The eLine Brand

Congratulations on choosing your eRibbon underoor heating product from the eLine

range of under oor heating solutions.

The eLine range has been manufactured to exceed all relevant standards and expectations

considering ease of installation and usability through the lifetime of the product.

The eRibbon Product

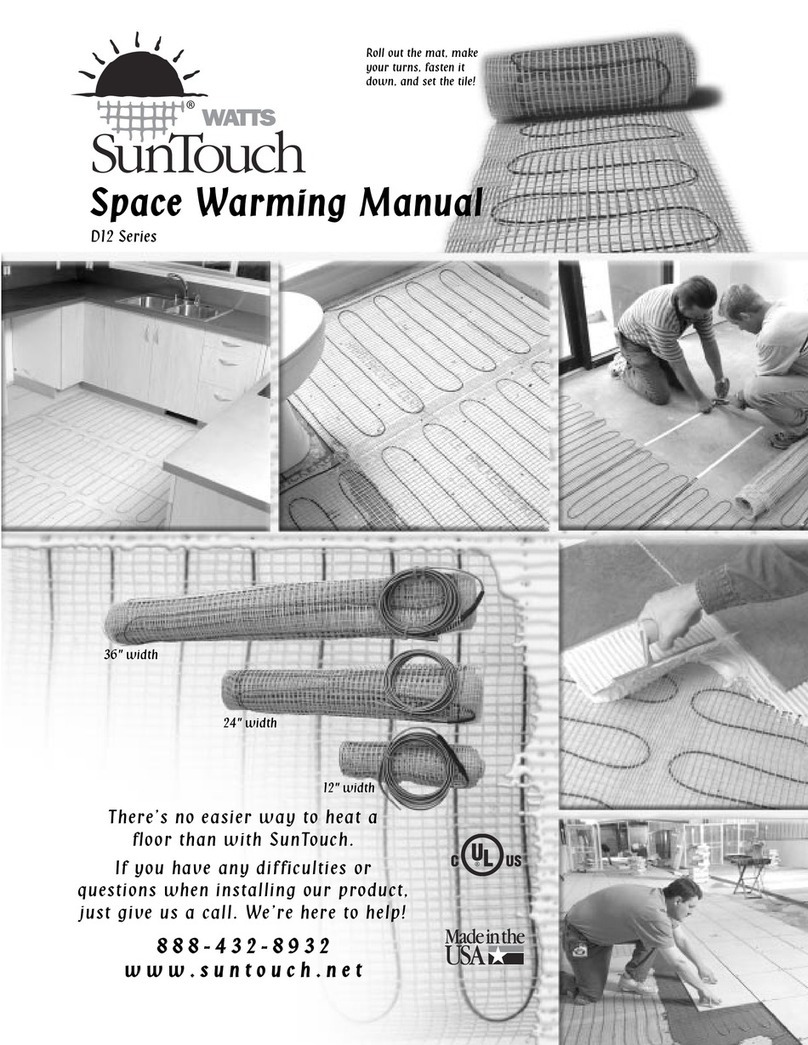

The eRibbon mats are constructed from at amorphous metal ribbons covered by two

layers of polyethylene electric insulation. The ribbons are evenly spaced on a mesh

mat providing a simple and easy to install product.

Introduction

Important notes, please read carefully before proceeding with installation

Do’s & Dont’s

Do

Carefully read this instruction manual before starting your installation and follow

the testing procedure as detailed on page 7. Throughout your installation:

• Ensure that the electric circuit that supplies electricity to the eRibbon heating

system is equipped with a 30Ma residual current device (RCD)

• Connect all cold tail leads from the eRibbon heating mats in parallel at the

low level junction box

• Ensure that the total current for all mats does not exceed more than 80% of

the current rating of the MCB/ Fuse

• Use insulation under the mats to reduce costs and warm up time. Check with

your installer to determine the R value of the sub-oor insulation layer

Don’t

• Install mats under walls or partitions, or in areas under heavy cabinets,

closets, or xtures (toilets, sinks, tubs, etc.).

• Install mats within 3cm of any heat conductive building part, such as cold

water pipes.

• Install mats within 5cm of one another, 10cm of any wall, or 15cm of a

replace or hot water pipe.

• Connect any other electrical appliance on the same electric fused spur or RCD

unit of the heating system.

• Install heating mats under wooden oor if the wooden oor is thicker than

18mm.

• Use carpet underlay with thermal resistance greater than 0.8 Tog.

• Install under carpet with thermal resistance greater than 2.0 Tog.

• Overlap heating mats.

• Fold or wrinkle eRibbon heating mats.

• Place heavy/sharp tools (or any other potentially damaging object) on top of

the heating mats.

• Walk unnecessarily on the heating mats.

• Use cellulose insulation.

• Install mats when the room temperature is below -5°C (23°F).

• Install underoor heating mats anywhere except inside buildings.

Tools needed for installation

You will require the following items to install and test the oor warming systems.

• Tape measure, drawing pad and pencil

• Utility knife, scissors

• Cable strippers, screw driver

• Resistance tester (multimeter), insulation resistance tester

You will also need the appropriate tools and materials to install your nished oor surface;

these will probably include products like double-sided tape, eFoam

and various other

tools and materials for your specic project.

Contents of eRibbon system

• Heating mat

• Installation instructions

• Warranty

The following pages contain all the information you will need about the eRibbon.

Please take the time to study this information thoroughly before you attempt to

install this product.

Glossary of Terms

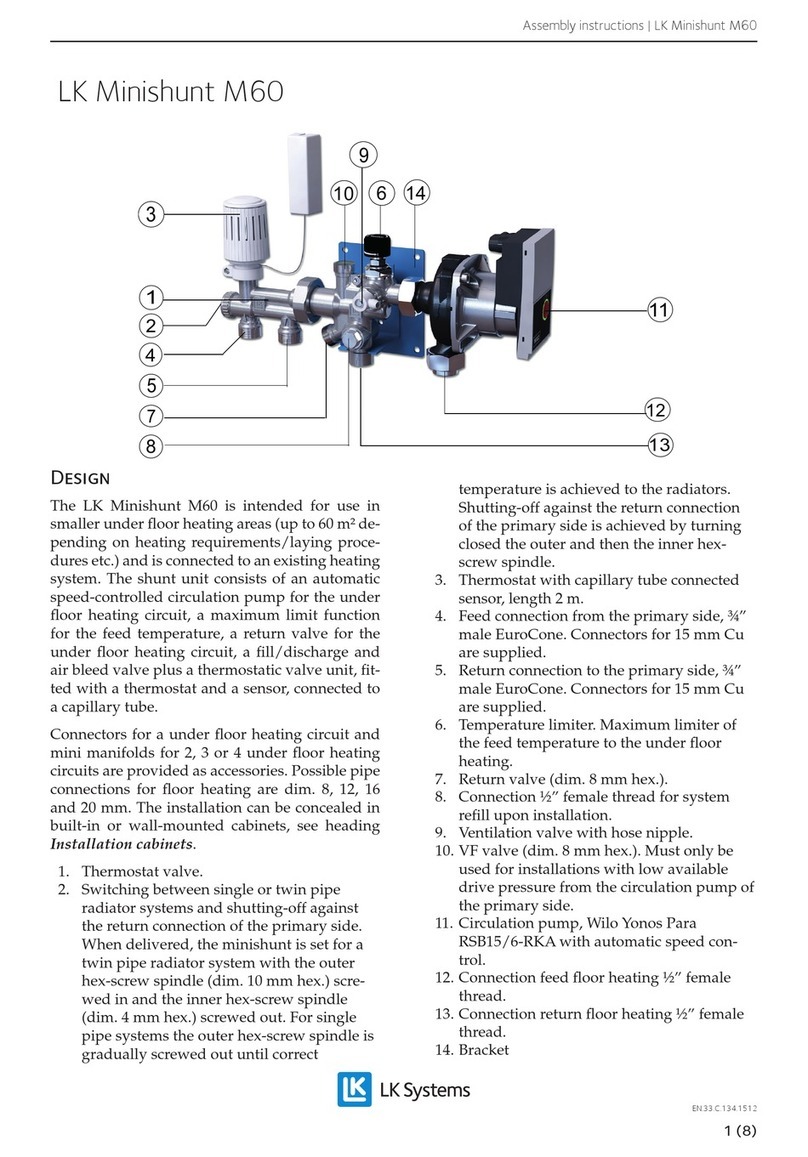

A – Heating element

B – Fibreglass backing mesh

C – Factory made cold tail joint

D – Cold tail power lead