1. Application and functionality

of HEL11C

The controller is designed for gate drives with 230Vac

motors. A perfect choice for continuous operation, the

controller can be used in community car parks, private

homes and corporate compounds. Applied Microchip

rolling code technology prevents from not authorized

entrance. The controller cooperates with monostable

pushbutton with Step-By-Step functionality,

(OPEN-STOP-CLOSE-STOP) The control unit perform

following operations: Autoclose, Open only and Automatic

wicket The are two available main versions. First one

with encoder input, and second one without it.

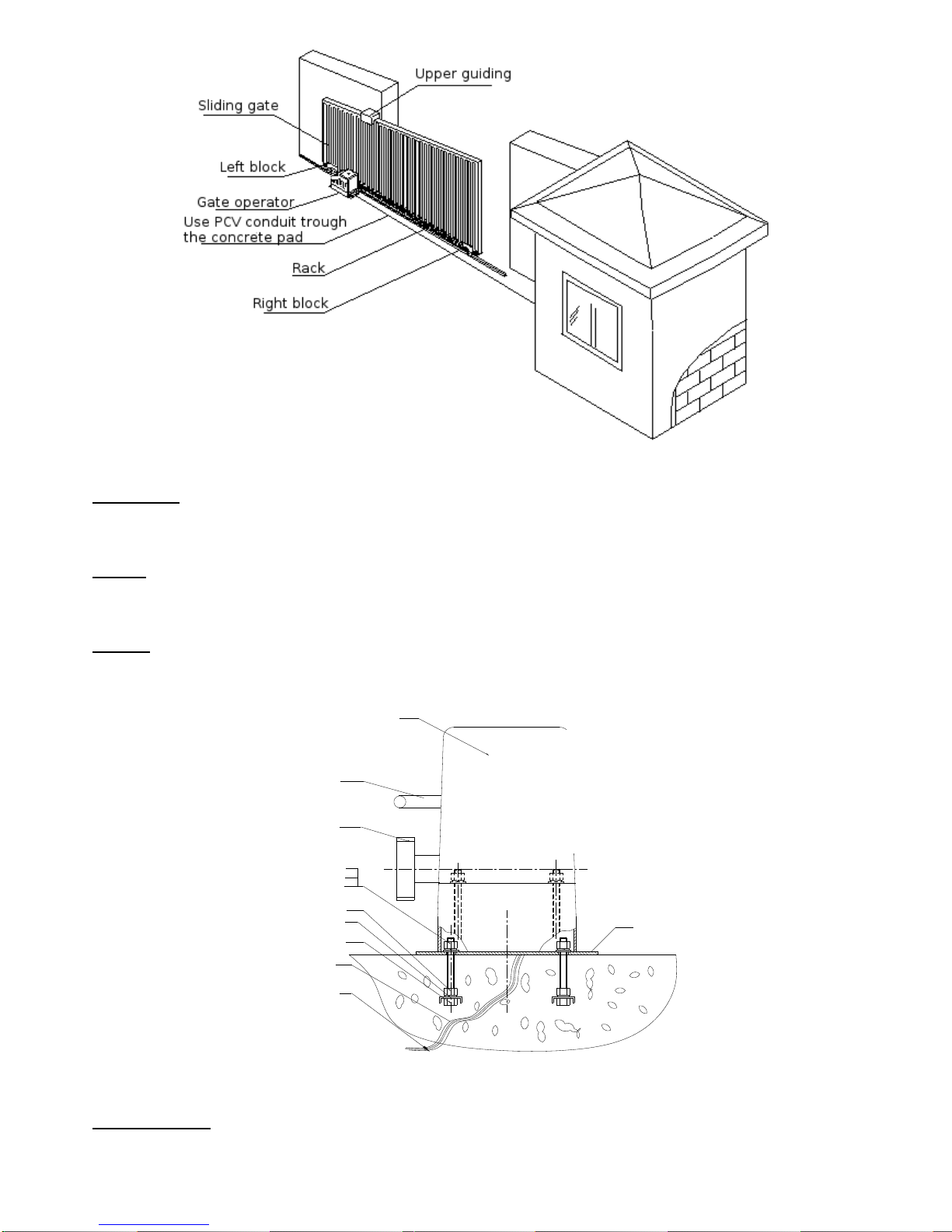

2. Installation

Install the controller into drive. All dimensions are in the

Picture 1. After correct installation continue with

electrical connection.

The manufacturer will not be liable for losses and

disruption in work resulting from non-observance of this

installation, operation manual and applicable regulations.

2.1 Limit switches connection

At first connect limit switches to the controller inputs

marked as (16,17,18). Check the gate condition: the gate

should not swing too much, it should move easily and

smoothly between limit positions. If necessary adjust

placements of magnetic parts.

16 (OL) —open limit,

17 (CL) —close limit,

18 (COM) —common, (white wire)

The controller cooperates with Normally Open or Normally

Closed limit switches. To change type of limit switches

solder the ZS jumper on PCB. With soldered jumper

version marked as NO cooperates with NC type switches

and version marked as NC cooperates with NO switches.

If you have cotroller without encoder input - skip point 2.2.

2.2 Encoder connection

Motor encoder must be connected to the inputs marked as

"ENCODER" (Pic.2)(21,22,23,24).

Connect the encoder wires to the plug according to wiring

diagram description. The controller uses encoder impulses

to calculate applicable force. Uncorrect connection may

cause unproper operation and hazardous situation to healt

and life.

21 - ─ ─ - encoder signal

22 - + + + - GND

23 - ─x─ - GND

24 - - supply (+5V)

Enkoder parameters: 717 impulses per second (speed

1450rpm)

2.3 Photocell connection

Photocell barrier is a necessary safety element which

must be connected to the controller. It increases safety

and prevents a gate wing from hitting a car, a person or an

object which are within the photocells’ range. In the

controller without encoder input it is necessary to connect

gate optical curtain or other safety elements preventing

from accidentally crush. It should be in series with

photocell.

12 –Photocell supply +24Vdc

13 –Photocell supply GND

13-14 –Normally Closed contact

Output (+24V) current cannot exceed < 450mA. Make

sure power consumption of all connected accesorries.

Example of photocell connection is shown on the wiring

diagram.