TR31 Trolleys

Part

No. Description

Length Width Weight

in mm in mm lb g

IN210.CLEAR* Trolley 2.63 66.8 2.06 52.32 0.56 254

IN212.CLEAR* Brake Trolley 2.73 69.2 2.6 66.04 0.60 270

*To order black hardcoat-anodized, remove .CLEAR from end of part number.

HOW DOES IT WORK?

The TR31 continuous rail and trolley system allows a

fully-harnessed crew member, safely tethered to the

trolley, to move freely along the rail during inspection

and maintenance, or when assisting in pilot transfer.

Rails can be either surface or stanchion mounted and

are designed so the user never has to unhook and

rehook the tether as he moves around the deck.

INSTALLATION AND MAINTENANCE

The system can be installed either at initial build or as a

retrofit. Flush clean with fresh water and mild detergent.

It is important to clean the trolley. Excessive build-up of

grease, dirt, and salt will affect trolley movement.

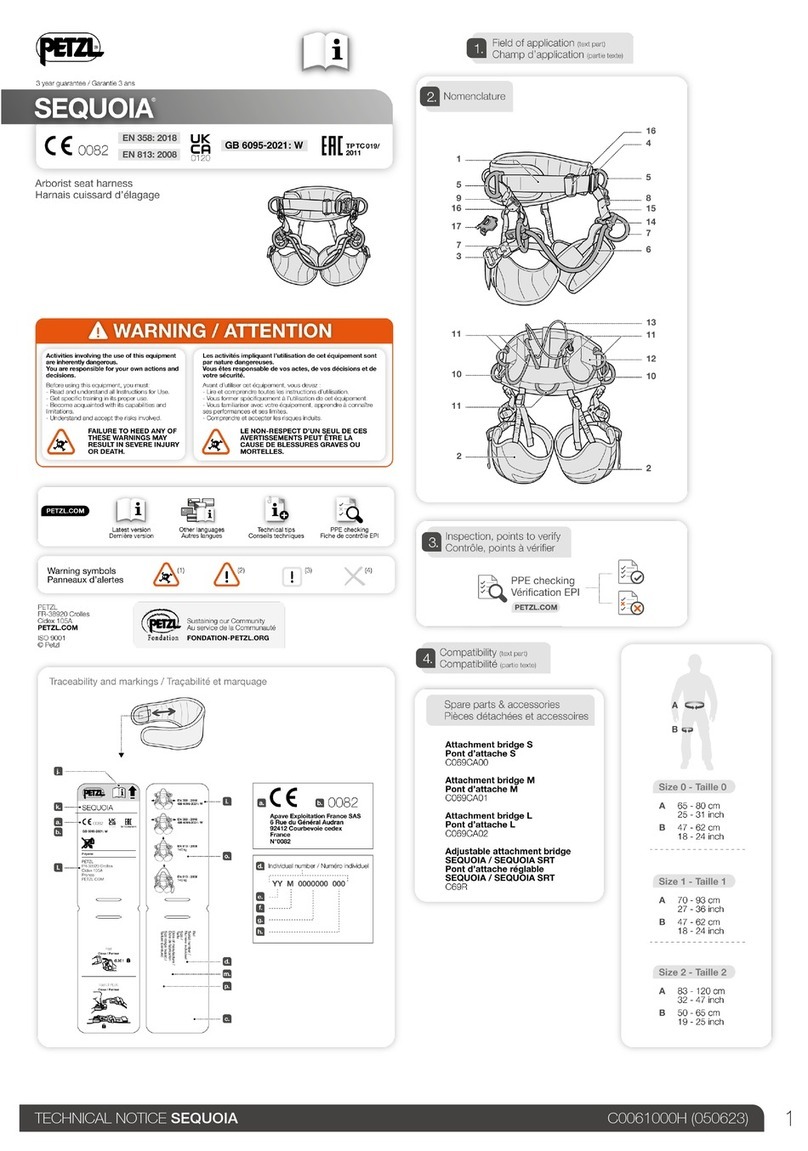

IN210.CLEAR

IN201.CLEAR

IN204.CLEAR

IN205.CLEAR

IN203.CLEAR

IN209.3M.CLEAR

IN213.3M.CLEAR

548

IN212.CLEAR

IN211

H-73945

IN202.CLEAR

IN207.CLEAR

IN208.CLEAR

IN206.CLEAR

CORNERS - HORIZONTAL BEND

90°

60°

45°

30°

CORNERS - VERTICAL BEND

TR31 Rail & Accessories

Part

No. Description Bend information

Bend radius Arc length** Weight Fasteners

mm ft/in m lb g mm

IN209.3M.CLEAR* Straight rail section Straight 200 9' 10 1/16" 3 8.47 3840 M10

IN213.3M.CLEAR* Straight rail section without holes Straight 200 9' 10 1/16" 3 8.49 3850

IN203.CLEAR* Corner rail Horizontal 30° 200 6 11/16" 0.17 0.57 260 M10

IN205.CLEAR* Corner rail Horizontal 45° 200 8 11/16" 0.22 0.77 350 M10

IN204.CLEAR* Corner rail Horizontal 60° 200 10 5/8" 0.27 0.98 440 M10

IN201.CLEAR* Corner rail Horizontal 90° 200 14 3/16" 0.36 1.39 630 M10

IN206.CLEAR* Corner rail Vertical 30° 200 7 1/16" 0.18 0.60 270 M10

IN208.CLEAR* Corner rail Vertical 45° 200 9 1/16" 0.23 0.81 370 M10

IN207.CLEAR* Corner rail Vertical 60° 200 11" 0.28 1.03 470 M10

IN202.CLEAR* Corner rail Vertical 90° 200 15 5/16" 0.39 1.46 660 M10

548 Endstop set (2.83"/71.8 mm) 0.13 60

IN211 Splice link 0.051 23

H-73945 Splice link with 10 mm thread 0.053 24

*To order black hardcoat-anodized, remove .CLEAR from end of part number. ** Arc length is to the inside of the radius.