HASHIMA HN-2880C User manual

検 針 機

检 针 机

NEEDLE DETECTOR

HN-2880C

HN-2790G

取 扱 い 説 明 書

使用说明书

INSTRUCTION MANUAL

この度はハシマ製品をご購入頂き、誠に有難うございます。

本機の性能を生かし、安全に使って頂くために、ご使用前にこの取扱い

説明書を必ずお読み下さい。

お読みになった後は、必ず保管して頂き、必要に応じてお読み下さい。

首先,非常感谢贵公司购买我司的产品。

为了更好地了解本机的性能并能

使用说明书

在阅读完后,请妥善保管; 以备必要时阅读使用。

Thank you very much for having bought our products.

Don’t fail to fulfill the matters that demand special attention mentioned

below so that you could put this machine to use for a long time with safety.

Don’t fail to read the user’s manual first of all before use.

Keep this user’s manual with care and read it as occasion demands.

-1-

Prior to use

.

Please read this manual carefully before using the HN-2880C・HN-2790G

to get the best results and stay safe follow maintenance procedures

and practice good safety.

Keep this user's manual treat it with care and read it as the occasion

demands.

HASHIMA CO. ,LTD.

BUSINESS OFFICE : 7-6, Ryoge Gifu City , Japan

Tel: 81-58-247-8400, 81-58-245-4501 Fax : 81-58-247-3366

SINGAPORE OFFICE : Tel: 65-62858131 Fax: 65-62858132

FACTORY/ KUNSHAN : Tel : 86-512-5777-1838 Fax : 86-512-5777-1848

Ensure the accessories

TestPiece

Spanner(24 ㎜)

PreCheck Bar

-2-

A

ttentions to be

p

aid for safet

y

Don’t fail to fulfill.

You should fulfill following explanations to prevent the user and the others from being hurt

and the properties from being damaged.

■ We classify and explain the degrees of peril and damage to be taken place when you

neglect the contents of the display and the machine erroneously.

DANGER This display tells you the contents that imagine “the imminence danger that

might result in death or a serious injury”.

WARNING

This display tells you the contents that imagine “the possibility of death or a

serious injury”.

CAUTION

This display tells you the contents that imagine “the possibility of resulting in

to be handicapped or material damages exclusively”.

■ We classify and explain the contents you should fulfill in accordance with the following

illustrations. (Following is an example of the illustrations.)

This illustration tells you the contents “that demand attention” you must pay.

This illustration tells you the contents of “prohibition” you should not do at all.

This illustration tells you the contents of “enforcement” you should execute without

fail.

DANGER

Don’t get the children to use alone and don’t use

where the infants can make contact with.

For fear of burn, electric shock

andinjury.

Never remodel at all.

For fear of fire and injury due

to unusual movement

Disassembly prohibited.

Don’t disassemble and repair

absolutely except the repair

technician.

Disassembly

prohibited.

For fear of fire and injury due to

unusual movement. (Contact the

dealers for repair in the case of

damage and troubles.)

Connect with the power source with

ratio consumption suitable

to the machine and don’t fail to

ground.

Unusual heat might

resultinfireorelectric

leak, when

you put machine to use along

with other apparatus.(Contact

the electric construction

work shops nearest by.)

Disconnect the power

source

(the plug and installed

breaker)

out of the origin.

For fear of burn as well as

electric shock and leak that

might result in fire.

WARNING

-3-

WARNING

Don’t fail to disconnect such

power source as the plug and the

setting breaker from the origin,

prior to the maintenance and

inspection.

For fear that the personnel

mightbe hurt due to electric

shock and unusual movement.

Install the machine in

accordance with the

designated way of installation.

For fear of overturning or

falling down resulting in

injury.

Pay sufficient attention to

the conveyors at the time

you inspect the needles.

For fear that some part of

your body and your clothes

would be caught in the machine,

resulting in injuries.

Don’t mount nor put things

on the main unit.

For fear of high temperature

resulting in burn and fire, and

there is a possibility of falling

down to be injured.

Install the machine on the

robust stand or onto the floor

horizontally.

For fear of overturning or

falling down resulting in in

jury.

Don’t put things easy to burn

around the machine.

For fear of causing fire and

so on.

CAUTION

■ Don’t install the machine to the site with high humidity.

(For fear of causing electric leaks.)

■ Don’t bend nor crush the power source cord.

(For fear of electric shock and shortage, resulting in fire.)

■ Don’t get the human being to go nearby except the operators.

PETITION

■ Don’t bring telephone cards, cash cards, wrist watches, cassette tapes, and so on close to

the machine for fear that it might be in trouble, as this is the machine designed to detect the

needles with the help of strong magnetism.

■ Understand well the operation of the switches and so on prior to the manipulation.

-4-

By putting “alarm label” onto every part of the machine, we rouse you to prevent the

user and others from being hurt and proprieties from being damaged.

Ensure the position and contents in regard to the “alarm label” prior to the use.

Never remove nor reform the “alarm label”.

Put a new one as early as possible, when the old “alarm label” is hard to read or

when it is coming off.

【1】

【3】

【2】

In addition, the repair technicians should pay attention to the fact that the “alarm

labels” are put even within the machine.

【3 】

【1 】

【2 】

【3 】

CONTENTS

PRIOR TO USE

ATTENTIONSTOBEPAIDFORSAFETY

INSTRUCTION MANUAL

FEATURES,USEFULNESS,

SPECIFICATIONS,PRECATIONS FOR USE,PRECATIONS FOR INSTALLATION

OPERATINGINSTRUCTIONS

IN REGARD TO NEEDLE DETECTIVE OPERATION

MATTERS THAT DEMAND SPECIAL ATTENTION AT THE TIME OF NEEDLE DETECTION

HOWTOADJUSTTHEBELTPOSITION

INSTRUCTION MANUAL

- 5 -

FEATURES :

○This machine is equipped with the LCD panel for checking the current detecting level.

○Position lamp identifies exact location of Fe materials so that you can find it easily.

○This machine has the “Key Switch” as standard equipment ,and this switch can lock various

settings not to be changed.

○When the device senses the material like the broken needle or setting pin, the buzzer sounds and

stops the belt conveyor .Then the defective products will be returned to your side, which increases

the efficiency.

○The device assures you of the setting of sensibility regulation, which can be finely adjusted by LCD

panel, in accordance with size and kind of the accessories of your garment, enabling a detection of

broken or forgotten needles mixed in the sewn products.

USEFULLNESS :

○The device is to be put to use to inspect Fe needles, broken needles and other Fe pieces remained

in such sewn products as clothes for gentleman, ladies and children, underwear , kimonos, jackets,

bedclothes and others.

- 6 -

SPECIFICATIONS

Model name HN-2880C HN-2790G

Detection method Magnetic induction type

Detection capacity Iron ball Fe0.8 mm or more (120 mm high)

Sensitivity adjustment Decimal (100 steps) and direct reading (6 steps)

Detection width 600mm

Detection height 120mm (standard)

Warning device Alarm and position detection

Belt speed 40~15m/min.

Power supply Single phase

Power consumption 150W

Airframe dimensions 2423(L) X 1040 (W) X 903(H)

Machine weight 374kg

Product guider Standard

Precautions for Use

1. Pass a sample of the needle and iron pieces to be detected before use through the machine and

check that the belt stops before starting work.

2. The material that can be detected is limited to steel.

Since stainless steel needles and marking pins cannot be detected, be sure to use iron.

3.For metal sewing accessories such as buttons, slide fasteners, and lock hocks, please designate

those labeled as "Needle detector-compliant" at the stage of design and specifications.

4. The metal objects worn by the operator must be removed because the machine reacts with the

moving metal objects.

Precautions for Installation

1. Install the machine in a horizontal position without vibration.

Secure the body horizontally with the four adjuster bolts on the main unit.

(If it’s not level, the conveyor belt might warp.)

3. Do not install the machine in the vicinity of a steel workbench or shelf.

4. Do not install the machine near the other machine that generates the magnetic field.

Machines using electromagnetic clutch motors, sewing machines, cutting machines,

packing machines, air conditioners, or inverters may cause electric or magnetic disturbance and

cause malfunction.

5. Keep away from large moving metal bodies such as railways and automobiles.

6. Separate as far as possible from the reinforcement or steel frame of the building, and

change the direction of the main body so that it can be installed in a place where no malfunction

occurs.

7. The needle detector generates magnetism.

Please note that the contents may change when magnetic cards such as credit cards are brought

closer.

8. Install the machine in a location within ambient temperature of 10°C to 40°C (non-condensing).

9. A needle detector may not be able to perform properly in a place where the installation

environment is bad.

Select the appropriate location by performing an environmental level test.

- 7 -

Operating instructions

Set the date and time first.

1.Turn on the power breaker.

The system on the LCD panel starts and the HOME screen opens.

2.Year, month, day, hour, minute, and second are displayed at the top of the screen.

3.At least , year, month, day, hour, and minute should be adjusted to local time as precisely as

possible.

4.If not, touch MENU key.

HOME SCREEN Date MENU Key

Power breaker

LCD Panel

Start/Stop Switch

- 8 -

5.Touch "Date and time setting" on the MAIN screen.

MAIN SCREEN

6.Touch the number to display the numeric keyboard.

Enter the correct value using the numeric keypad and press ENT to change the value.

7.Touch Back to return to the MENU screen.

8.Touch Back to return to the HOME screen.

*The machine operates normally without setting the date and time.

If the LAN is used to connect and expand the machine to other equipment in the future, the data

may become inconsistent if the time between the devices does not match.

Date and time setting

- 9 -

How to use

1.Turn on the power breaker.

The system on the LCD panel starts and the HOME screen is displayed.

Explanation of the HOME screen

①Start/Stop button・・ Start and stop the conveyor belt.

②MENU button・・・・Moves to the menu screen.

③Sensitivity display・・Indication of Sensitivity level.

④Position lamp・・・・ The lamp at the position where foreign matter such as iron strips

is detected lights.

⑤Counter display・・・ Indicates the counted value of the total number, defective parts,

defective parts, and round-trip number.

⑥Counter reset・・・・ The count value to 0.

⑦Belt speed・・・・・・ Indicates the speed of the conveyor belt.

Adjusting the belt speed (40 m/min.-15 m/min.)

Touchthenumericvaluetodisplaythenumerickeyboard.

EnteravalueandtouchtheENTkey.

The speed changes.

⑧Mode display・・・・ Setting Mode.

P:Productionmode T:Testcardmode.

*HN-2790G is in test card mode only.

⑨Return position・・・ Belt return distance is set. (3-10 stage switching)

Touch the button to display the numeric keyboard.

Enter the correct value using the numeric keypad and press ENT

to change the value.

⑧

①

②

③

④

⑤ ⑥ ⑨

⑦

- 10 -

Main menu

・M/C setting: Sets various modes.

・Date: Sets year, month, day, hour, minute, and second.

・History: Displays the history.

・Counter: Sets the counter.

・Sensitivity: Set the sensitivity.

・Administration: Register the administrator.

・Printer: Prints data.

・Language: Sets Japanese, Chinese, and English.

・Check: Used for maintenance.

・Information: Displays the current machine information.

・HOME: Returns to the HOME screen.

- 11 -

1. Mode setting

The test card mode or the production mode can be selected.

* Set normally in production mode.

The photoelectric sensor recognizes the product passing through the belt in the production mode.

When the inspecting sensor detects a piece of iron, the belt stops and returns the product to the

front.

In the test card mode, regardless of the photoelectric sensor, the inspecting sensor detects a piece

of iron, etc. Then, the belt stops and returns the product to the front.

Select sencer:F.sensor R.sensor

Sensitivity Set : Selection of direct reading (6-step) and decimal method (100-step)

☆When the photoelectric sensor does not recognize a thin product (1 cm or less in

thickness), switch to the test card mode.

☆When a test card or accessory unit is placed directly on the belt for detection test,

or when carrying out the inspection of thinner products (fabrics or interlining with a

thickness of 1 cm or less) Be sure to switch to test card mode.

- 12 -

Adjustment of the belt speed (40 m/min.-15 m/min.)

Touch the numeric value to display the numeric keyboard.

Enter a value and touch the ENT key.

The speed changes.

2.Date

Set the year, month, day, hour, minute, and second.

Touch the numeric value to display the numeric keyboard.

Enter the correct value and touch the ENT key.

- 13 -

3.History

NO. : 0 is the latest information.

Event : shows either START, STOP, or DETECT.

START: Press the Start button to display the time at which the meter reading starts.

STOP: Press the Start button to display the time at which the meter reading stops

DETECT - displays the time when DETECT - detection is performed and stopped.

The last number represents the coil number.

F / R : This property indicates the sensitivity of the meter reading.

Operator: When the operator password setting is turned on in the management

screen, the operator name is displayed in the operator field to determine

which operator has changed the sensitivity.

Time: Indicates the date of the meter reading operation.

Toward: Moves to the previous page.

Backward: Go to the next page.

History list: You can download to a PC via USB.

ByinsertingaUSBintotheUSBport

Touch the History list button.

Print out: The optional printer can be used to print the history.

Clear: Deleterecordeddata.

- 14 -

4.Counter

Indication of defective products, defective products, and total number.

Set the number of loops.

Printing counter quantity Photoelectric tube setting

Loop Count Setting allows the User to set the number of times to restart automatically after

detection.

You can set the number of times between 1 and 999 (maximum).

Photoelectric tube Set the minimum loading interval between the product and the product.

※Distance for sensitivity

SENSITIVITY Distance

10ms 4.5mm

30ms 9.0mm

50ms 13.5mm

70ms 18.0mm

90ms 22.5mm

110ms 27.0mm

130ms 31.5mm

150ms 36.0mm

170ms 40.5mm

190ms 49.5mm

210ms 54.0mm

…

…

5070ms 2250mm

*Calculating formula

SENSITIVITY ( ms ) ×0.6mm

= Distance

- 15 -

5.Sensitivity

Displays either the straight-reading or decimal method selected in the device setting.

Note: If you set the password, you cannot change the sensitivity without entering the password.

- 16 -

6.Pass word change

password entry input: You can set the password for one administrator and three workers on the

machine.

Initial password administrator A 88888 Always ON state

operatorB 111111 OFFstatus

operator C 222222 OFF status

operator D 333333 OFF status

The administrator can freely cancel and change the password of himself and three workers.

The operator cannot cancel or change the password.

When the operator's password is turned on (checked), the password is enabled.

When you set the password, the password is required when the following functions are used.

・Device settings

・Date

・Sensitivity change

・Deleting a history

・Inspection

・Information

For HN-2790G key button is displayed on the management screen.

When thekey is turned on, the password is required at restart when the detection reaction stops.

- 17 -

7.Printer

You can print the following data

《Counter printing》 《Printing History》

《Printing auto-pre-checker results》 《 Printing of environmental noise measurement results》

8.Language

You can switch the language to Japanese, English, or Chinese.

This manual suits for next models

1

Table of contents

Other HASHIMA Security Sensor manuals

Popular Security Sensor manuals by other brands

Ludlum Measurements

Ludlum Measurements 44-7 manual

AVS Electronics

AVS Electronics SPECTRUM PA WALL manual

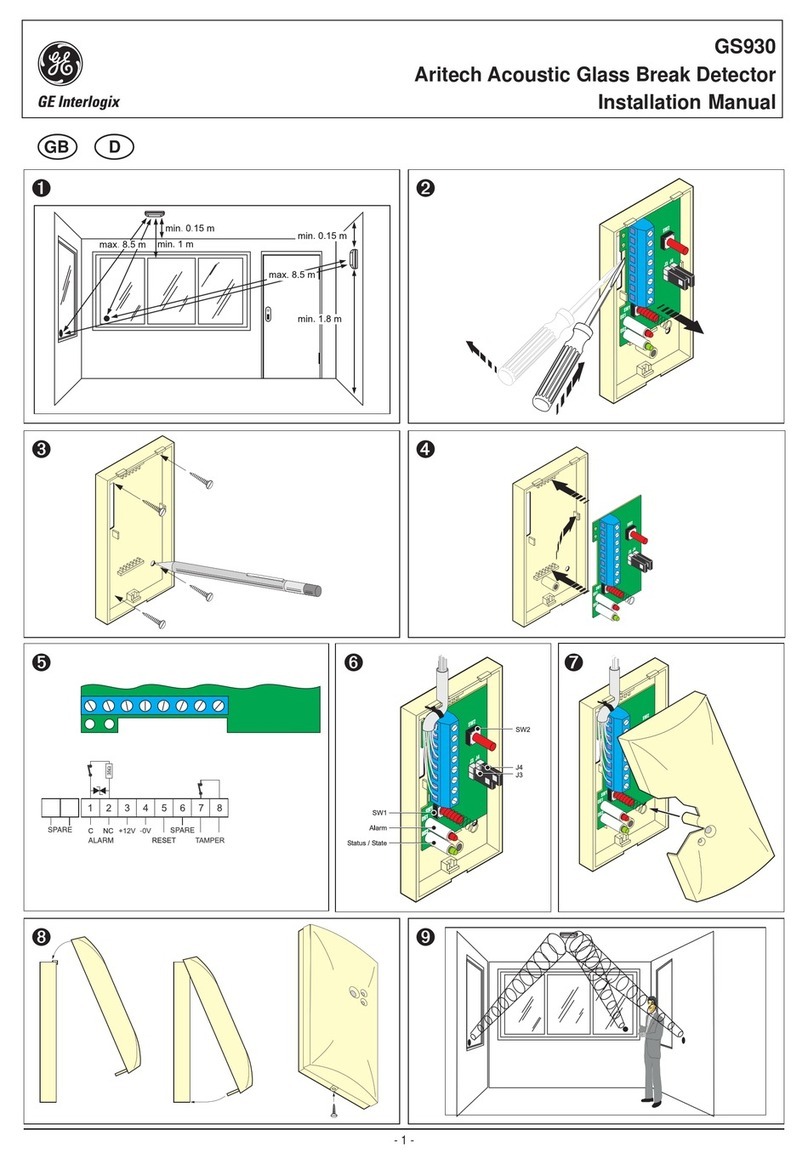

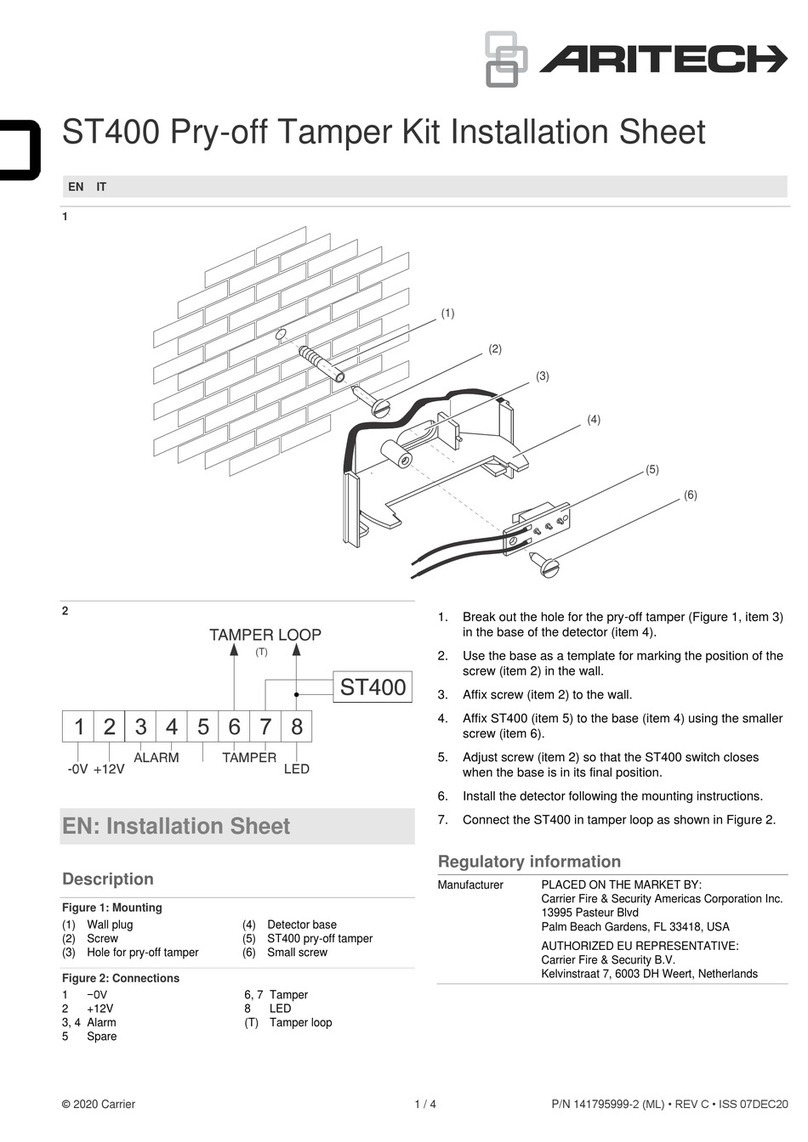

Aritech

Aritech ST400 Installation sheet

Agilent Technologies

Agilent Technologies NPD installation guide

Honeywell

Honeywell Ex-Or MR1500P Installation and commissioning instructions

HumanTechnik

HumanTechnik lisa user manual