SMC Networks LVD Series User manual

Other SMC Networks Industrial Equipment manuals

SMC Networks

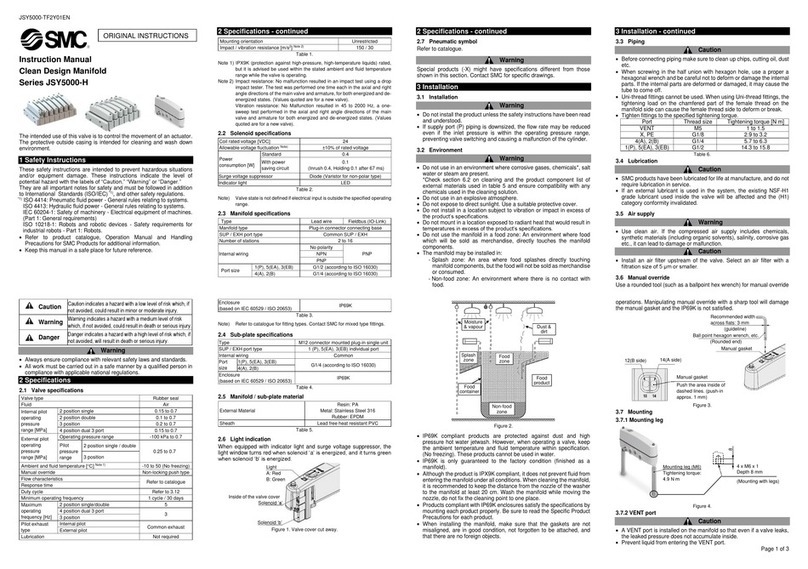

SMC Networks JSY5000-H Series User manual

SMC Networks

SMC Networks HF2A-ASG V Series User manual

SMC Networks

SMC Networks VQD1000-V Series User manual

SMC Networks

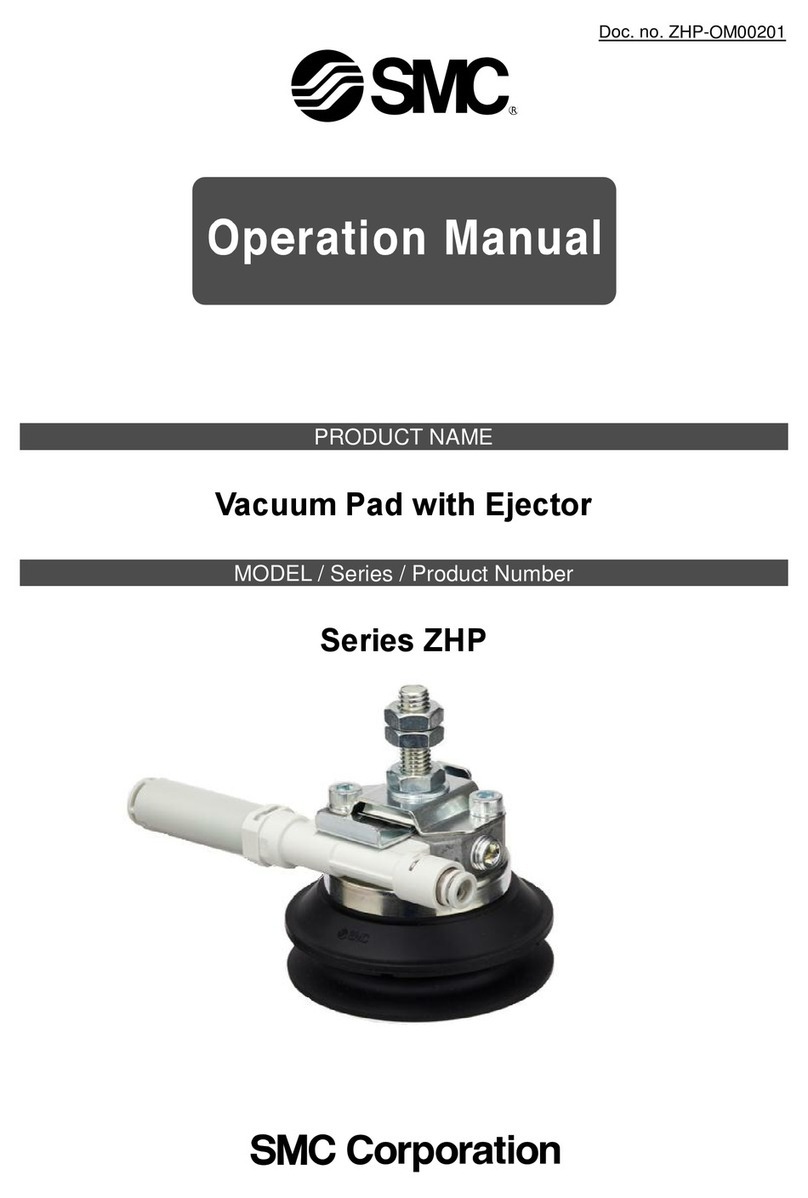

SMC Networks ZHP Series User manual

SMC Networks

SMC Networks MSZ Series User manual

SMC Networks

SMC Networks LFE series User manual

SMC Networks

SMC Networks MRQ Series Manual

SMC Networks

SMC Networks AFD20 D Series User manual

SMC Networks

SMC Networks ZSE20C Series User manual

SMC Networks

SMC Networks EX600-ED Series User manual

SMC Networks

SMC Networks LEHR Series User manual

SMC Networks

SMC Networks ZVB Series User manual

SMC Networks

SMC Networks ZXP7 41-X1 Series User manual

SMC Networks

SMC Networks EX12 SCS Series User manual

SMC Networks

SMC Networks MY2 Series User manual

SMC Networks

SMC Networks EX260-VEN1 User manual

SMC Networks

SMC Networks ZXP7 Series User manual

SMC Networks

SMC Networks MGZ Series User manual

SMC Networks

SMC Networks CP96N Series User manual

SMC Networks

SMC Networks MGJ Series User manual