Hardi SARITOR Self Propelled Assembly instructions

Other Hardi Farm Equipment manuals

Hardi

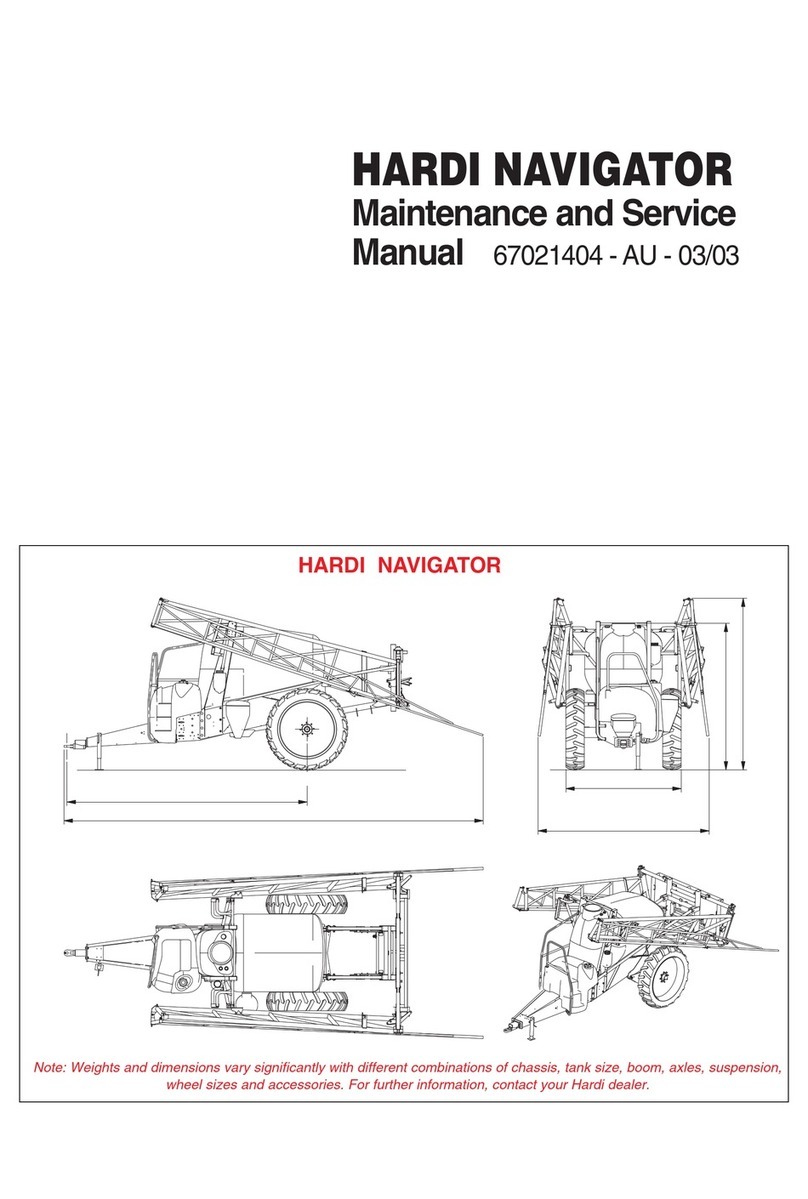

Hardi Navigator Series Manual

Hardi

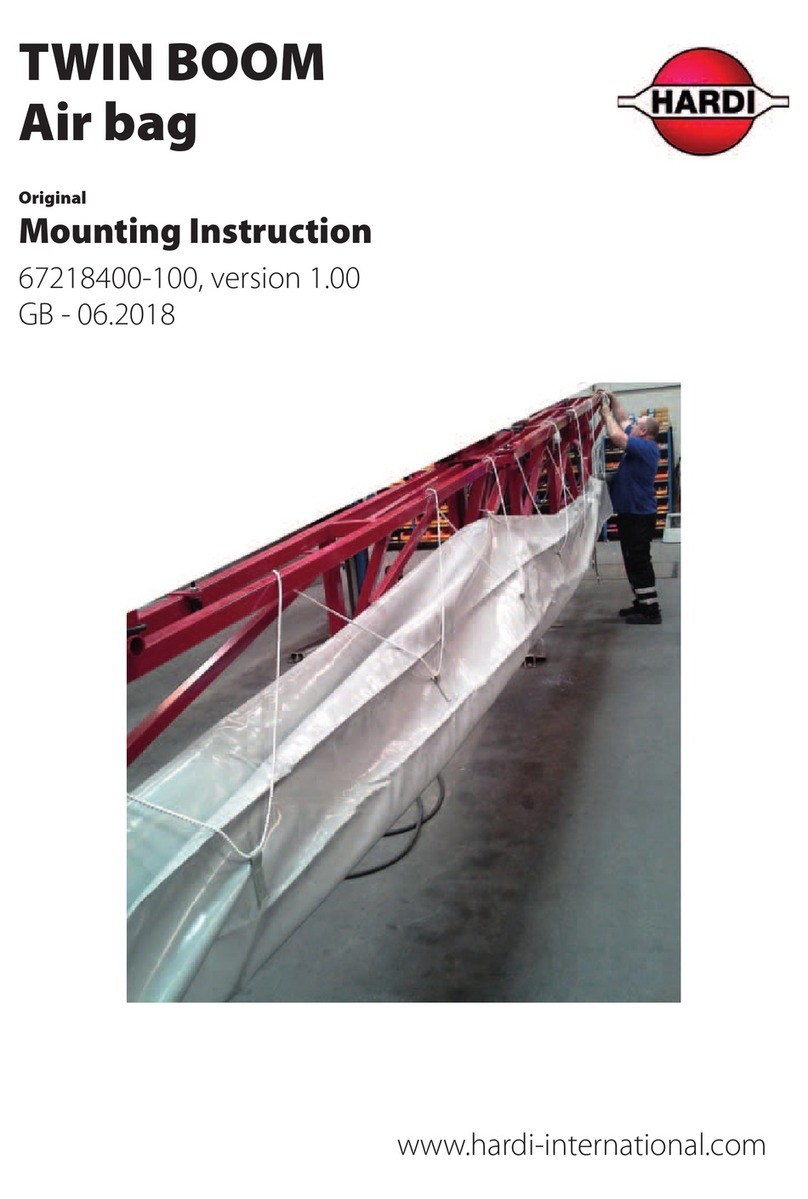

Hardi TWIN BOOM User guide

Hardi

Hardi PRESIDIO 2700 User manual

Hardi

Hardi AEON CENTURA TWIN FORCE User manual

Hardi

Hardi Master Plus User manual

Hardi

Hardi COMMANDER DELTA FORCE User manual

Hardi

Hardi NAVIGATOR 4000 User manual

Hardi

Hardi NAVIGATOR DELTA FORCE User manual

Hardi

Hardi ALPHA evo ALU-TWIN FORCE User manual

Hardi

Hardi ALPHA EVO EcoDrive 5100 User manual

Hardi

Hardi MASTER VHY Series User manual

Hardi

Hardi ZATURN User manual

Hardi

Hardi COMMANDER 4500 User manual

Hardi

Hardi ALPHA evo EcoDrive TWIN FORCE User manual

Hardi

Hardi KS Series User manual

Hardi

Hardi TERRA FORCE BOOM User manual

Hardi

Hardi DEMOUNT User manual

Hardi

Hardi COMMANDER TWIN FORCE User manual

Hardi

Hardi MASTER plus HYS User manual

Hardi

Hardi RANGER 2500 TR2 User manual

Popular Farm Equipment manuals by other brands

Farm King

Farm King 1450 Operator and parts manual

Raven

Raven SmarTrax installation manual

ROPA

ROPA KS 475 Translation of the original operating manual

SOLANO HORIZONTE

SOLANO HORIZONTE RT 65 P / E manual

Gaspardo

Gaspardo HCS USE AND ASSEMBLY INSTRUCTIONS / SPARE PARTS

aivituvin

aivituvin XZ7002 instruction manual