2

www.varnabuildings.com

INTRODUCTION ................................................................................................

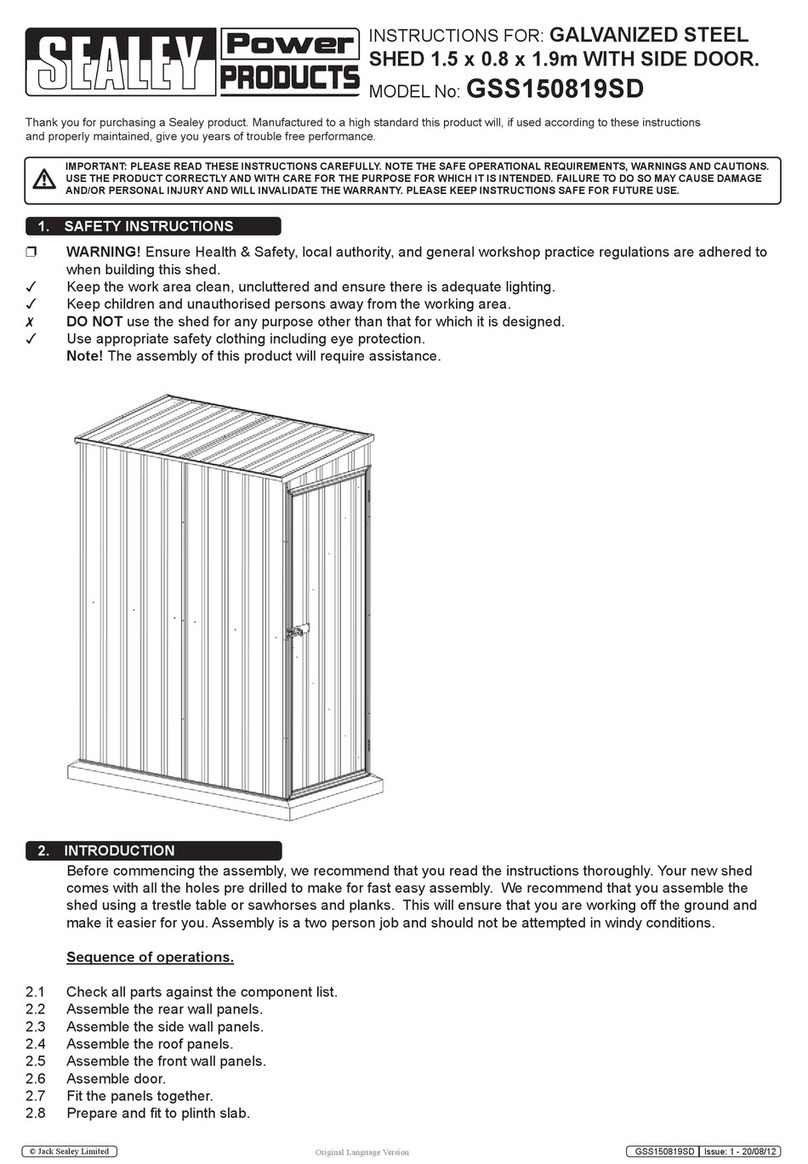

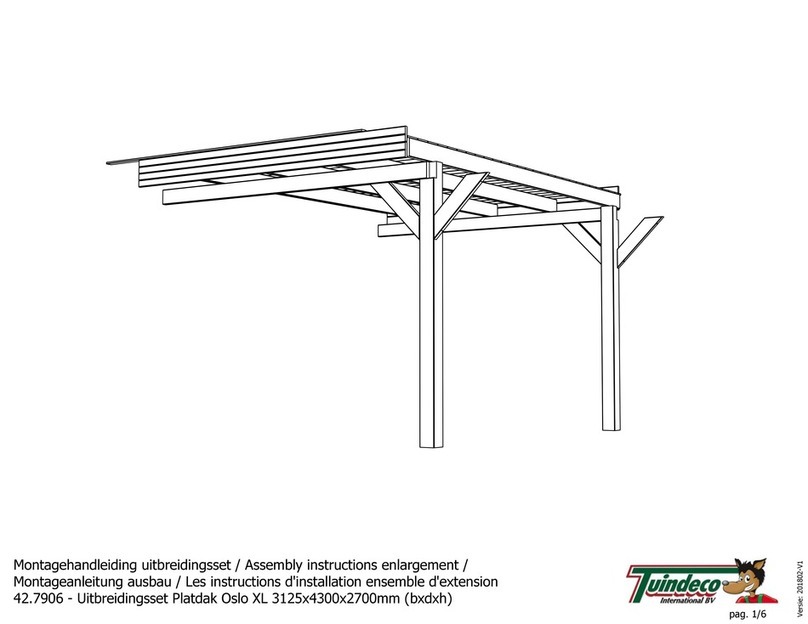

ASSEMBLY INSTRUCTIONS ............................................................................

USAGE INSTRUCTIONS ...................................................................................

SHELTER SPECIFICATIONS ............................................................................

COMPONENT LIST ...........................................................................................

......................................................................NOITALLATSNIDNAYLBMESSA

TOOLS REQUIRED FOR INSTALLATION ........................................................

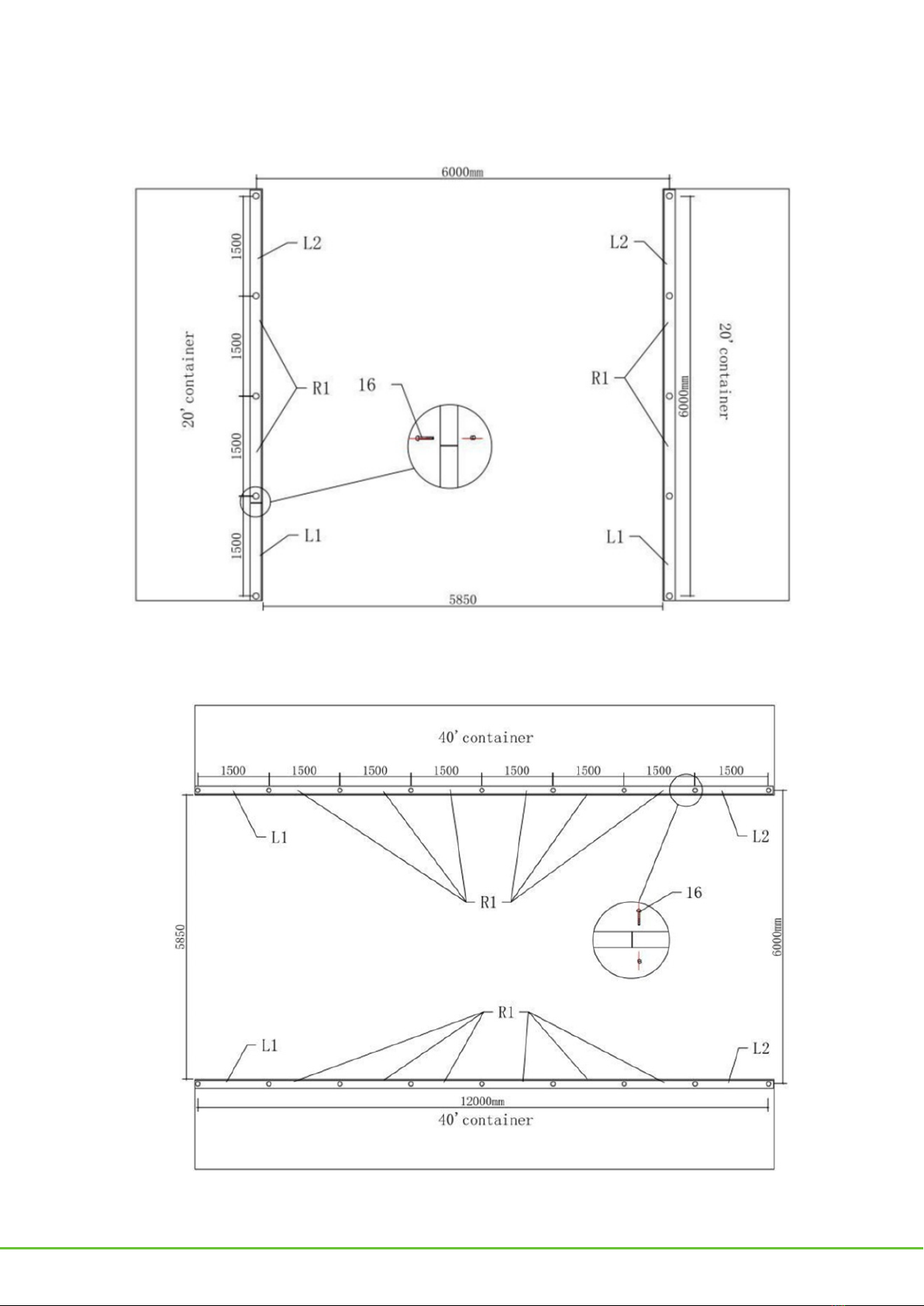

SITE PREPARATION .........................................................................................

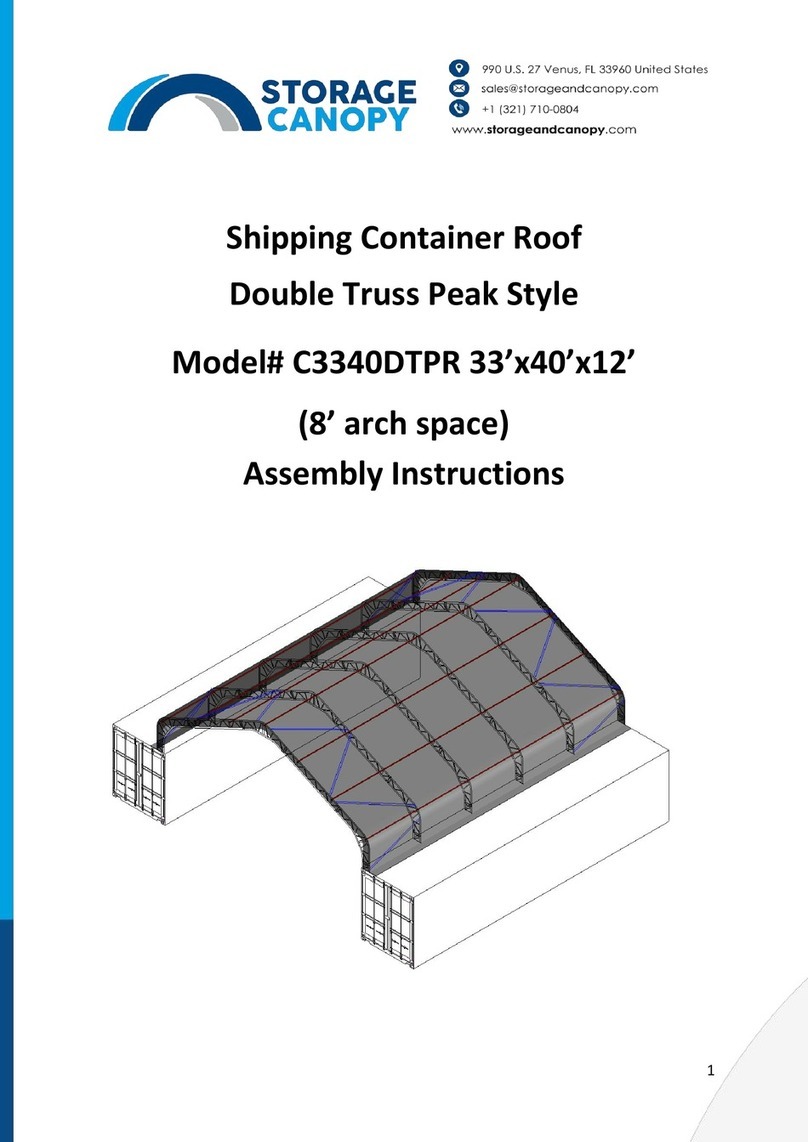

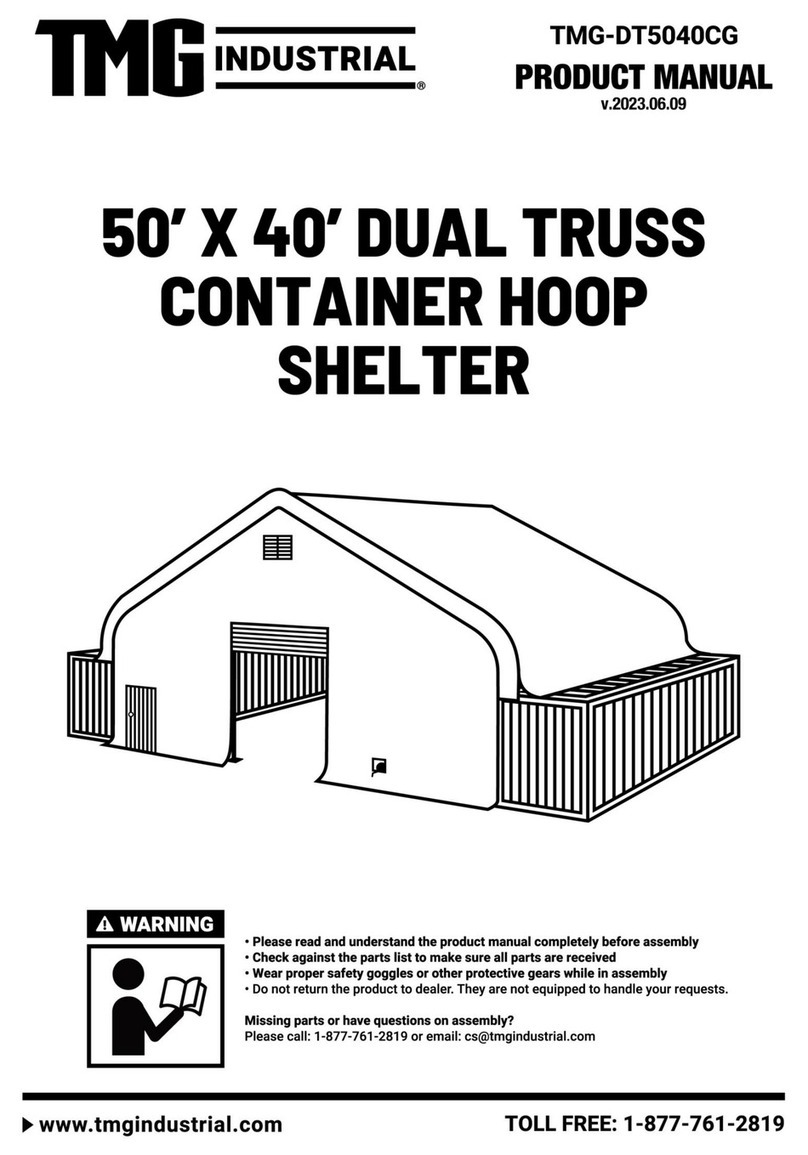

CONTAINER SHELTER PLACEMENT...............................................................

BASE PLATE INSTALLATION.............................................................................

...........................................................................................YLBMESSAEMARF

FRAME INSTALLATION ....................................................................................

ROOF COVER INSTALLATION .........................................................................

BACK COVER INSTALLATION .........................................................................

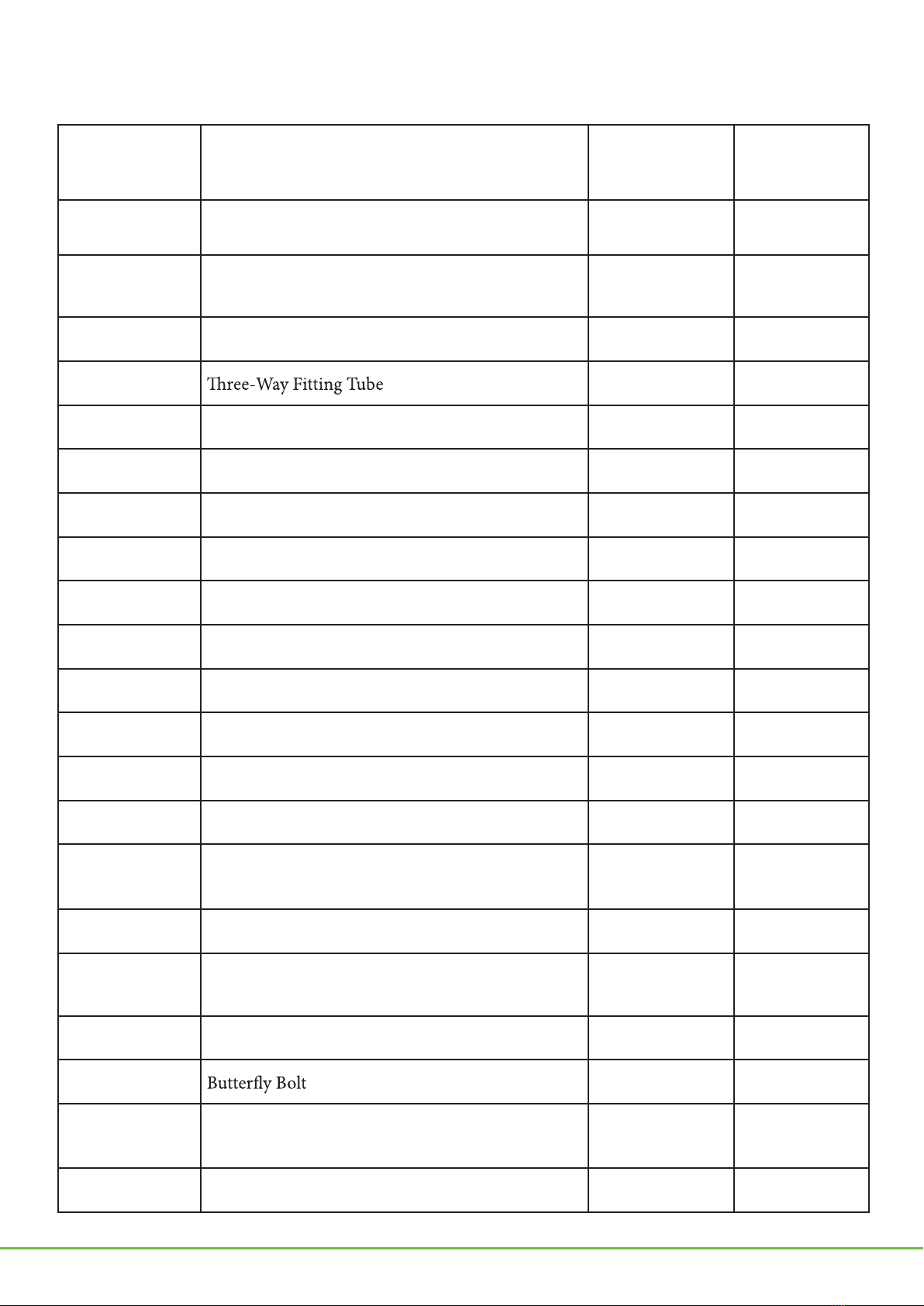

BACK COVER COMPONENT LIST ..................................................................

INSTALLING THE BACK COVER .....................................................................

MAINTENANCE .................................................................................................

TABLE OF CONTENTS

03

04

04

04

05

06

06

06

07

08

09

11

12

17

17

17

19