8

Warmset is an electrical product. The appropriate precautions and

care that are associated with electrical installations should be taken.

Always be aware of risks of electric shock, re, and/or injury to

persons. Please read carefully and observe all precautions listed in

these pages.

Attention!

<

<

<

<

<

<

<

<

Caution

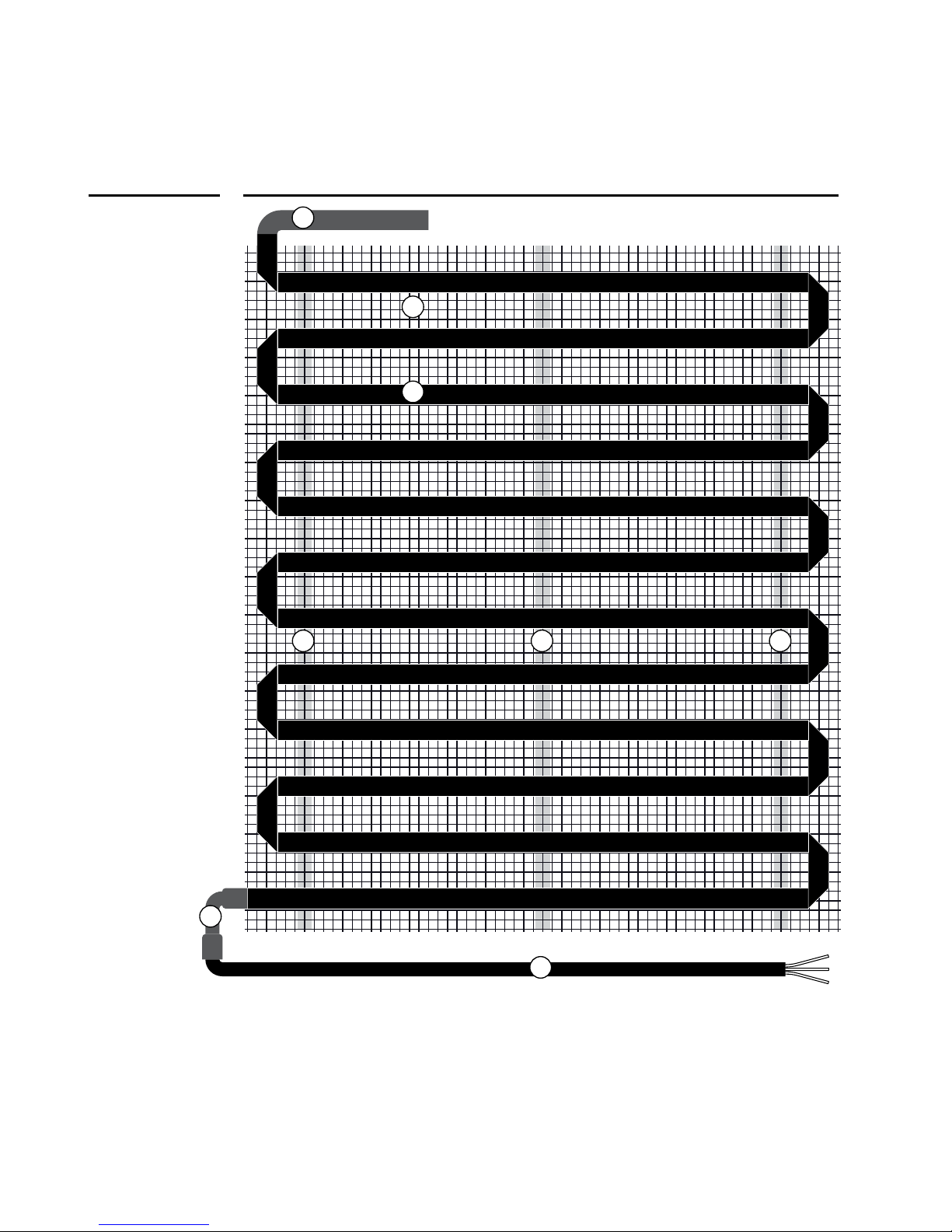

Always install a Class “A” GFCI or EGFPD circuit breaker with each Warmset

mat installation. Note: All Warmset thermostats come equipped with a built-

in Class “A” GFCI or EGFPD.

Always use caution when working with tools around Warmset mats. Be

careful not to nick or cut the heating ribbon.

Always completely embed Warmset mats in minimum 3/8”self-leveling

compound and thinset mortar, or other polymer-modied, cement-based

mortar.

Always adhere to all power limitations of the breaker, thermostat, and

chosen Warmset Mat. Be sure the Voltage and Current are appropriate for the

system.

Always install Warmset mats on a dedicated 20 A circuit.

Always make sure all electrical work is done by qualied people in

accordance with local electrical and building codes.

Always use copper wiring to complete the connections in the Warmset

system.

Always seek help or clarity if problems arise. If in doubt about any

installation procedures, or if the product appears to be damaged, please

contact Warmset before starting the installation process.

All Installations must be performed by qualied personnel

in accordance with all local regulations and building codes.

Thoroughly read and follow the installation instructions and

warnings before beginning installation.

Failure to do so can result in electric shock, re, property

damage, personal injury, and/or death.

Always