Energenics MAX-ASSURE UV-MAX ULTRA User manual

1

www.max-assure.com

________________________________________________________________________________________________________________

1470 Don Street ∙ Naples, Florida 34104 Telephone (239) 643-2778

Customer Service (800) 944-1711

Fax (239) 643-6081

Installation & Operations Manual

UV-MAX ULTRA Mobile Surface Disinfection Unit

Table of Contents……………………………………………………………………...1

Advisories (Purpose/Contents)……………………………………………………... 2

UV-MAX Safe Operation Procedure………………………………………………...3

Safety Guidelines…………………………………………………………………….. 4

System Description……………………………………………………………………5

System Delivery………………………………………………………………………..6

Operation Overview……………………………………………………...……………7

Operation Settings (Default)………………………………………………………….8

Operation Settings (Customizable)………………………………………………….9

Room Sensing………………………………………………………………..………10

E-Stop / System Interruptions…………………………………………………..…..11

Alerts / Service Indicators / Alarms………………………………………………...12-13

System Care………………………………………………………………………..…14

Troubleshooting……………………………………………………………………....15

FAQ…………………………………………………………………………………….16-17

2

Advisories

Purpose

The Energenics UV-MAX ULTRA system has been designed to offer direct disinfection

exposure to surface areas. The system design allows for microbial disinfection control.

The Energenics UV-MAX ULTRA device was developed utilizing Ultraviolet Light (UV) for direct

exposure disinfection. The system can disinfect 360 degrees from the system center.

Contents

This manual will serve as your reference guide for installation, operation, and service of your

UV-MAX system.

This manual covers the system/equipment/products listed below:

oUV-MAX ULTRA

Disposal of Mercury Added Lamps

Germicidal ultraviolet lamps, like standard fluorescent lamps contain small amounts of

mercury. Mercury added lamps should not be placed in the trash. Dispose of properly.

For further information regarding the disposal and recycling of lamps containing mercury,

along with Federal and State requirements visit LampRecycle.org.

3

UV-MAX Safe Operation Procedure

1.

Always wear personal protective equipment (PPE) when operating UV-MAX

ULTRA to limit exposure to UV-C light

2.

Place UV-MAX ULTRA in area to betreated

3.

Ensure a PIR Sensor (Passive Infrared) is positioned toward the entryway. PIR

sensors operations are explained in the FAQ section at the end of this manual.

4.

Connect UV-MAX ULTRA to 120vac plugreceptacle

5.

Press Start Cycle on UV-MAX ULTRA control and exit treatment area

6.

Adhere to recommended safety precautions to avoid potential injury

Safety

1.

You should never look directly at a UV lamp inoperation without wearing approved

safety glasses. Safety glasses should be made of any material other than Quartz or

Teflon.

2.

The space should be vacant and closed prior to UV-MAXULTRAoperation

3.

Never command the system on when the treatment space is occupied

Safety Observation: It is required for the person(s) responsible

for the installation of this equipment, operators of this equipment, and

operation personnel managers to review and understand this manual.

USE OF LISTED SYSTEM / EQUIPMENT MUST COMPLY WITH

INSTRUCTIONS AND SAFETY REQUIREMENTS.

4

Safety Guidelines

Long term exposure to ultraviolet light is dangerous. UV-C can produce eye injuries and skin

irritation similar to a sun burn over prolonged exposure. These effects are considered

transient. UV-C may also be carcinogenic but since it has very limited penetrating ability it is

unlikely to cause damage to anything besides the outer layer of skin or other exposed

surfaces.

The UV-MAX ULTRA is designed for zero user exposure to UV-C; however, we will review

safety factors regarding UV-C for better knowledge and understanding.

Protective Clothing and Eyewear

It is not recommended that any personnel be subject to direct UV-C exposure. In the event

such exposure is probable, personnel should wear clothing providing full coverage of exposed

skin and appropriate eye protection.

Polycarbonate safety glasses designed to filter UV and those of the wrap-around type are

recommended.

OSHA Guidelines for Ultraviolet Exposure

OSHA provides technical guidance regarding protecting employees from ultraviolet light with

respect to laser hazards only.

OSHA has two standards that cover employee exposure to radiation: Nonionizing

Radiation (29 CFR 1910.97) and Ionizing Radiation (29 CFR 1910.1096). You may access a

copy of the OSHA radiation standards from their website at http://www.osha.gov.

The non-ionizing radiation standard only covers the radio frequency region, including

microwaves. The ionizing radiation standard covers alpha, beta, gamma, and X-rays;

neutrons; high-speed electrons and protons; and other atomic particles; but does not

include sound or radio waves, or visible, infrared, or ultraviolet light. Therefore, there are

no OSHA-mandated employee exposure limits to ultraviolet radiation.

5

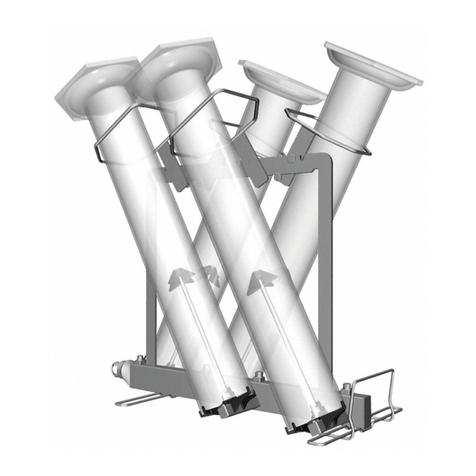

System Description

The UV-MAX ULTRA is designed for maximum disinfection through the

shortest exposure time. More UV-C wattage allows shorter surface

exposure times. Exposure times vary based on furthest distance from the

UV-C source. The system design provides the optimum in:

oUV dosage output to footprint served

oRugged design build

oEase of use controls

oUser safety protection

INDUSTRIAL STRENGTH

FRAME AND STRUCTURE

CORROSION PROOF

CONSTRUCTION

6” INDUSTRIAL CASTERS

HIGH OUTPUT PRE-HEAT

LAMPS FOR LONG RUN

TIME LENGTH

ROOM SENSING

TECHNOLOGY

PIR SENSOR DETECTION

SAFETY SHUTOFF

INDIVIDUAL LAMP

FAILURE/MONITOR

INDICATOR LED’S

EMERGENCY STOP

BUTTON

BUILT TO IP56 WATER

AND DUST STANDARDS

SELECTABLE TARGET

PATHOGEN

6

System Delivery

When you receive your UV-MAX ULTRA, you will need to unpack and

inspect the system. Please perform the following procedure:

1.

Unpack your new system and stand upright

2.

Inspect fully for damage

If damage present, contact MaxAssure, Inc prior to use(239) 643-2778

3.

Verify secure lampinstallation

4.

Plug in system power cord

5.

Power on the unit

Your UV-MAX ULTRA system is now ready for operation

(See Operation Overview)

7

Operation Overview

The UV-MAX is designed to operate in the following manner:

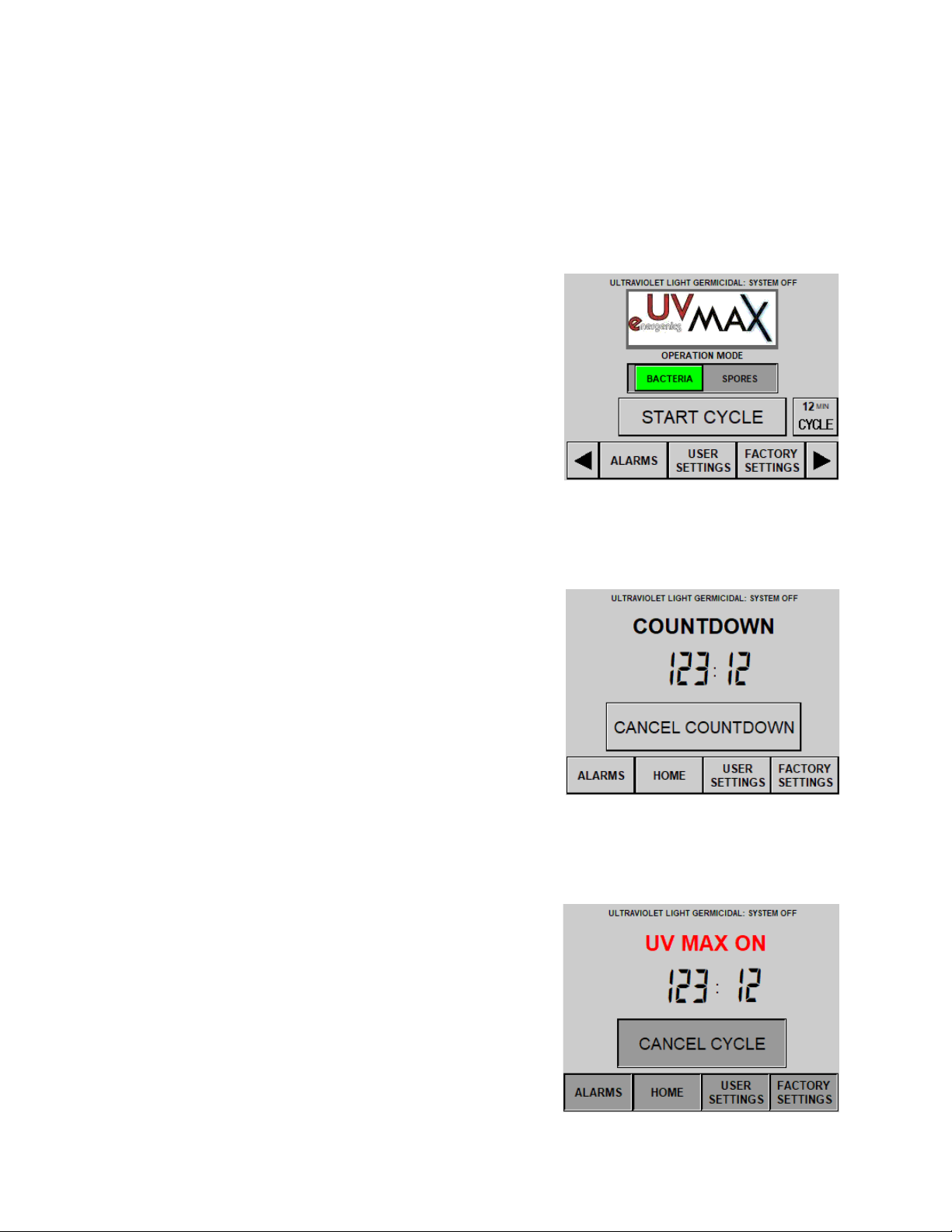

Start Sequence

1.

Locate unit in unoccupied space positioned for operation

2.

Plug system into power supply

3.

Press “Bacteria” or “Spores” Operation Mode

4.

Initiate system cycle by pressing “Start Cycle”

5.

Evacuate space

Audio and Visual Indicators

1.

Audio Alarm

There is no audible alarm for countdown or run cycle on the UV-MAX ULTRA as

not to interfere with medical facility monitoring equipment alert systems

2.

Visual Indicators

a.

Countdown Timer display present during countdown cycle

b.

Flashing “System On” during run cycle

c.

Home Screen displayed upon completion of cycle

3.

Display of System

a.

Operations

b.

Controls

c.

Indication of SystemFunctions

8

Operation Settings

Normal operation for factory default settings are covered on this page.

1.

Review system forcondition.

a.

There should be no physical damage to

the system

b.

Lamps shall be clean

c.

System frame shall be in goodcondition

d.

Display of system shall beclean

2.

Plug in system powercord

3.

Ensure all personnel are out of treatment area

4.

Operate system

a.

Select “Start Cycle”to initiate treatment

cycle

b.

The system will enter Countdown mode

c.

Once process is complete, panel will revert

to Home screen

9

Customizable Operation Settings

Customizing settings for normal operation are covered on this page.

Target Pathogen Selection Options

1.

From Start Cycle home screen, user may

select either “Bacteria” or “Spores” Operation

Mode (System default is Bacteria Mode)

2.

Selection may also be made by selecting

“User Settings” and choosing Operation Mode

Countdown Timer Customizing

1.

From Start Cycle home screen, press “User

Settings”

2.

The User Settings screen is displayed with

Countdown Timer Adjustment arrows

available to increase or decrease countdown

cycle time

*Countdown Timer–control for time delay

from when Start Cycle button is pressed to

when system lamps come on

3.

After adjusting to preferred settings, press

HOME button to return to StartCycle screen

4.

Press START CYCLE button to begin

customized treatmentcycle

10

Status Screens

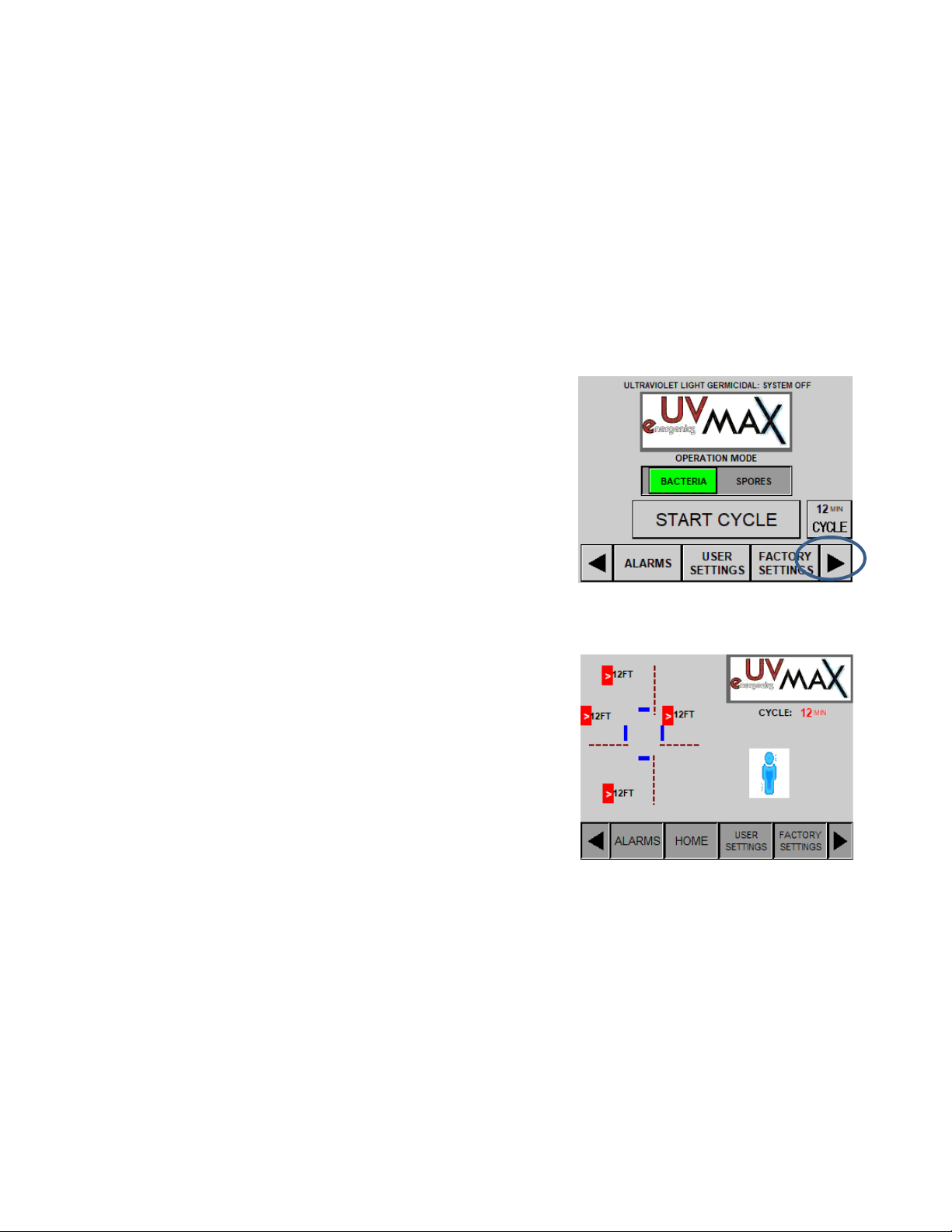

Room Sensing Technology covered on this page.

Room Sensing Feature

The UV-MAX ULTRA is equipped with Room Sensing Technology in which the device will

calculate the distance between walls and calculate the required machine run-time depending

on Operation Mode (Bacteria or Spores) selected.

1. From Home Screen, press Right Arrow at

bottom right of screen.

2. Room Sensing Screen will appear with

distance shown between each measuring

laser and wall. This screen is for observation

only.

a. Each laser will measure up to a 16’

radius for a total of 32’ forward and

backward and 32’ side to side

b. The machine will always calculate run-

time based on the longest measured

point ensuring a sufficient treatment

dose

c. If any distance measure is greater than

16’, the machine will automatically run

30-minute cycle on Bacteria setting and

60-minute cycle on Spores setting.

3. Cycle time is displayed on Room Sensing

screen and can be observed automatically

adjusting with movement of the machine and

selection of target Operation mode

4. Press “Home” button to return to Start Cycle

screen for initiating treatment

11

Status Screens

Cycle stop displays for normal system operation are covered on this page.

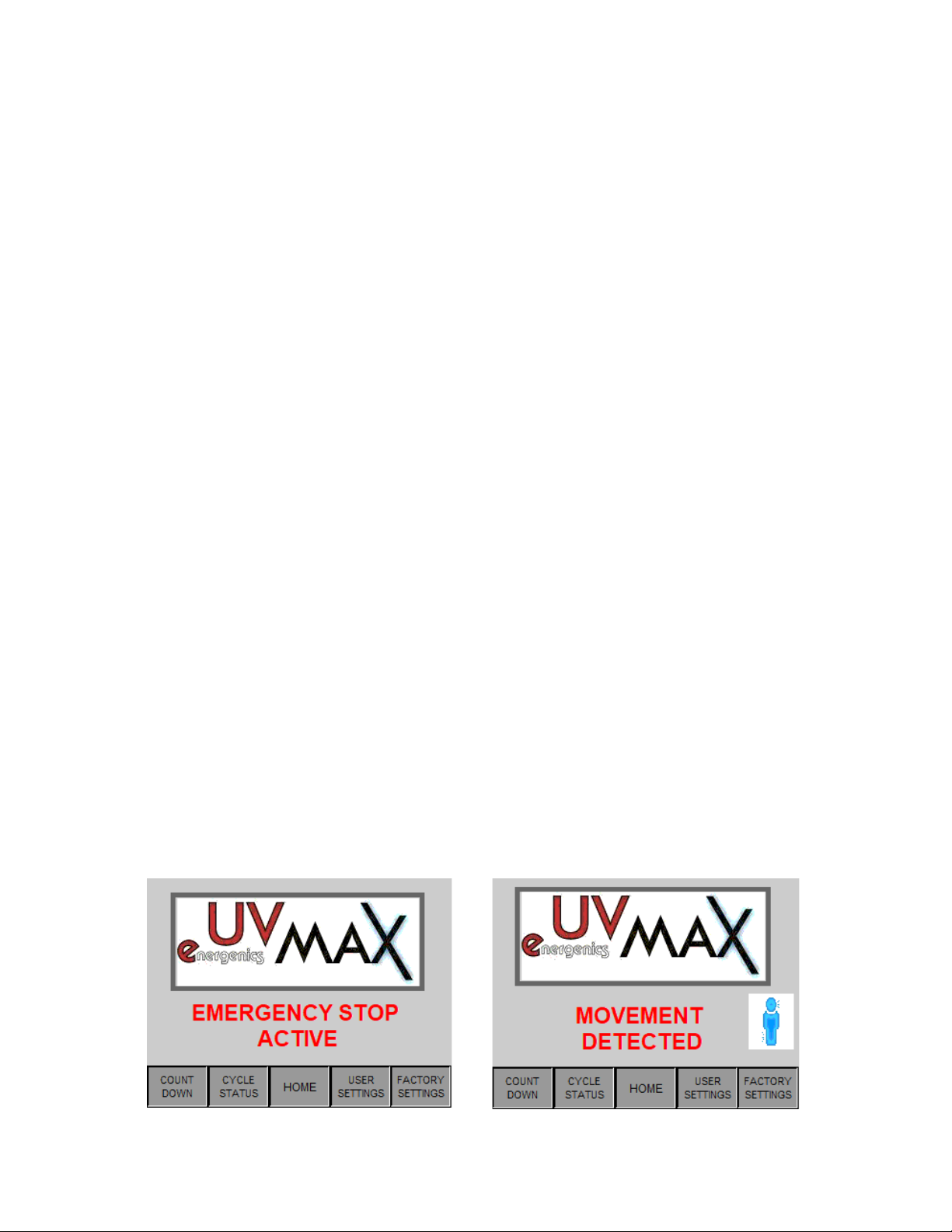

Emergency Stop

Should cycle deactivation occur by engagement of the Emergency Stop button, the following

method will be required to reset the system:

1.

Observe Emergency Stop Active status on control screen

2.

Release Emergency Stop by pulling up on the red knob

3.

Press “Cycle Status” to see treatment time remaining

4.

Select “Home” button to return to main screen

5.

Press “Start Cycle” to resume normal operation ofsystem

PIR Sensor Cycle Interruption

Should cycle interruption occur by means of a PIR sensor activation, the following will be

required:

1.

Observe the interruption status type on the controlpanel

2.

Ensure no one is in treatment area

3.

Select HOME button to return to main screen

4.

Press START CYCLE to restart normal safe operation ofsystem

12

Status Screens

System lamp faults and service indicators are covered on this page.

Alerts

A Service or Alarm indicator may be illuminated on the Home screen. Should this occur, the

following steps should be taken to address the alert:

1.

Observe the alert type on the controlpanel

2.

Ensure all system alerts have been properly

addressed

3.

Select HOME button to return to main screen

4.

Press START CYCLE to resume normal system

operation

Service Indicators

The “Service” alert will illuminate every 8 run hours as a “clean lamps” notification or when

lamps need replacement. The User Setting screen will differentiate need to perform:

1. Lamp Cleaning

a. Press “Service” button on home screen

b. Lamp Clean indicators will be illuminated in

Yellow

c. Wipe lamps with isopropyl alcohol and

clean cloth

d. Press “Factory Settings” on bottom right

of screen

e. Enter Passcode (1470) and press Enter

f. Press “Reset Service Light” button to

clear alert

13

Status Screens

(con’t)

g. Press “Home” to return to Start Cycle screen

Lamps are designed for 12,000 run hours after which point, they will only provide 80% of

original UVC dosage output and will continue to degrade. The device will alert for lamp

replacement at 8,000 run hours. It is recommended that lamps be replaced at this time for

optimal dosage output.

2. Replace Lamp(s)

a. Press “Service” button on Home screen

b. Lamp Replacement indicators will be

illuminated in Red

c. Replace lamps as indicated

d. Press “Factory Settings” button

e. Enter Passcode (1470) and press enter

f. Press “Reset Service Light” to clear alert

g. Press “Home” to return to Start Cycle screen

Alarm Indicators

In the “Alarm” indicator is illuminated on the Home screen:

1.

Press “Alarm” indicator to observe the Alarm Log

2.

Ensure all system alerts have been properly

addressed

3.

Select HOME button to resume normal system

operation

4.

Should Alarm persist, contact MaxAssure, Inc customer service (239) 643-2778

14

System Care

The UV-MAX ULTRA system is designed for repeat performance with consistent results.

Based on system designs, minimal maintenance is required. Adherence to the following

regular service of your system should provide years of disinfection.

Each Duty Cycle

1.

Inspect the system interior, exterior, and lamps for cleanconditions

2.

Clean as needed

Monthly

1.

Inspect the system interior, exterior,and lamps for cleanconditions

2.

Clean as needed

3.

It is recommended to test system performance using an ATPmeter

Bi-Annual

1.

Inspect the system interior and exterior lamp for cleanconditions

2.

Clean as needed

3.

It is recommended to test system performance using an ATPmeter

“Service Machine” Message

1. Every 8 running hours it is recommended that lamps be wiped down with clean cloth

and isopropyl or rubbing alcohol. This will remove any debris that may have

accumulated on the lamp. Once cleaned, you can reset this message by pressing

USER SETTINGS button followed by RESET SERVICE LIGHT

Note: The above steps are listed as the basic level of care, should the system be utilized

in a heavy work environment, further care may be required.

15

Troubleshooting

The below statements are listed as troubleshooting guidelines. Further information is available

through Energenics support.

Q: What should I do if the unit will not turn on?

A: Verify there is power to the system

A: Verify the display is reads correctly

A: Verify the Emergency Stop is not engaged

Q: Why does the unit turn off when I enter the room?

A: Safety features turn off lamps based on detection by the PIR sensor.

Q: My system will turn on, but the lamps will not come on.

A: Verify the start cycle button is pressed

A: Inspect the lamp for age or physicalfailure

A: Contact Energenics Support for further information

Q: My system is running fine, how do I verify the lamp output is correct?

A: The system has a status screen at the end of the cycle

A: Faults will indicate if the system is not performing correctly

Q: The touchscreen has presented a flashing “Service Machine” icon.

What does this mean?

A: Every 8 running hours it is recommended that lamps be wiped

down with isopropyl or rubbing alcohol. This will remove any

debris that may have accumulated on the lamp. Once cleaned,

you can reset this message by pressing USER SETTINGS

button followed by RESET SERVICE LIGHT

16

FAQ (continued)

Q: What is a PIR (Passive Infrared) Sensor?

A: Passive InfraRed sensors (PIRs) are electronic devices which are used in some

security alarm systems to detect motion of an infrared emitting source, usually a human

body.

Radiation (energy) is invisible to the human eye but can be detected by electronic devices

designed for such a purpose.

The term 'passive' in this instance means the PIR does not emit any energy of any type

but merely sits 'passive' accepting infrared energy through the 'window' in its housing.

An intruder entering the protected area is detected when the infrared energy emitted from

the intruder's body is focused by a Fresnel lens or a mirror segment and overlaps a

section on the chip which had previously been looking at some much cooler part of the

protected area.

That portion of the chip is now much warmer than when the intruder wasn't there.

As the intruder moves, so does the hot spot on the surface of the chip.

This moving hot spot causes the electronics connected to the chip to de-energize the

relay, operating its contacts, thereby activating the detection input on the alarm control

panel.

Q: Is UV-C disinfection strictly line of sight?

A: Yes, it needs to shine on the surface to disinfect. It will not go around objects or

disinfect shadowed areas.

Q: Does UV-C light reflect off surfaces?

A: Yes, it reflects off many surfaces, but loses intensity dramatically if the surface is not

highly polished like the Stainless-Steel center installed on our unit.

Q: Is the UV-C light I can see under the door dangerous?

A: Zero exposure to people is imperative so block it or protect your eyes and skin (please

note: 254nm UV-C wavelength is invisible, what is seen is visible light)

17

FAQ (continued)

Q: Does UV-C light go through glass or windows?

A: Standard window glass blocks almost 100% of UV-C light according to the IUVA.

(Normal glass, as used in a window, is transparent to UV radiation to a wavelength of

about 330 nm (UV-A). The transparency is quite high so almost all UV-A light will pass

through glass. Below 330 nm (UV-B and UV-C), almost 100% is blocked by normal

glass.

Q: Can I use an ATP Meter with the UV MAX

A: Yes, it can be used to measure how clean a surface is

Q: Can I use a response card with the UV MAX?

A: Yes, it can be used to indicate the correct dosage (intensity x

time x distance) has been applied to a surface

Q: What is the difference between bacteria and sporicidal modes?

A: Your UV-MAX Ultra is equipped with two modes of operation, Bacterial and Sporicidal. It is

important for the user to understand the difference between the two. For sporicidal mode, the

time function is doubled. Spores are the more difficult microorganism to target due to the

composition of the cell membrane. In order to be categorized as a spore a rigid protective layer

on the cell membrane must exist. Most common bacteria and viruses do not have this

protective layer or have a layer of less rigid protection like lipids and are much easier to

deactivate using UV-C light. A common example of a sporicidal target is Clostridium difficile, or

C. Diff.

Below is a chart to illustrate ease of deactivation among common organisms.

Table of contents

Other Energenics Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Miele professional

Miele professional A 306/1 operating instructions

CORNING

CORNING Spin-X UF 6 Technical data and operating instructions

Thermo Scientific

Thermo Scientific STERI-CYCLE i160 LK user manual

DIATECH PHARMACOGENETICS

DIATECH PHARMACOGENETICS EasyPGX qPCR instrument 96 user manual

Heidolph

Heidolph Hei-MIX Unimax 2010 operating manual

Gardner Denver

Gardner Denver WELCH LVS 600 T Operation manual