Harris RF-5800H User guide

PUBLICATION NUMBER: 10515-0124-4200

FEBRUARY 2001

Rev. A

Tactical Radio Products

next level solutions

RF-5800H

125-WATT COMMUNICATION

SYSTEM

SYSTEM INSTALLATION/

MAINTENANCE MANUAL

LIMITED ONE YEAR WARRANTY

HARRIS CORPORATION (RF COMMUNICATIONS DIVISION)

FROM HARRIS TO YOU – This warranty is extended to the original buyer and applies to all Harris Corporation, RF

Communications Division equipment purchased and employed for the service normally intended, except those products

specifically excluded.

WHAT WE WILL DO – If your Harris Corporation, RF Communications Division equipment purchased from us for use outside the

United States fails in normal use because of a defect in workmanship or materials within one year from the date of shipment, we

will repair or replace (at our option) the equipment or part without charge to you, at our factory. If the product was purchased for

use in the United States, we will repair or replace (at our option) the equipment or part without charge to you at our Authorized Repair

Center or factory.

WHAT YOU MUST DO – You must notify us promptly of a defect within one year from date of shipment. Assuming that Harris

concurs that the complaint is valid, and is unable to correct the problem without having the equipment shipped to Harris:

•Customers with equipment purchased for use outside the United States will be supplied with information for the return

of the defective equipment or part to our factory in Rochester, NY, U.S.A., for repair or replacement. You must prepay

all transportation, insurance, duty and customs charges. We will pay for return to you of the repaired/replaced equipment

or part, C.I.F. destination; you must pay any duty, taxes or customs charges.

•Customers with equipment purchased for use in the United States must obtain a Return Authorization Number, properly

pack, insure, prepay the shipping charges and ship the defective equipment or part to our factory or to the Authorized

Warranty Repair Center indicated by us.

Harris Corporation Telephone: (716) 244-5830

RF Communications Division Fax: 716-242-4755

Customer Service http://www.harris.com

1680 University Avenue

Rochester, NY 14610, U.S.A.

Harris will repair or replace the defective equipment or part and pay for its return to you, provided the repair or replacement is due

to a cause covered by this warranty.

WHAT IS NOT COVERED – We regret that we cannot be responsible for:

•Defects or failures caused by buyer or user abuse or misuse.

•Defects or failures caused by unauthorized attempts to repair or alter the equipment in any way.

•Consequential damages incurred by a buyer or user from any cause whatsoever, including, but not limited to

transportation, non-Harris repair or service costs, downtime costs, costs for substituting equipment or loss of anticipated

profits or revenue.

•The performance of the equipment when used in combination with equipment not purchased from Harris.

•HARRIS MAKES NO OTHER WARRANTIES BEYOND THE EXPRESS WARRANTY AS CONTAINED HEREIN. ALL

EXPRESS OR IMPLIED WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR MERCHANTABILITY ARE

EXCLUDED.

SERVICE WARRANTY – Any repair service performed by Harris under this limited warranty is warranted to be free from defects

in material or workmanship for sixty days from date of repair. All terms and exclusions of this limited warranty apply to the service

warranty.

IMPORTANT – Customers who purchased equipment for use in the United States must obtain a Return Authorization Number

before shipping the defective equipment to us. Failure to obtain a Return Authorization Number before shipment may result in a

delay in the repair/replacement and return of your equipment.

IF YOU HAVE ANY QUESTIONS – Concerning this warranty or equipment sales or services, please contact our Customer Service

Department.

PUBLICATION NUMBER: 10515-0124-4200

FEBRUARY 2001

Rev. A

HARRIS CORPORATION RF COMMUNICATIONS DIVISION

1680 University Avenue Rochester, New York 14610-1887 USA

Tel: 716-244-5830. Fax: 716-242-4755. http://www.harris.com

RF-5800H

125-WATT

COMMUNICATION

SYSTEM

Information and descriptions contained herein are the property of Harris Corporation. Such information

and descriptions may not be copied or reproduced by any means, or disseminated or distributed without

the express prior written permission of Harris Corporation, RF Communications Division, 1680 University

Avenue, Rochester, New York 14610-1887.

Copyright 2001

By Harris Corporation

All Rights Reserved

RF-5800H 125-WATT COMMUNICATION SYSTEM

ii

For more information about these and other life–saving techniques, contact your Red Cross chapter for training.

“When Breathing Stops”reproduced with permission from an American Red Cross Poster.

When an Adult Stops Breathing

Does the Person

Respond?

GTap or gently shake

victim.

GShout, “Are you OK?”

1

Roll Person

Onto Back

GRoll victim toward you

by pulling slowly.

3

Open Airway

GTilt head back and lift

chin.

4

Give 2 Full

Breaths

GKeep head tilted back.

GPinch nose shut.

GSeal your lips tight

around victim’s mouth.

GGive 2 full breaths for

1 to 1-1/2 seconds each.

6

Check for Pulse

at Side of Neck

GFeel for pulse for

5 to 10 seconds.

7

Begin Rescue

Breathing

GKeep head tilted back.

GLift chin.

GPinch nose shut.

GGive 1 full breath

every 5 seconds.

GLook, listen, and feel for

breathing between breaths.

9

Shout, “Help!”

GCall people who can

phone for help.

2

Check for

Breathing

GLook, listen, and feel

for breathing for

3 to 5 seconds.

5

Phone

for Help

GSend someone to call

an ambulance.

8

Recheck Pulse

Every Minute

GKeep head tilted back.

GFeel for pulse for

5 to 10 seconds.

GIf victim has pulse but is

not breathing, continue

rescue breathing. If no

pulse, begin CPR.

10

WARNING

DO NOT attempt to perform the rescue breathing techniques provided

on this page, unless certified. Performance of these techniques by

uncertified personnel could result in further injury or death to the victim.

RF-5800H 125-WATT COMMUNICATION SYSTEM

TABLE OF CONTENTS

iii

TABLE OF CONTENTS

Paragraph Page

CHAPTER 1 – GENERAL INFORMATION

1.1 INTRODUCTION 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 SAFETY PRECAUTIONS 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 MAINTENANCE LEVELS 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 Level I 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Level II 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.3 Level III 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.4 Level IV 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 WARRANTY 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 GENERAL SYSTEM DESCRIPTION 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.1 RF-5800H 125-Watt Vehicular System 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.2 RF-5800H 125-Watt Base Station System 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.3 RF-5800H 125-Watt Transit Case System 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.4 Related Equipment Manuals 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6 GENERAL EQUIPMENT DESCRIPTIONS 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.1 RF-5832H-PA 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.2 RF-5051PS 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.3 RF-382A (Optional) 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.4 Unit Identification 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.6.5 Specifications 1-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.7 LIST OF ITEMS REQUIRED BUT NOT SUPPLIED 1-13. . . . . . . . . . . . . . . . . . . . . .

1.8 LIST OF MANUFACTURERS 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 2 – INSTALLATION

2.1 INTRODUCTION 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 SITE INFORMATION 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 General Guidelines 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1.1 Grounding 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1.2 Vehicular Configuration Grounding 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1.3 Base Station Configuration Grounding 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1.4 Transit Case Configuration Grounding 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1.5 Environmental 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 TOOLS AND MATERIALS REQUIRED 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 UNPACKING AND REPACKING 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Unpacking 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.2 Repacking 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 EQUIPMENT INSTALLATION 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Power Requirements 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Access Clearance and Ventilation Requirements 2-4. . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 Vehicular Shock Mounts 2-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.4 Jumper/DIP Switch Settings 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.5 Unit Removal and Installation Procedures 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.6 System Cabling Interconnect Information 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF-5800H 125-WATT COMMUNICATION SYSTEM

TABLE OF CONTENTS

iv

TABLE OF CONTENTS –Continued

Paragraph Page

CHAPTER 2 –INSTALLATION –Continued

2.5.7 Antenna Considerations 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 INSTALLATION CHECKOUT 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 Inspection and Pre-Power Up Procedures 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Initial Settings and Power Up 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 3 –OPERATION

CHAPTER 4 –FUNCTIONAL DESCRIPTION

4.1 INTRODUCTION 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 SIGNAL PATHS 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.1 RF/Audio Signal Path 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.2 Control Path 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3 Power Distribution Path 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3.1 RF-5800H 125-Watt Vehicular System 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2.3.2 RF-5800H 125-Watt Base Station and Transit Case Systems 4-2. . . . . . . . . . . . .

CHAPTER 5 –SCHEDULED MAINTENANCE

5.1 PREVENTIVE MAINTENANCE 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 6 –TROUBLESHOOTING

6.1 INTRODUCTION 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 General 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Scope of this Chapter 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 TROUBLESHOOTING PROCEDURES 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 General 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Maintenance Turn-On Procedure 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.3 Non-BIT Troubleshooting 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.4 BIT Troubleshooting 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.5 TAPs 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 TROUBLESHOOTING SUPPORT DATA 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.1 Protective Device Index 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3.2 Troubleshooting Index 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 TROUBLESHOOTING DIAGRAMS 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4.1 General 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 INTERCONNECT INFORMATION 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5.1 General 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHAPTER 7 –PARTS LIST

7.1 INTRODUCTION 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 LRUS 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 LRU DIAGRAMS 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF-5800H 125-WATT COMMUNICATION SYSTEM

TABLE OF CONTENTS

v

LIST OF FIGURES

Figure Page

1-1 Typical RF-5800H 125-Watt Communication System

1-2 Maintenance Flow Chart 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Relationship of Units in RF-5800H 125-Watt Vehicular System

Typical Configuration 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 RF-5800H 125-Watt Vehicular System Family Tree

Typical Configuration 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5 Relationship of Units in RF-5800H 125-Watt Base Station System

Typical Configuration 1-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6 RF-5800H 125-Watt Base Station System Family Tree

Typical Configuration 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-7 Relationship of Units in the RF-5800H 125-Watt Transit Case System

Typical Configuration 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-8 RF-5800H 125-Watt Transit Case System Family Tree Typical

Configuration 1-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1 RF-5800H 125-Watt Vehicular System Installation and

Maintenance Clearances 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 RF-5800H-125 Watt Base Station Installation and Maintenance

Clearances 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 RF-5800H-125 Watt Transit Case Installation and Maintenance

Clearances 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 RF-5071VSM Shock Mount Dimensions 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5 RF-5211VSM Shock Mount Dimensions 2-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6 RF-5211-01VSM Shock Mount Dimensions 2-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-7 RF-5800H 125-Watt Vehicular System Installation Typical

Configuration 2-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8 RF-5800H 125-Watt Base Station System Installation

Typical Configuration 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-9 RF-5800H 125-Watt Transit Case System Installation

Typical Configuration 2-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-10 RF-5800H 125-Watt Vehicular System Cable Interconnects 2-21. . . . . . . . . . . . . . .

2-11 RF-5800H 125-Watt Base Station or Transit Case System Cable

Interconnects 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1 RF-5800H 125-Watt Communication System RF/Audio and

Control Paths 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Vehicular Power Distribution Diagram 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Base Station or Transmit Case System Power Distribution Diagram 4-5. . . . . . . .

6-1 Troubleshooting Process Used in this Chapter 6-1. . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Sample Fault Code Display 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1 RF-5832H-PA 125-Watt Power Amplifier 7-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 RF-5051PS Power Supply 7-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3 RF-5071VSM Shock Mount Assembly 7-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4 RF-5211VSM Shock Mount Assembly 7-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-5 RF-5211-01VSM Shock Mount Assembly 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-6 RF-5800H-125 Watt Base Station Mount Assembly

Typical Configuration 7-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-7 RF-5800H-125 Watt Transit Case Mount Assembly

Typical Configuration 7-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-8 R/T-PA Coaxial Cable Assembly (10181-9821) 7-12. . . . . . . . . . . . . . . . . . . . . . . . . .

RF-5800H 125-WATT COMMUNICATION SYSTEM

TABLE OF CONTENTS

vi

LIST OF FIGURES –Continued

Figure Page

7-9 DC Power Cable Assembly (10181-9826-020) 7-12. . . . . . . . . . . . . . . . . . . . . . . . . .

7-10 PA-R/T Cable Assembly (10535-0720) 7-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-11 AC Power Cable Assembly (10181-9831) 7-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-12 PA-Coupler RF Cable Assembly (10181-9824) 7-15. . . . . . . . . . . . . . . . . . . . . . . . . .

7-13 PA-Coupler Control Cable Assembly (10181-9823) 7-17. . . . . . . . . . . . . . . . . . . . . .

7-14 KY-99A Audio/Black Data Cable Assembly (10535-0701) 7-19. . . . . . . . . . . . . . . . .

7-15 RS-232 Black Data to Encryption Device Cable Assembly

(10535-0702) 7-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-16 ASCII Remote and PS Control Cable Assembly, Y (10535-0730) 7-25. . . . . . . . . .

7-17 KG-84C Black Data Cable Assembly, Y (10535-0750) 7-27. . . . . . . . . . . . . . . . . . . .

7-18 ASCII Remote Control Rear D-Connector Cable Assembly

(10535-0760) 7-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-19 Sync/Async RS-232 DTE Data Cable Assembly (10535-0770) 7-31. . . . . . . . . . . .

7-20 Synchronous RS-232 DTE Data Cable Assembly (10535-0780) 7-33. . . . . . . . . . .

7-21 Asynchronous Data (PPP) Cable Assembly (10535-0775) 7-35. . . . . . . . . . . . . . . .

7-22 DC Power Cable Assembly (10181-9833) 7-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-23 Speaker Power Cable Assembly (10535-0706) 7-38. . . . . . . . . . . . . . . . . . . . . . . . .

7-24 Speaker Cable Assembly (10535-0707) 7-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-25 Ground Strap Cable Assembly (10400-1136) 7-40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF TABLES

Table Page

1-1 RF-5800H 125-Watt Configurations 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Related Equipment Manuals 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Required Tools, Test Equipment, and Materials 1-13. . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 List of Manufacturers 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Daily Preventive Maintenance Checks and Services 5-1. . . . . . . . . . . . . . . . . . . . .

5-2 Weekly Preventive Maintenance Checks and Services 5-1. . . . . . . . . . . . . . . . . . .

6-1 Non-BIT Fault Symptoms/Run Time Fault Codes 6-3. . . . . . . . . . . . . . . . . . . . . . . .

6-2 RF-5800H 125-Watt Communication System Operator Initiated BIT

Fault Codes 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3 Troubleshooting Analysis Procedures 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4 Protective Device Index 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5 Troubleshooting Index 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1 RF-5800H 125-Watt Vehicular System LRUs 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 RF-5800H 125-Watt Base Station System LRUs 7-1. . . . . . . . . . . . . . . . . . . . . . . .

7-3 RF-5800H 125-Watt Transit Case System LRUs 7-2. . . . . . . . . . . . . . . . . . . . . . . . .

7-4 RF-5071VSM Shock Mount Assembly Parts List (10181-5071) 7-2. . . . . . . . . . . .

7-5 RF-5071VSM Ancillary Kit Parts List (10181-9030) 7-2. . . . . . . . . . . . . . . . . . . . . .

7-6 RF-5211VSM Shock Mount Assembly Parts List 7-2. . . . . . . . . . . . . . . . . . . . . . . . .

7-7 RF-5211VSM Ancillary Kit Parts List (10372-0875-01) 7-3. . . . . . . . . . . . . . . . . . . .

7-8 RF-5051PS Power Supply Assembly Parts List (10299-5051-03) 7-3. . . . . . . . . .

7-9 RF-5051PS Ancillary Kit Parts List (10181-9010) 7-3. . . . . . . . . . . . . . . . . . . . . . . .

7-10 Available Power Cables (Purchased Separately) 7-3. . . . . . . . . . . . . . . . . . . . . . . .

7-11 Available Option Cables (Purchased Separately) 7-4. . . . . . . . . . . . . . . . . . . . . . . .

RF-5800H 125-WATT COMMUNICATION SYSTEM

SAFETY SUMMARY

vii

SAFETY SUMMARY

1. INTRODUCTION

All operators and maintenance personnel must observe the following safety precautions during operation and

maintenance of this equipment. Specific warnings and cautions are provided in the manual and at the end of this

Safety Summary. Warnings, Cautions, and Notes appear before various steps in the manual and will be used as

follows:

•WARNING –Used when injury or death to personnel and damage to equipment is possible

•CAUTION –Used when there is a possibility of damage to equipment

•NOTE –Used to alert personnel to a condition that requires emphasis

2. PERSONNEL AND EQUIPMENT SAFETY

Basic safety precautions consider factors involved in protecting personnel from injury or death. Electrical,

mechanical, electromagnetic radiation (EMR), material, or chemical hazards are the most common types of

hazards found in electronic equipment. The following are types of hazards that may exist:

ELECTRICAL –Hazardous voltage and current levels may exist throughout the equipment. Contact

with these hazards could cause electrocution, electrical shock, burns, or injury due to

involuntary reflexes of the body.

MECHANICAL –Mechanical hazards are created when heavy assemblies and components must be

removed and replaced. Moving parts (such as fan blades) and hot surfaces are

potential mechanical hazards.

THERMAL –Burn hazards may exist in the equipment that could cause personal injuries and/or

serious equipment damage. Internal surfaces of the equipment may be in excess of

65°C, the point at which personnel could be burned. Extreme caution should be used

when working with any hot assemblies (for example, power supply or power amplifier

assemblies). Physical injury or damage may result to personnel and/or equipment as a

result of a reflex action to a burn.

CHEMICAL –Chemicals or materials used for servicing the equipment may present potential

hazards. Many chemical agents, such as cleaners and solvents, may be toxic, volatile,

or flammable. If used incorrectly, these agents can cause injury or death.

EMR –Overexposure to electromagnetic radiation resulting from amplified radio frequencies

that may produce a health hazard.

3. OPERATIONAL AND MAINTENANCE SAFETY GUIDELINES

Good safety discipline is critical to prevent injury to personnel. All other safety measures are useless if personnel

do not observe the safety precautions and do not follow safety disciplines. Once aware of a hazard, personnel

should ensure that all other personnel are aware of the hazard. The following basic safety disciplines are stressed:

a. Read a procedure entirely before performing it. Personnel must always perform each assigned task in a

safe manner.

b. Prior to applying equipment power after maintenance, personnel must ensure that all unsecured hand

tools and test equipment are disconnected from the serviced/maintained equipment and properly stored.

RF-5800H 125-WATT COMMUNICATION SYSTEM

SAFETY SUMMARY

viii

c. Power to the equipment must be removed before a piece of equipment is removed.

d. Extreme care must be used when adjusting or working on operating equipment. Voltages in excess of

70 V or current sources in excess of 25 A are covered with barriers. Barriers include warning information

about the hazard encountered upon barrier removal.

e. Personnel must react when someone is being electrically shocked. Perform the following steps:

1. Shut off power.

2. Call for help.

3. Administer first aid if qualified.

Under no circumstances should a person come directly in contact with the body unless the power has

been removed. When immediate removal of the power is not possible, personnel must use a

non-conductive material to try to jolt or pry the body away from the point of shock.

f. Personnel should work with one hand whenever possible to prevent electrical current from passing

through vital organs of the body. In addition, personnel must never work alone. Someone must be

available in the immediate area to render emergency first aid, if necessary.

g. Lifting can cause injury. Items weighing more than 37 pounds must be lifted by two or more people.

h. Some electrolytic capacitors contain aluminum oxide or tantalum. If connected incorrectly, the capacitor

will explode when power is applied. Extreme care must be used when replacing and connecting these

capacitors. The capacitor terminals must always be connected using the correct polarity: positive to

positive and negative to negative.

The next section contains general safety precautions not directly related to specific procedures or equipment.

These precautions are oriented toward the maintenance technician. However, all personnel must understand and

apply these precautions during the many phases of operation and maintenance of the equipment. The following

precautions must be observed:

DO NOT SERVICE EQUIPMENT ALONE

Never work on electrical equipment unless another person familiar with the operation and hazards of the

equipment is near. When the maintenance technician is aided by operators, ensure that operators are aware of

the hazards.

GROUNDING

Always ensure that all equipment and assemblies are properly grounded when operating or servicing.

TURN OFF POWER AND GROUND CAPACITORS

Whenever possible, power to equipment should be turned off before beginning work on the equipment. Be

sure to ground all capacitors that are potentially dangerous.

KEEP AWAY FROM LIVE CIRCUITS

Operators and maintainers must observe all safety regulations at all times. Do not change components or

make adjustments inside equipment with a high voltage supply on unless required by the procedure. Under

certain conditions, dangerous potentials may exist in circuits with power controls off, due to charges retained

by capacitors.

RF-5800H 125-WATT COMMUNICATION SYSTEM

SAFETY SUMMARY

ix

DO NOT BYPASS INTERLOCKS

Do not bypass any interlocks unnecessarily. If it is necessary to employ an interlock bypass for equipment

servicing, use extreme care not to come in contact with hazardous voltages.

USE CARE HANDLING HEAVY EQUIPMENT

Never attempt to lift large assemblies or equipment without knowing their weight. Use enough personnel or a

mechanical lifting device to properly handle the item without causing personal injury.

HEED WARNINGS AND CAUTIONS

Specific warnings and cautions are provided to ensure the safety and protection of personnel and equipment.

Be familiar with and strictly follow all warnings and cautions on the equipment and in technical manuals.

PROTECTIVE EYEWEAR

All personnel must wear protective eyewear when servicing or maintaining equipment. Protective eyewear

must be worn at all times when using tools.

4. PROTECTION OF STATIC-SENSITIVE DEVICES

Diode input-protection is provided on all CMOS devices. This protection is designed to guard against adverse

electrical conditions such as electrostatic discharge. Although most static-sensitive devices contain protective

circuitry, several precautionary steps should be taken to avoid the application of potentially damaging

voltages to the inputs of the device.

To protect static-sensitive devices from damage, the following precautions should be observed.

a. Keep all static-sensitive devices in their protective packaging until needed. This packaging is

conductive and should provide adequate protection for the device. Storing or transporting these

devices in conventional plastic containers could be destructive to the device.

b. Disconnect power prior to insertion or extraction of these devices. This also applies to PWBs

containing such devices.

c. Double check test equipment voltages and polarities prior to conducting any tests.

d. Avoid contact with the leads of the device. The component should always be handled carefully by

the ends or side opposite the leads.

e. Avoid contact between PWB circuits or component leads and synthetic clothing.

f. Use only soldering irons and tools that are properly grounded. Ungrounded soldering tips or tools

can destroy these devices. SOLDERING GUNS MUST NEVER BE USED.

RF-5800H 125-WATT COMMUNICATION SYSTEM

SAFETY SUMMARY

x

5. EXPLANATION OF HAZARD SYMBOLS

The symbol of drops of a liquid onto a hand shows that the material will cause burns or

irritation of human skin or tissue.

The symbol of a person wearing goggles shows that the material will injure your eyes.

The symbol of a flame shows that a material can ignite and burn you.

The symbol of a skull and crossbones shows that a material is poisonous or a danger to life.

The symbol of a human figure in a cloud shows that vapors of a material present danger to your

life or health.

RF-5800H 125-WATT COMMUNICATION SYSTEM

GENERAL INFORMATION

RF-5800H

125-WATT

COMMUNICATION

SYSTEM

RF-5800H 125-WATT COMMUNICATION SYSTEM

GENERAL INFORMATION

5800H-125-V120A

BASE STATION TRANSIT CASE

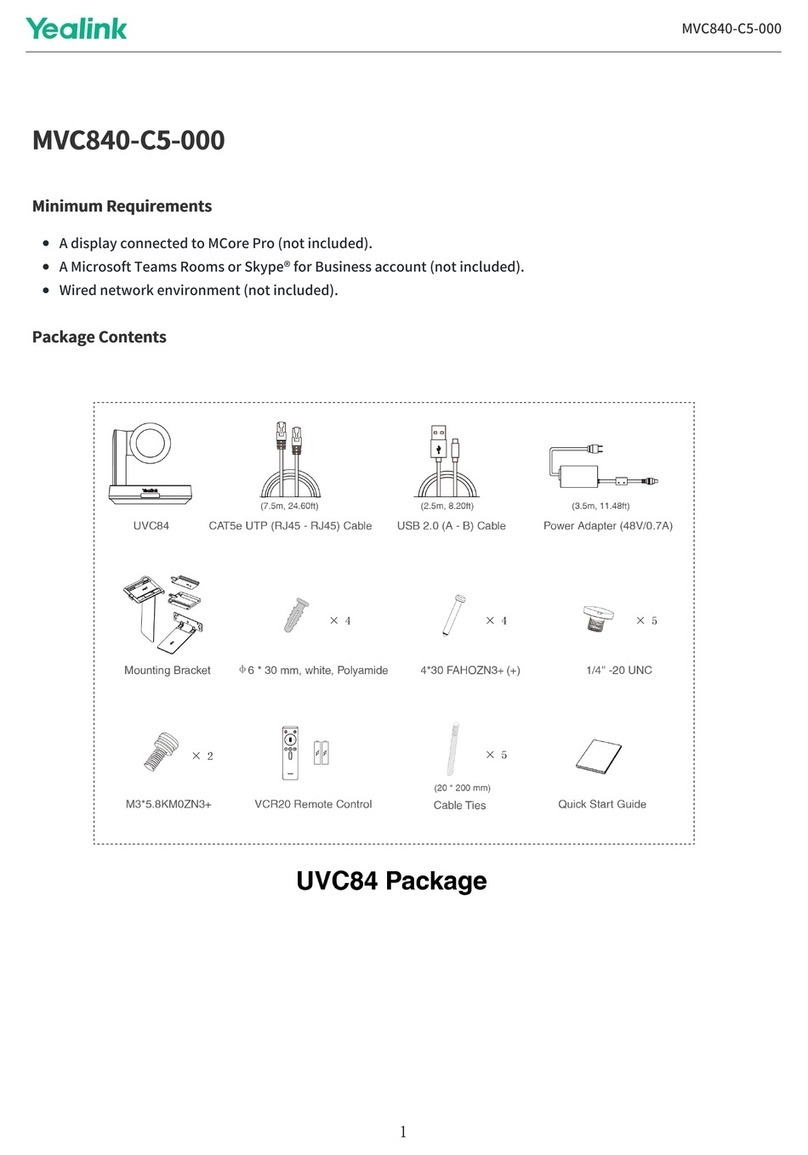

Figure 1-1. Typical RF-5800H 125-Watt Communication System

RF-5832H-PA

RF-5800H-MP

RF-5800H 125-WATT COMMUNICATION SYSTEM

GENERAL INFORMATION

1-1

CHAPTER 1

GENERAL INFORMATION

1.1 INTRODUCTION

This manual provides the maintainer with all technical information required to support Level II maintenance as

described in Paragraph 1.3.2.

The overall intent of this manual is to help the maintainer expedite repair of the unit in a reasonable amount of

time, resulting in reduced downtime and increased system availability. Detailed information that will be useful to

the maintainer is provided in the following areas:

•Installation

•Configuration

•Equipment specifications

•Fault isolation and repair techniques

•Required tools and test equipment

•Functional descriptions at the system level

1.2 SAFETY PRECAUTIONS

All safety precautions necessary for the protection of personnel and the equipment are cross-referenced here. The

WARNING or CAUTION is referenced to the paragraph number where it is used in the manual, and a brief

subject phrase indicating the content is provided. It is recommended that these items be read in their entirety

before performing the referenced procedure. References are as follows:

•WARNING –Paragraph 2.2.1.1 –Inadequate or defective grounding presents a personnel hazard that

could result in injury or death.

•CAUTION –Paragraph 2.2.1.1 –Inadequate or defective grounding could damage the equipment.

•CAUTION –Paragraph 2.2.1.3 –Inadequate or defective grounding could damage the equipment.

•CAUTION –Paragraph 2.2.1.4 –Inadequate or defective grounding could damage the equipment.

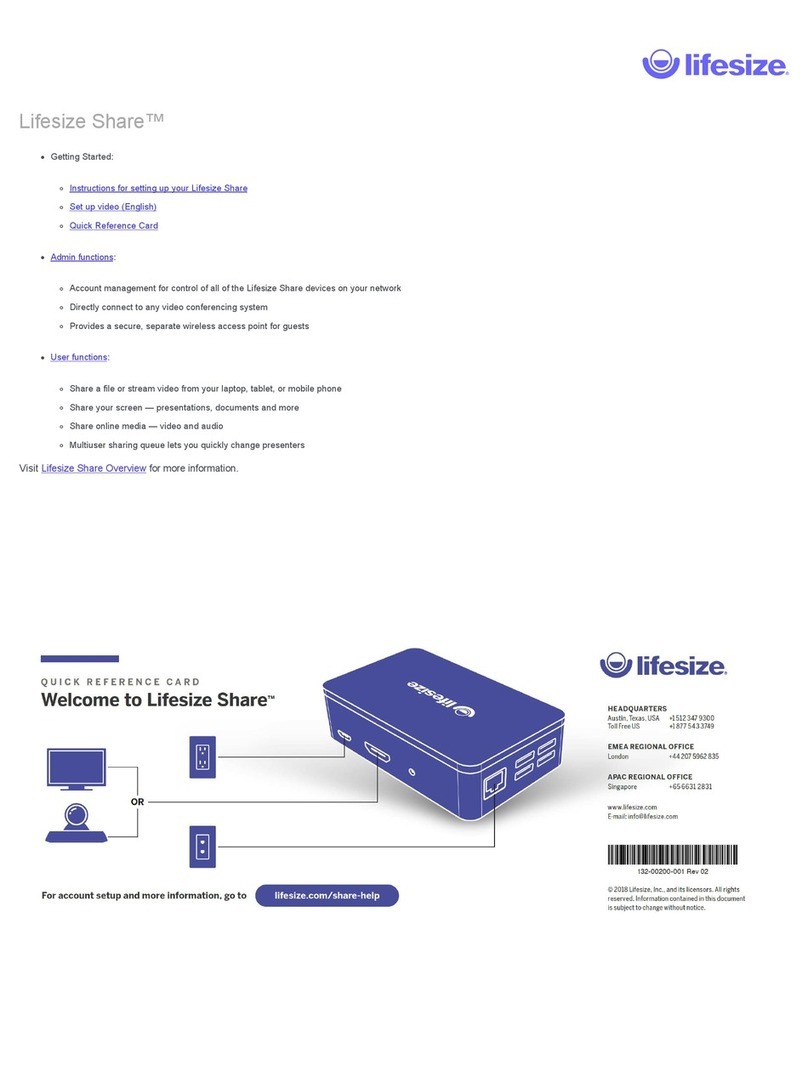

1.3 MAINTENANCE LEVELS

Harris/RF Communications designs its products and systems to be supported by up to four maintenance levels.

See Figure 1-2. Each maintenance level relies on a defined set of support documentation and equipment in order

to fulfill its maintenance tasks. The tasks performed at each level grow in complexity as fault isolation is

narrowed to the component causing the fault. This concept assists the maintainer by supplying only the

information and materials required for that maintenance level. These levels may be combined to sustain any

particular user maintenance philosophy. The four maintenance levels are described in Paragraphs 1.3.1 through

1.3.4.

1.3.1 Level I

This level is restricted to fault recognition and detection. Fault isolation is not usually performed at this level. An

operator who detects a faulty condition alerts Maintenance Level II for repair.

RF-5800H 125-WATT COMMUNICATION SYSTEM

GENERAL INFORMATION

1-2

1.3.2 Level II

The maintenance technician repairs the radio system by utilizing a System (Level II) manual to fault isolate to the

faulty unit (for example, receiver-transmitter, power amplifier, antenna coupler, etc.). The faulty LRU is replaced

with a spare and sent to Maintenance Level III.

1.3.3 Level III

The faulty unit is serviced at a facility that has support equipment available, typically a hot test bed radio system.

The suspected faulty unit is inserted into the hot test bed radio system to isolate the faulty assembly using a

Maintenance (Level III) manual. The faulty SRU or module is replaced with a spare and passed to Maintenance

Level IV.

1.3.4 Level IV

The faulty SRU or module is returned to Harris/RF Communications for repair. If Level IV maintenance

capabilities are available on-site, the maintenance technician can identify the faulty component on the SRU using

a Depot Maintenance (Level IV) manual that outlines the electronic maintenance techniques and test fixtures

necessary to repair the SRU.

RF-5800H 125-WATT COMMUNICATION SYSTEM

GENERAL INFORMATION

1-3

Figure 1-2. Maintenance Flow Chart

LEVEL I SYSTEM

OPERATIONAL YES

NO

NORMAL

OPERATION

TECHNICIAN

REPLACES UNIT

OR CABLE

REPAIRED

UNIT

DEFECTIVE

UNIT

TECHNICIAN REPLACES

MODULE

LEVEL II

LEVEL III

LEVEL IV

YES

NO

SYSTEM

OPERATIONAL

NO

UNIT

OPERATIONAL

YES

NO

UNIT/MODULE

OPERATIONAL

REPAIRED

UNIT

5800H-027

START

DEFECTIVE

MODULE

TECHNICIAN REPAIRS

MODULE

YES

REPAIRED

MODULE

REPAIRED

SYSTEM

RF-5800H 125-WATT COMMUNICATION SYSTEM

GENERAL INFORMATION

1-4

1.4 WARRANTY

Harris Corporation guarantees that if the equipment fails from normal use within one year from the date of

shipment due to a defect in workmanship or materials, Harris will repair or replace the equipment at no charge.

Repairs made by Harris to the equipment under this warranty are warranted to be free from defects in material and

workmanship for 60 days from the date of repair.

For information on how to process a claim under this warranty, and on what is not covered by this warranty, refer

to the warranty information printed on the inside front cover of this manual.

1.5 GENERAL SYSTEM DESCRIPTION

Table 1-1 identifies the RF-5800H 125-Watt Communication System configurations. Paragraphs 1.5.1 through

1.5.3 describes the configuration.

Table 1-1. RF-5800H 125-Watt Configurations

Description

125-Watt Vehicular System

125-Watt Base Station System

125-Watt Transit Case System

1.5.1 RF-5800H 125-Watt Vehicular System

Figure 1-3 shows the relationship of the units contained in the RF-5800H 125-Watt Vehicular System and Figure

1-4 is the family tree. This system contains an RF-5832H-PA 125-Watt Power Amplifier (herein after referred to

as RF-5832H-PA), interconnect cables, ground strap, and two shock mounts. The RF-5211VSM Vehicular Shock

Mount (herein after referred to as RF-5211VSM) is used with the RF-5800H-MP Manpack Radio (herein after

referred to as RF-5800H-MP) and the RF-5071VSM Vehicular Shock Mount (herein after referred to as

RF-5071VSM) is used with the RF-5832H-PA. The RF-5800H-MP and the optional RF-382A Automatic

Antenna Coupler (herein after referred to as RF-382A) are ordered separately.

1.5.2 RF-5800H 125-Watt Base Station System

Figure 1-5 shows the relationship of the units contained in the RF-5800H 125-Watt Base Station System. Figure

1-6 is the family tree. This system contains an RF-5832H-PA, an RF-5051PS Power Supply (herein after referred

to as RF-5051PS), and an external speaker. The RF-5800H-MP and RF-382A are ordered separately.

1.5.3 RF-5800H 125-Watt Transit Case System

Figure 1-7 shows the relationship of the units contained in the typical configuration of the RF-5800H 125-Watt

Transit Case System. Figure 1-8 is the family tree. This system consists of a transit case containing an

RF-5832H-PA, an RF-5051PS, and a shock mount for the RF-5832H-PA. A mounting tray for an RF-5800H-MP

and an external speaker are mounted in a separate transit case. The RF-5800H-MP and RF-382A are ordered

separately.

RF-5800H 125-WATT COMMUNICATION SYSTEM

GENERAL INFORMATION

1-5

1.5.4 Related Equipment Manuals

Table 1-2 identifies the manuals that may be necessary to configure and maintain the RF-5800H 125-Watt

Communication System in its various configurations.

Table 1-2. Related Equipment Manuals

Part Number Manual Description

10515-0008-4300 RF-382, CU-2397 Antenna Coupler Intermediate

Maintenance Manual

10515-0117-4200 RF-5800H Operations Manual

10515-0117-4300 RF-5800H-MP Intermediate Maintenance Manual

10515-0124-4300 RF-5832H-PA 125-Watt Power Amplifier Intermediate

Maintenance Manual

10515-0071-4100 RF-5056PS 12/24 V DC/DC Power Converter Supplement

10515-0164-4300 RF-5845-PP Pre/Postselector Intermediate Maintenance

Manual

This manual suits for next models

2

Table of contents