Contents

1、Safety Notes......................................................................................................................................................... 1

1.1 Safety Matters...................................................................................................................................................... 1

1.2 Installation Environment ..................................................................................................................................... 1

1.3 Delivery Inspection.............................................................................................................................................. 2

2、Characteristics & Scope of Application............................................................................................. 2

2.1 Scope ofApplication............................................................................................................................................ 2

2.2 Characteristics ..................................................................................................................................................... 2

3、Safety Regulations........................................................................................................................................... 2

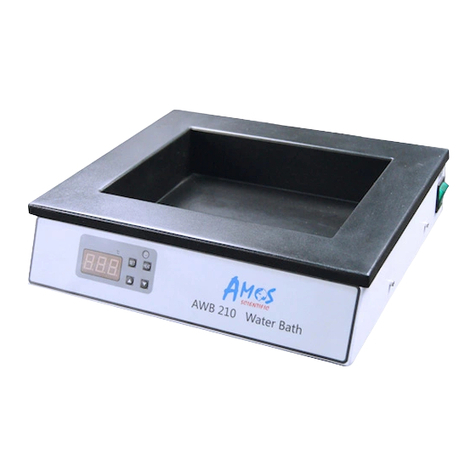

4、Overview- Instrument Components..................................................................................................... 3

5、Technical Specification................................................................................................................................. 3

6、Operation.............................................................................................................................................................. 4

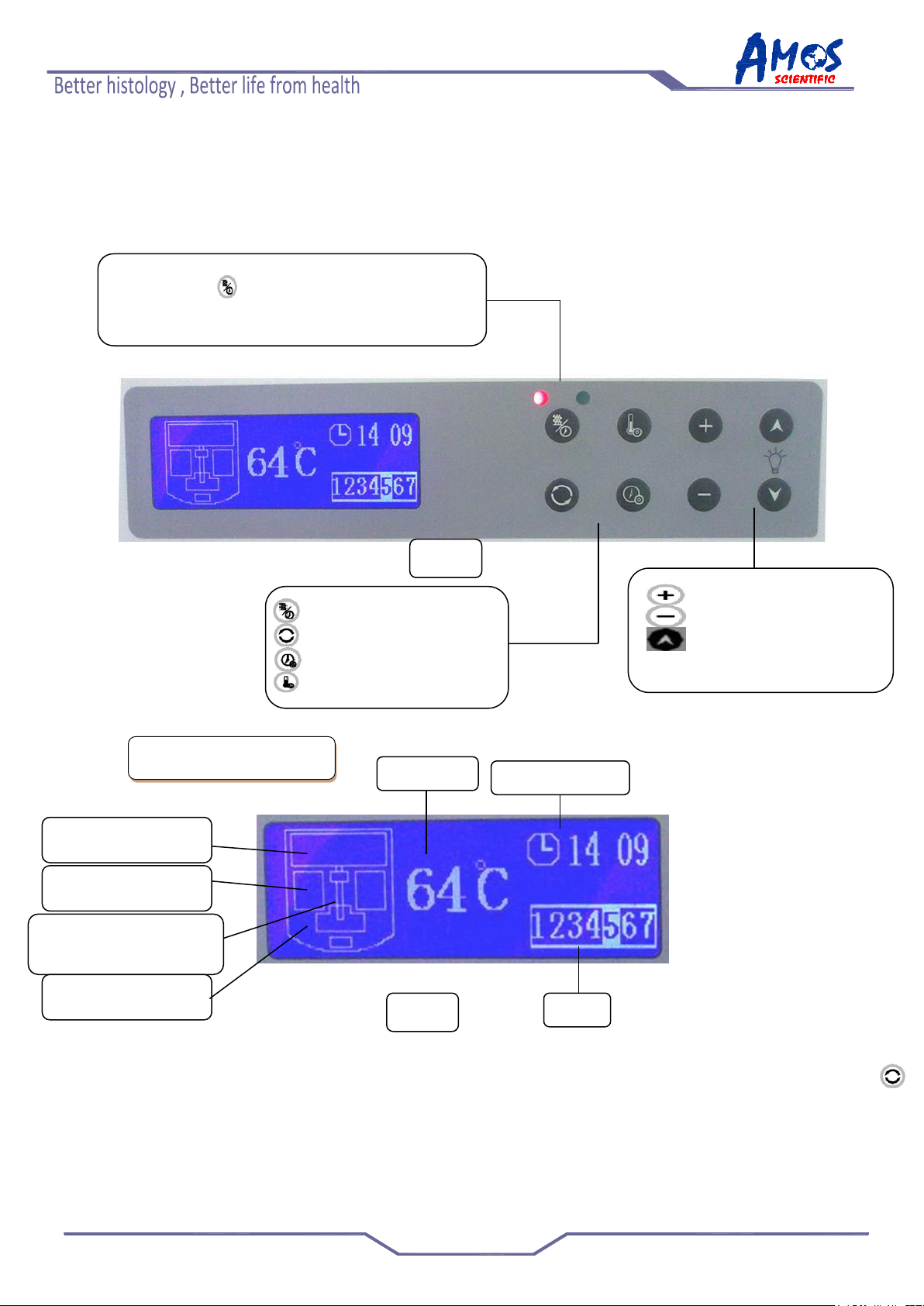

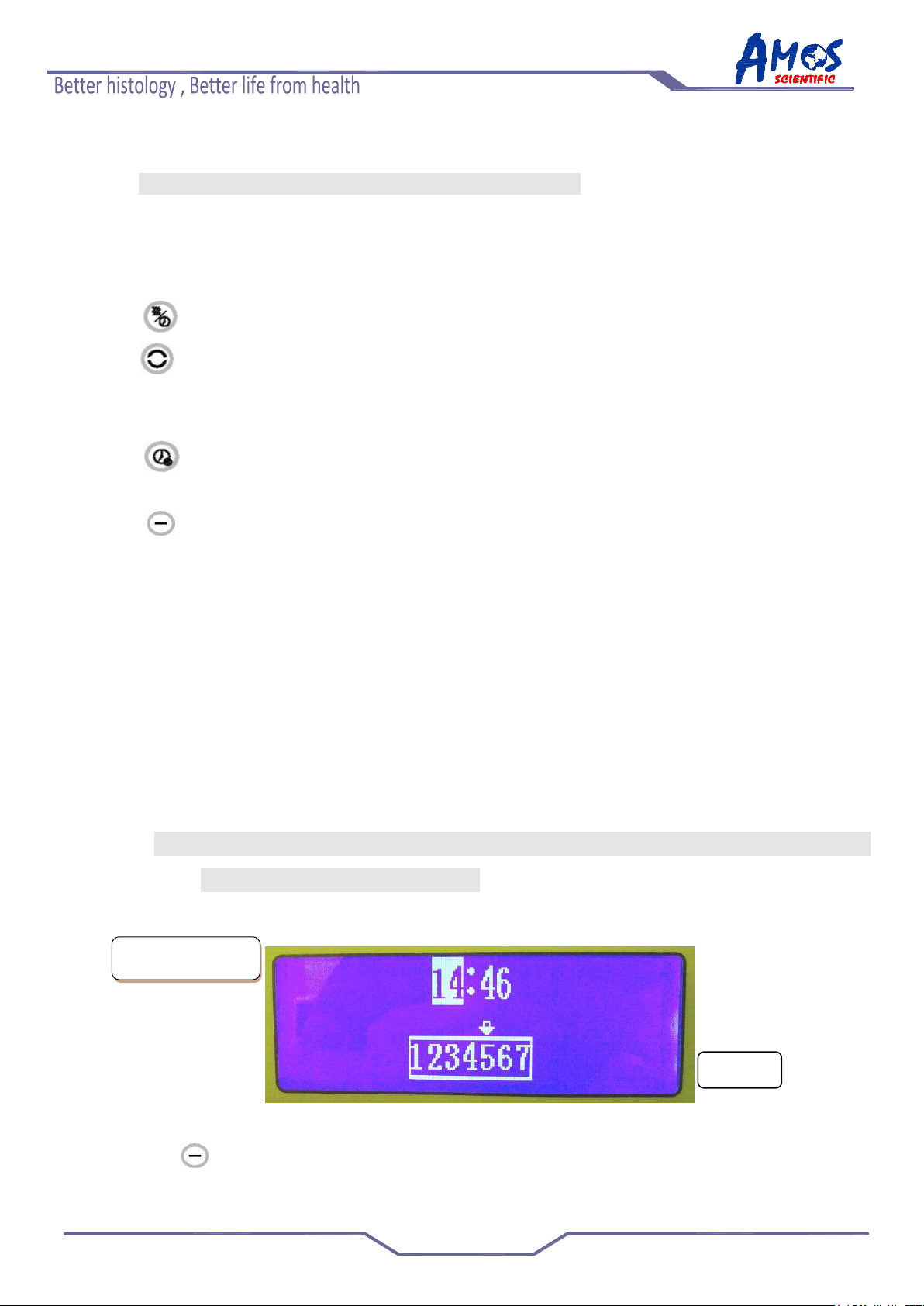

6.1 Key board Function & Instruction....................................................................................................................... 4

6.2 Operation Instruction........................................................................................................................................... 5

6.2.1 Start up time and day of the week Set .......................................................................................................... 5

6.2.2 Temperature of Working area check and Set .............................................................................................. 6

6.2.3 Timing Heating Or Sleep Set ...................................................................................................................... 6

6.2.4 Heating Mode and Sleep Mode Manually Set.............................................................................................. 8

6.2.5 The Use of Peltier cold spot.......................................................................................................................... 8

6.2.6 Finger touchpad or foot pedal to control paraffin flow................................................................................. 8

6.2.7 Lamp open/close and Lamp intensity adjustable.......................................................................................... 9

6.2.8 The Use of Magnifier.................................................................................................................................... 9

7、Trouble Shooting............................................................................................................................................ 10

8、Clearance & Maintenance.........................................................................................................................11

8.1 Cleaning The Instrument ....................................................................................................................................11

8.2 Maintenance....................................................................................................................................................... 12

9、Instrument Diagram.................................................................................................................................... 13