 up to 12 amps 14 1DP 15 or 20 A

240 up to 15 amps 12 1DP 20 A

* Recommended only. Follow local codes for wire gauge size.

** SP= single-pole, DP=double-pole

Table 5

STEP 2.2:

Install Electrical Boxes

SunStat Thermostat:

Install an extra-deep electrical box for the SunStat thermostat. Follow the instructions included

with the SunStat for complete information on location and wiring. The thermostat must be

located at least 4 feet (1.2 meters) away from shower openings to avoid being exposed to

water or touched by a person while in the shower area.

SunStat Relay:

Install an extra-deep electrical box for any SunStat Relay(s). The SunStat Relay is used when

more than 15 amps must be controlled by one SunStat Thermostat. Follow the instructions

included with the SunStat Relay for complete information on location and wiring.

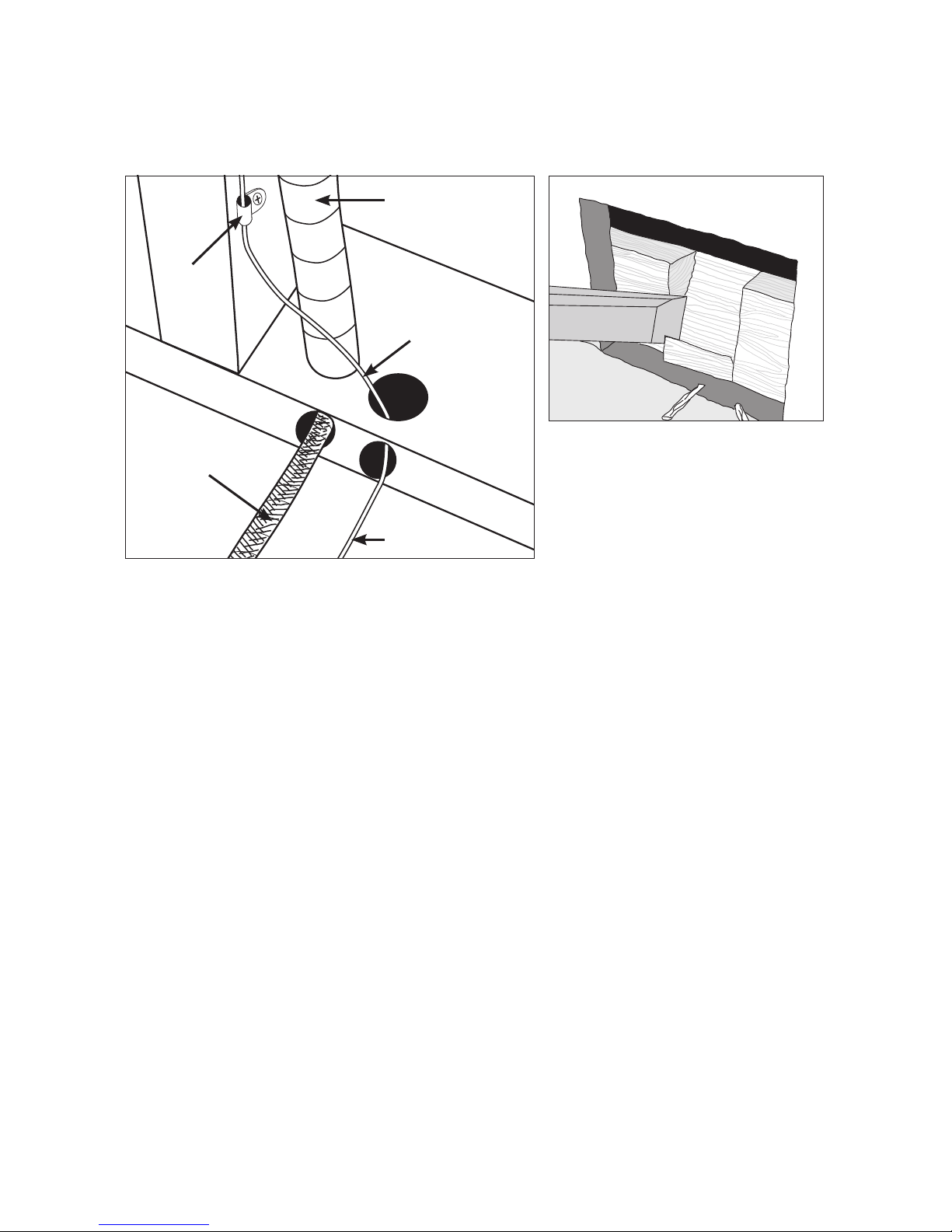

Junction Boxes:

If a mat is to be located so its Power lead is not long enough to reach the SunStat Control or

SunStat Relay directly, a junction box must be installed. Do not attempt to make a connection

to other wiring without a junction box. Use a standard junction box with a cover, mounting

it below the subfloor, in the attic, in the wall, or in another location easily accessible after all

coverings are complete. If the SunStat sensor wire is not long enough to reach the SunStat

Control directly, it may be extended. A junction box may be required by local code to make this

connection. Follow the installation instructions included with the SunStat Control for details.

For construction with an existing wall or where the wall is covered, cut the necessary openings

to mount the electrical boxes listed above. Wait to install the boxes until all wiring is fed into

these locations to make it easier to pull the wire.

It may be possible to tap into

an existing circuit as long as

there is adequate capacity for

the mat(s) and any additional ap-

pliance, such as a hair dryer or

vacuum cleaner. Avoid circuits

which have lighting, motors,

exhaust fans, or hot tub pumps

due to possible interference.