Hardy Diagnostics QUICKSLIDE GramPRO-80 Operation instructions

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 1 of 94

Automated Multiple Slide Gram Stainer

User Operating Manual

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 2 of 94

Revision History

Revision

Description

_

Initial Release for Software Version 1.0.01L

05/28/2014

Revise Sec 5, add Sec 10 & various Menu updates for V1.0.01W

06/23/2014

Add STAT double-spacing note-pg. 15&17, Slide Prep DiaGram-pg. 13

10/31/2014

Revise Run Mode Message summary table –pg. 25

10/31/2014

Add Operational Trouble-Shooting Guide –section 12

11/10/2014

Add Clean Interval Menu –section 6.3.2.3

12/11/2014

Add Auto & Manual Eject Slots to Idle Delay Menu –section 6.4.6

01/26/2015

Revise sample placement instruction –3/4” below frosted area (section 5.2)

02/04/2015

Minor typo corrections & clarifications, & added gripper lube picture (section 10.1)

04/03/2015

Added On-Screen Help & revised menus to new style & color scheme

04/14/2015

Revised Stain Error trouble-shooting guide (section 12.13) for V1.1.02e.

01/06/2016

Added Specifications, pg. 4.

01/06/2016

Added Power On / Off & Caution symbol definitions on pg. 9.

01/06/2016

Revised power consumption on pg. 10: was 200 W, is 180 W.

01/06/2016

Added electrical connection notes on pg. 11.

01/06/2016

Added Power On symbol to pg. 20.

01/06/2016

Replaced all SDS sheets with updated (2015) versions, pg. 87 - 104.

01/11/2016

Added safety and CE standards to Specifications page.

02/06-2016

Updated logo product model and company information

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 3 of 94

Congratulations!

You have made an excellent choice for your Lab. QUICKSLIDE thanks you for the trust you have

placed in us.

This operating manual has been designed to help you gain an understanding of the operation and

possible applications of our GRAMPRO-80. For optimal utilization of all functions, we recommend that

you thoroughly study this manual prior to beginning operation.

This manual has been prepared as an aid for all operations and maintenance procedures which can

be carried out in the customer’s facility. It provides the operator with instructions for the operation of

the GramPRO-80automated Gram stainer.

The QUICKSLIDE Company Quality Management System

Our devices for the medical lab are developed, produced, and distributed according to the

requirements of ISO 9001:2008. All products are shipped to you from our manufacturing facility

located at 3411 McNiel Ave Suite 302, Wichita Falls, Texas 76308

Unpacking and inspecting

Unpack the GramPRO-80 and accessories and check for damages incurred during transit. Keep all

packing material until you are sure the unit operates properly. Any damage to the shipping box should

be reported to the responsible carrier, railway, or postal authority, and a request for a damage report

should be made. These instructions must be followed fully for us to guarantee our full support of your

claim for protecting against loss from concealed damage. The form required for filing such a claim will

be provided by the carrier.

Printed in U.S.A. Changes without prior notification reserved

Important: Keep operating manual for future use.

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 4 of 94

Specifications

Dimensions/Weight

Width 83.8 cm (33.0 in.)

Height 40.6 cm (16.0 in.)

Depth 31.8 cm (12.5 in.)

Weight 20.41 Kg (45.00 lbs.)

Power Requirements

Input 12 VDC, 15 A, 180 W maximum

(For reference, GramPRO-80uses an external power supply module that may be supplied

with 60 Hz, 110 VAC or 50 Hz, 230 VAC line power. Standard power cords are supplied to meet local

standards.)

Temperature, Ambient Operation

16-32 Degrees C (60-90 Degrees F)

Humidity

0 to 95% without condensation

Operator Adjustments

Individual Adjustable Stain Times on Both Short and Long Cycles

Adjustable Sleep Mode

Adjustable Audible Sound Volume Control

Operator Entry

Moisture Proof, Touch Screen

Standards

IEC-61010-1:2010 (Third Edition)

EN55022; CISPR 22 Ed. 6.0:2008 Class A

CFR 47, Part 15, Subpart B, Class A, 2011

ICES-003 Issue 4, 2004 CAN/CSA-CIE/IEC CISPR 22;02 Class A

EN61326-1: 2010

Warranty

One Year Standard

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 5 of 94

Table of Contents

1. INTRODUCTION .............................................................................................................................9

2. WORK AREA REQUIREMENTS: IMPORTANT! ...........................................................................10

3. RECEIVING & UNPACKING...........................................................................................................10

4. REAGENT SUPPLY KITS .............................................................................................................11

4.1 General information ..................................................................................................................11

4.2 Ordering information..................................................................................................................11

4.3 Reagent Kit Installation..............................................................................................................11

5. GramPRO-80OPERATIONS OVERVIEW ...................................................................................13

5.1 Background –Gram's Stain Technique......................................................................................13

5.2 Sample Slide Preparation ..........................................................................................................14

5.3 GramPRO-80Preparation...........................................................................................................15

5.4 Loading Slides into the GRAMPRO-80 ......................................................................................15

5.5 GramPRO-80Stain Processing ..................................................................................................16

5.6 Quick Guide –MGS Stain Operation .........................................................................................17

6. SYSTEM SOFTWARE OPERATION .............................................................................................19

6.1 Software Operation Overview.................................................................................................19

6.2 Main Menu..............................................................................................................................20

6.3 RUN command button ............................................................................................................21

6.3.1 Process Slides Menu .....................................................................................................22

6.3.1.1 Process Slides / Run Mode Messages........................................................................23

6.3.1.2 Run Mode Message Table..........................................................................................24

6.3.2 Clean Unit Menu ............................................................................................................25

6.3.2.1 Wash Unit Process......................................................................................................26

6.3.2.2.1 Pre-Scrub Purge Stain Prompt.................................................................................27

6.3.2.2.2 Pre-Scrub Prime Cleaner Prompt.............................................................................28

6.3.2.2.3 Run Scrub Cycle Prompt..........................................................................................29

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 6 of 94

6.3.2.2.4 Scrub Unit Process ..................................................................................................30

6.3.2.2.5 Scrub Complete Menu..............................................................................................31

6.3.2.2.6 Post-Scrub Prime Reagents Prompt.........................................................................32

6.3.2.3 Clean Interval Menu....................................................................................................33

6.4 SET-UP command button.......................................................................................................34

6.4.1 Stain Delays Menu.........................................................................................................35

6.4.2 Consumables Menu.......................................................................................................36

6.4.2.1 Reagent Kit Registration Menu....................................................................................37

6.4.2.2 Tubing Kit Registration Menu......................................................................................38

6.4.3 Date / Time Menu...........................................................................................................39

6.4.4 Test Decolorizer Menu...................................................................................................40

6.4.5 Speaker Volume Menu...................................................................................................41

6.4.6 Idle Delays Menu ...........................................................................................................42

6.4.7 Soak Delays Menu........................................................................................................43

6.4.8 DI Water Sensor Calibration Menu.................................................................................44

6.4.9 Waste Container Menu ..................................................................................................45

6.5 Self-Test command button......................................................................................................46

6.5.1 Self-Test Review Menu..................................................................................................47

6.6 Service Mode Access Menu....................................................................................................48

6.6.1 Software Update Menu ..................................................................................................49

6.6.1.1 GramPRO-80Software Update Confirmation Menu......................................................50

6.6.1.2 XZA Controller Update Confirmation Menu ..................................................................51

6.6.1.1.3 Pump Master Controller Update Confirmation Menu .................................................52

6.6.1.1.4 TMD Pump Controller Update Selection Menu..........................................................53

6.6.1.1.4.1 TMD Pump Controller Update Confirmation Menu .................................................54

7. QUALITY CONTROL.....................................................................................................................55

Quality Control Checks....................................................................................................................55

Self Calibration Errors......................................................................................................................55

8. USAGE TRACKING........................................................................................................................56

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 7 of 94

Reagent Consumption.....................................................................................................................56

Recommended Wash Interval..........................................................................................................56

Total Stain Cycles............................................................................................................................56

9. “IDLE” Activities ..............................................................................................................................56

STIR Operation................................................................................................................................56

AUTO-PRIME-ALL Operation..........................................................................................................56

10. GramPRO-80Periodic Maintenance..............................................................................................57

10.1 General Maintenance.......................................................................................................57

10.2 Reagent Kit Replacement ................................................................................................57

10.3 Tubing Kit Replacement...................................................................................................58

10.4 Wash Procedure..............................................................................................................59

10.5 Scrub Procedure..............................................................................................................59

11. Pump Tube Replacement Procedure for GRAMPRO-80..............................................................60

12. GramPRO-80Operational Trouble-Shooting Guide ......................................................................62

12.1 Cover OPEN Warning Trouble-Shooting Guidelines................................................................63

12.2 Load Slide Disabled Warning Trouble-Shooting Guidelines.....................................................63

12.3 Slide Motion Disabled Warning Trouble-Shooting Guidelines ..................................................64

12.4 Out Feed Eject Busy Warning Trouble-Shooting Guidelines....................................................64

12.5 Scrub or Wash Warning Trouble-Shooting Guidelines.............................................................64

12.6 DI Water Bottle Volume Low Alert Trouble-Shooting Guidelines..............................................65

12.7 Waste Container FULL Alert Trouble-Shooting Guidelines.......................................................66

12.8 Reagent Kit Exhausted Alert Trouble-Shooting Guidelines ......................................................66

12.9 Tubing Kit Exhausted Alert Trouble-Shooting Guidelines.........................................................67

12.10 Load Position Alert Trouble-Shooting Guidelines...................................................................68

12.11 Out-Feed Full Alert Trouble-Shooting Guidelines...................................................................68

12.12 Decolorizer Self-Calibration Error Trouble-Shooting Guidelines.............................................68

12.13 Cuvette Stain Error Trouble-Shooting Guidelines...................................................................70

12.14 Air Pressure LOW Error Trouble-Shooting Guidelines ...........................................................71

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 8 of 94

12.15 Slide Transfer Error Trouble-Shooting Guidelines..................................................................71

12.16 Cuvette N Occupied Error Trouble-Shooting Guidelines ........................................................72

12.17 X Home Operation Error Trouble-Shooting Guidelines...........................................................73

12.18 Z Home Operation Error Trouble-Shooting Guidelines...........................................................74

13. GramPRO-80Unit shut down for shipping .....................................................................................75

14. GramPRO-80Warranty .................................................................................................................76

15. Material Safety Data Sheets.........................................................................................................77

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 9 of 94

1. INTRODUCTION/ Operator Responsibility/ User Safety

This Operation Manual is provided to guide the user in all aspects of unit set-up, operational use, and

user-level maintenance of the QUICKSLIDE Automated Multiple Slide Gram Stainer (GramPRO-80)

unit.

The GramPRO-80 is a microscope slide stainer capable of automatically performing a Gram Stain

sequence on a slide containing biological material. An on-board computer running software specially

designed to accomplish correct Gram Stain results for any type of sample controls the entire staining

process.

The GramPRO-80 software provides a series of menus for operator control of the unit. By pressing a

key corresponding to a menu item, the operator directs program flow to the various logic paths of the

software. All program functions are accessed in this manner.

Section 5 of this manual provides a quick start script for a Gram Stain operation.

Section 6 of this manual provides a complete overview and description of all the system menus and

associated operations.

Operator Responsibility –Safety Instructions

The GramPRO-80 ensures safe operation when installed, operated, and maintained according to

common safety regulations. This section explains all the potential dangers that may arise when

operating the GramPRO-80 and also specifies the most important safety precautions to obtain a high

degree of mitigation.

It is the operator’s to be properly qualified to operate the GramPRO-80. The operator and personnel

are also advised to refer to this Operating Manual and/or “call me” letter that is packaged with unit.

In addition, the operator is to be qualified, familiar with, and follow the laboratories safety rules.

Explanation of Symbols

| - Power On

O - Power Off

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 10 of 94

Caution –refer to marked paragraphs in this manual for details

2. WORK AREA REQUIREMENTS IMPORTANT!

The GramPRO-80unit requires a level counter top surface of 34 inches wide by 14 inches deep with a

vertical clearance of 18 inches. The Reagent Supply Kit sits on the counter immediately beside or

behind the instrument and is connected with tubing.

The GramPRO-80 unit requires a water jug, preferably DI water, which is connected with tubing.

Several tubes from the GramPRO-80 unit drain waste fluids. The GramPRO-80 unit should be placed

near a drain or other disposal container to accommodate this waste fluid.

The GramPRO-80 consumes less than 180 W of power and uses an external power supply module

that may be supplied with 60 Hz, 110 VAC or 50 Hz, 230 VAC line power. The unit requires power

from a grounded outlet.

There are no special environmental requirements for operation of the GramPRO-80.

The GramPRO-80 is supplied with tubing sets to connect the instrument to reagents. Connect the

Leur fittings on the reagent lines to the respective fittings on the instrument of the same color. The

other end of the reagent supply line is equipped with a rigid tube to immerse in the reagent supply.

Labels attached to those lines indicate which reagent is to be used with each line.

In addition, the line with the green Leur fitting is to be immersed in the water supply to indicate

available water.

The supplied tubing set is long enough to permit the reagent containers to be placed at floor level, if

desired.

3. RECEIVING & UNPACKING

Unpacking and set-up assistance for the GramPRO-80 may be obtained by calling the Service

Dept. of QUICKSLIDE at 800-295-9588 during the hours of 8 –5 Central Time, Monday through

Friday.

The GramPRO-80is for use only with provided external power supply Model No. GS220A12, or

equivalent. The power supply ratings are:

Input 100-240 VAC, 50/60 HZ, 4.0 A

Output 12 VDC, 15 A, 180 W

The external power supply is a Class I supply that must be connected to an earthed (grounded) main

power outlet. Failure to connect the GramPRO-80 as specified will prevent electrical safety protection

features to function as designed.

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 11 of 94

The power supply is equipped with one attached power cord and one removable power

cord. The attached power cord is equipped with a connector that plugs into the GramPRO-

80 rear panel receptacle near the power switch. The removable power cord adapts the IEC

style connector on the power supply to the local standard AC outlet. The cord supplied by

G G & B is appropriate for the country of destination.

4. REAGENT SUPPLY KITS

4.1 General information

The GramPRO-80 accomplishes automatic Gram Staining by systematically staining, rinsing,

decolorizing, and counter-staining the provided biological sample and slide. It is critical for the

success of this automated process that the composition of the reagents employed be carefully

controlled and be of exceptionally high qualify.

NOTE: For quality control purposes, Reagent Supply Kits are labeled with Kit Number, Lot Number,

and Expiration Date. These values are used to track and identify the Reagent Supply Kit used in the

unit, and are entered into the system as part of the Change Reagents procedure.

4.2 Ordering information

The GramPRO-80 software monitors consumption of the Reagent Supply Kit. When starting each

Stain Cycle, the system displays a count of the remaining number of stain cycles available in the

current kit. This remaining count should be carefully monitored so that fresh reagents may be ordered

and available when needed. Call QUICKSLIDE at 800-295-9588 to order supplies.

4.3 Reagent Kit Installation

The GramPRO-80 reagents are supplied to the unit through tubes connected to the individual

reagent containers. Each tube is clearly labeled, and must be inserted into the correct reagent

container. Tubes are also provided for connection to a water source, and to a waste fluid drain.

Use care to insure that these lines are properly connected before use of the GramPRO-80unit.

5. GramPRO-80 OPERATIONS OVERVIEW

5.1 Background –Gram's Stain Technique

The Gram staining method, named after the Danish bacteriologist who originally devised it in 1882,

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 12 of 94

Hans Christian Gram, is one of the most important staining techniques in microbiology. It is almost

always the first test performed for the identification of bacteria. The primary stain of the Gram's

method consists of staining with crystal violet which is then fixed with iodine. The microorganisms

that retain the crystal violet-iodine complex appear purple under microscopic examination and are

commonly classified as Gram-positive. Others that are not stained by crystal violet are referred to

as Gram-negative, and appear red as a result of counter-staining with safranin.

Gram staining is based on the ability of bacteria cell wall to retain the crystal violet dye during

solvent treatment. The cell walls for Gram-positive microorganisms have a higher peptidoglycan

and lower lipid content than Gram-negative bacteria. Bacteria cell walls are stained by the crystal

violet. Iodine is then added as a mordant to form the crystal violet-iodine complex so that the dye

cannot be removed easily. Subsequent treatment with a decolorizer, which is a solvent, dissolves

the lipid layer from the Gram-negative cells. The removal of the lipid layer enhances the leaching

of the primary stain from the cells into the surrounding solvent. In contrast, the solvent dehydrates

the thicker Gram-positive cell walls, closing the pores as the cell wall shrinks during dehydration.

As a result, the diffusion of the violet-iodine complex is blocked, and the bacteria remain stained.

The length of the decolorization is critical in differentiating the Gram-positive bacteria from the

Gram-negative bacteria. A prolonged exposure to the decolorizing agent will remove all the stain

from both types of bacteria. Some Gram-positive bacteria may lose the stain easily and therefore

appear as a mixture of Gram-positive and Gram-negative bacteria (Gram-variable). Finally, a

counter-stain of safranin is applied to the smear to give decolorized Gram-negative bacteria a red

or pink color.

The decolorization step is especially critical and must be timed correctly; the crystal violet stain is

removed from both Gram-positive and negative cells if the decolorizing agent is left on too long.

This can be particularly problematic for smears varying excessively in thickness –thicker smears

require longer exposure for proper decolorization than thinner smears. This is the most sensitive

and variable step of the procedure, and requires experience to know just how much to decolorize

manually. Many labs performing manual Gram Stains have considerable quality control problems

for this reason. The GramPRO-80 incorporates a patented computerized “electronic eye” to

perfectly time the decolorization of every sample, guaranteeing that all slides are processed

correctly every time.

5.2 Sample Slide Preparation

5.2.1. Transfer a drop of the suspended culture to be examined on a slide with an inoculation loop.

If the culture is to be taken from a Petri dish or a slant culture tube, first add a drop or a few loop

full of water on the slide and aseptically transfer a minute amount of a colony from the Petri dish.

Note that only a very small amount of culture is needed; a visual detection of the culture on an

inoculation loop already indicates that too much is taken. If staining a clinical specimen, smear a

very thin layer onto the slide, using a wooden stick. Do not use a cotton swab, if at all possible, as

the cotton fibers may appear as artifacts. The smear should be thin enough to dry completely

within a few seconds. Stain does not penetrate thickly applied specimens, making interpretation

very difficult.

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 13 of 94

5.2.2. Spread the culture with an inoculation loop to an even thin film over a circle of 1.5 cm in

diameter, approximately the size of a dime. Position the smear at least 3/4” below the frosted

area, and 1/4” from the left and right edges of the slide to provide the necessary clearances

for GramPRO-80 processing. Take care to avoid placing labels on the slide that might

interfere with the GramPRO-80 mechanism. Labels cannot wrap around the sides of the

slide and should not extend below the frosted area. Labels may wrap over the top of the slide if

fitted tightly & flush onto the slide. See diaGram on next page for details.

5.2.3. Air-dry the culture. Once dried the sample must be fixed to the slide with either a methanol

or heat fixing method. With methanol, flood or dip the sample in methanol and allow the slide to

completely dry before processing. Alternately the sample may be heat fixed over a gentle flame,

while moving the slide in a circular fashion to avoid localized overheating. Fixing the sample helps

the cell adhesion on the glass slide to make possible the subsequent rinsing of the smear with

water without a significant loss of the culture. Heat can also be applied to facilitate drying the

smear. However, ring patterns can form if heating is not uniform, e.g. taking the slide in and out of

the flame.

See following diagram, page 14.

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 14 of 94

SLIDE Prep Diagram

FROSTED

NO SAMPLE HERE

(3/4” BELOW FROSTED AREA)

SAMPLE HERE

SAMPLE MATERIAL SHOULD BE

PLACED AT LEAST 3/4” BELOW

FROSTED PORTION OF SLIDE

& 1/4” FROM EITHER EDGE

<-1/4”-> <-1/4”->

min min

LABEL CANNOT BE

WRAPPED AROUND

SIDES OR BELOW

FROSTED PORTION BUT

MAY BE WRAPPED OVER

TOP IF FLUSH

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 15 of 94

5.3 GramPRO-80 Preparation

5.3.1. Insure all reagent and water supply tubes are properly inserted into the correct containers.

Insure all drain tubes are positioned for proper disposal of waste fluids. Confirm that all lines are

properly primed (this is done automatically by the power-on Self-Test process).

5.3.2. Confirm correct registration and availability of a Reagent Kit & a Tubing Kit (these are also

checked automatically by the Self-Test process). Confirm reagent fluids are present in the supply

containers.

5.3.3.Confirm water is present in the supply container. Confirm the waste container has space for

anticipated waste fluids. Software monitors water and waste fluids as displayed in the lower right

portion of the screen. The system will provide water or waste error messages when appropriate.

5.3.4. Insure there are no slides in the seven processing cuvettes. The presence of slides (as

noted by optical sensors) prevents the device from starting the staining process.

5.3.5. Check for space available in the out-feed screw for the unloading of processed slides. An

optical sensor detects slides in any of the last seven positions, and prevents the device from

starting the staining process if any are present. Unload slides as necessary.

5.4 Loading Slides into the GramPRO-80

5.4.1 Normal Loading

To load slides, open the clear cover door over the in-feed screw on the left side of the GRAMPRO-

80. Up to 80 slides may be pre-loaded into the instrument before processing starts. The slides

must be positioned with the sample smear side facing to the right side of the instrument.

The slides must be loaded into the screw threads so that the slide is perpendicularly aligned to the

screws. Positioning sensors at the load station detect incorrectly loaded slides and provide a

message to inform the operator of the load error. The cover door must be closed for processing to

commence.

Additional slides may be loaded into the in-feed screw while processing continues. Open the

cover door to suspend load operations, and insert additional slides for processing as desired.

Close the cover door to resume load operations.

Use care when placing slides in the GramPRO-80. The slides present sharp corners that

if accidently bumped may result in injury or a broken slide.

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 16 of 94

5.4.2 STAT Loading

The GramPRO-80 includes a STAT load station to accommodate the immediate loading and

processing of a STAT slide. Simply open the STAT Slide Drawer by retracting it from the panel,

insert a slide, and then close the STAT Slide Drawer. (Note: The GramPRO-80 must be in Run

Mode BEFORE closing the Stat Slide Drawer.) Optical sensors detector the presence of the

STAT slide and the system preempts the normal loading sequence to insert the STAT slide as the

next slide for processing, effectively allowing it to “cut in line” ahead of the slides in the normal load

queue in the in-feed screw.

5.4.3 Processed Slide Order

Processed slides arrive in the out-feed screw in the same order as they were loaded into the in-

feed screw, except that any STAT slides will be inserted as encountered. Marking the edges of

STAT slides with a Sharpie, or similar marker, can aid in identifying and retrieving processed STAT

slides from the out-feed screw. Slides loaded from the STAT drawer are double-spaced in the out-

feed screw after processing to aid in identification.

5.5 GramPRO-80 Stain Processing

The GramPRO-80 employs seven cuvettes for the Gram Stain process: two for crystal violet

staining (#1 & #2); two for Grams' Iodine fixing (#3 & #4); one for decolorizing (#5); and two for

safranin counter-staining (#6 & #7). Slides are transported from station to station during the

process, moving in sequence from load to crystal violet stain to iodine fix to decolorize to safranin

counter-stain and finally to unload, traveling either a route of load to cuvette #1 to #3 to $5 to #7 to

unload, or of load cuvette #2 to #4 to #5 to #6 to unload. The “even cuvettes” and “odd cuvettes”

paths are alternated for each new slide.

One of three pre-programmed sets of Stain Delays, (i.e. Short, Medium, or Long Delays) is

selected when a run is started. The soak times for crystal violet, Gram's iodine, and safranin are

determined by this selection. Note that the three soak times (for CV, GI & SAF) of each of the

three sets may be altered as desired by the facility administrator. The default settings are:

Short Medium Long

CV 40 50 60

GI 40 50 60

SAF 40 50 60

Decolorization duration is determined automatically (by a patented electronic method) for each

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 17 of 94

slide as it is decolorized. GramPRO-80 processing includes an automatic self-calibration of the

decolorizer sensor prior to decolorizing each slide to further insure the reliability and consistency of

the processed result. Self-calibration errors are detected and noted to permit any required

corrective action.

Once started, processing can be suspended by entering the PAUSE SLIDE TRAVEL command.

Loading can be suspended by opening the cover door and resumed by closing the cover door.

Loading may also be suspended by entering the SUSPEND NEW LOADS command, and then

resumed with the RESUME LOADING command.

Optical sensors monitor the progress of slides traveling through the sequence of cuvettes. Errors

are reported any time a slide is detected in a cuvette that should be empty, or when an empty

cuvette is detected that should be occupied. Messages and possible corrective actions are

provided for any detected errors.

Fluid level detectors are utilized to insure the cuvettes are filled with fluid to the proper level.

These detectors insure the same fill level, even when slides of various thicknesses are batched

together in the same run. The fluid detectors are also monitored to confirm the proper presence, or

absence, of fluid in the cuvettes at specific points in the processing cycle. Errors detected can

indicate an out-of-reagent condition, a clogged line, or a malfunctioning pump. Messages and

possible corrective actions are provided for any detected errors.

Completed slides are placed into the out-feed screw for drying. Drying fans are used to dry the

slides in about two minutes. An EJECT function is available to gain access to completed slides

more quickly. Slides loaded from the STAT drawer are double-spaced in the out-feed screw after

processing to aid in identification.

The last seven slots of the out-feed screw are monitored for the presence of slides. Detection of a

slide in these positions triggers a count-down of processing for a maximum of seven more slides

(the maximum already loaded & process) before processing is suspended. Processing resumes

after slides are removed from the out-feed screw.

5.6 Quick Guide –GamPRO-80 Stain Operation

This chapter provides the minimum instruction sequence for staining a slide. See Section 6 for the

complete description of the GramPRO-80 system options and capabilities. Reagent and waste

disposal tubes must be properly connected for proper unit operation. Enter the listed menu

command selections in sequence to initiate a Gram Stain operation.

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 18 of 94

5.6.1 Turn the system power switch ON

During the power up process, the system identification screen is briefly displayed. Once the

system completes loading, the Self-Test procedure (refer to section 6.5) validates system

operational parameters and prepares the unit for use. Any error conditions encountered are

flagged in the Self-Test Review Menu –please refer to section 6.3.1.1 for error resolution

methods. Otherwise, upon normal completion the Main Menu is displayed (refer to section 6.2),

continue to next step.

5.6.2 Load slides

Optionally, slides to be stained may now be loaded (with the sample side facing right) into the

Load Screw and/or Stat Load Drawer. Slides have sharp corners. Use care when installing slides

to avoid injury. (Note: The GramPRO-80 must be in Run Mode BEFORE closing the Stat Slide

Drawer.)

5.6.3 Press the RUN

Press the RUN command button in the Main Menu to proceed to the Run Menu (refer to section

6.3).

5.6.4 Select & press RUN SHORT, MEDIUM or LONG STAINS

Press one of the stain command buttons (RUN SHORT STAINS, RUN MEDIUM STAINS, or RUN

LONG STAINS) to select the desired stain delay times for the run.

5.6.5 Automated Gram Staining Process Begins

The unit may now be left unattended as slides are automatically loaded from the Load Screw

and/or the Stat Drawer for Gram Stain processing. Additional slides may be inserted (with the

sample side facing right) as desired into either load location for processing. Staining continues

automatically until all available slides have been processed, or the ABORT command button is

pressed.

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 19 of 94

6. SYSTEM SOFTWARE OPERATION

This chapter provides a detailed description of the operator interface methods of the GramPRO-

80system.

6.1 Software Operation Overview

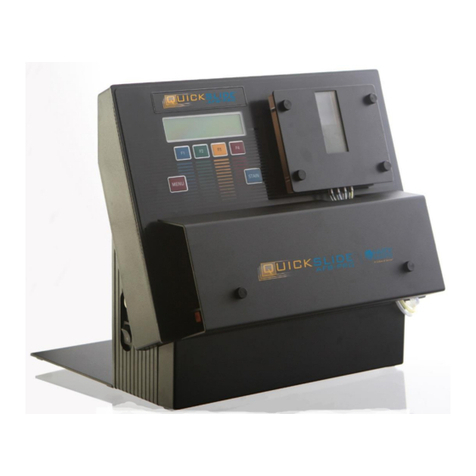

A LCD touch-screen device is the basis for a menu-driven system of message displays and

operator commands. Figure 1 details the general lay-out and usage of the video screen. The

upper left portion of the screen may contain up to 10 menu command buttons. Only active

buttons are displayed. An optional keypad for numeric entries may appear in the upper right

portion, if appropriate for the current menu. Just above the keypad, in red, the entered digits

are echoed. The lower left portion may display normal operational status information in gray

text or error messages in red text as needed. The lower right area displays operating

parameters and the system date & time.

GramPRO-80

User Operating Manual

Doc: GRAMPRO-80-UM Release Date: Feb 6, 2016

QUICKSLIDE

A Div. of Hardy Diagnostics 3411 McNiel Ave, Suite 302

800-295-9588 Wichita Falls, TX 76308

Page 20 of 94

6.2 Main Menu

Figure 6.2 –Main Menu

The Main Menu is the top-level menu of the system as shown in figure 2. Press RUN for access to

automated Gram Stain operations. Press SET-UP for instrument calibration and parameter set-up

menus. Press SELF TEST to initiate a complete unit self diagnostic and priming procedure. Press

SERVICE to access “service mode” operations (these procedures are accessible to qualified service

personnel only). Press SHUT DOWN, and then confirm by pressing SHUT DOWN again, to initiate the

power down preparation procedure which purges all fluid lines and positioned the gripper assembly for

shipment.

Table of contents

Other Hardy Diagnostics Laboratory Equipment manuals

Hardy Diagnostics

Hardy Diagnostics QuickSlide HemaPRO Mounting instructions

Hardy Diagnostics

Hardy Diagnostics QuickSlide HemaPRO Mounting instructions

Hardy Diagnostics

Hardy Diagnostics QuickSlide HemaPRO User manual

Hardy Diagnostics

Hardy Diagnostics QuickSlide AFB-PRO Mounting instructions

Hardy Diagnostics

Hardy Diagnostics QuickSlide HemaPRO Mounting instructions