20/03/19 ENGLISH 11

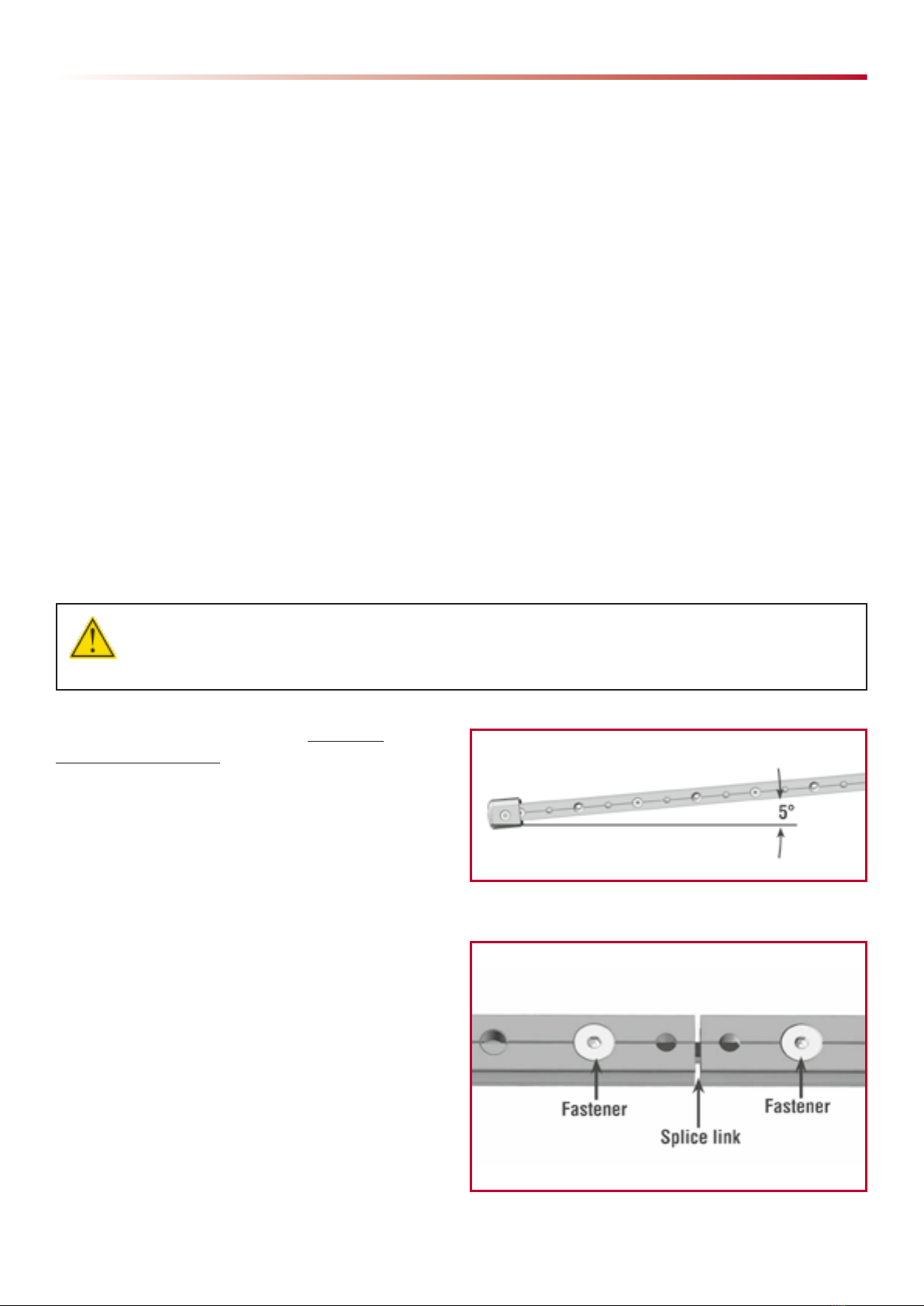

•Load angle limitations: IN9606, IN9606.CLEAR,

IN9565, IN9565.CLEAR, IN9608 and IN9608.CLEAR

Trolleys - Rail must run within 5° of horizontal, but

can be mounted at various angles on the horizontal

mounting structure. Harken IN9606, IN9606.CLEAR,

IN9565, IN9565.CLEAR, IN9608 and IN9608.CLEAR

trolleys have the ability to handle loading at an angle

up to 15° beyond vertical. Loads beyond 15° from

vertical will overload trolley. See image at right.

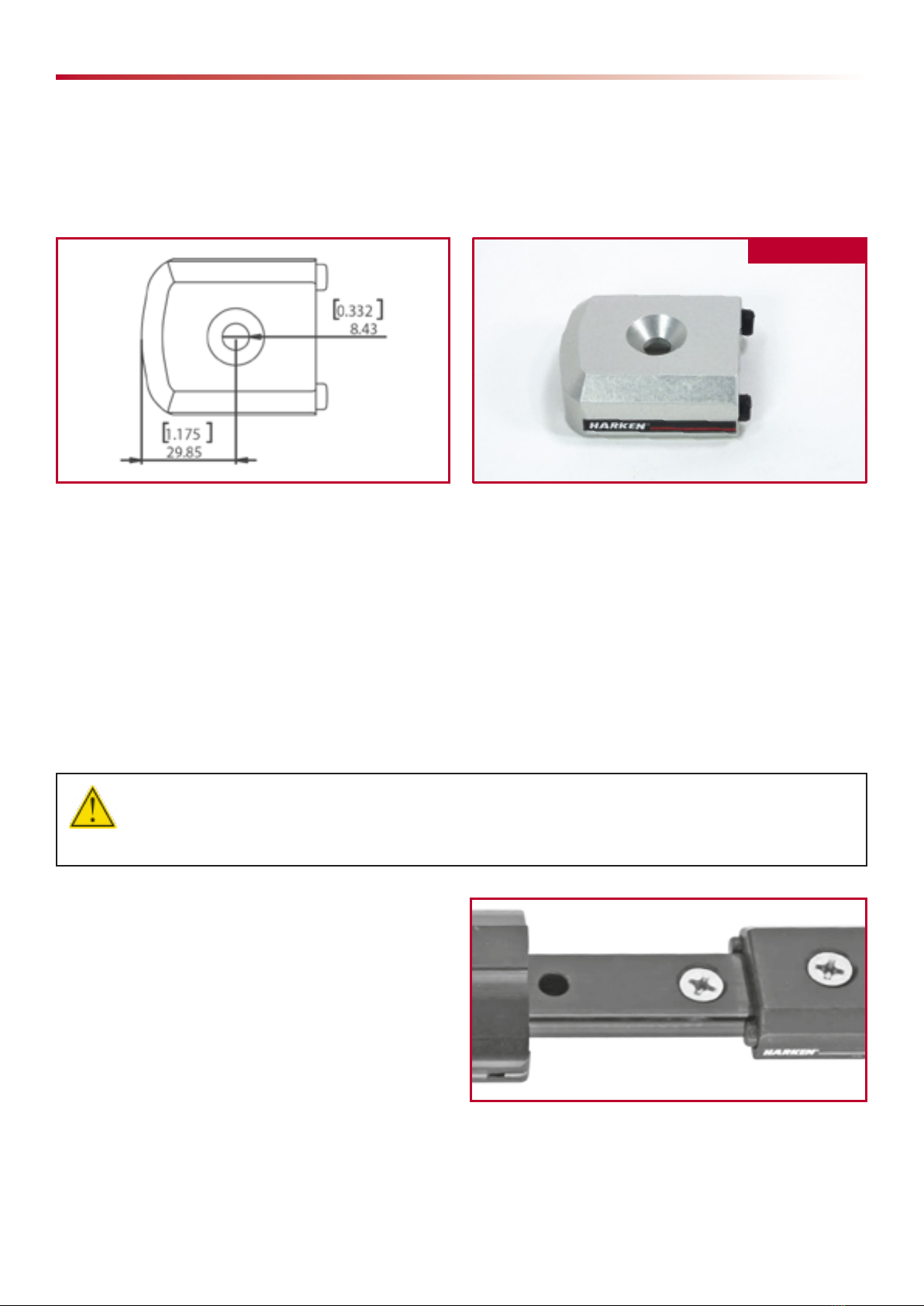

•Load angle limitations: IN10567, IN10567.CLEAR,

IN10614, IN10614.CLEAR, IN10615 and

IN10615.CLEAR Trolleys - Trolleys with wheeled

toggles are designed to run along a surface,

mounted so that the toggle overhangs the edge.

Ensure that the whole wheel width is in good

contact with the surface to which the rail is

attached. Ensure that the surface is strong enough

to sustain the expected working load and wear.

Trolley

Mounted on angle: Trolleys with

wheeled toggle face outward

Mounted in recess: trolleys with

wheeled toggle for loading over an edge

Trolley with wheeled toggle

DESIGN

DESIGN

Preliminary info

The fall arrest system must be suitably designed by a qualified professional, since the correct installation

and subsequent safety of the users depend on its correct design.

The following are of the utmost importance:

•analysis of the installation location, in order to define the position where the rail will be installed.

•definition of anchor points (where the fasteners will be placed)

•distance between fasteners

•how to fasten the rail to the supporting structure.

Consider all factors that will affect safety during use of this equipment. Rail must be laid out and positioned

strictly in accordance with drawings and specifications supplied by the project authorized architect or other

suitably qualified person. System must meet controlling work at height regulations for country of use.

Installer shall ensure suitability of base materials and structural materials to which rail is fixed, follows

controlling work at height regulations for country of use, and ensures base and structural materials are

capable of sustaining a proof test force.

The weakest structural materials have been simulated in laboratory to evaluate the anchor device and its fastening.

Anyway, the test results don't supply any information on the strucure capability to bear the loads, which can occur

during the use. The capability to bear the loads connected to a fall arrest is subjected to different assessments,

which are excluded from the application of the Regulations for which the product is certified.