HARBEN 4018 US Van Pack Manual

Harben Inc.

P.O. Box 2250, Cumming, GA 30028

Toll Free: (800)-327-5387 Tel: (770)-889-9535 Fax: (770)-887-9411

email: sale[email protected]m web: www.harben.com

Operation & Maintenance Manual

Original Instructions

Unit 4018 US Van Pack

903-1314

Section 1 Introduction

Section 2 Scope of Supply

Section 3 Technical Data

Section 4 Operation

Section 5 Routine Maintenance

Section 6 Fault Finding

Section 7 Harben P-Type Pump

Section 8 Circuit Diagrams

Section 9 Engine

Section 10 Parts List / Spares / Auxiliary Components

Section 11 Service Documents

Section 12 Warranty & Certification

Section 13 Health & Safety Manual 903-1308

Read the Health and Safety Manual before

operating any equipment. Failure to do so could

cause serious injury or death.

1

Operation & Maintenance Manual for:

UNIT: Unit 4018 US Van Pack – R/1 (B11238/A)

ISSUE DATE: 6/20

ISSUE No: 6

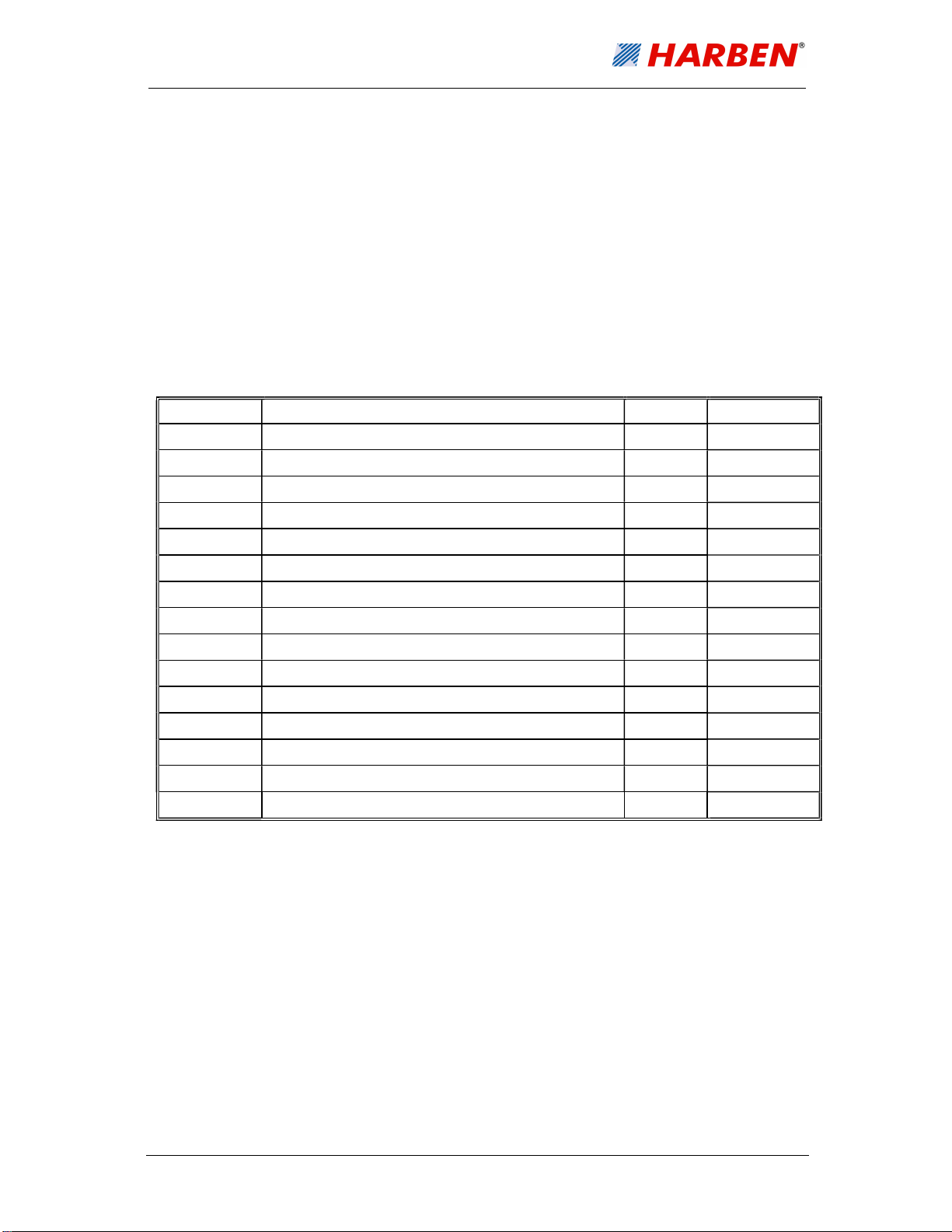

AMENDMENTS

Change Changes Date Signature

1 NEW ADDITION 09/19 JJ

2 UPDATE WARRANTY POLICY 10/19 JJ

3 Minor Changes. Added part number 5/20 GT

4 Added multiple sections. Minor changes 6/20 GT

5 Added Pictures to Anti-Freeze Section 6/20 GT

6 Updated manual to code 6/20 GT

2

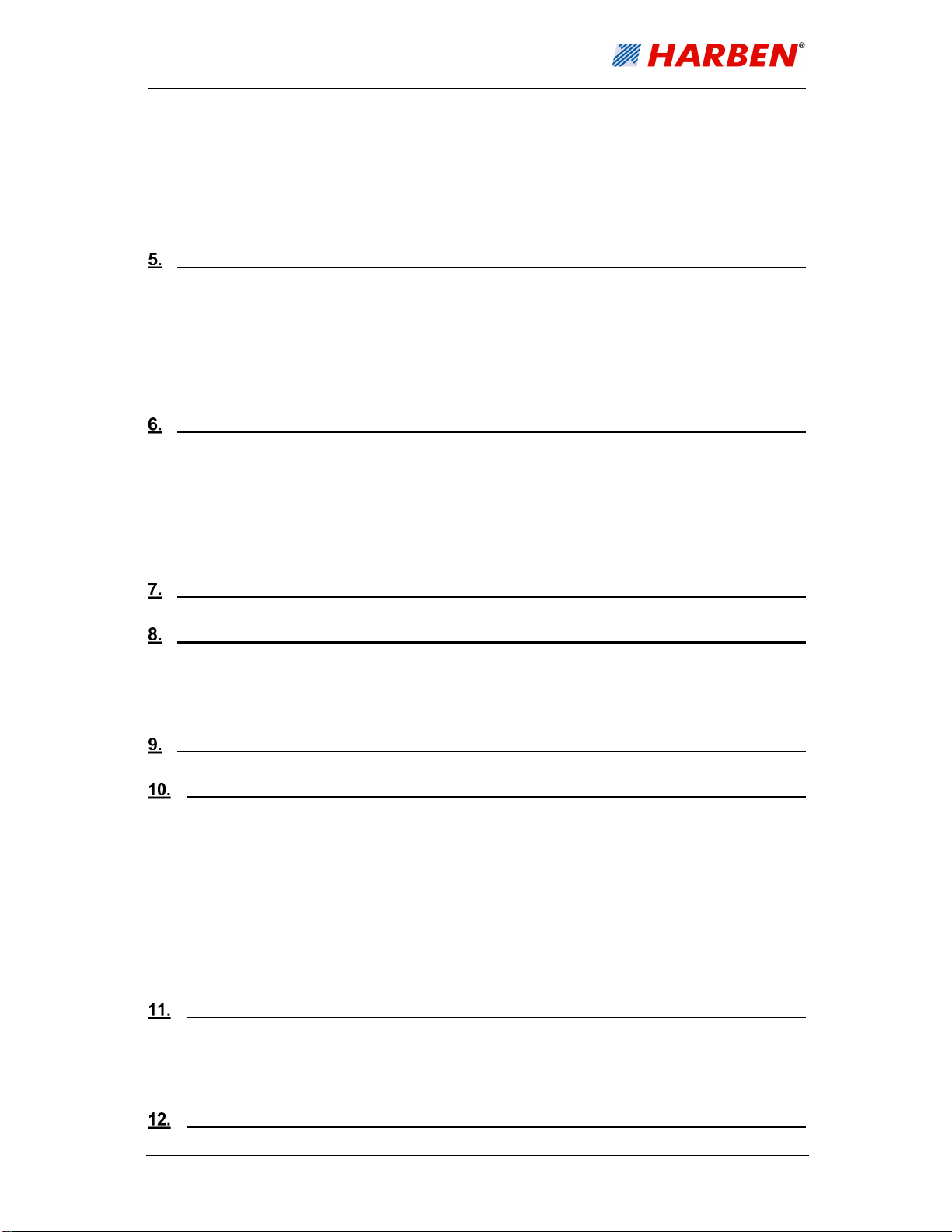

Section 1 – Introduction & Contents

1.1.

Contents

SECTION 1 – INTRODUCTION & CONTENTS ....................................................................2

1.1. C

ONTENTS ....................................................................................................................2

1.2. INTRODUCTION ..............................................................................................................5

1.3. SCOPE OF THIS MANUAL ................................................................................................6

1.4. THE VANPACK ...............................................................................................................6

1.5. COMPOSITION OF THIS MANUAL......................................................................................7

SCOPE OF SUPPLY ......................................................................................................8

2.1. SCOPE OF SUPPLY ........................................................................................................8

2.2. PUMP ASSEMBLY ..........................................................................................................8

2.3. DETAILED DRAWINGS ....................................................................................................8

TECHNICAL DATA ...................................................................................................... 11

3.1. TECHNICAL DATA ........................................................................................................ 11

3.1.1. PUMP DATA .............................................................................................................. 11

3.1.2. MAIN COMPONENTS .................................................................................................. 12

3.1.3. ANCILLARIES ............................................................................................................ 12

3.1.4. SERVICES REQUIRED ................................................................................................ 12

3.2. TECHNICAL DESCRIPTION ............................................................................................ 13

3.2.1. PRIMARY COMPONENTS ............................................................................................ 13

3.2.2. ENGINE MONITORING ................................................................................................ 13

OPERATION ................................................................................................................ 14

4.1. OPERATING CONDITIONS ............................................................................................. 14

4.2. DAILY CHECKS ............................................................................................................ 14

4.3. PRE-START CHECKS & PROCEDURES ........................................................................... 14

4.4. CONTROL PANEL LAYOUT AND FUNCTION ...................................................................... 15

4.4.1. CONTROL KEYS ........................................................................................................ 15

4.4.2. TOGGLE SWITCH OPERATION ..................................................................................... 15

4.4.3. SCREEN LAYOUTS ..................................................................................................... 16

4.4.4. RADIO CONTROL LAYOUT ........................................................................................... 18

4.5. RUNNING THE ENGINE (MANUAL MODE)........................................................................ 18

4.6. RUNNING THE ENGINE (RADIO MODE) ........................................................................... 19

4.7. RUNNING THE VANPACK .............................................................................................. 19

4.8. HARBEN

®

JUMP JET .................................................................................................... 20

3

4.9. B

YPASS VALVE OPERATION ......................................................................................... 21

4.10. HOSE REEL WINDING AND UNWINDING ....................................................................... 22

4.11. FROST PRECAUTIONS ................................................................................................ 23

4.11.1. TO ANTI-FREEZE THE MACHINE WITH AN ANTI-FREEZE TANK ....................................... 23

4.11.2. TO DE-ANTIFREEZE THE MACHINE ............................................................................. 24

ROUTINE MAINTENANCE ........................................................................................... 26

5.1. MAINTENANCE PROCEDURES ....................................................................................... 26

5.2. DAILY MAINTENANCE (H&S SECTION 11) ..................................................................... 27

5.3. PUMP LUBRICATING CHART ......................................................................................... 28

5.4. BURST DISCS .............................................................................................................. 29

FAULT FINDING .......................................................................................................... 30

6.1. FAULT FINDING - ELECTRICAL ...................................................................................... 30

6.2. FAULT FINDING - HYDRAULIC ....................................................................................... 31

6.3. PUMP FAULT FINDING .................................................................................................. 32

6.4. SELECTOR FAULT FINDING ........................................................................................... 34

PUMP ........................................................................................................................... 35

CIRCUIT DIAGRAMS ................................................................................................... 36

8.1. WATER CIRCUIT FOR VANPACK ................................................................................. 36

8.2. HYDRAULIC CIRCUIT FOR VANPACK ........................................................................... 36

ENGINE ........................................................................................................................ 37

PARTS LIST / SPARES ............................................................................................. 38

10.1. INTRODUCTION .......................................................................................................... 38

10.2. ORDERING SPARE PARTS .......................................................................................... 38

10.3. ROUTING MAINTENANCE / CONSUMABLE ITEMS ........................................................... 38

10.4. CONSUMABLE COMPONENTS ...................................................................................... 38

10.5. PARTS LIST ............................................................................................................... 39

10.5.1. REMOTE ................................................................................................................... 39

SERVICE DOCUMENTS ............................................................................................ 43

11.1. SERVICE CHECKLIST .................................................................................................. 43

11.2. SERVICE LOGBOOK ................................................................................................... 44

WARRANTY ............................................................................................................... 45

4

12.1. WARRANTY OF NEW PRODUCTS: ................................................................................ 45

12.2. WARRANTY OF MAJOR COMPONENTS: ....................................................................... 45

12.3. LIMITATIONS OF WARRANTY:...................................................................................... 47

This manual suits for next models

1

Table of contents

Popular Cleaning Equipment manuals by other brands

Suevia

Suevia 130.5011 EASYCLEANER Mounting instructions

i-MO

i-MO Öko 2000 user guide

unGer

unGer Hydro Power Ultra UNP01 operating instructions

Black & Decker

Black & Decker BHPC130 Original instructions

Uni-ram

Uni-ram UG5000E operating manual

Axi

Axi MTC HC-300 Installation, operating and maintenance manual