Hathorn M7 User manual

1

OPERATOR’S MANUAL FOR

M7 CAMERA SYSTEM

For Safe and Effective Operation:

Before operation of your system, it is advised that

this manual be read carefully.

2

CONTENTS

PAGE 3 LIMITED WARRANTY

PAGE 4 LIMITATION OF WARRANTY / SER-

VICE / FREIGHT

PAGE 5 NON-WARRANTY CHARGES / PROD-

UCT FEATURES

PAGE 6 USER INSTRUCTIONS

PAGE 7-9 INSPECTION PROCEDURE

PAGE 10-11 FEATURE IDENTIFICATION

PAGE 12-15 USB RECORDING & PLAYBACK

PAGE 16 TROUBLESHOOTING

PAGE 17 MAINTENANCE

PAGE 18 USA REPAIR FACILITIES

PAGE 19 CANADA REPAIR FACILITIES

PAGE 20 WARRANTY REGISTRATION

3

LIMITED WARRANTY

This Limited Warranty provides one full year of cover-

age under our manufacturer’s standard new product

warranty. Hathorn warrants to the original purchaser of

the product herein registered that the product shall

function properly for a period of one year from the

original date of purchase under normal and proper us-

age. This one-year Limited Warranty covers malfunc-

tions resulting from defects in materials or workman-

ship only. If the product fails to function properly under

normal and proper usage due to defects in materials or

workmanship during the period of this Limited Warran-

ty, the manufacturer will repair, adjust or replace defec-

tive parts as it deems appropriate.

This Limited Warranty is only available to the original

purchaser; it is not transferable under any circumstanc-

es.

The manufacturer’s responsibility under this Limited

Warranty is limited to the repair, adjustment or replace-

ment of defective parts as determined by Hathorn in its

sole discretion. Routine cleaning and normal cosmetic

wear and tear are not covered by this Limited Warranty.

4

LIMITATION OF LIABILITY

By your acceptance of this limited warranty, you agree that

Hathorn shall have no liability to you for any damages re-

sulting from delay or loss of use of the product in service or

repair. Hathorn shall have no liability for general, special,

incidental or consequential damages arising out of breach of

this limited warranty. Hathorn assumes no responsibility for

warranties either expressed or implied beyond that which is

contained herein.

SERVICE

If the product requires service, please contact the Hathorn

service centre nearest to you or one of our authorized dis-

tributors. Service locations are listed on page 18 of this doc-

ument. Hathorn is not responsible for damages or loss in-

curred in connection with mailing and/or transportation of

product.

FREIGHT

After completing your “Return Authorization Sheet,” ship

the item(s) PREPAID and INSURED to the appropriate ser-

vice center. After the repair, the items(s) will be returned via

the same method. (i.e. shipped in via UPS, returned via

UPS. Shipped via air, returned via air.)

RETURN FREIGHT

Warranty: Pre-Paid as above

Non-Warranty: Freight Collect

MAINTENANCE

Inspection Camera - After every use, the camera should be

cleaned and checked for possible damage. External scuffing

of the camera case is normal and should be of no concern.

The camera view port is made of sapphire and should be

cleaned with a soft, damp cloth. Grease, dirt or scratches

will affect the quality of the video and if the lens is badly

5

NON-WARRANTY CHARGES

Repairs centers will charge direct for non-warranty repairs

and may require payment prior to repair. Should you have

any further questions regarding service or sales, please con-

tact Hathorn at: 1-905-604-7040

PRODUCT FEATURES

With the M7 reel you can complete pipe inspections with-

out the use of a traditional monitor and with the ease of a

system that runs on external 18V Milwaukee compatible

batteries (not included) or the 12V AC/DC adapter.

Features include:

• NO cords and NO heavy monitor cases

• Powerful SONDE transmitter that works with any

512Hz locator

• Auto-iris camera element that automatically adjusts pic-

ture lighting, no LED light dimming required

• Recording of video files to USB stick

• If you opted for the Wi-Fi option, then you can easily

transfer wireless video from reel to any mobile device

or tablet. The system connects up to four Wi-Fi ena-

bled devices at once.

• 6” wheels for easy transport of system

6

USER INSTRUCTIONS

Setting Up the System for Use

Connect DC power plug to the jack on the back of the con-

trol box, then plug the AC power plug into the outlet. Press

the power button on the monitor. At this point you should

have lights on the camera and a picture on the monitor. You

are now ready to perform the inspection procedure.

Alternatively, you may wish to use 18V Milwaukee com-

patible batteries for ultimate portability. Standard 3.0Ah

batteries should allow the user to run for 4-6 hours in a sin-

gle charge. Batteries are sold separately.

Locating Sonde

Push the “Counter/Sonde” button to turn the sonde on or

off. A symbol will appear next to the footage counter on

screen when the sonde is on. Use any brand of 512hz loca-

tor to find the sonde when underground. Sondes are locata-

ble up to 15ft. dependent upon thickness of concrete and

presence of steel/cast iron pipe.

Footage Counter

Push the “Counter/Sonde” button to move the counter

around the screen or hold it for 3 seconds and the counter

will flash, let it go and the count will reset.

Camera Lights

Camera lights can be controlled using the light up/down

buttons on the front of the monitor.

7

INSPECTION PROCEDURE

Skids or sleeves should ALWAYS be used to protect the

camera head. Depending on the size of the pipe you are

inspecting, you may need to use a skid, so the camera is

centered or off the floor of the line. Care should be taken so

the skids do not snag in the line.

Under normal operating situations, the camera is used with

a smaller protective sleeve in lines under 4” in diameter or

a larger grooved skid in 4” lines and larger.

1. Slowly push the camera into the pipe and negotiate the

camera into position to feed down the pipe making

sure the flex neck does not kink or double back on it-

self.

2. Push the camera slowly and carefully during the in-

spection taking note of the pipe condition for possible

hazards that may entangle or damage the camera on

entry or retrieval.

3. When negotiating a corner, care should be taken not to

butt the nose of the camera against the sidewall with

any force. It would be better to let the camera “work”

its way around the corner. If resistance is encountered

when turning the corner and there are no visible signs

of blockage, turning the push rod or pulling the cam-

era back and forth sometimes helps

4. Should resistance become extreme, or the camera get

entangled or stuck, slowly push it back and forth to

free it. Sometimes turning the push rod may also help.

If the camera is visible, you may be able to free it with

your hand or some other means.

5. Upon completion of the inspection and retrieval of the

camera, it may be necessary to ‘manipulate’ the cam-

era around the initial bend (clean out) in the pipe with

a pole or other device if required.

8

6. NEVER use the camera to unclog a drain or clear de-

bris in the pipe. Doing so can cause damage to the

camera head or lens.

7. NEVER force the camera down a pipe as this may

cause a kinked cable which will require expensive re-

pairs.

8. NEVER use a pressure washer to clean any part of the

system. High pressure water can cause degradation of

the electronic parts causing damage.

9. NEVER unspool all of the rod from a reel. Always

leave a few turns of rod on the reel to aid with re-

spooling.

9

LOCATING THE 512 Hz SONDE

Insert the sonde in the drain and locate it while it is still just

in view at the drain or duct entrance. Hold the locator verti-

cal directly over the sonde with the antenna in line with the

sonde. Adjust the locator sensitivity so the bar graph reads

between 60% and 80%. Push the sonde along the pipe to

the desired area.

1. Approach the peak of the signal working perpendicular

to the pipe. Move the locator backwards and forwards

and stop when the bar graph indicates a Peak.

2. Push the camera 4-6 ft. further, pinpoint, and mark the

position. Repeat this pinpoint procedure at similar in-

tervals along the line of the drain or duct until the sur-

vey is completed.

3. Most locators will automatically display the depth of a

located sonde providing the locator is correctly orient-

10

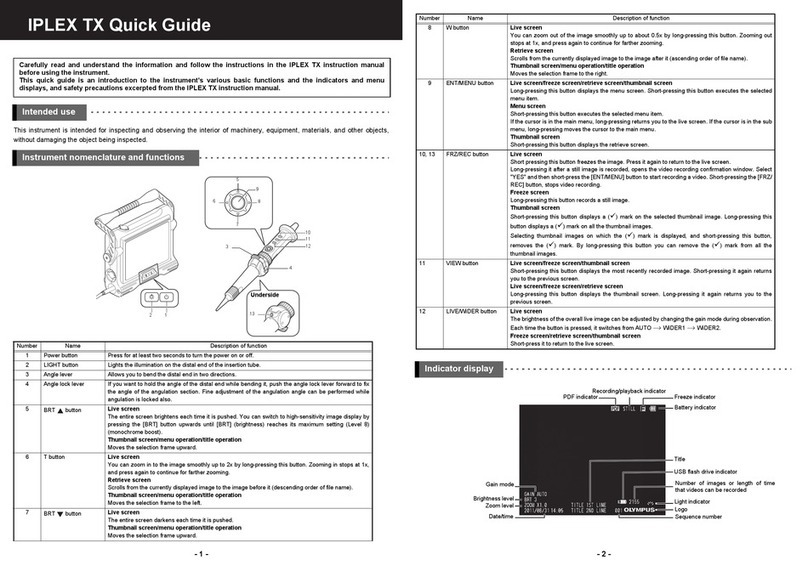

FEATURE IDENTIFICATION

18V Baery

Cradle and

AC/DC

7.4” Monitor

6” Wheels

LED Lights

Sapphire Camera Lens

Plasc Skid/Sleeve

11

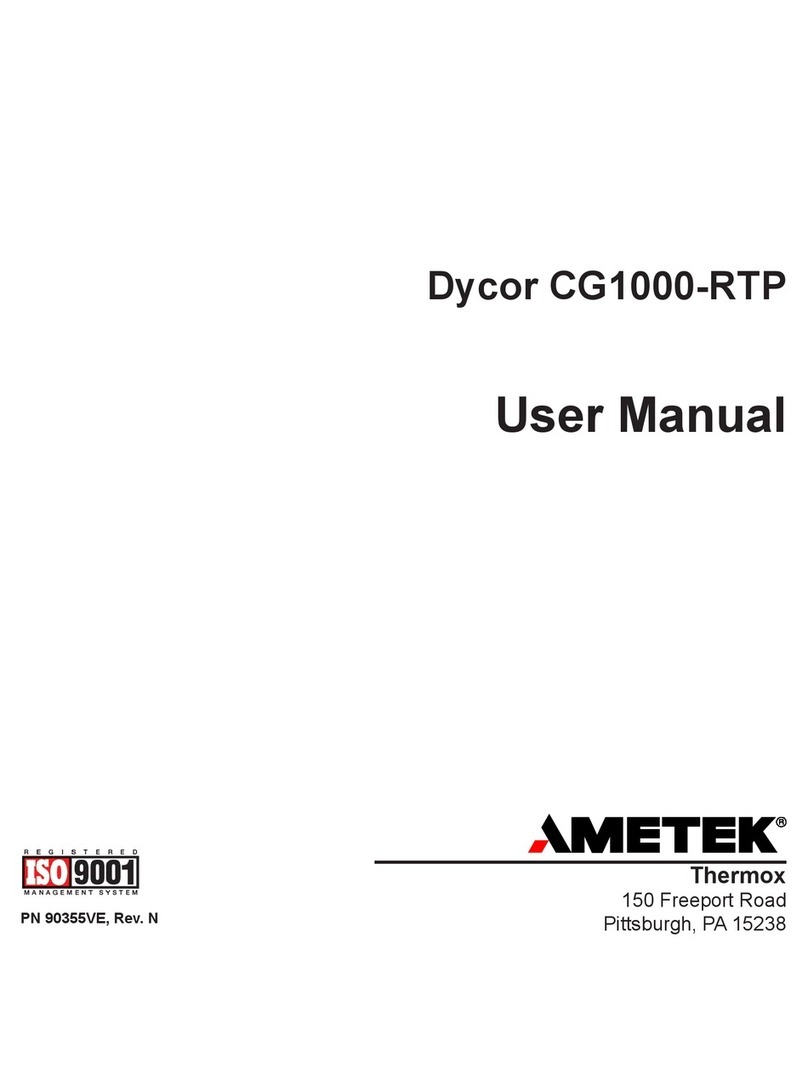

7.4” LCD

Screen

Recording

Board

ON/OFF

System

ON/OFF

Home

Menu

Enter

Menu Navigaon

Play, Stop recording and Pause Video Files

Recording Board Power ON & One Touch

Recording

Text Writer

and Navigator Camera

Lights

Sonde

ON/OFF

& Coun-

ter

Baery

Indicator: On-

ly applicable

on internal

baery units

12

SETTING UP YOUR MONITOR

1. Press Recording Board Power button and wait for re-

cording system to boot up (about 15 seconds).

2. Press the Home button and navigate over to the

“Setup” screen. Press enter.

3. From this screen the user has the ability to change the

brightness, contrast, hue, saturation and noise reduc-

tion on the screen and video playback.

4. The user can also change the input of the camera from

NTSC to PAL to other resolutions. It is recommended

that users do not change this setting.

SETTING UP THE RECORDING QUALITY

1. Press the Home button and navigate over to the

“Setup” screen. Press enter.

2. Navigate to the right again until you reach the “REC”

tab. From here the user can adjust the recording quali-

ty and the recording device.

3. The recording quality is set as HQ (High Quality) at

the factory but the user has a choice of HQ, SP, LP, EP

and SLP in order of reducing quality but with smaller

file sizes.

4. The M7 system always records in MPEG4 format.

5. Do not change the recording device from USB to

HDD as an HDD is not installed. If this is changed no

recording can happen until changed back to USB.

13

RECORDING TO A USB STICK

1. Press Recording Board Power button and wait for re-

cording system to boot up (about 15 seconds). It’s red

light should now be on.

2. Insert the USB stick into the USB jack and wait for

the system to recognize its presence. This may take 5

seconds. A notification in the top left of the LCD will

show when the USB stick is recognized.

3. When the USB stick is recognized, press the recording

button on the control pad. This will power up the re-

cording module within the system. When it is ready

the system will say “Recorder Ready”.

4. Press the red recorder button once. The system is now

recording the video file to the USB stick.

5. To stop the video recording simply press the stop re-

cording button.

Note: Video files are always stored in MPEG4 format for

optimal quality and file size. The longer a recording the

larger the video size.

Note: If the system does not record when USB inserted and

recording button is pressed then remove USB stick and re-

peat steps 1-4.

14

PLAYING BACK VIDEO FILES

1. Press the home button and then navigate left or right

to “Browse USB Stick” and press the Enter button.

2. Press enter again at the USB icon. Note: this system

does not come with an HDD.

3. Press enter again on the file and then enter again on

the file “REC”. Scroll for the file you recorded.

4. Each video file is named with the date of the recording

and a unique number. To play a file back press “Play”

button.

DELETING/RENAMING FILES

1. Highlight the file you wish to change and press the

Menu button.

2. This will give you the option to rename or delete the

file in questions or press enter to return to the previous

menu.

RETURNING TO A HIGHER MENU

1. From the file list, highlight the symbol “/…/” and

press enter.

2. This will take you to a higher file menu on your USB

stick.

15

OTHER SYSTEM OPTIONS

1. Press the home buon and then navigate le or right to

“Setup” and press the Enter buon.

2. Navigate to the “System” tab which will display system op-

ons. Including the opportunity to ash the system with an

update, change the me, date and me zone, format the

HDD (not applicable to the M7), and reset the system to the

factory default sengs.

3. Seng the me and date is the most important feature for

the average user. To access this area press “Enter” buon

when “Time” tab is highlighted.

4. Tab down to “Time Zone” to set the me zone applicable to

the market you are located.

5. Tab down to “Manual” to change the current year, month,

day and me. Press enter to conrm the me and date.

Then press the home buon to return to the main menu.

6. All systems are set to EST on the current date when they

leave the factory.

Note: Seng the date and me are important as these will aect

the naming convenon of the les stored to your USB sck.

16

Contact Service Department at 1-905-

604-7040 or [email protected]

If a problem not shown on this chart is found please

contact a Hathorn service center.

TROUBLESHOOTING

17

MAINTENANCE

Inspection Camera - After every use, the camera

should be cleaned and checked for possible damage.

External scuffing of the camera case is normal and

should be of no concern. The camera view port is made

of sapphire and should be cleaned with a soft, damp

cloth. Grease, dirt or scratches will affect the quality of

the video and if the lens is badly scratched it should be

replaced.

LED Light Replacement - The camera heads use LED

lighting and cannot be replaced by the operator. These

lights use very little power and unless physically dam-

aged or extreme voltage is applied to them, should last

indefinitely. If replacement is necessary, the camera

should be returned to the factory.

Reel and Cable Assembly Maintenance - The reel

and cable assembly should be kept clean from dirt,

slime, grit, etc. When winding the cable back onto the

reel after an inspection, it is good practice to use a

clean cloth to wipe off any debris.

WARNING

NEVER USE A POWER WASHER TO CLEAN

THIS EQUIPMENT. PRESSURIZED WATER

MAY GET INTO UNSEALED AREAS SUCH

AS THE REEL HUB ASSEMBLY AND SLIP

RING HOUSING CAUSING DAMAGE AND

VOIDING WARRANTY.

18

REPAIR FACILITIES - USA

Repairs, warranty or otherwise, returned to Hathorn

must be submitted with a “Return Maintenance Au-

thorization.” For “RMAs” please contact:

Reliable Drain Camera Repairs Ltd.

Address: 739 North Wilson Road, Columbus, OH, 43204

Phone: 1-855-863-9226 FAX: 1-905-604-3400

Email: service@sewercamerarepairs.com

Website: www.sewercamerarepairs.com

Kaiser Premier USA – Mobile Repairs South West

Address: 6108 Wild Fox Court, Elk Grove, CA 95757

Phone: 1-916-995-2743

Email: eric.montgomery@kaiserpremier.com

Website: www.kaiserpremier.com

Utility Equipment Technology Ltd.

Address: 382 Stevens Rd., Rockwall, TX 75032

Phone: 1-972-771-8958 FAX: 1-972-772-8195

Email: utilityequipment@gmail.com

Website: www.utilityequipmenttechnology.com

Dynamic Repairs

Address: 40 Arnot St., Unit 20, Lodi, NJ 07644

Phone: 1-973-478-0893 FAX: 1-973-478-0895

Email: dynamiccablerepairs@yahoo.com

Website: www.dynamicrepairs.net

Visual Imaging Resources

Address: 12600 Newburgh Rd, Livonia, MI 48150

Phone: 734-744-5557

email: antoine@visualimagingresources.com

Website: www.visualimagingresources.com

19

AZ Locators

Address: 13041 N 35th Ave c6, Phoenix, AZ 85029

Phone: 602-375-5337

email: info@azlocators.com

Website: www.azlocators.com

REPAIR FACILITIES - CANADA

Hathorn Corporation - Eastern Canada

Address: 255 Shields Court “C”, Markham, ON L3R 8V2

Phone: 1-905-604-7040 FAX: 1-905-604-3400

Email: info@hathorncorp.com

Website: www.hathorncorp.com

The Drain Camera Shop – Western Canada

Address: 780 Kilmalu Road, Mill Bay, BC V0R 2P1

Phone: 1-888-913-3419

Email: info@thedraincamerashop.com

Website: www.thedraincamerashop.com

20

Hathorn Canada

255 Shields Court, Unit C

Markham, Ontario, Canada

L3R 8V2

+1 (866) HATHORN

Hathorn USA

739 North Wilson Road

Columbus, Ohio, USA

43204

+1 (855) 863-9226

This manual suits for next models

1

Table of contents

Other Hathorn Analytical Instrument manuals