Table of Contents

PNEG-2113 36' Recessed Dura-Lok Plank and Support Manual 3

Contents

Chapter 1 Introduction ..........................................................................................................................................4

Chapter 2 Safety .....................................................................................................................................................5

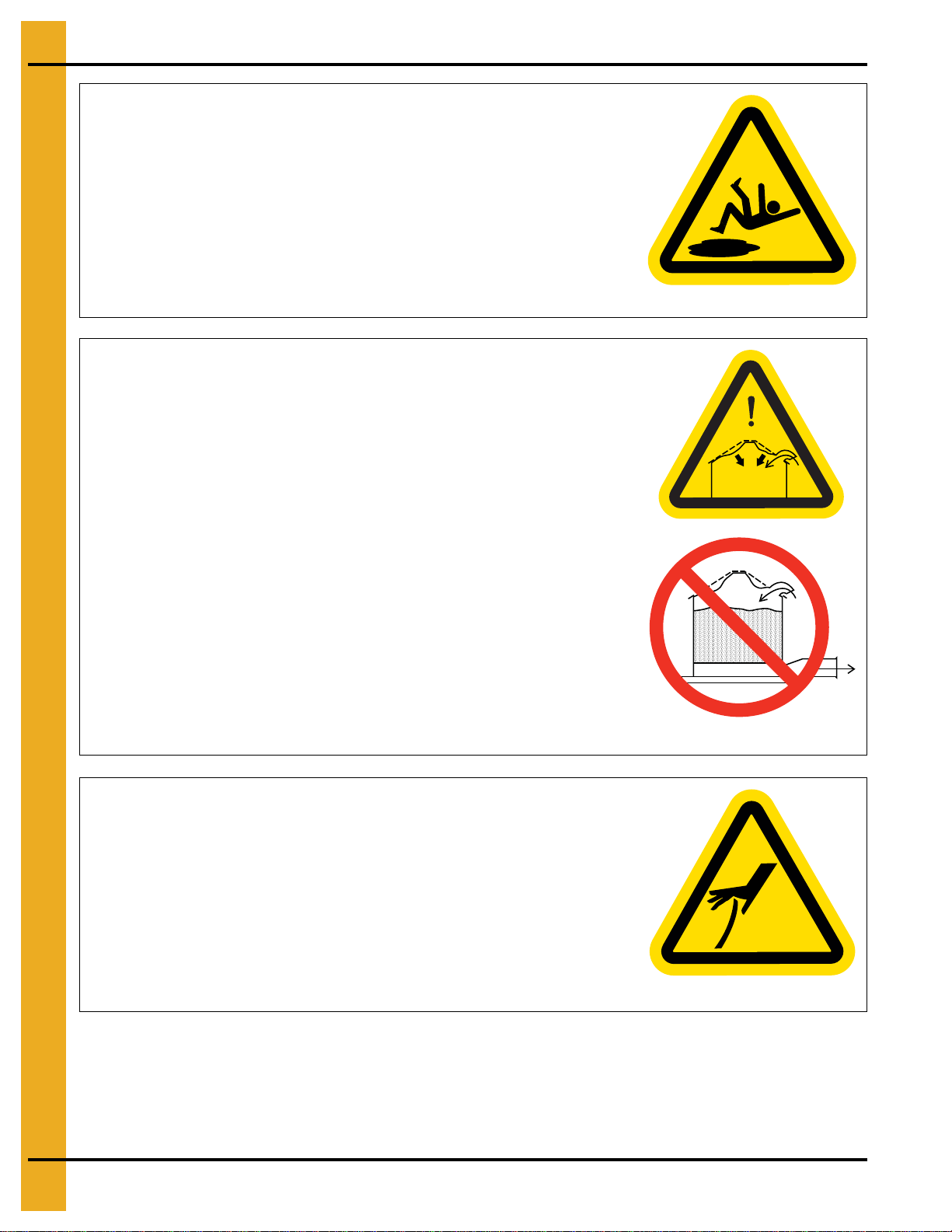

Safety Guidelines .................................................................................................................................. 5

Cautionary Symbols Definitions ............................................................................................................ 6

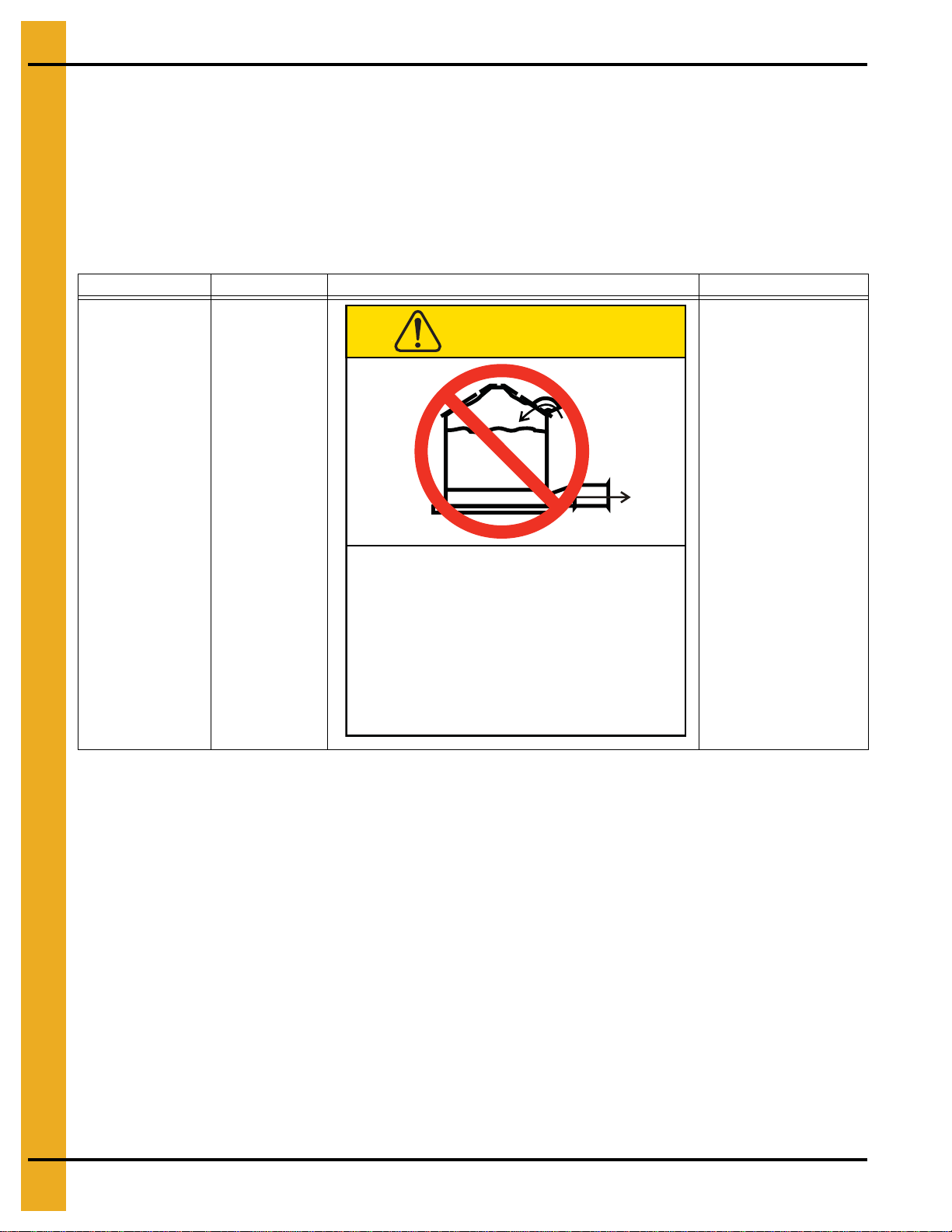

Safety Cautions ..................................................................................................................................... 7

Safety Sign-Off Sheet ........................................................................................................................... 9

Chapter 3 Decals ..................................................................................................................................................10

Chapter 4 Monorail Installation ..........................................................................................................................12

Fan Placement Diagram ..................................................................................................................... 12

Tie Bar Detail ...................................................................................................................................... 13

Tie Strap Detail ................................................................................................................................... 14

Assembling Legs to Rail ...................................................................................................................... 15

Monorail Splice Detail ......................................................................................................................... 17

Outer Perimeter Rail Details ............................................................................................................... 19

Chapter 5 Flooring - Planks ................................................................................................................................20

Flashing Installation ............................................................................................................................ 20

Center Well Assembly Details ............................................................................................................. 22

Intermediate Well Assembly Details .................................................................................................... 23

Chapter 6 Layouts ................................................................................................................................................24

36'-10" Rail Spacing Layout ................................................................................................................ 24

36'-10" Monorail Spacing Layout ........................................................................................................ 25

36'-16" Rail Spacing Layout ................................................................................................................ 26

36'-16" Monorail Spacing Layout ........................................................................................................ 27

36'-17" Rail Spacing Layout ................................................................................................................ 28

36'-17" Monorail Spacing Layout ........................................................................................................ 29

36'-18" Rail Spacing Layout ................................................................................................................ 30

36'-18" Monorail Spacing Layout ........................................................................................................ 31

36'-20" Rail Spacing Layout ................................................................................................................ 32

36'-20" Monorail Spacing Layout ........................................................................................................ 33

36'-22" Rail Spacing Layout ................................................................................................................ 34

36'-22" Monorail Spacing Layout ........................................................................................................ 35

36'-26" Rail Spacing Layout ................................................................................................................ 36

36'-26" Monorail Spacing Layout ........................................................................................................ 37

36' Recessed Floor Bundle Layout ..................................................................................................... 38

36' Recessed Floor Plank Layout ........................................................................................................ 39

Chapter 7 Warranty ..............................................................................................................................................41