4

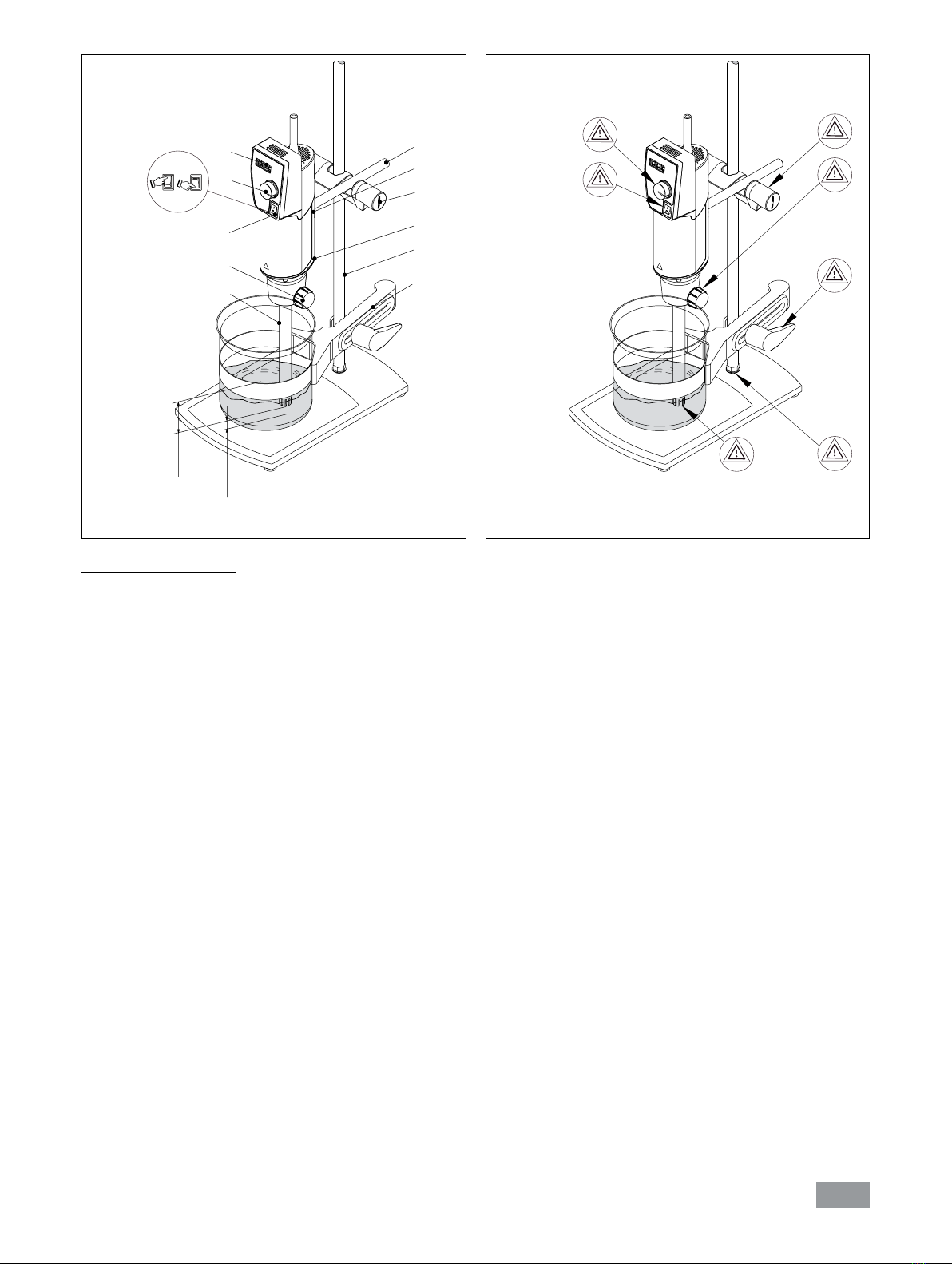

Wear your personal protective

equipment in accordance with the

hazard category of the media to be

processed. Otherwise there is a risk from:

- splashing and evaporation of liquids

- body parts, hair, clothing and jewellery getting caught.

• Set up the stand in a spacious area on an even, stable,

clean, non-slip, dry and fireproof surface.

• Check the appliance and accessories beforehand for dam-

age each time you use them. Do not use damaged com-

ponents.

• The appliance is not suitable for manual operation.

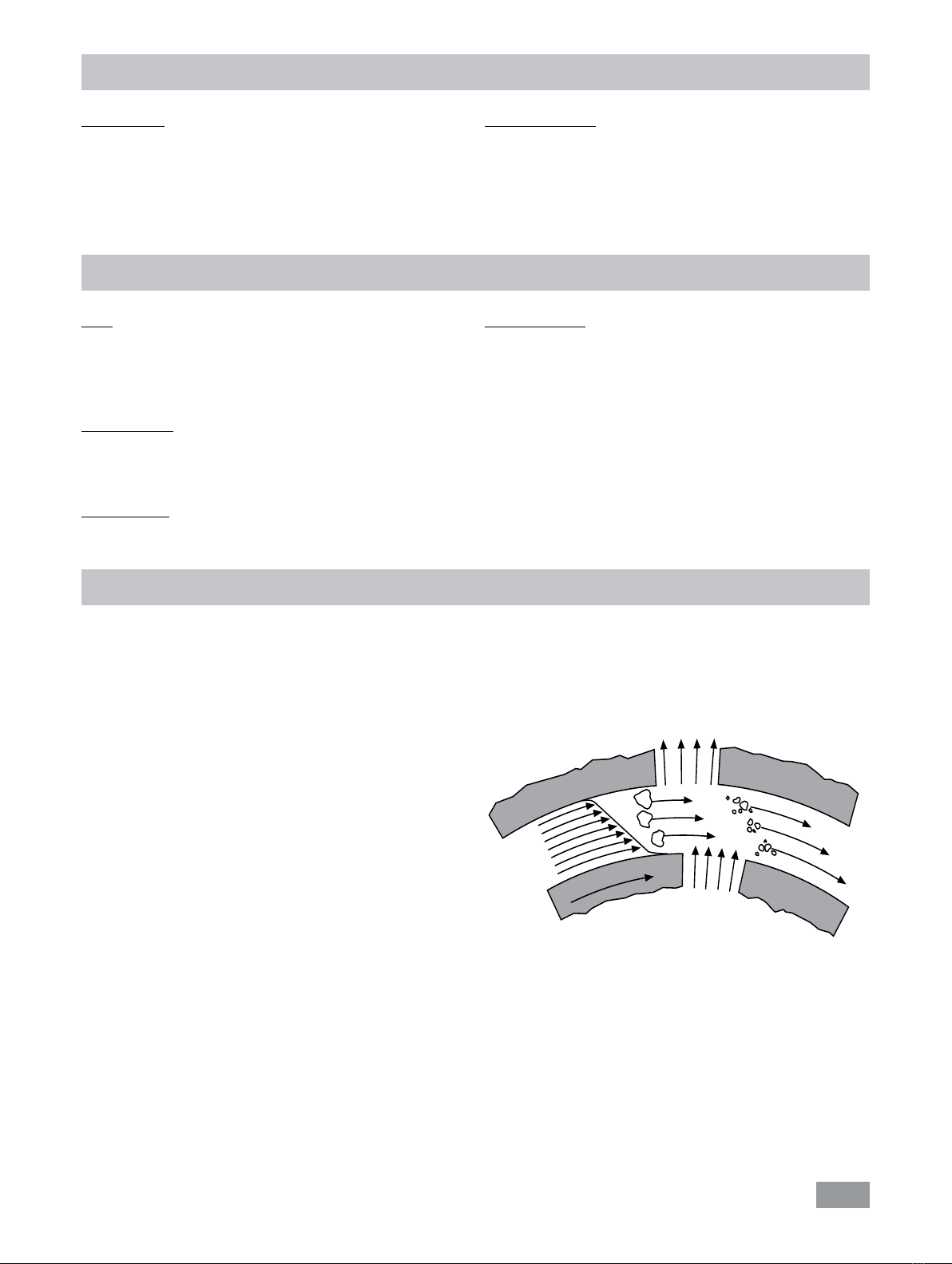

• The agitation vessels used for dispersing have to be se-

cured. Consider on a good stability of the entire structure.

• Secure the agitation vessel against twisting.

• Check that the turning knobs are secure and tighten if

necessary.

• Glass vessels must always be secured with a clamp to

prevent them spinning. When working with flasks elastic

couplers must be used to prevent fracture of the glass.

• Note the operating instructions of the dispersing tool and

accessories.

• Only dispersing elements approved by IKA may be used.

• Please observe the permitted speed for the dispersing ele-

ment. Never set higher speeds.

• Do not use the appliance without a dispersing element.

• Use the dispersing tool always inside the stirring vessel.

• Never run dispersion tools dry, as the gasket and bearings

will be destroyed if the tools are not cooled by the medium.

If a dispersing element is not insert-

ed into the drive flange as far as the

mark it can become extremely hot

in operation and thus suffer damage.

• Make certain that the unit is set at the lowest speed be-

fore commissioning; otherwise, the unit will begin run-

ning at the speed last set. Gradually increase the speed.

• Reduce the speed if the medium splashes out of the vessel

because the speed is too high.

•

Before switching on the dispersing instrument make sure

that its shaft is immersed min. 45 mm in the medium to

prevent the medium from splashing out.

•

The distance between the dispersion tool and the vessel bot-

tom should not be less than 10 mm.

• Ensure that the stand does not start to move.

•

In the event of unbalance or unusual noises, switch off the

appliance immediately. Replace the dispersing element. If

there is no difference after the change of the dispersing

tool, return it to the dealer or the manufacturer along with

a description of the fault.

Do not touch rotating parts during op-

eration.

• When in operation, the dispersing element and the cou-

pling flange can become hot.

WARNING

NOTICE

DANGER

DANGER

DANGER

• Do not cover the ventilation slots on the drive in order to

ensure adequate cooling of the drive.

Beware of the risk of:

- flammable materials

- glass breakage

- sharp edges on the dispersing tool.

• Process pathogenic materials only in closed vessels under

a suitable extractor hood. Please contact IKA if you have

any questions.

Do not use the device in explosive

atmospheres, it is not EX-protected.

With substances capable of forming an explosive mixture,

appropriate safety measures must be applied, e.g. work-

ing under a fume hood.

To avoid body injury and property damage, observe the rele-

vant safety and accident prevention measures when process-

ing hazardous materials.

Only process media that will not react dangerously to the

extra energy produced through processing. This also ap-

plies to any extra energy produced in other ways, e.g.

through light irradiation.

• There may be electrostatic discharges between the medi-

um and the dispersing instrument shaft which could pose

a direct danger.

• Only process media that will not react dangerously to the

extra energy produced through processing. This also ap-

plies to any extra energy produced in other ways, e.g.

through light irradiation.

• Meter powder not too close to the flange. Powder can be

blown away by air turbulences of the drive.

•

Safe operation is only guaranteed with the accessories de-

scribed in the ”Accessories” chapter.

• Always disconnect the plug before fitting accessories.

• The appliance can only be disconnected from the mains

supply by pulling out the mains plug or the connector plug.

• The socket for the mains cord must be easily accessible.

• The appliance does not start up again automatically fol-

lowing a cut in the power supply.

• Abrasion of the dispersion equipment or the rotating ac-

cessories can get into the medium you are working on.

For protection of the equipment:

• The appliance may only be opened by experts.

• The voltage stated on the type plate must correspond to

the mains voltage.

• Removable parts must be refitted to the appliance to pre-

vent the infiltration of foreign objects, liquids etc..

• Protect the appliance and accessories from bumps and

impacts.