ONLINE INSTRUCTIONS

40 mm, 57 mm, 75 mm Carbo®Ratchets

Strictly follow all instructions to avoid an accident, damage to your vessel, personal injury

or death. See www.harken.com for additional safety information.

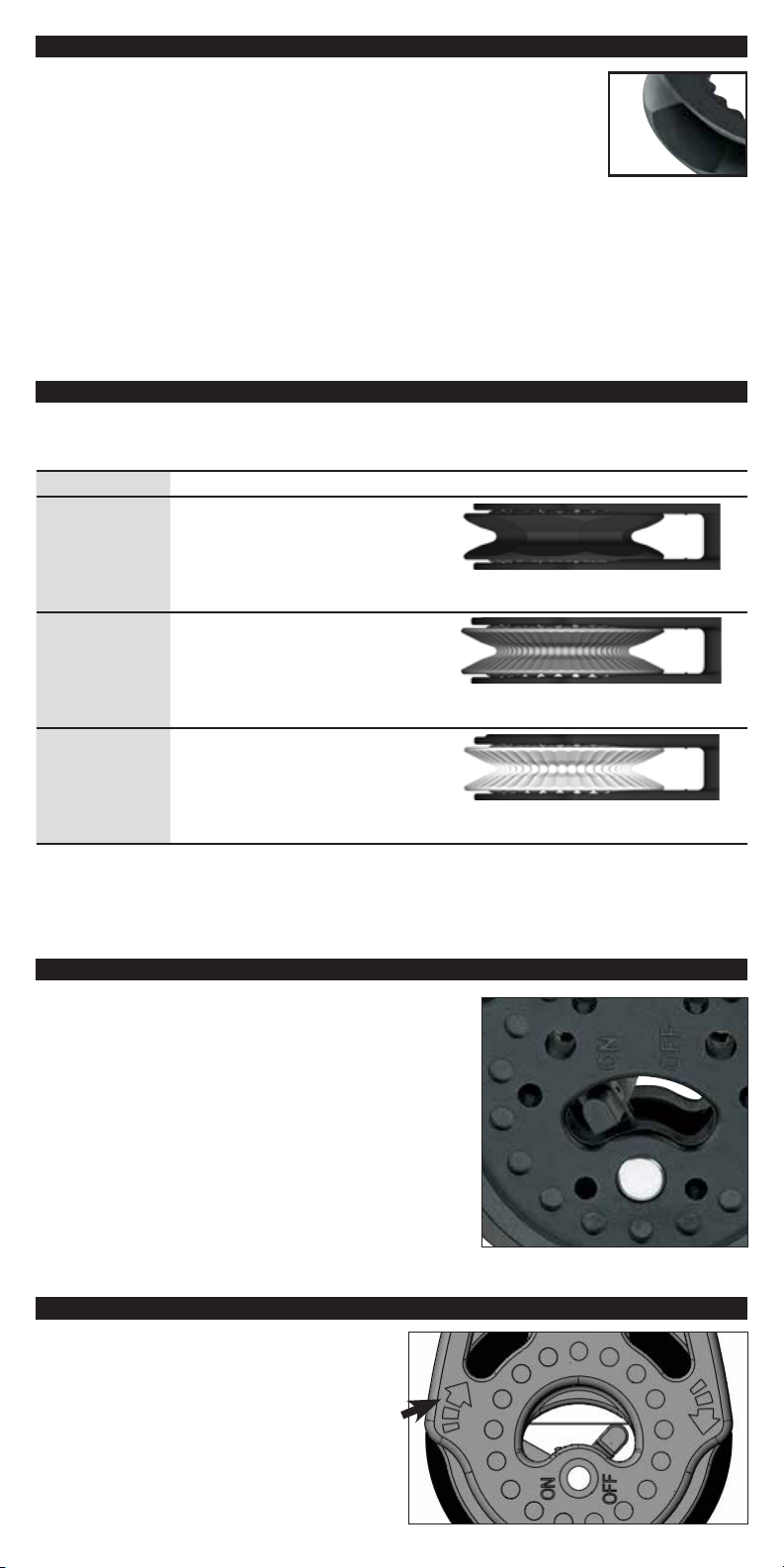

A

B

C

Glass-filled nylon sideplates: load-carrying curved bearing

races.

Machined hardkote-anodized aluminum sheaves: strength

and corrosion resistance.

Fast trim: Free-running ball bearings.

Hand-hold and release loaded line: Faceted aluminum sheave

grips line securely. Ratchets provide mechanical advantage.

Multi-faceted Power3 sheaves: very aggressive holding power.

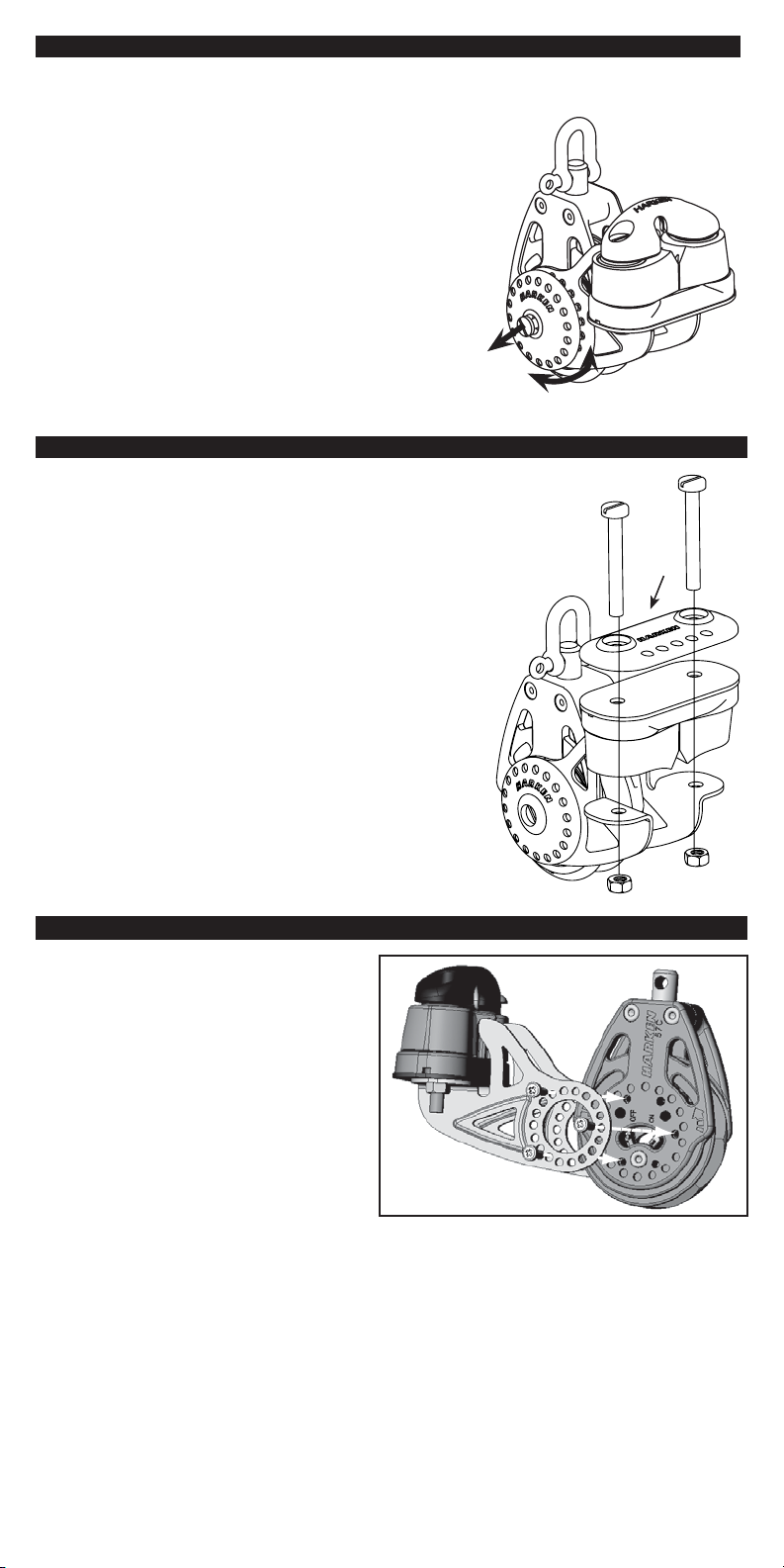

Ratchet on/off switch: 40 mm–2608/2609/2614;

57/75 mm–all blocks.

Ratchet always on: 2610/2611.

Cam arm locking plates: allows cam arms to be locked in more

than five positions for fair leads.

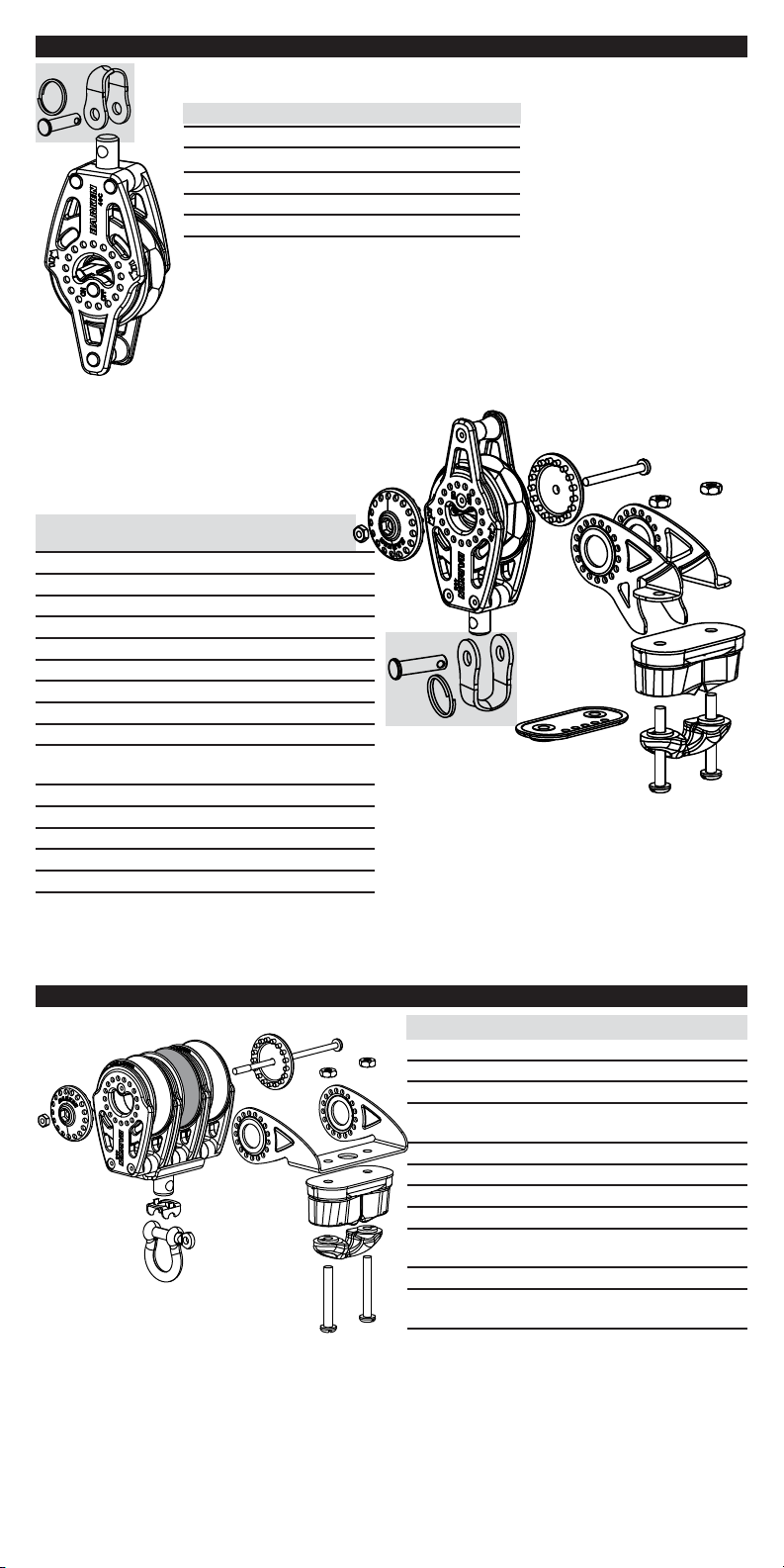

Cheek: line-shedding, small mounting footprint and drain holes.

Common uses: Main/jib/spinnaker sheets on dinghies and

sportboats; control lines on boats of all sizes.

Features

Part

No.

ABC

Max line

Ø

Maximum

working load*

Breaking

load*

Description in mm in mm in mm in mm lb kg lb kg

40 mm

2608 Single/swivel 1

9

/

16

40 3

3

/

8

86

5

/

32

4

3

/

8

10 300 136 1000 454

2609 Single/swivel/becket 1

9

/

16

40 4 102

5

/

32

4

3

/

8

10 300 136 1000 454

2610 Single/swivel/471 Carbo-Cam* 1

9

/

16

40 3

3

/

8

86

5

/

32

4

1

/

4

6 150 68 300 136

2611 Single/swivel/471 Carbo-Cam/becket* 1

9

/

16

40 4 102

5

/

32

4

1

/

4

6 300 136 600 272

2612 Triple/swivel/471 Carbo-Cam** 1

9

/

16

40 3

11

/

16

94

3

/

16

5

1

/

4

6 750 340 1500 680

2613 Triple/swivel/471 Carbo-Cam/becket 1

9

/

16

40 4

5

/

16

110

3

/

16

5

1

/

4

6 900 408 1800 816

2614 Cheek 1

9

/

16

40 2

3

/

4

70 — —

3

/

8

10 300 136 1000 454

2619 Triple/471 Carbo-Cam/29 mm/becket 1

9

/

16

40 4

3

/

4

121

3

/

16

5

1

/

4

6 900 408 1800 816

57 mm

2135 Single/swivel 2

1

/

4

57 4

1

/

16

103

3

/

16

5

3

/

8

10 500 227 2000 907

2166 Single/swivel/Power3/1.5x grip/titanium 2

1

/

4

57 4

1

/

16

103

3

/

16

5

3

/

8

10 500 227 2000 907

2169 Single/swivel/Power3/2x grip/silver 2

1

/

4

57 4

1

/

16

103

3

/

16

5

3

/

8

10 500 227 2000 907

2136 Single/swivel/becket 2

1

/

4

57 4

15

/

16

125

3

/

16

5

3

/

8

10 500 227 2000 907

2137 Cheek 2

1

/

4

57 3

1

/

4

83 — —

3

/

8

10 500 227 2000 907

2138 Single/swivel/150 Cam-Matic* 2

1

/

4

57 4

1

/

16

103

3

/

16

5

3

/

8

10 300 136 750 340

2139 Single/swivel/150 Cam-Matic/becket* 2

1

/

4

57 4

15

/

16

125

3

/

16

5

3

/

8

10 600 272 1500 680

2140 Triple/swivel/150 Cam-Matic*+2

1

/

4

57 4

1

/

16

103

3

/

8

10

1

/

4

6 1500 680 3750 1700

2141 Triple/swivel/150 Cam-Matic/becket 2

1

/

4

57 4

15

/

16

125

3

/

8

10

1

/

4

6 1800 816 4500 2041

2673 57 mm fiddle/ratchet 2

1

/

4

57 4

5

/

8

118

3

/

8

10

3

/

16

5 793 360 2380 1080

2674 57 mm/fiddle/ratchet/becket 2

1

/

4

57 5

5

/

8

143

3

/

8

10

3

/

16

5 793 360 2380 1080

2675 57 mm/fiddle/ratchet/150 Cam-Matic 2

1

/

4

57 4

5

/

8

118

3

/

8

10

3

/

16

5 793 360 2380 1080

2676 57 mm/fiddle/ratchet/150 Cam/becket 2

1

/

4

57 5

5

/

8

143

3

/

8

10

3

/

16

5 793 360 2380 1080

75 mm

2174 Single/swivel/Power3/1.5x grip/titanium 2

15

/

16

75 5

3

/

8

137

1

/

4

6

7

/

16

12 750 341 3000 1361

2176 Single/swivel/Power3/2x grip/silver 2

15

/

16

75 5

3

/

8

137

1

/

4

6

7

/

16

12 750 341 3000 1361

2670 Single/swivel 2

15

/

16

75 5

3

/

8

137

1

/

4

6

7

/

16

12 750 341 3000 1361

2671 Single/swivel/becket 2

15

/

16

75 6

1

/

2

165

1

/

4

6

7

/

16

12 750 341 3000 1361

2672 Cheek 2

15

/

16

75 4

1

/

16

103 — —

7

/

16

12 750 341 3000 1361

2694 75 mm/fiddle/ratchet 2

15

/

16

75 6

3

/

16

157

1

/

2

12

1

/

4

6 1212 550 3637 1650

2695 75 mm/fiddle/ratchet/becket 2

15

/

16

75 7

7

/

16

189

1

/

2

12

1

/

4

6 1212 550 3637 1650

2696 75 mm/fiddle/ratchet/150 Cam-Matic*++ 2

15

/

16

75 6

3

/

16

157

1

/

2

12

1

/

4

6 900 408 3350 1020

2697 75 mm/fiddle/ratchet/150 Cam/becket 2

15

/

16

75 7

7

/

16

189

1

/

2

12

1

/

4

6 1212 550 3637 1650

*Maximum working loads and breaking loads for blocks based on cam strengths.

**Can be used as becket block – add 281 eyestrap.

+Can be used as becket block – add 137 eyestrap and (2) HFS929 panhead screws (M5X45).

++ Can be used as becket – add 137 eyestrap.

IMPORTANT: See Inspection and Maintenance

at end of manual.

Do not apply a load greater than the maximum working load (MWL) of the Carbo®Ratchet blocks listed below.