© 2023 Hatco Corporation2

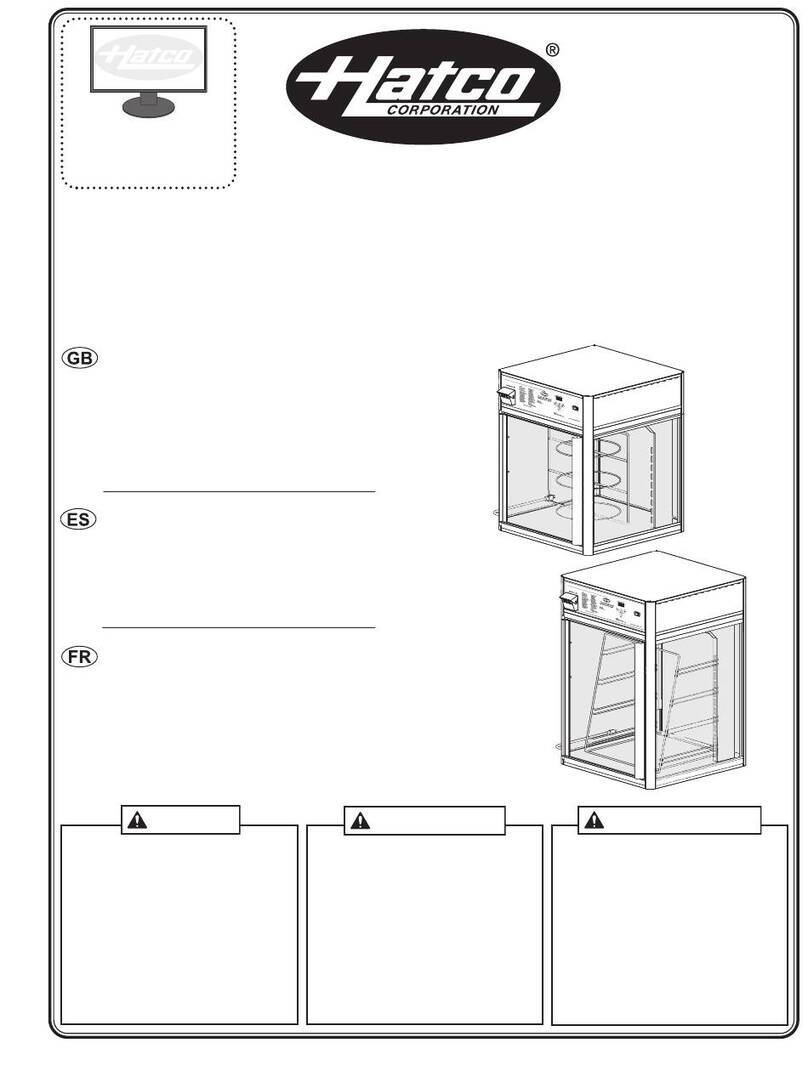

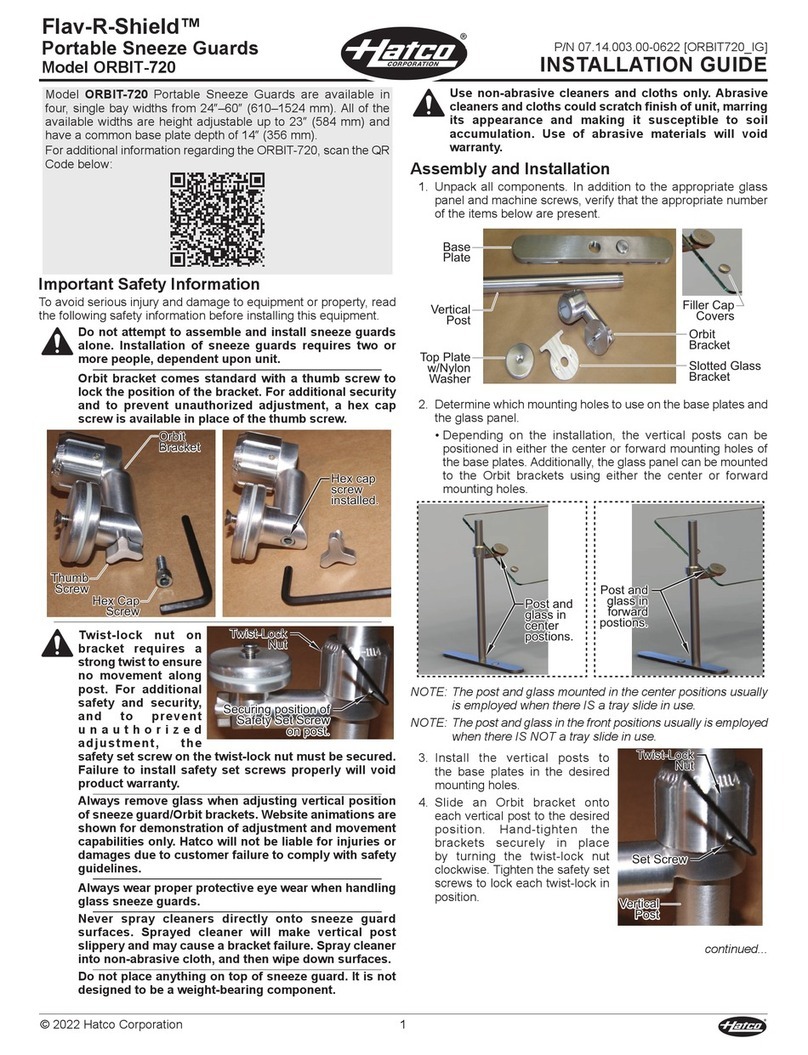

Nylon

Washer

Orbit Bracket

Top Plate

Machine

Screw

Thumb Screw

Glass Panel

installed onto

post using

Orbit bracket.

Lip

3. Adjust the height of the glass face panel, if necessary. NOTICE:

Two people are required for this step.

a. Simultaneously loosen the twist-lock nut counterclockwise

on each face panel Orbit bracket, move the panel to the

desired height, and re-tighten the twist-lock nuts by turning

clockwise.

b. Tighten the safety set screw on each twist-lock nut to secure

the Orbit brackets in position.

4. Adjust the angle of the glass face panel, if necessary. NOTICE:

Two people are required for this step.

• The angle of the glass panel can be adjusted in 15°

increments.

• Simultaneously loosen the thumb screw/hex cap screw on

each Orbit bracket, carefully rotate the glass panel to the

desired position, and re-tighten the thumb screws/hex cap

screws securely.

Cleaning/Maintenance

Clean the unit daily using non-abrasive cloths and cleaners.

• Always spray/apply cleaner to the cloth, then wipe down the

sneeze guard. Do not spray cleaner directly onto the sneeze

guard.

• The glass panel can be cleaned using a standard glass cleaner.

Options and Accessories

End Panels

End panels with a depth of 18″ (457 mm) are available for all

ORBIT360 portable sneeze guards.

LED Light Bar

An LED light bar is available as a factory-installed option for certain

sizes and can be configured with a cord and plug or a battery pack.

7. Install the Orbit brackets onto each post assembly.

Set Screw

• Hand-tighten each Orbit bracket in

place by turning the twist-lock nut

clockwise. Do not tighten the safety

set screw on the twist-lock until the

brackets are in their final position.

• If optional end panels are present,

install the Orbit brackets that came

with the end panels underneath the

face panel Orbit brackets on the post

assemblies.

8. IMPORTANT! Refer to the “Securing the Glass” procedure on

this sheet before beginning installation of any glass panels.

9. Install the glass face panel(s). Refer to the “Securing the Glass”

section.

10. Install each glass end panel, if equipped. Refer to the “Securing

the Glass” section.

11. For NSF compliance, apply NSF-approved silicone sealant to

the screw heads of all set screws and nylon set screws.

NOTE: For NSF compliance, the bottom edge of all end panels

cannot be positioned higher than 1-1/2″ (38 mm) above the

installation surface.

Securing the Glass

Glass face panels and end panels are attached to the post

assemblies using adjustable Orbit brackets. Use the following

procedure to install the glass panels. CAUTION! Always wear

proper protective eye wear when handling glass.

1. Prepare to install the glass face panel(s).

• There are two mounting holes provided on each side of a

glass face panel. Choose the hole position that will work for

the installation. Install the provided filler cap assembly in the

unused holes using a coin to hand-tighten.

Filler Cap

Cover

Filler Cap

Cover

Use coin

here.

Underside

of glass

panel.

Filler Cap

Assembly

installed.

Top side

of glass

panel.

2. Install the glass panels. To install a glass panel:

a. Loosen the thumb screw/hex cap screw on each Orbit

bracket, and adjust the brackets so that the glass panel will

be in the horizontal position during installation.

b. Install a nylon washer on top of each Orbit bracket.

NOTE: Always position nylon washers with the raised lip facing the

glass.

c. Position the glass panel on top of the nylon washers.

d. Place a nylon washer followed by a top plate on top of the

glass panel aligned with each Orbit bracket, and secure in

position using an included machine screw. Tighten the screw

until it holds the glass securely—do not over-tighten.

HATCO CORPORATION

P.O. Box 340500

Milwaukee, WI 53234-0500 U.S.A.

414-671-6350

www.hatcocorp.com

Custom Units

Scan this QR code or click the link

below to access information regarding

custom units including sizes, glass,

hardware, and lighting.

www.hatcosneezeguards.com