Always

~ear

gloves

~hen

~"

"

0"

"P-ER

A'T"~

"ION

~"~-

~""

~-

"

operating

the

stove.

1-\

GeneralConsiderations

Draft

Before

you

install and operate your Oakwwod

wood

stove,

please

read

the

entire

contents

of

this

manual.

Pay

particular

attention

to

the;;

explanation

of

draft

and

its

effect

on

stove

performance

in

thelnstallationsection.

By

following the installationand

operating guidelines, you willensureproperdraftandgain

maximum

efficiency andenjoymentfrom

your

stove.

Fuel Your

Oakwood

bums

wood

very efficiently.

Here are some guidelines concerning log size and mois-

ture content that will help you obtain the best perfor-

mance. Selectdry seasoned wood.

For

example, itshould

be

checked

or

cracked on the ends and

not

exposed to

rain

or

extremely damp conditions. Hardwoods are fa-

voredbecause

they

areheavier and contain moreheating

capacity

(BTU's)

per

load

than

do

softwoods. Wood

should

be

split and storedundercoverfor "seasoning" - a

year is

recommended~

Your stove is

not

an incinerator -

do

not

burn garbage, painted

or

treated wood, plastic,

or

other debris.

Keep the area around the stove free from clut-

ter. Keepallcombustibles,including fuel, beyondthecode-

required clearancedistance (48"

or

1215

mm

in

the U.S.,

1525

mm

or

60"

in

Canada).

Never

store fuel

in

front

of

the stove where

it

could interfere with

door

operation,

safe loading, and ash removal.

Do

not

burn

garbage

or

flammablefluids such

as gasoline,

naptha,

or

engine oil.

CAUTION:

Always wear fire

retardant

gloves

when operating the stove.

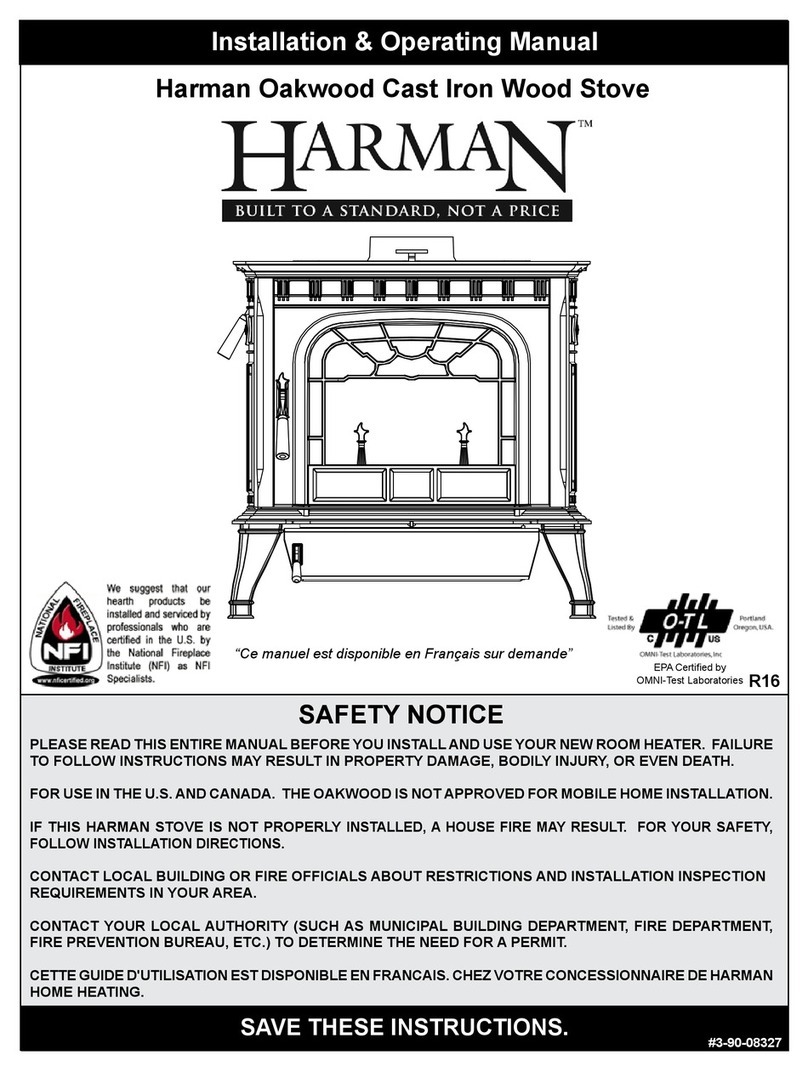

SAFETY

NOTICE

IF THIS HARMAN OAKWOOD STOVE IS

NOT PROPERLY INSTALLED, OPERATED

AND MAINTAINED, A HOUSE FIRE MAY

RESULT. FOR YOUR SAFETY, FOLLOW

INSTALLATION DIRECTIONS. CONTACT

LOCAL BUILDING

OR

FIRE OFFICIALS

ABOUT RESTRICTIONS AND INSTALLA-

TION INSPECTION REQUIREMENTS

IN

YOURAREA.

" "

The Stove

Doors Your stove has a large glass-paneled door for

loading and fireviewing, a separate smaller door for re-

moving ashes and a top loading door.

Front Door

Beforeopening, always checkforwood, embers,

or

ash that may

be

ready to

fallout

of

the door.

To openthe glass door, openbypassdamperfirst,

then

lift the handle and pull out; to close the door,

push

door

closed with handle

in

the

open

position, then

push

handle

down

to engage the latch.

Ash

Door

To open the ash door, lift up the handle and pull

out.

Close

the door

by

pushing

in

andpushingthehandle

all the

way

down.

Top

Load Door

To openthe top loaddoor, openthe bypass damper

and then open the top load door.

All doors must

be

closed while the stove

is

in

nor-

maloperation, andthegasketsroutinelyexaminedforwear

and replaced

when

necessary.

Good

door seals are im-

portantfor maintaining control

of

the stove.

Never

oper-

ate with the ash door open. Operating the stove with the

ash door open,

or

with a doorinadequately sealed, could

create a serious overftring condition (discussed later

in

this section).

NEVEROPERATE

WITH

MORE

THAN

ONEDOOROPENATATIME

The

glass

used

in

your Oakwood is manufactured

to exact standards to withstand the high heat

of

the fire,

but

like all glass,

it

must

be

treated with common sense

and

care. Never abuse the glass

by

slamming the door

shut

or

strikingthe glass with a heavy object.

If

theglass

isbroken

or

damaged, do notoperatethe stove until ithas

been

replaced

(See instructions

in

the Maintenance section.)

Grates

The

Harman

Oakwood's unique grate system con-

sists

of

one flat bottom grate, and two front andirons.

The

bottom

gratehas slots whichallow the ashto fall into

the ash

pan

by

passing a

poker

back

and

forth across the

grate. The andirons keep the fuel from coming into di-

rect contact with the glass,

and

keep

hot

coals and

em-

bers from spilling outwhile reloading. Neverbuild a fIre

directly against the glass.

The grates and andirons

must

remain

in

place at all

times.

Do

not

tamperwithorchangetheconfiguration

of

this grate system.

Harman

Oakwood 7