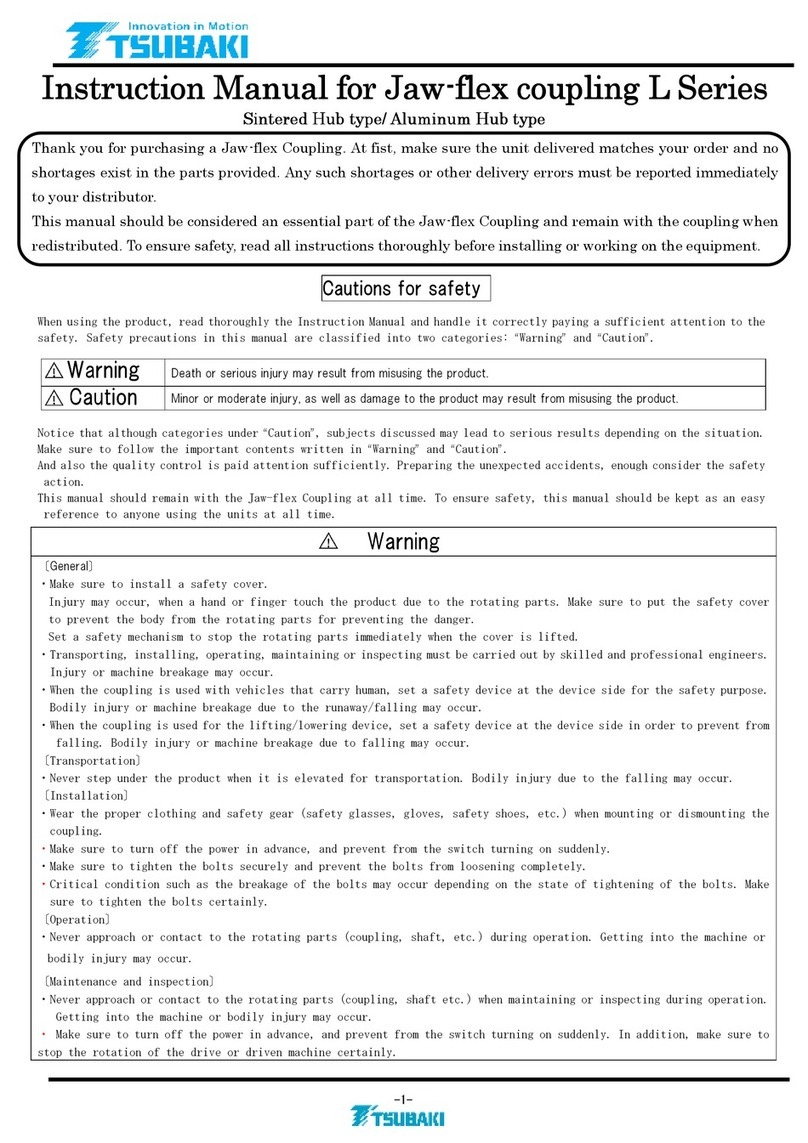

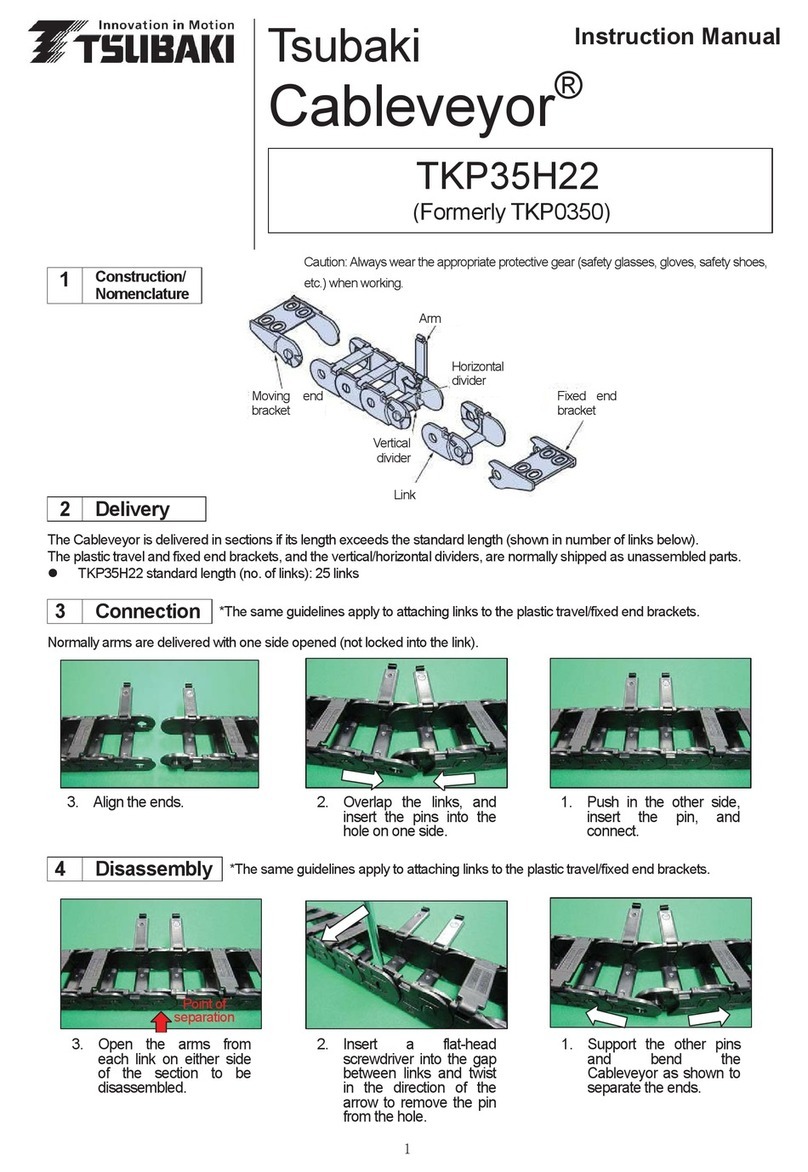

For Safe Use

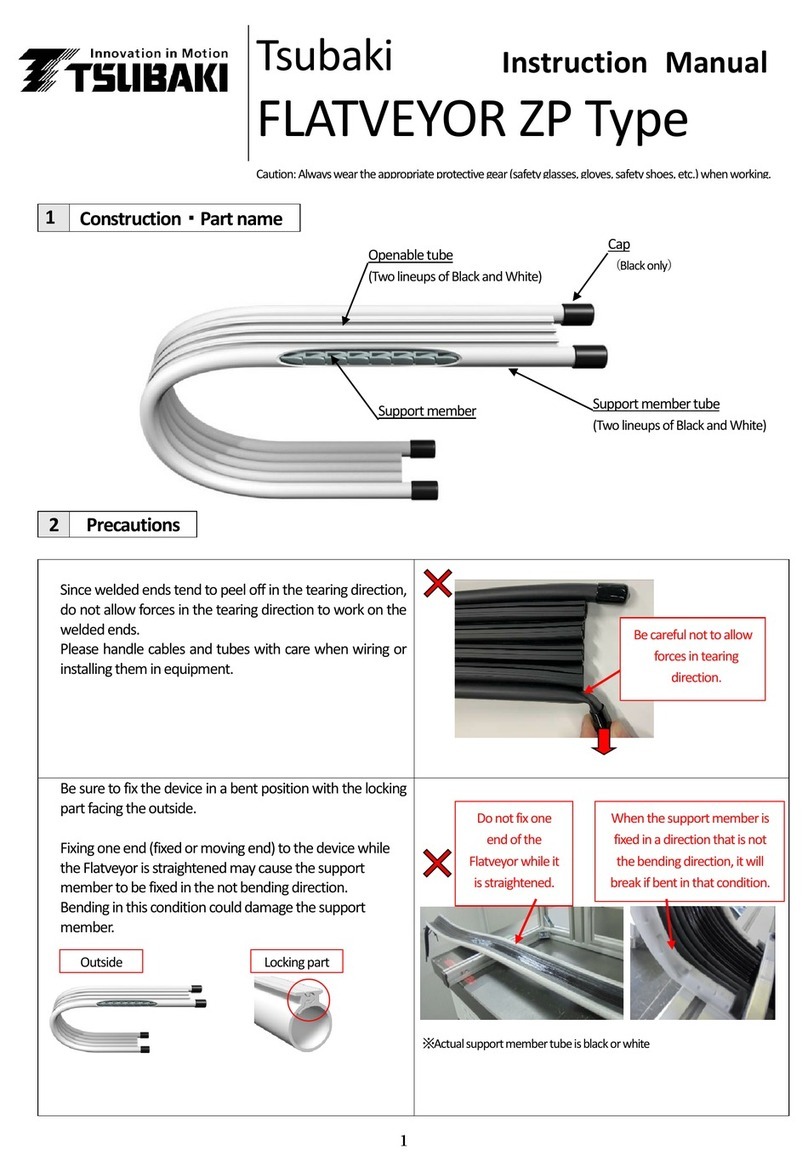

●Do not use the cable carrier and its accessories (including Cleanveyor and Flatveyor) for anything other than their

original purpose.

●Do not stand or ride on the cable carrier. There is a risk of damage and falls.

●Never perform additional work on the cable carrier or the accessories (except fitting connectors

on Cleanveyor or Flatveyor).

・Do not clean the cable carrier or the accessories with acids or alkalis, as they may

cause cracking.

・Never electroplate the cable carrier or the accessories, as this may cause cracking due to

hydrogen embrittlement.

・Do not weld the cable carrier or the accessories, as the heat may cause cracking or a

reduction in strength.

●Observe all appropriate labor safety codes and standards for your region or area.

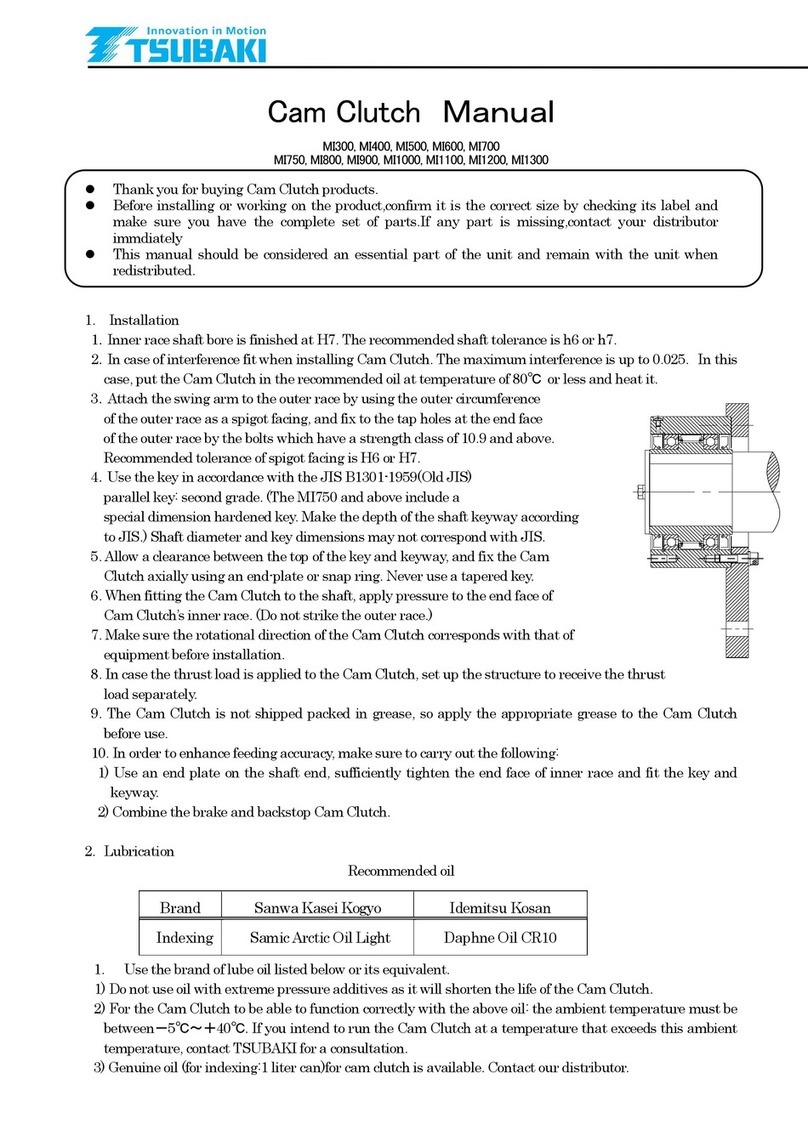

●When there is a need to replace a damaged (fractured) portion of a cable carrier or an accessory, always replace the

whole cable carrier or the accessory with a new product rather than replacing only the damaged or fractured portion.

●Immediately stop using the cable carrier or the accessories if they come into contact with a substance that can

cause embrittlement cracking (acid, strong alkali, battery fluid, etc.) and replace with a new cable carrier or

accessory.

●Observe the following when connecting, installing, removing, servicing, and inspecting the cable carrier or the

accessories.

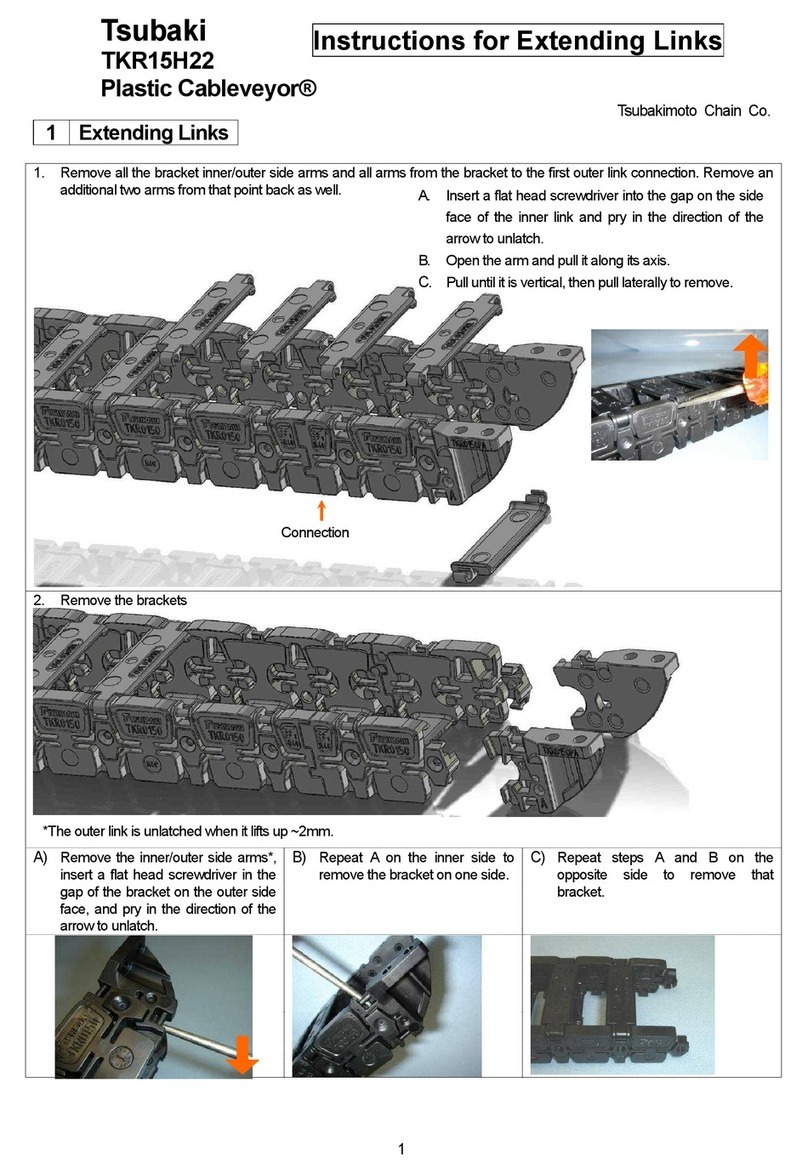

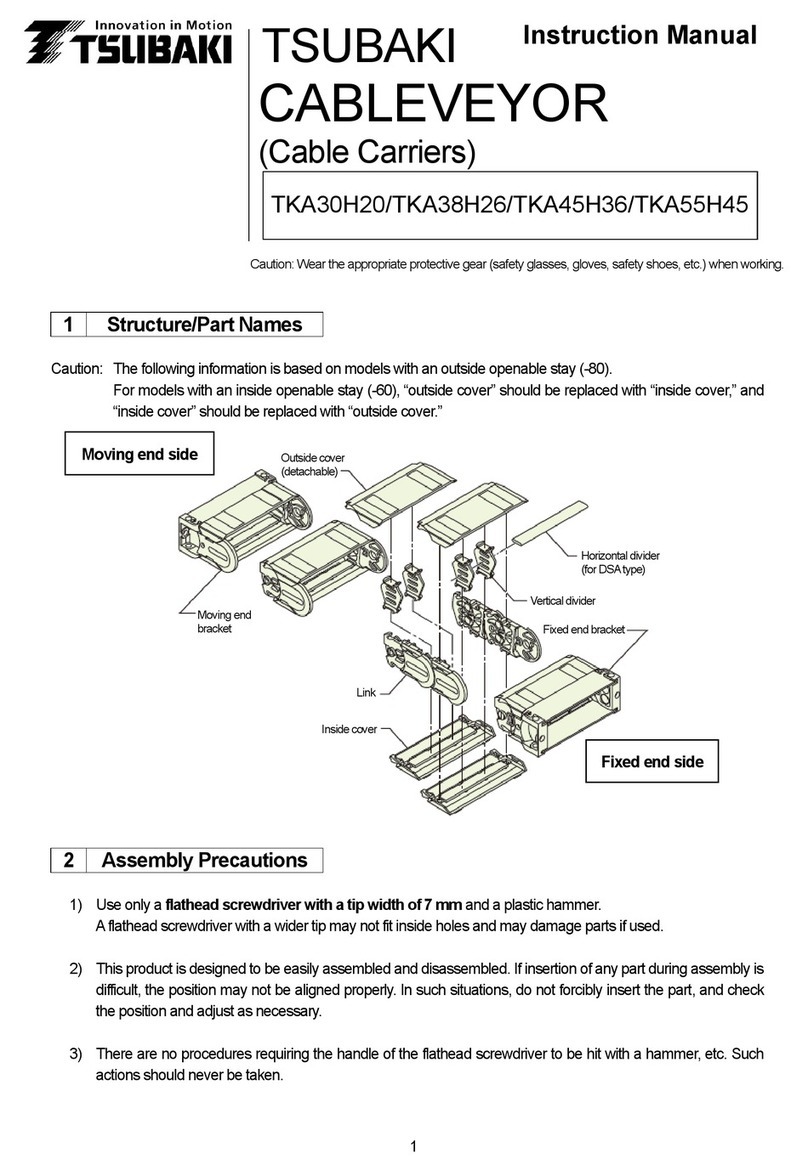

・Perform the procedure as specified in the instruction manual, catalog, or documentation specially provided to the

customer.

・Secure the cable carrier and the accessories so they do not move freely. The cable carrier may move on its own or

collapse under its own weight.

・Be careful not to pinch, crush, or entangle hands in the bending

section of the cable carrier.

・Wear suitable clothing and protective equipment for the work (such

as safety goggles, gloves and safety shoes).

・Always turn off the source power supply beforehand, and take care

not to accidentally operate switches.

・Only experienced personnel should handle the cable carrier.

●Carefully understand the construction and specifications of the cable carrier or the accessories before handling.

●Inspect the cable carrier or the accessories for damage during transport before installation.

●The cable carrier or the accessories should be periodically serviced and inspected.

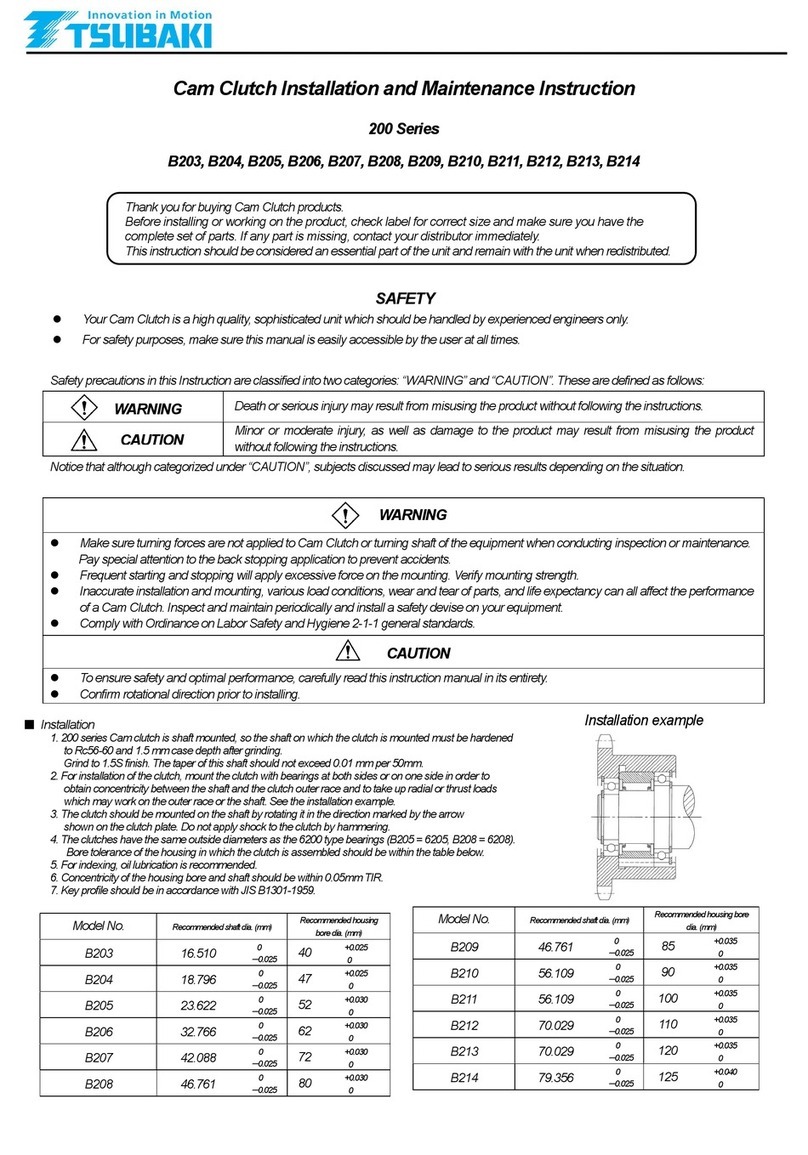

●Cable carrier capacity varies according to manufacturer. When selecting a chain based on a Tsubaki catalog always

use the corresponding Tsubaki product.

●Always ensure that the final customer receives the instruction manual.

・If you do not have the instruction manual, contact a Tsubaki representative with the product name, series name,

and chain/model number to receive the appropriate manual.

●The product information given in this catalog is mainly for selection purposes. Thoroughly read the instruction

manual before actually using the product, and use it properly.