Hatteland HT 221 User manual

Please visit www.hattelandtechnology.com for the latest electronic version of this manual.

HT 221Hx STC-yzz-zzzz

where x=CPU type, y=OS, z=conguration

HT 221 - Maritime Rack Computer

USER MANUAL

User Manual HT 221

Updated: 07 Jul 2021 Doc Id: INB100084-2 (Rev 12)

Created: 363 Approved: 6987

Copyright © 2021 Hatteland Technology AS

Eikeskogvegen 52, N-5570 Aksdal, Norway.

All rights are reserved by Hatteland Technology AS. This information may not, in whole or in part, be

copied, photocopied, reproduced, translated or reduced to any electronic medium or machine-

readable form without the prior written consent of Hatteland Technology AS. Review also:

www.hattelandtechnology.com/hubfs/pdf/misc/doc100703-1_permission_to_create_user_manuals.pdf

The products described, or referenced, herein are copyrighted to the respective owners.

The products may not be copied or duplicated in any way. This documentation contains proprietary

information that is not to be disclosed to persons outside the user’s company without prior written consent

of Hatteland Technology AS.

The copyright notice appearing above is included to provide statutory protection in the event of

unauthorized or unintentional public disclosure.

All other product names or trademarks are properties of their respective owners !

WARNING: This is a class A product. In a domestic environment this product may cause radio interference

in which case the user may be required to take adequate measures.

Statement above last revised 31 Jul. 2019

3

IND100206-27

Contents

Contents.................................................................................... 3

Contents of package.......................................................................................... 5

General ...................................................................................... 7

IEC62368 policy - Introduction .......................................................................... 8

About this manual.............................................................................................. 9

About Hatteland Technology.............................................................................. 9

www.hattelandtechnology.com .......................................................................... 9

Contact Information ........................................................................................... 9

Computers introduction ................................................................................... 10

Product Labels (Examples) ..............................................................................11

Serial Number Label Placement and Layout (external) .............................. 11

Operating System Product Key Label Placement (external)....................... 12

Installation............................................................................... 13

Installation and mounting of computers........................................................... 14

General mounting instructions......................................................................... 15

Cables ............................................................................................................. 15

Ferrite .............................................................................................................. 16

Unit Upgrade Precaution Note......................................................................... 17

Housing / Terminal Block Connector Overview ............................................... 18

Installing PCI / PCIe Card / Rework PCI Bracket Options - Notice ................. 20

User Controls................................................................................................... 21

User Controls................................................................................................... 22

Physical Connections ..................................................................................... 23

PCI Bracket Expansion Matrix......................................................................... 26

Module Expansion Matrix ................................................................................ 27

Factory Preset COM Port Numbering.............................................................. 28

Specications ......................................................................... 29

Specications - HT 221Hx STC-yzz-wzzz ....................................................... 30

Contents

4

IND100206-27

Specications Factory Options............................................. 31

Specications - NMEA / IEC COM Module RS-422 / RS-485 ......................... 32

PCA200828-1 ............................................................................................. 32

Specications - CAN Module with CO-Processor............................................ 36

ZIA0001310-B............................................................................................. 36

Specications - Isolated Digital Input/Output Module ...................................... 37

PCA100297-1 ............................................................................................. 37

Specications - LAN Module ........................................................................... 39

PCA100298-1 ............................................................................................. 39

Specications Accessories ................................................... 41

Technical Drawings - 20” Slide Rails (for 19” Rack) ........................................ 42

1282219-KD................................................................................................ 42

Technical Drawings - 26” Slide Rails (for 19” Rack) ........................................ 43

1282220-KD................................................................................................ 43

Specications - External Modules (USB)......................................................... 44

Technical Drawings ................................................................ 47

Technical Drawings - HT 221Hx STC-yzz-wzzz .............................................. 48

Appendixes ............................................................................. 49

BIOS - Hybrid Multi Monitor Conguration ...................................................... 50

BIOS - On-board COM Ports Conguration .................................................... 52

BIOS - How to create RAID volume ................................................................ 55

SSD Selection Guide....................................................................................... 59

Pinout Assignments ......................................................................................... 63

IEC62368 policy for Hatteland Technology products....................................... 67

Trouble-shooting.............................................................................................. 69

Declaration of Conformity ................................................................................ 70

Return Of Goods Information .......................................................................... 71

General Terms and Conditions ........................................................................ 72

Signal Output Combinations............................................................................ 73

Notes ............................................................................................................... 74

Revision History............................................................................................... 76

5

IND100207-16

Item Description Illustration

TP52/TC11-1.8M

1 pcs of power cable European Type F “Schuko” to IEC.

Length 1.8m

EUR TYPE F

IEC

TP11/TC11-1.8M

1 pcs of power cable US Type B plug to IEC.

Length 1.8m US TYPE B IEC

DVI-4

1 x DVI-I > RGB/VGA adapter

DVI-I 24+5P (Dual Link) Male to DSUB 15P Female

1 pcs of Cable Relief Bracket KIt including screws.

Note: Entries listed below are for Standard factory shipments. Customized factory shipments may deviate from this list.

Contents of package

Plastic Bag (zip lock) with:

1 x TP52/TC11-1.8M (AC)

1 x TP11/TC11-1.8M (AC)

1 x DVI-4

1 x 742 712 21 Ferrite

1 x Cable Relief Bracket Kit

(packed inside bubble wrap)

Plastic Bag (zip lock) with:

1 x Product Declaration

1 x Computer Checklist

1 x BurnInTest Certificate

Grab hold of center piece and

lift up to reveal the computer

unit underneath.

...list continues on next page...

Contents of package

6

IND100207-16

Package may also include: (based on accessories/options ordered)

Item Description Illustration

Terminal Block Connectors

Depending on factory mounted options, connector kit as follows:

Front:

4 x 4-pin Terminal Block 3.81 for CAN Interface (HT 00254 OPT-A1)

4 x 5-pin Terminal Block 3.81 for RS-422 / RS-485 NMEA COM (PCA200828-1 / PCA100293-1)

4 x 5-pin Terminal Block 3.81 for Digital Input/Output (HT 00268 OPT-A1)

Rear/External:

4 x 5-pin Terminal Block 3.81 for RS-422 / RS-485 NMEA COM (PCA100293-2)

Front Module

Rear w/PCI bracket option

Terminal Block

Connector Kit

Depending on External Module options, connector kit as follows (incl. cover hood/cable housing):

4 x 4-pin Terminal Block 3.81 for CAN Interface (HT 00264 OPT-A1)

+ 4 x Cover Hood - BCZ 3.81 AH04 BK BX (4-pin)

4 x 5-pin Terminal Block 3.81 - for RS-422/485 NMEA COM (HT 00262 OPT-A1)

+ 4 x Cable Housing - KGG-MC 1,5/ 5 (5-pin)

4 x 5-pin Terminal Block 3.81 for Digital Input/Output (HT 00268 OPT-A1)

+ 4 x Cable Housing - KGG-MC 1,5/ 5 (5-pin)

1282219-KD (20 inch)

1282220-KD (26 inch)

Mounting rails kit options:

- 1282219-KD: 2 x 20 inch long ball bearing sliding rails. 19 inch Rack compatible.

- 1282220-KD: 2 x 26 inch long ball bearing sliding rails. 19 inch Rack compatible.

?For computers that include 3rd party hardware; the package / accessories box may also include

additional CD / HW / Information from 3rd party supplier(s).

Würth 742 712 21

(split, 10.5mm)

1 pcs - Würth 742 712 21

This ferrite is required when using 100/110/115V AC voltage on the power

supply (not required for 230V AC) to be fully compliant with type approvals.

Review installation chapter for more information.

Test Reports papers:

1 pcs of Product Declaration

1 pcs of Computer Checklist

1 pcs of BurnInTest Certificate

7

General

8

IND100078-81

General

IEC62368 policy - Introduction

Safety Instructions

Please read and understand the material in the manual in its entirety before doing any installation/servicing/upgrades.

Personnel who are allowed to do work on the unit is detailed in the “IEC62368 policy for Hatteland Technology

product” section later in this manual. Symbols pertaining to different personnel in regard to operations is described in

the user manual.

Based on requirements EN 62368-1:2014 and IEC 62368-1:2018

Authority Description

Children This equipment is not suitable for use in locations where children are likely to be present.

Ordinary person/

Sailor/End-User

Not allowed to open unit.

Not allowed to install the unit.

Not allowed to terminate/connect cables to the unit.

Instructed person Allowed to open hatches/latches which does not require tools, such as Disktrays.

Allowed to open "battery-hatch" to change the battery even if tools are required.

Allowed to install the unit.

Allowed to terminate/connect cables to the unit indoors.

Skilled person Allowed to open and disassemble the unit.

Allowed to install the unit.

Allowed to terminate/connect cables to the unit indoors and outdoors.

Allowed to terminate/connect earth/ground wire.

Note: Be aware that additional denition for “skilled person” may apply, country dependent.

9

Hatteland Technology AS

IND100077-1

General

About this manual

The manual contains electrical, mechanical and input/output signal specications. All specications in this manual,

due to manufacturing, new revisions and approvals, are subject to change without notice. However, the last updated

and revision date of this manual are shown both on the frontpage and also in the “Revision History” chapter. This

user manual is a standard/general manual that applies to all variations of its product family, i.e. deviation from actual

conguration may exist.

About Hatteland Technology

Hatteland Technology is the leading technology provider of specialized display and computer products, delivering high

quality, unique and customized solutions to the international maritime, naval and industrial markets.

The company represents innovation and quality to the system integrators worldwide. Effective quality assurance and

investment in sophisticated in-house manufacturing methods and facilities enable us to deliver Type Approved and Mil

tested products. Our customer-oriented approach, technical knowledge and dedication to R&D, makes us a trusted

and preferred supplier of approved solutions, which are backed up by a strong service network.

www.hattelandtechnology.com

You will nd our website full of useful information to help you make an informed choice as to the right product for your

needs. You will nd detailed product descriptions and specications for the entire range on Displays, Computers and

Panel Computers, Military solutions as well as the range of supporting accessories. The site carries a wealth of

information regarding our product testing and approvals in addition to company contact information for our various

oces around the world, the global service locations and the technical help desk, all ensuring the best possible

support wherever you, or your vessel, may be in the world.

Contact Information

Head oce, Aksdal / Norway:

Hatteland Technology AS

Eikeskogvegen 52

N-5570 Aksdal, Norway

Switchboard:

Tel: +47 4814 2200

mail@hattelandtechnology.com

Sales oce, Frankfurt / Germany:

Hatteland Technology GmbH

Werner Heisenberg Strasse 12,

D-63263 Neu-Isenburg, Germany

Uwe Scheumann:

Tel: +45 2463 9565

Elke Freisens:

Tel: +49 173 6174753

Sales oce, Oslo / Norway:

Hatteland Technology AS

Strandveien 35

N-1366 Lysaker

Norway

Switchboard:

Tel: +47 4814 2200

mail@hattelandtechnology.com

Sales oce, Aix-en-Provence / France:

Hatteland Technology SAS

Actimart- 1140, rue Ampère, CS 80544

13594 Aix-en-Provence, Cedex 3

France

Mehdi Bounoua (Sales Director Europe, Middle East & Africa):

Tel : +33 6 88 33 64 93

Sales oce, Vista / USA:

Hatteland Technology Inc

450 South Melrose Drive,

Suite #107

Vista, CA 92081

USA

Donna Pallonetti:

Tel: +1 858-282-0659

Fax: +1 858-408-1834

For an up-2-date list, please visit https://www.hattelandtechnology.com/contact

10

Computers

IND101057-2

General

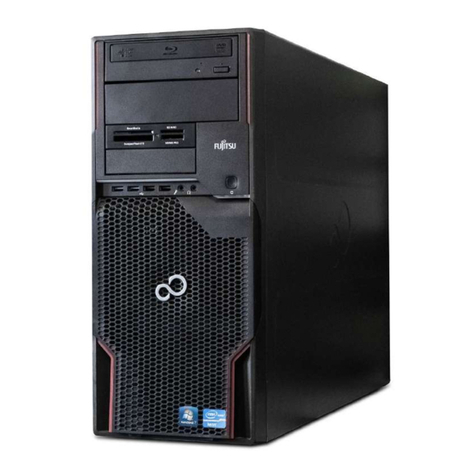

Computers introduction

Hatteland Technology’s range of type-approved computers is designed to

perform in harsh environments while providing the performance and flexibility

you expect. We offer rack mount and black box/standalone computer solutions

for every need. Our computers are used by system integrators, boat builders

and end-users and can be found on all vessel types, all over the world.

If you are looking for a high quality computer for navigation, monitoring or

entertainment solutions, Hatteland Technology can fulfil your high expectations

at a reasonable cost.

Our computer range covers all eventualities and requirements. We offer a wide

range of processor choices, HDD/SSD and power options, and solid state

technology, neatly engineered within industry standard form factors such as 19”

rack mount, 2U and 4U solutions.

We continually develop our computers portfolio to make the best use of emerging

computer technology so you can be sure that your Hatteland Technology

computer offers the power needed to run modern applications, with the flexibility

to be installed wherever you want, for any marine use.

Designed to perform in harsh environments...

260,00 10,24 74,60 2,9457,70 2,27

47,50 1,87 250,00 9,84 47,50 1,87

4x M6 mounting holes

392,30 15,44 33,00 1,30

8,28 0,33

345,00 13,58

133,00 5,24

345,00 13,58

133,00 5,24

173,00 6,81173,00 6,8114,50 0,57

8,70 0,34

22,00

0,87

13,00 0,51 67,00 2,64 53,00 2,09

5x M4 mounting holes

Shown with optional 4COM and PCIe modules

TOP VIEW

BOTTOM VIEW

Shown with tie-wrap plate (included)

FRONT VIEW (2-BAY)

FRONT VIEW (4-BAY)

SIDE VIEW

BACK VIEW (AC)

BACK VIEW (AC+DC)

H

1

2

G

F

E

3

4

5

6

D

C

B

A

1

2

3

4

5

6

7

8

7

8

G

F

E

9

10

D

C

B

11

12

A

9

10

11

12

H

Hatteland Technology AS

Eikeskogvegen 52

N-5570 Aksdal

A012767

Projection:

This document is the property of Hatteland Technology AS.

This document and any authorized reproduction thereof, must not be used in

any way against the interest of Hatteland Technology AS.

Any authorized reproduction, in whole or in part, must include this legend.

01

Revision:

Approved by:

Drawing number:

A1

1:2

Scale:

Last rev. date / by: /

Creation date / by: /

7258

20.10.20

ISO 2768-mK

Tolerance

Units: mm [inches]

132,50 5,22

436,00 17,17

120,00 4,7292,00 3,6292,00 3,6292,00 3,62

44,00 1,73

8 x M3

MAX. 8mm depth

57,10 2,25

37,70 1,48

465,00 18,31

21,20 0,83

FRONT VIEW

SIDE VIEW BACK VIEW

BOTTOM VIEW

TOP VIEW

ISOMETRIC VIEW

SALES DRAWING HTS-31470

,

SIDE VIEW

H

1

2

G

F

E

3

4

5

6

D

C

B

A

1

2

3

4

5

6

7

8

7

8

G

F

E

9

10

D

C

B

11

12

A

9

10

11

12

H

Hatteland Technology AS

Eikeskogvegen 52

N-5570 Aksdal

A012666

Projection:

This document is the property of Hatteland Technology AS.

This document and any authorized reproduction thereof, must not be used in

any way against the interest of Hatteland Technology AS.

Any authorized reproduction, in whole or in part, must include this legend.

01

Revision:

Approved by:

Drawing number:

A1

1:5

Scale:

Last rev. date / by: /

Creation date / by: /

8755

13.11.20

ISO 2768-mK

Tolerance

Units: mm [inches]

Hatteland Technology AS

Eikeskogvegen 52

N-5570 Aksdal

Hatteland Technology AS

Eikeskogvegen 52

N-5570 Aksdal

11

General

IND100240-11

Product Labels (Examples)

Serial Number Label Placement and Layout (external)

Serial Number Label Layout Example

Label Size and Types

ID Label Layout Description Specication

Type : Serial Number Label

Name : Label B

Size : 60mm wide x 22mm high (rectangle size)

Note: Text content of label will match specications de-

rived from Data Sheet.

Silver with glue on back, non-

tearable and made for thermal

transfer printing.

Barcode type: CODE128 (used extensively world wide in shipping and packaging

industries. The symbology was formerly dened as ISO/IEC 15417:2007.)

Type : Operating System (OS) label.

Size : 70mm wide x 23mm high (rectangle size)

Note: Label only present if OS was part of factory

option order. Linux OS does not have any label.

As per delivered from supplier.

Label applies for:

Windows® 7 Professional

Windows® 7 Ultimate

Type : Operating System (OS) label.

Size : 22mm wide x 9mm high (rectangle size)

Note: Label only present if OS was part of factory

option order. Linux OS does not have any label.

As per delivered from supplier.

Label applies for:

Windows® Emb. Standard 7

Windows® 10 IoT Enterprise

Type : Quality Control (QC) Label

Size : 30mm wide x 23mm high (oval size)

This label indicates that the unit is produced, tested and

packed according to the manufacture’s QA specications.

It will include a Personal ID and signature by the

personnell responsible for approving the unit in

production, test and warehouse departments.

Ordinary sticker with glue on

back.

Please note that typenumber shown above is a generic sample only. May not reect products mentioned in this manual. Please review

actual product S/N label.

Only present if the unit was delivered with factory installed Operating System (OS) such as

Microsoft® Windows® Embedded Enterprise. The same Product Key is also printed on the

“Product Declaration” sheet that follows the unit, check contents of package. Note: For certain OS,

there is no physical Product Key Label required or a Product Key Number that must be entered

during installation / usage of the unit.

Manufacturer/Country

Input Voltage(s)

Type+Serial Number

Barcode (TYP+SNO)

Power Rating Max/Typ

Date of Production (YYYY-MM-DD)

Compass Safe Distance

IP Rating

Lowest value used, higher may apply,

check specications.

12

Product Labels (Examples)

General

IND100240-11

Operating System Product Key Label Placement (external)

Label Size: 7cm x 2.8cm

Only present if the unit was delivered with factory installed Operating System (OS) such as Microsoft® Windows®

Embedded Enterprise. Label size is 7cm wide x 2.8cm high. The same Product Key is also printed on the “Product

Declaration” sheet that follows the unit, check contents of package. Note: For certain OS, there is no physical Product

Key Label required or a Product Key Number that must be entered during installation / usage of the unit.

Quality Control (QC) Label

This label indicates that the unit is produced, tested and packed according to the manufacturer’s QA

specications. It will include a Personal ID and signature by the personnell responsible for approving

the unit in production, test and warehouse departments. Label size is 3cm wide x 2.3cm high.

13

Installation

14

Installation

IND100210-19

General Installation Recommendations

Installation and mounting of computers

1. Units may be intended for various methods of installation or mounting (rack mounting, panel mounting,

bracket mounting, ceiling/wall mounting); for details, please see the relevant mechanical drawings.

2. Adequate ventilation is a necessary prerequisite for the life of the unit. The air inlet and outlet openings must

denitely be kept clear; coverings which restrict ventilation are not permissible. The product might be without

any ventilation aperatures which means pt.2 does not apply.

3. Exposure to direct sunlight can cause a considerable increase in the temperature of the unit, and might under

certain circumstances lead to overtemperature. This point should already be taken into consideration when

the bridge equipment is being planned (sun shades, distance from the windows, ventilation, etc.)

4. Space necessary for ventilation, for cable inlets, for the operating procedures and for maintenance, must be

provided.

5. To further improve the cooling of the unit we recommend installing Cooling Fans underneath blowing upwards

into the unit air inlet. This may be required in high temperature applications and also when there is reason to

expect temperature problems due to non-optimal way of mounting.

6. Products with AC input shall be grounded to protective Earth (Safety Ground) when necessary via the bolt

(usually on terminal plate) available on the product.

Products with DC input shall be grounded to protective Earth (Safety Ground) via the bolt (usually on terminal

plate) available on the product. A shorter and thicker cable gives better grounding. A 6mm² is recommended,

but a 4mm² or even 2.5mm² can be used for this purpose.

7. Expose to heavy vibration and acoustic noise might under certain circumstances aect functionality and

expected lifetime. This must be considered during system assembly and installation. Mounting position must

be carefully selected to avoid any exposure of amplied vibration.

8. Additional rules may apply to certain procedures where the symbols and are present. For more

information, review “IEC62368 policy for Hatteland Technology product” section later in this manual.

15

General Installation Recommendations

Installation

IND100210-19

General mounting instructions

1. The useful life of the components of all Electronics Units generally decreases with increasing ambient

temperature; it is therefore advisable to install such units in air-conditioned rooms. If there are no such

facilities, these rooms must at least be dry, adequately ventilated and kept at a suitable temperature in order

to prevent the formation of condensation inside the unit.

2. With most Electronic Units, cooling takes place via the surface of the casing. The cooling must not be

impaired by partial covering of the unit or by installation of the unit in a conned cabinet.

3. In the area of the wheel house, the distance of each electronics unit from the magnetic standard compass or

the magnetic steering compass must not be less than the permitted magnetic protection distance. This

distance is measured from the centre of the magnetic system of the compass to the nearest point on the

corresponding unit concerned. The exact distance is often mentioned in the specic product specications.

4. Transportation damage, even if apparently insignicant at rst glance, must immediately be examined and be

reported to the freight carrier. The moment of setting-to-work of the equipment is too late, not only for

reporting the damage but also for the supply of replacements.

5. The classication is only valid for approved mounting brackets provided by Hatteland Technology. The unit

shall be mounted stand-alone without any devices or loose parts placed at or nearby the unit. Any other type

of mounting might require test and re-classication.

6. Additional rules may apply to certain procedures where the symbols and are present. For more

information, review “IEC62368 policy for Hatteland Technology product” section later in this manual.

Cables

Use only high quality shielded signal cables. For RGB/DVI cables use only cables with separate coax for Red, Green

and Blue.

16

IND100210-9

General Installation Recommendations

Installation

Ferrite

The ferrite prevents high frequency electrical noise (radio frequency interference) from exiting or entering the

equipment. This ferrite is required when using 100/110/115V AC voltage on the power supply (not required

for 230/240V AC) to be fully compliant with type approvals.

The ferrite should be mounted (clipped in place on the cable) and

located as close as possible to the connector piece that connects to

the rear of computer.

When ready: Open the ferrite, place the cable inside as shown in

FIG1, and then gently close it until a click can be heard (FIG2). You

may close and re-open them as many times as required during the

installation.

Typenumber Ferrite Type Dimetric View Perferred distance of ferrite. Side view.

HT C02Hx STC-xxx-xxxx

HT 221Gx STC-xxx-Mxxx

1 x Würth 742 712 21 Red Line indicate 5cm [1.97 inch] limit from connector. Do not

mount ferrites (orange square) located beyond the red line!

FIG1

To computer

FIG2

To computer

17

IND100210-4

General Installation Recommendations

Installation

Unit Upgrade Precaution Note

Users which needs to open the unit to expose and reveal electronics, make sure that prior to touching / removing

parts, proper ESD measurements must be taken!

1. Operator should ground himself by using a wrist band.

2. The wrist band should be connected to ground via a ground cord.

3. A one megaohm resistor, installed in the wrist connection end of the ground cord, is a safety requirement.

4. Hatteland Technology recommends to use an Static-dissipative ESD work mat positioned at the workplace. The

3M™ 8501 Portable Field Service Kit is a good choice for this purpose. Make sure that the mat, operator and product

is wired/grounded together.

All assisting persons who might come into contact with the endangered boards must also use the ESD equipment.

CAUTION

This unit contains electrostatic sensitive devices.

Observe precautions for handling.

18

General Installation Recommendations

Installation

IND100210-20

Housing / Terminal Block Connector Overview

Housing / Terminal Block connectors are available in dierent sizes (example 2-pin, 4-pin, 5-pin) which plug into the

connector area of the unit. They are mounted by factory default and delivered with the unit. The housing / terminal

block connectors have steering rails, which ensures that it can not be mounted wrong. The color of these connectors

may vary between black, green and orange depending on manufacturer. You may use approved equivalents of these

connectors, but note that the warranty will be void if any damage would occur to either the unit’s original PCB terminal

socket connector or inside the unit (electronic components, boards etc.). The table below is applicable for any

Series X products, such as Display and Panel Computers, including newer type of Stand-Alone Computers.

Illustration Pins Manufacturer Details Connector used for module

If your installation require additional cable fasteners support, please use the provided Cover Hood and Cable Housing

shipped with the unit for accessories (contents of package). Illustrations below are approximate, actual Housing and

Hood may deviate slightly, but function remains the same.

5-pin Cable Housing - Illustration 4-pin Cover Hood - Illustration

KGG-MC 1,5/ 5 (5-pin) BCZ 3.81 AH04 BK BX (4-pin)

For 5-pin:

“https://www.phoenixcontact.com/online/portal/us?uri=pxc-oc-itemdetail:pid=1834372&library=usen&pcck=P-11-02-01&tab=1”

For 4-pin

“http://catalog.weidmueller.com/procat/Product.jsp;jsessionid=B040D5EB6832629E567C884809FDF6C1?productId=(%5b1005290000%5d)”

Tx- Tx+ COM Rx- Rx+

5-pin MC 1,5/ 5-STF-3,81

Screwdriver: SZS 0,4X2,5mm

VDE, slot-headed.

Tightening torque min. 0.22 Nm.

Tightening torque max 0.25 Nm.

• RS-422 / RS-485 NMEA

(PCA200828-1 / PCA100293-1)

• Digital Input/Output (PCA100297-1)

Identi ed on Hatteland Technology product datasheet as:

“Terminal Block 3.81”

4-pin BCZ 3.81/04/180F SN BK BX

Screwdriver: 0.4x2.5mm DIN 5264.

Tightening torque min.. 0.2 Nm.

Tightening torque max. 0.25 Nm.

• CAN Interface (ZIA0001310-B / ZIA0001310-SLCAN)

Identi ed on Hatteland Technology product datasheet as:

“Terminal Block 3.81”

2-pin MSTB 2,5/ 2-STF-5,08 BK

Screwdriver: SZS 0,6x3,5, slot-

headed.

Tightening torque min. 0.5 Nm.

Tightening torque max 0.6 Nm.

• DC Power IN - Single Input

Identi ed on Hatteland Technology product datasheet as:

“Terminal Block 5.08”

19

General Installation Recommendations

Installation

IND100210-20

Conguring Housing / Terminal Block connectors

Below is a brief illustration that might be useful during conguration and installation of such connectors. You will need

suitable pre-congured cable(s) and tools to congure the connector(s) and cable(s) that are present in your

installation environment. Below is a sample procedure for a 2-pin DC power connector. The procedure is the same for

other connectors of this type as listed in table above. Unit used as illustration below is for reference only.

FIG 5

FIG 1

FIG 4 FIG 6

FIG 2

FIG 3

Requires assembly. It is expected that the technician has experience in electronics and assembling cables and connectors.

Warning: Do not connect or disconnect cables/connectors to the unit’s connector while the unit is powered on. Failure to do so may result in

damaged electronics.

FIG 1: Unscrew (from top) or make sure that the screw terminal is fully open, so you can secure the inserted cables

correctly to the loose housing connector (it may already be plugged into the unit as per factory installation).

FIG 2: Strip carefully the insulation from the cable to expose the wire(s) inside.

FIG 3: Ensure that the wire(s) is without any loose threads to ensure good connection.

FIG 4: Insert cables* (from front) and screw / secure the cables by turning the screw on top of the housing to secure

the cables properly. Check that the cables are rmly in place and do not appear loose or fall out when pulling gently.

*Note: Required polarization verication (for instance -/+ for DC power input) should conform with the markings on

the connector area of the unit. Ignoring the markings on the unit or its add-on modules might damage the unit and/or

external equipment in which end, warranty will be void.

FIG 5: Plug the housing into the appropriate connector area of the unit and check again that the cables secured

conform with the markings on the connector area of the unit. Finalize the installation by fastening the screws located

in front on each side of the housing connector (FIG 6).

Connector / Function Recommended Cable Thickness

2-pin DC Power Input (Terminal Block 5.08) Minimum 20 AWG - Maximum 18 AWG

4-pin CAN (Terminal Block 3.81) Minimum 22 AWG - Maximum 20 AWG

5-pin NMEA COM (Terminal Block 3.81) Minimum 22 AWG - Maximum 18 AWG

5-pin DIO (Terminal Block 3.81) Minimum 22 AWG - Maximum 18 AWG

20

General Installation Recommendations

Installation

IND100210-17

Installing PCI / PCIe Card / Rework PCI Bracket Options - Notice

All factory options are done in-house by our production facility prior to delivery. If you however need to install your

own PCI/PCIe cards later and any of the PCI Bracket Options are already pre-installed, please review:

“Physical Connections/ Added functionality through 4 x PCI Sized Metal Brackets” chapter later in this manual.

Note: Areas of interest are marked in this section with RED color. Please disconnect ALL cables from the computer

unit before proceeding!

1: Identify if either of the PCI Bracket Options (PS/2

and AMP) are present (as indicated). If yes, proceeed

to step 2,3,4. If no, install the PCI/PCIe card into

appropriate slot.

2: Observe the tie wrap and positioning of cables.

You may have to cut the tie-wrap that holds the cable to

the inner chassis, in order to insert the new PCI/PCIe card

and t the cable again.

3: Either move the PCI Bracket Option into any of the

other free slots, or make sure the original cables are

routed under the PCI/PCIe card when you install the

new PCI/PCIe card (depending on which slot you have

to use).

4: After installing the PCI/PCIe card, observe that the PCI

Bracket Options cables are not damaged, loose or are

subject for getting damaged after long use. Notice also

some PCI/PCIe card components may get hot. If possible,

add a tie wrap to secure the cables further to keep clear of

potentional heat.

Table of contents

Other Hatteland Desktop manuals

Hatteland

Hatteland HT C01 Series User manual

Hatteland

Hatteland JH I2TOI MMC User manual

Hatteland

Hatteland HT 205P4 STD User manual

Hatteland

Hatteland HT 403XE STD User manual

Hatteland

Hatteland HT 416 User manual

Hatteland

Hatteland JH 15T17 MMC series User manual

Hatteland

Hatteland HT B17 Series User manual

Hatteland

Hatteland X G2 Series User manual

Hatteland

Hatteland JH 23T02 MMC User manual

Hatteland

Hatteland HT 405P4 STD User manual