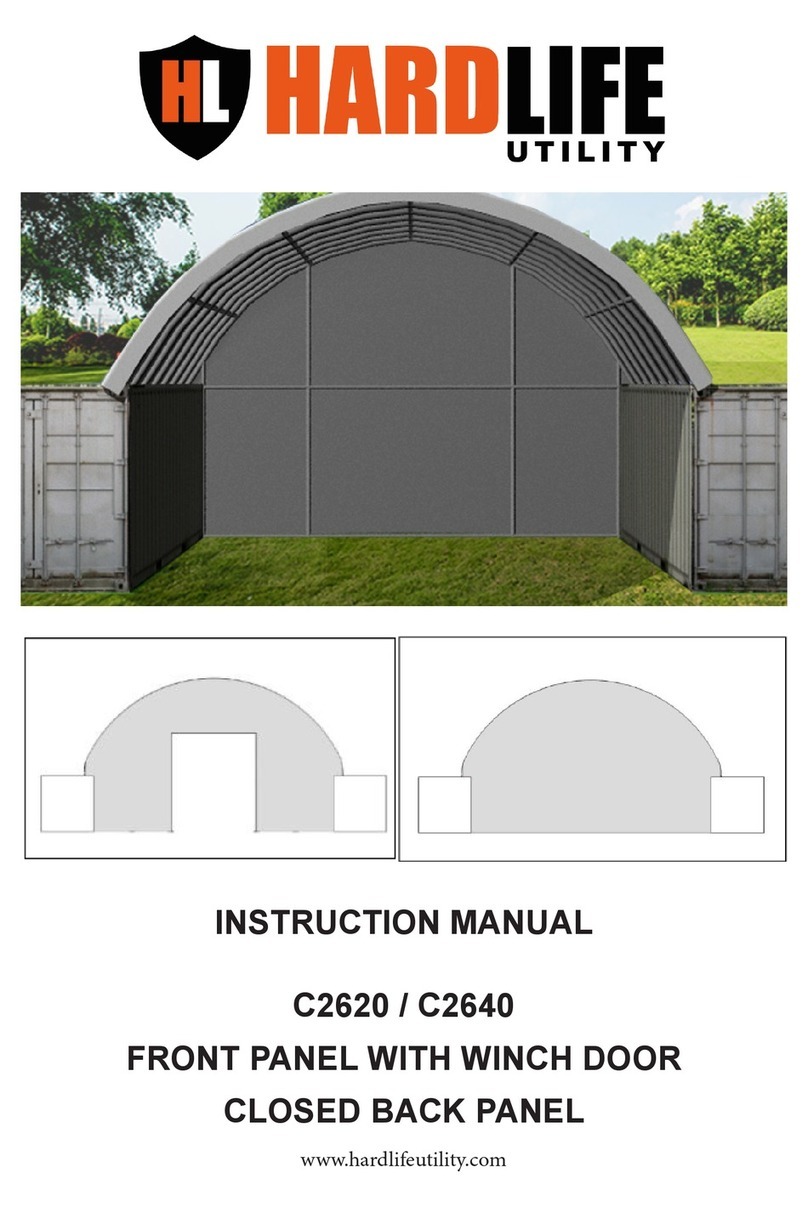

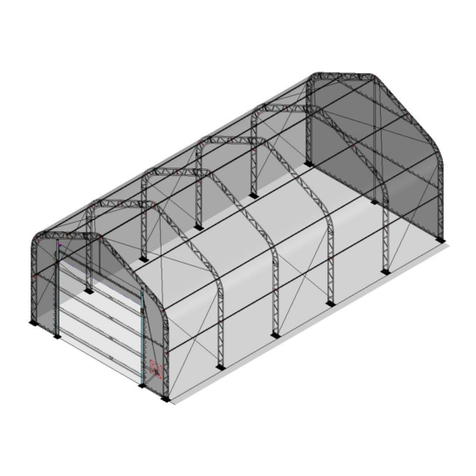

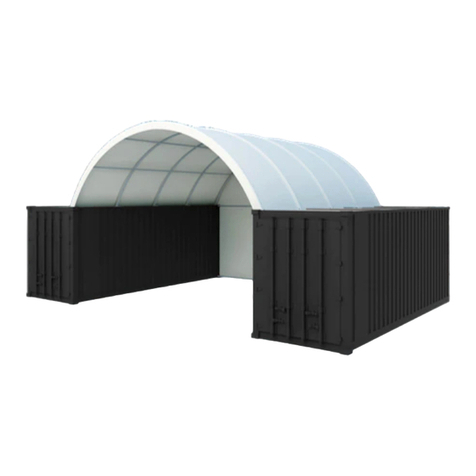

Hardlife Utility C2620 User manual

Other manuals for C2620

1

This manual suits for next models

1

Table of contents

Other Hardlife Utility Shelter manuals

Hardlife Utility

Hardlife Utility C2020H User manual

Hardlife Utility

Hardlife Utility C2620 User manual

Hardlife Utility

Hardlife Utility C2020 User manual

Hardlife Utility

Hardlife Utility 204016DP User manual

Hardlife Utility

Hardlife Utility C4040 User manual

Hardlife Utility

Hardlife Utility C2020 User manual

Popular Shelter manuals by other brands

Shelters4Less

Shelters4Less Derby Assembly instructions

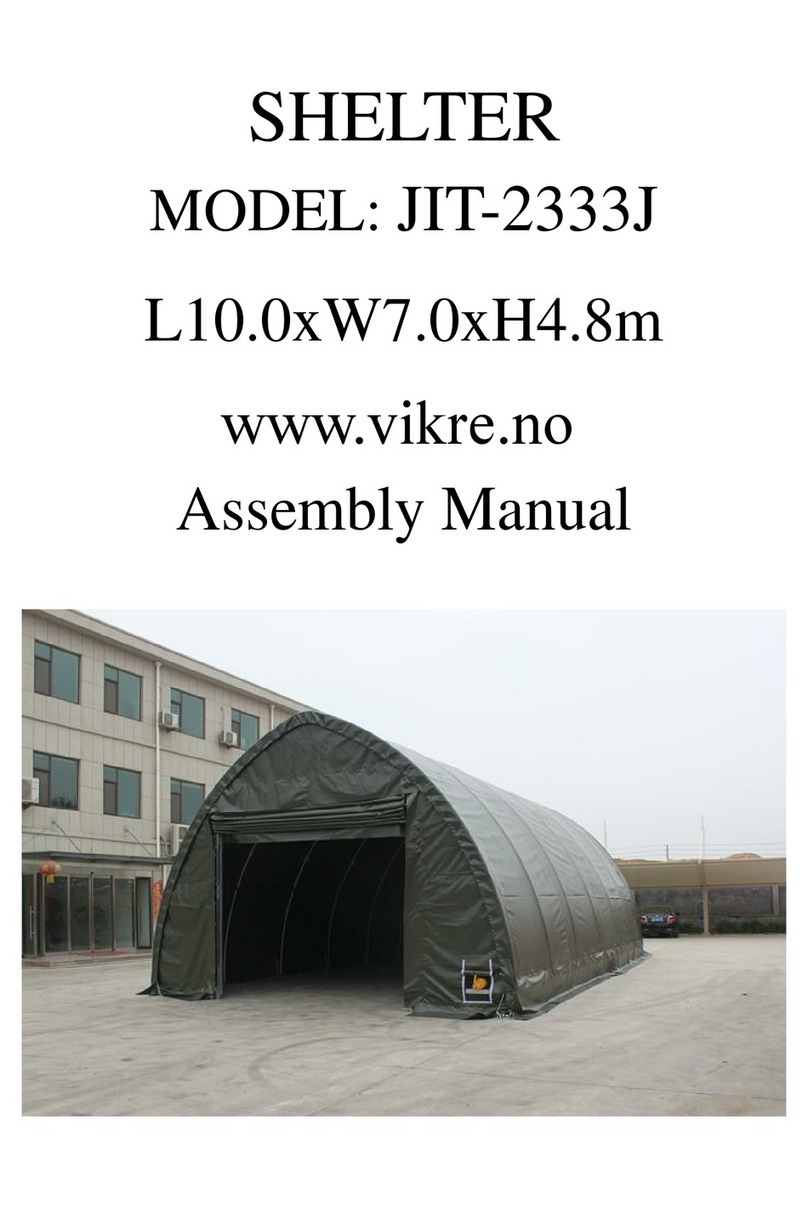

Vikre Handel AS

Vikre Handel AS JIT-2333J Assembly manual

Shelters4Less

Shelters4Less SR1586 Assembly instructions

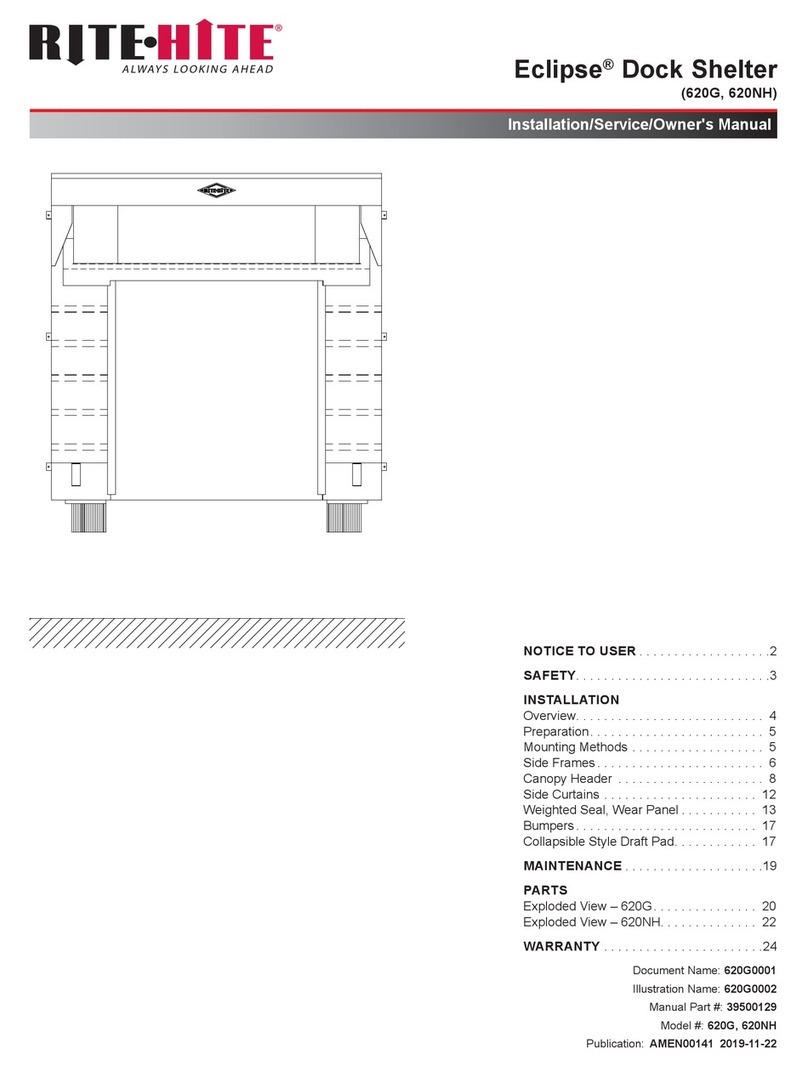

RITE-HITE

RITE-HITE Eclipse 620G Installation/Service/Owner's Manual

EzyFast

EzyFast EFAT631 instruction manual

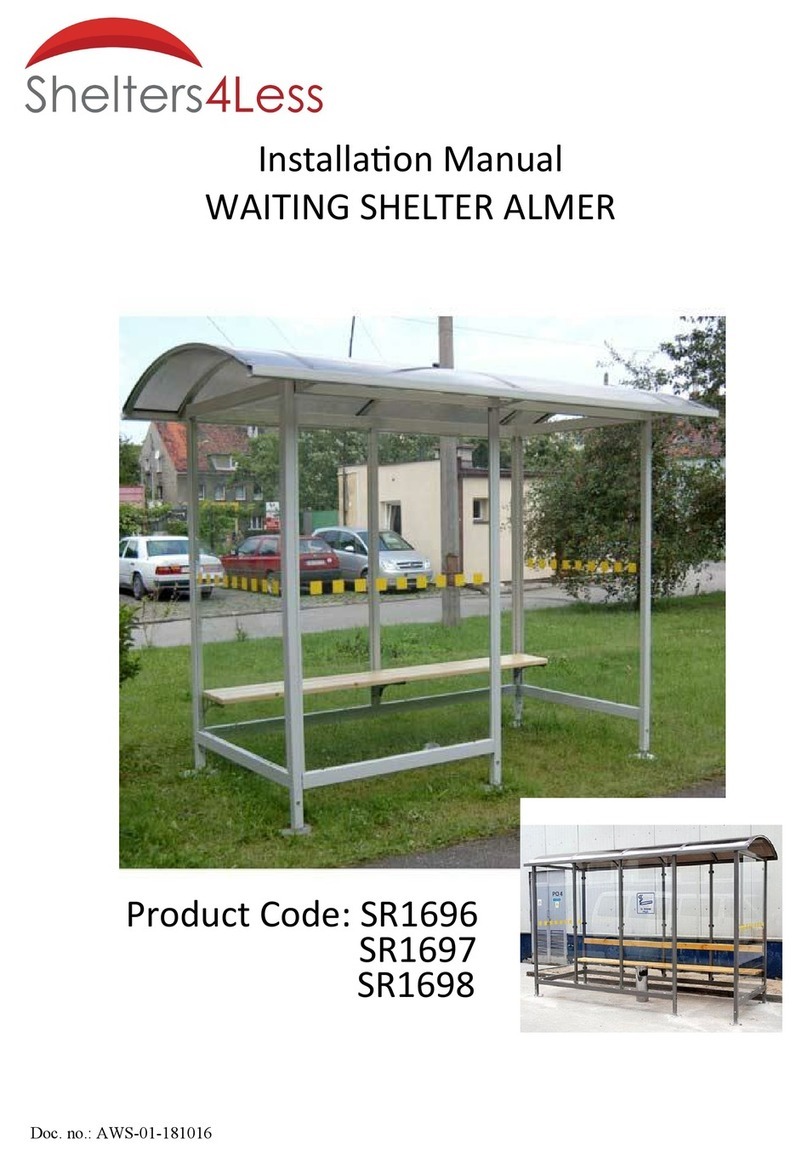

Shelters4Less

Shelters4Less SR1696 installation manual

Duratuf KIWI

Duratuf KIWI SHEDS MK4A Assembly instructions

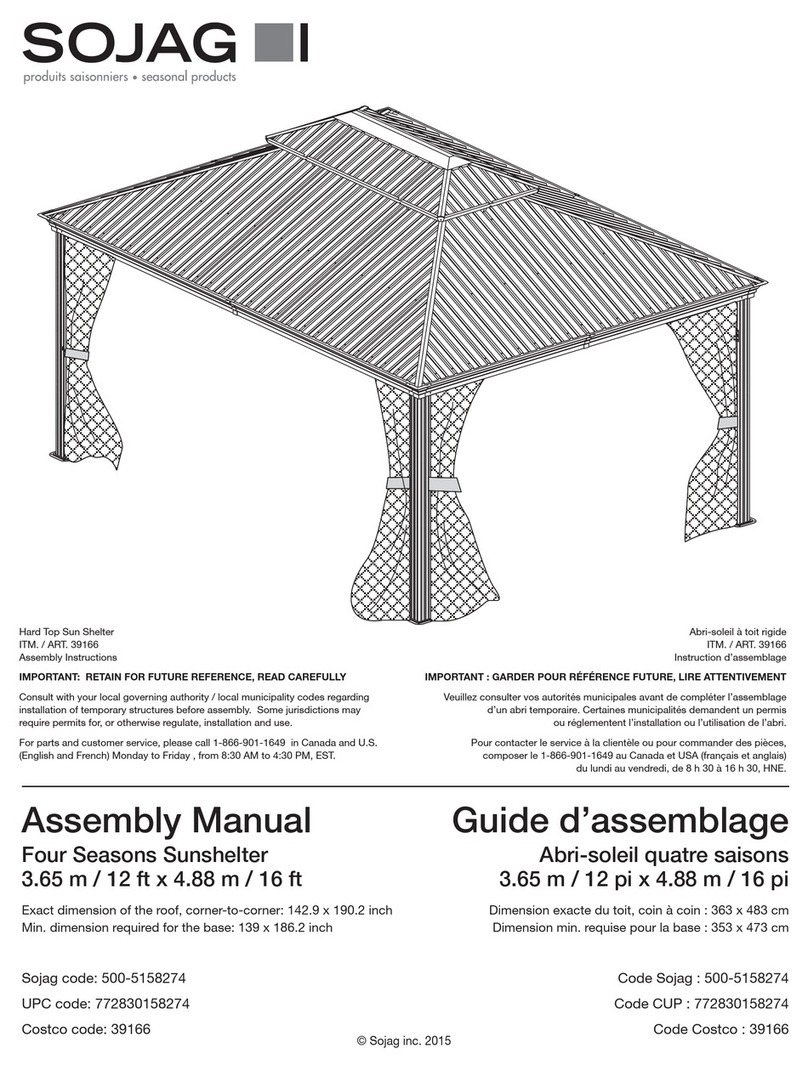

Sojag

Sojag 39166 Assembly manual

No Butts Bin

No Butts Bin SR1584 Assembly instructions

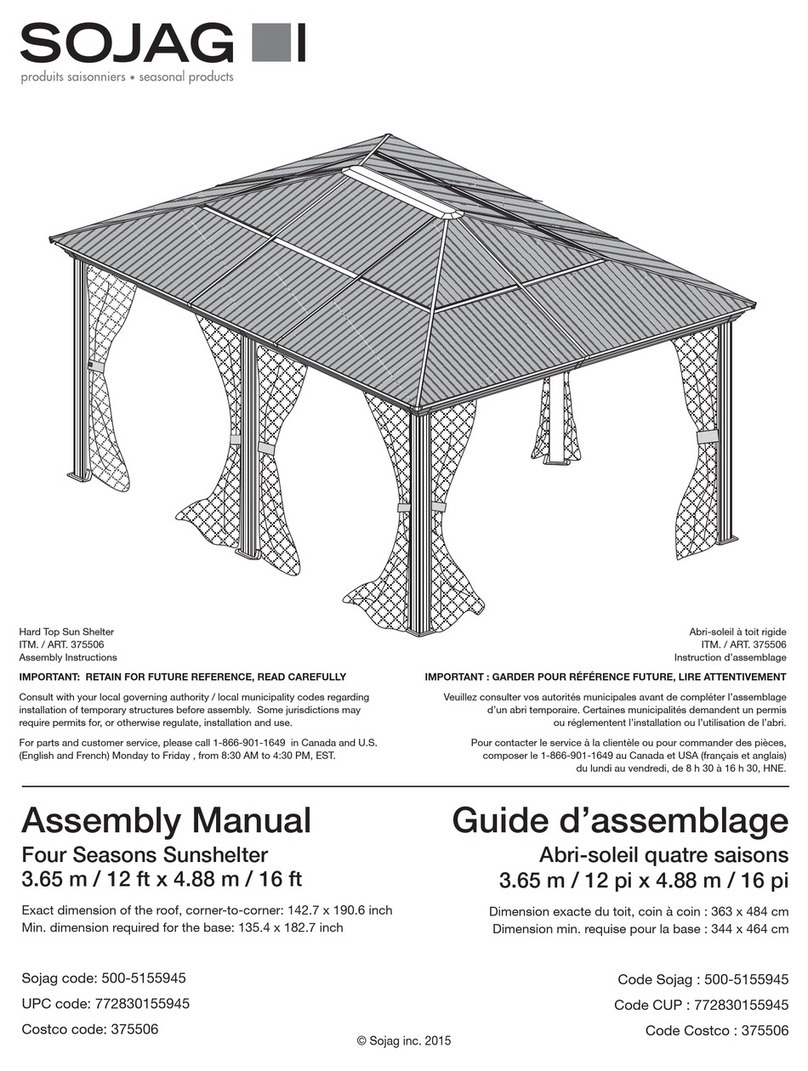

Sojag

Sojag 375506 Assembly manual

No Butts Bin

No Butts Bin SR1588 Assembly instructions

Kozyard

Kozyard 12'x20' Alexander hardtop gazebo with double... Assembly manual

Sojag

Sojag 500-9165463 Assembly manual

TMG

TMG TMG-CP1220 product manual

Costway

Costway NP10385 user manual

USP

USP Duramax Palladium Owner's manual & assembly instructions

Rowlinson Garden Products

Rowlinson Garden Products Bondi BBQSHEL Assembly instructions

No Butts Bin

No Butts Bin SR1562 Assembly instructions