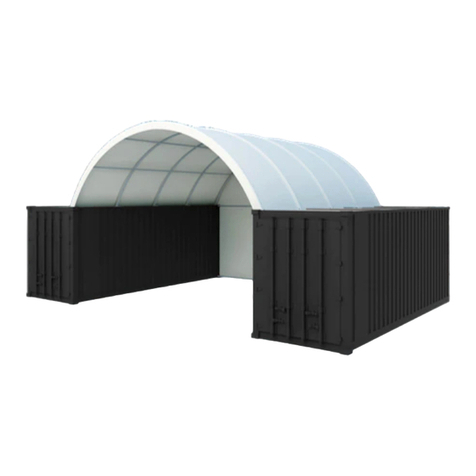

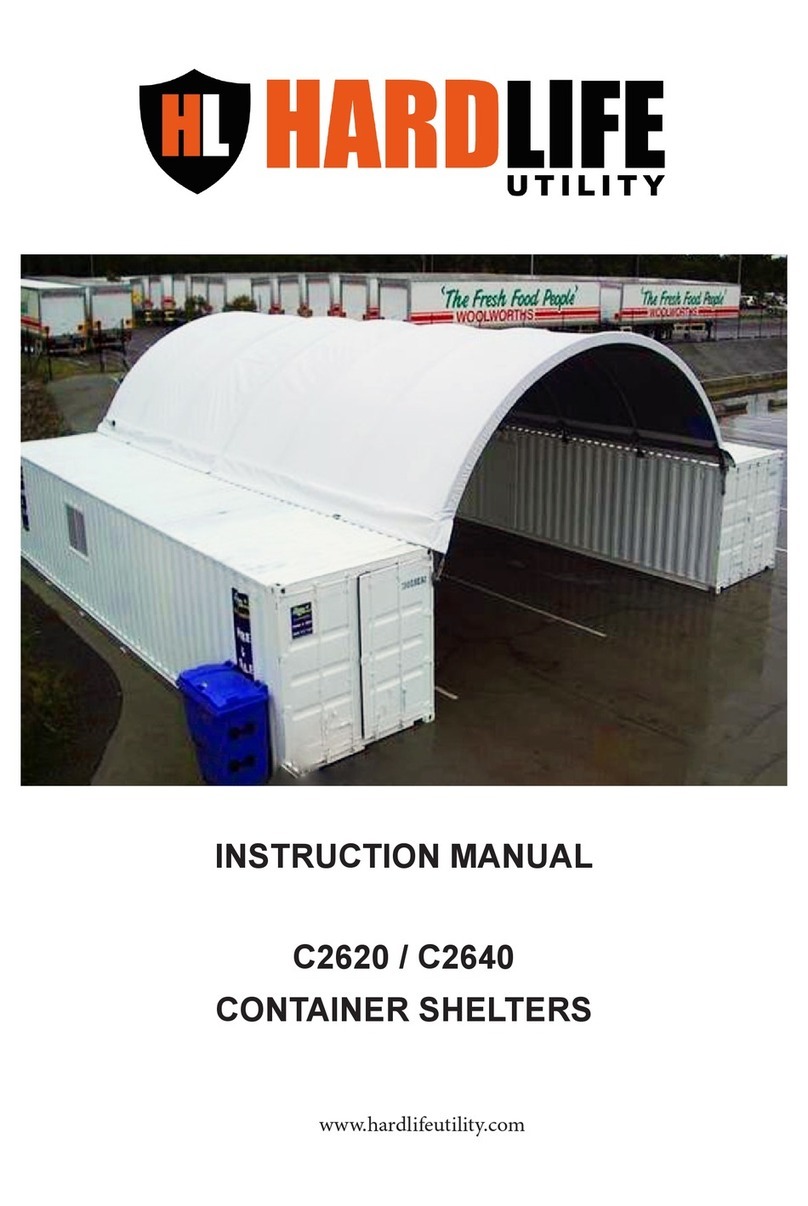

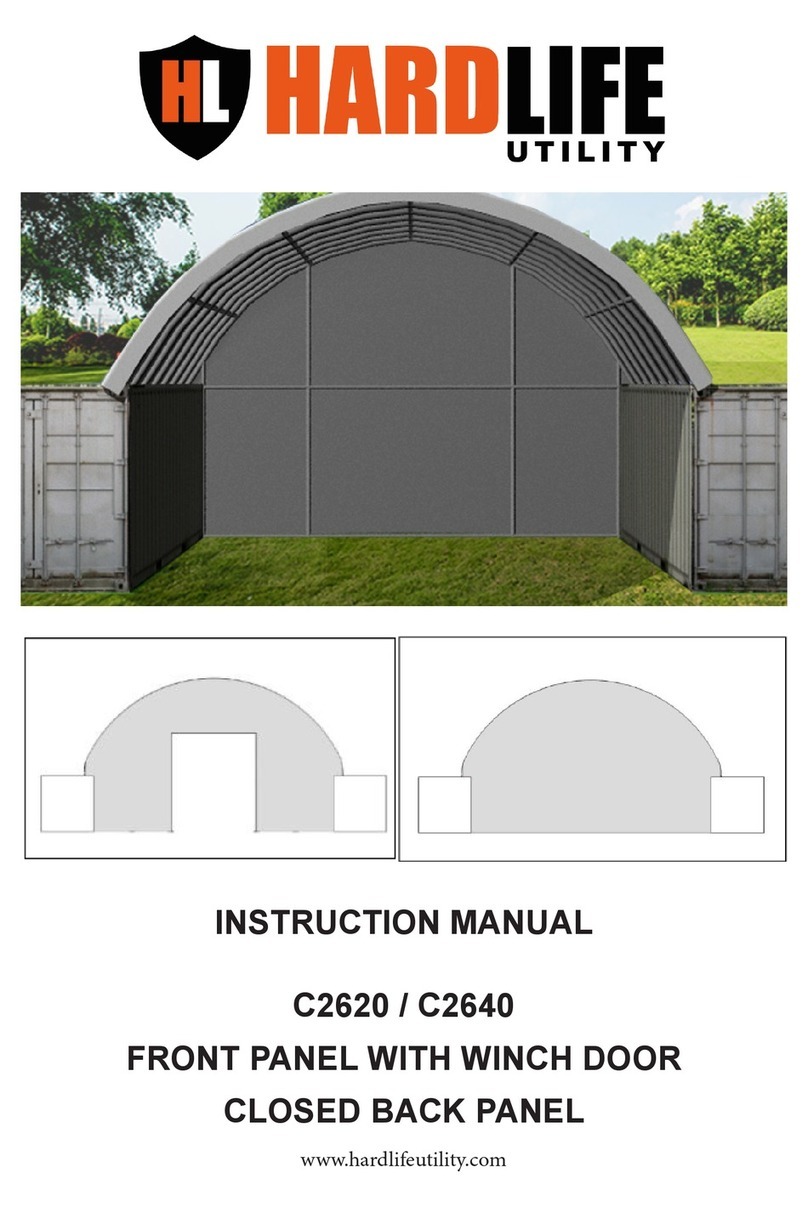

Hardlife Utility C2020 User manual

Other manuals for C2020

1

This manual suits for next models

1

Table of contents

Other Hardlife Utility Shelter manuals

Hardlife Utility

Hardlife Utility C2020 User manual

Hardlife Utility

Hardlife Utility C2620 User manual

Hardlife Utility

Hardlife Utility C2020H User manual

Hardlife Utility

Hardlife Utility C2620 User manual

Hardlife Utility

Hardlife Utility 204016DP User manual

Hardlife Utility

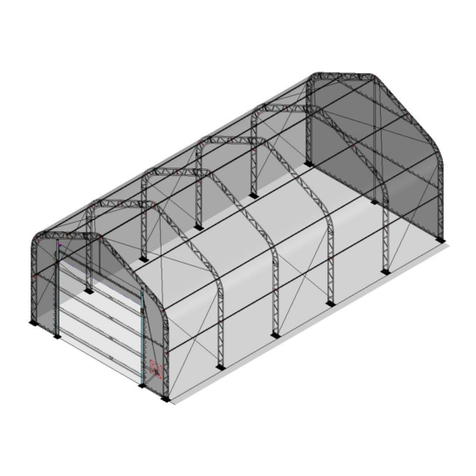

Hardlife Utility C4040 User manual

Popular Shelter manuals by other brands

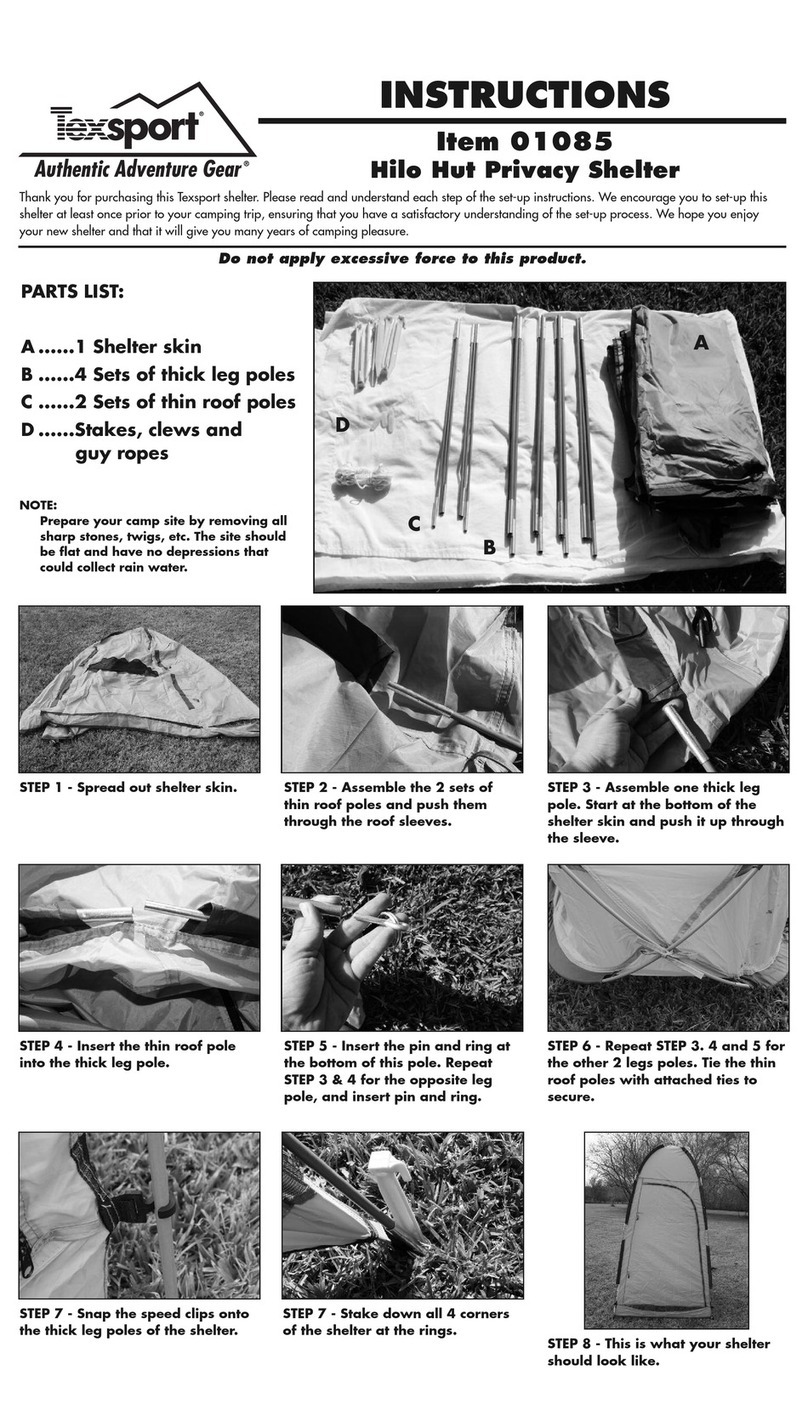

Texsport

Texsport Item 01085 instructions

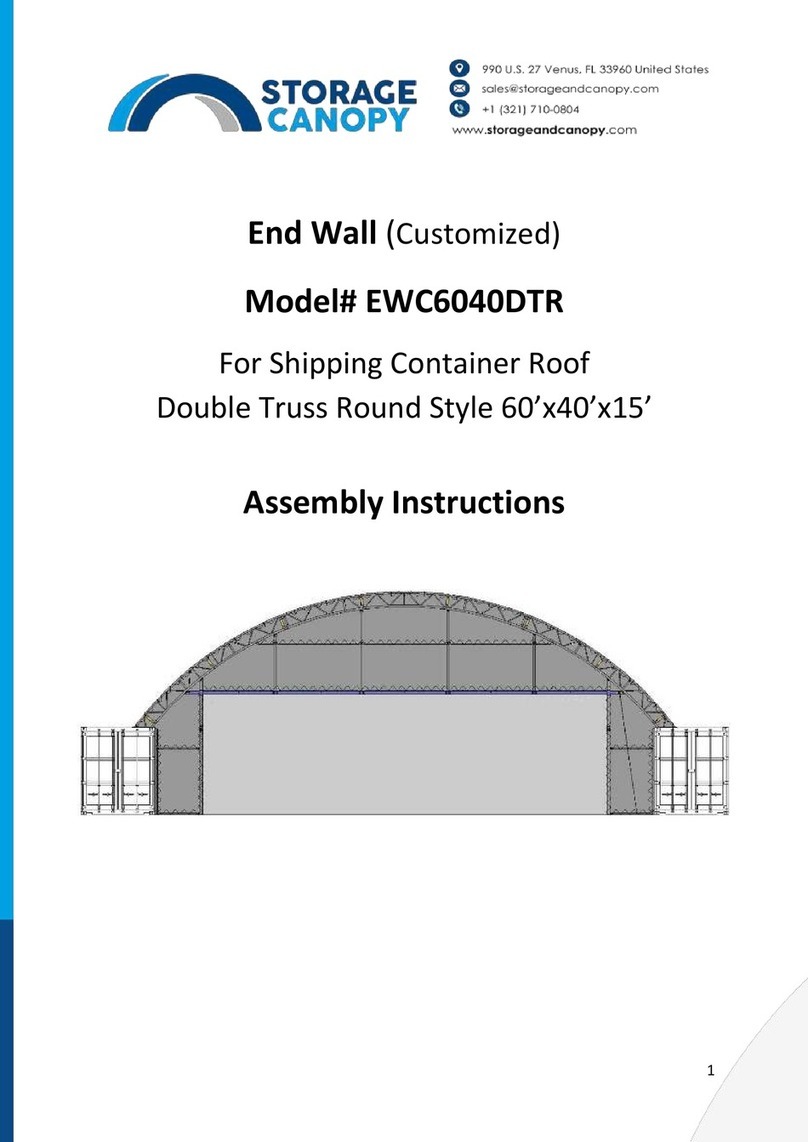

Storage Canopy

Storage Canopy EWC6040DTR Assembly instructions

Storage Canopy

Storage Canopy 26x40x10 Container Shelter Single truss Assembly manual

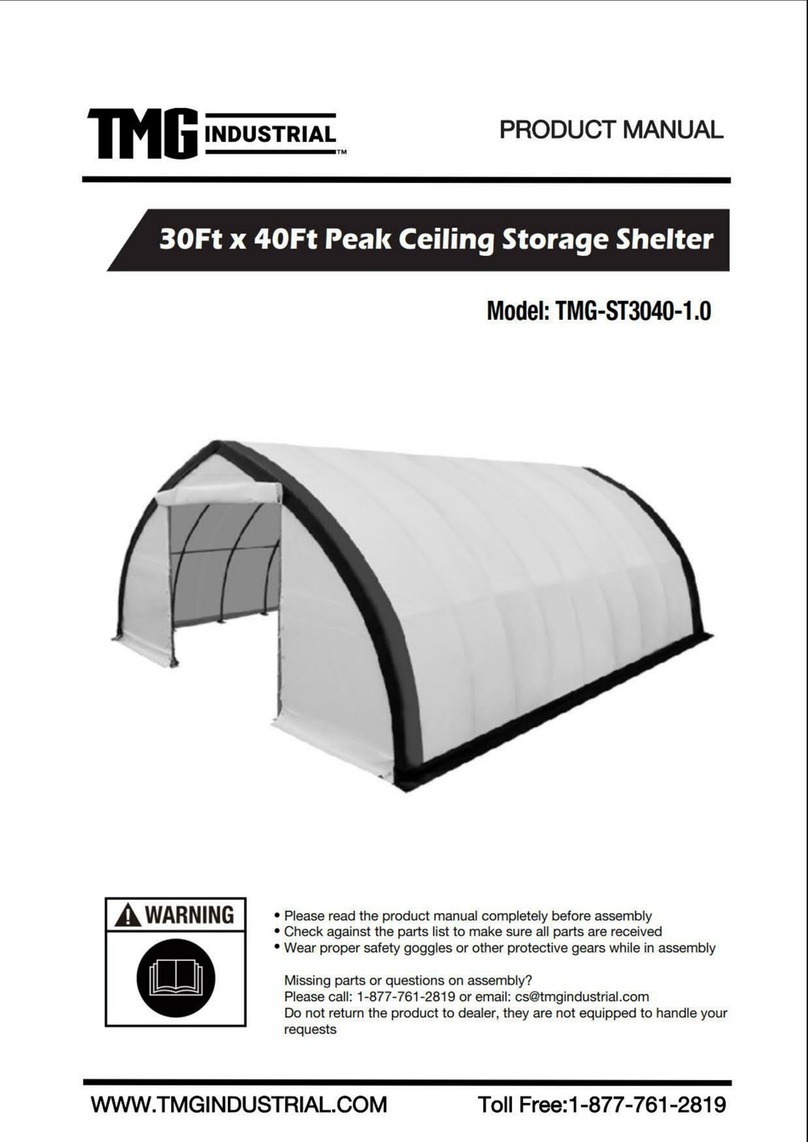

TMG

TMG TMG-ST3040-1.0 product manual

ShelterLogic

ShelterLogic Shed-in-a-Box 70401 Assembly instructions

AMERICANA OUTDOORS

AMERICANA OUTDOORS COLONIAL Assembly instructions

TMG

TMG TMG-DT3063-PRO product manual

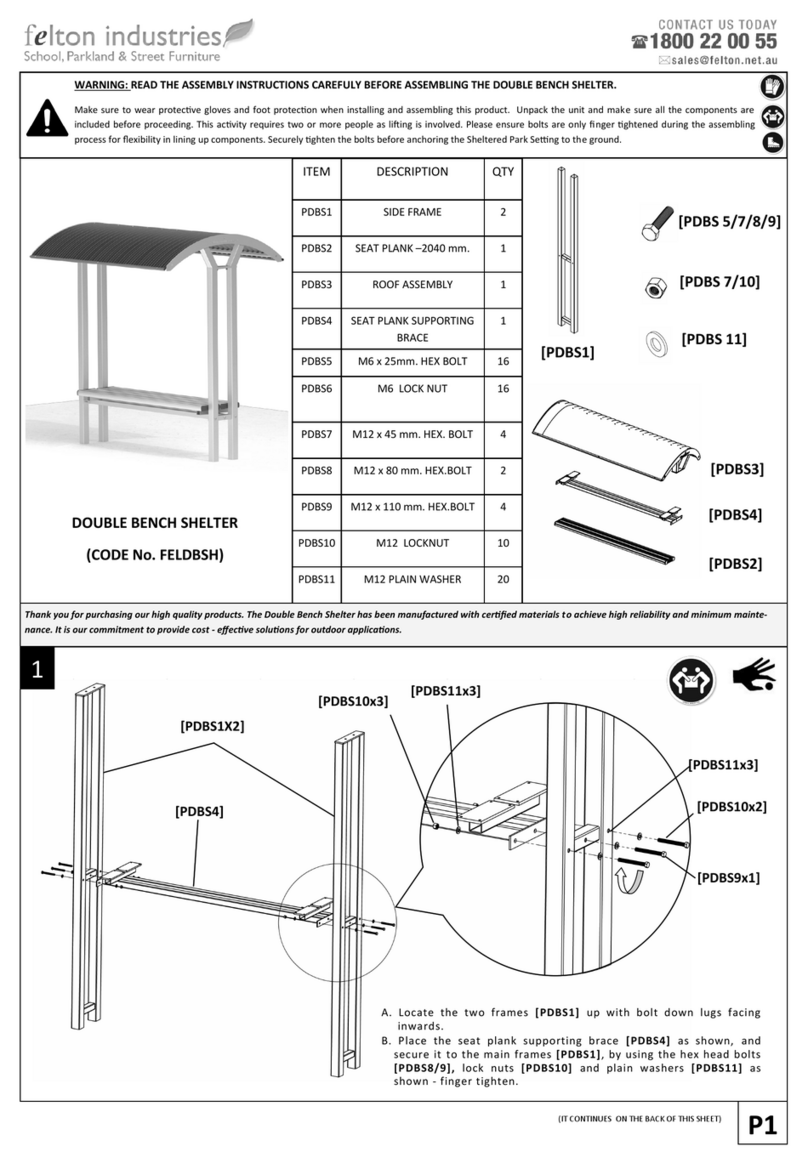

felton industries

felton industries FELDBSH Aassembly Instructions

Shelters4Less

Shelters4Less SR1553 Assembly instructions

Storage Canopy

Storage Canopy C3340S Assembly manual

Kozyard

Kozyard 12'x20' Alexander hardtop gazebo with double... Assembly manual

ShelterLogic

ShelterLogic ShelterCoat 12'W x 8'H Peak manual