Haupon TM-500 User manual

HVLP PAINT SPRAYER

TM-500 / TM-663A+

PLEASE READ AND SAVE THIS INSTRUCTION MANUAL ENGLISH

WARNING

TO REDUCE THE RISK OF INJURY, USER MUST READ AND UNDERSTAND

INSTRUCTION MANUAL. KEEP CHILDREN AWAY FROM WORKING AREA.

MADE IN TAIWAN

2

Specifications :

Voltage 100V-120V 220V-240V 50 Hz / 60 Hz

WATTS 300-450 watts

Air supply 1.5-1.9 m3/min. (67cu.ft./min.)

Container capacity 0.8L (28 oz)

Weight 2.5 lbs. (1.2 kg)

Motor speed 34,000 rpm

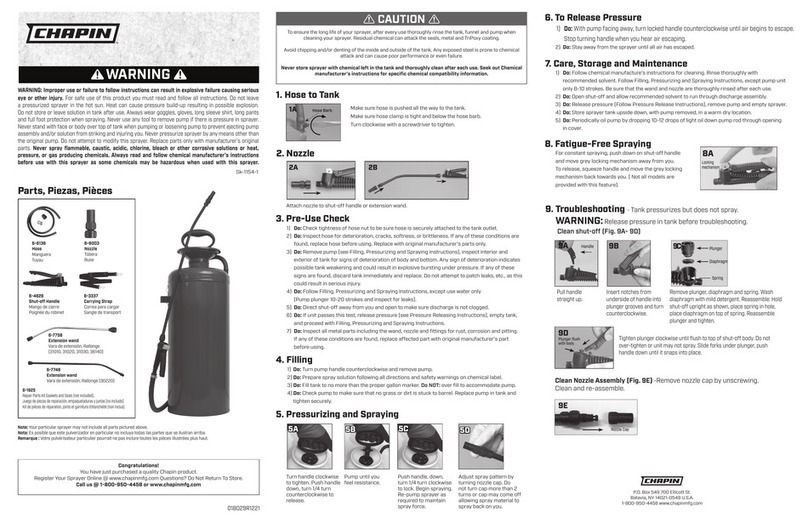

Component Introduction:

MOTOR LID

RETAINING NUT

AIR CAP

VISCOSITY CUP

AIR BLOWING NOZZLE

PAINT CONTAINER

PAINT CONTROL NUT

SWITCH TRIGGER

3

Read instruction manual before operating and observe all warning.

WARNING:

DO NOT aim sprayer at yourself or anyone else at all times, in the event of an injury occurring

seek expert medical consultant immediately.

DO NOT allow any part of the body to come in contact with the fluid stream.

DO NOT cover the nozzle with any part of your body, high velocity jet could cause accidental

injuries.

DO NOT spray any hazardous materials (for example: easy flammable, very toxic, toxic, less toxic,

corrosive or irritating substances).

DO NOT spray any textured materials containing particles or fibers such as asbestos fibers.

DO NOT spray flammable liquid.

DO NOT clean guns with flammable solvents.

DO NOT spray any material where the hazard is not known.

DO NOT use the spray gun outside when it is raining to reduce the risk of electric shock.

DO NOT use the spray gun at any stuffy area. Ensure adequate ventilation at all time when using

the unit.

DO NOT disassemble the sprayer without skill’s direction for avoiding danger.

DO NOT tamper with electrical motor, switch wiring or plug.

DO NOT leave your sprayer unclean or allow paint to dry in the gun. An unclean sprayer will not

work next time and you could void the one-year warranty.

DO NOT use the power tool if the switch does not turn it on and off.

NEVER immerse the sprayer into water or other liquids for preventing electric shock.

ALWAYS place the sprayer upright (do not place the sprayer upside down or on its side) to prevent

liquid or paints flow into motor.

ALWAYS wear mask, goggles, ear protectors and eye protectors while operating the sprayer.

ALWAYS unplug the cord to prevent accidental spraying when you stop spraying or servicing.

ALWAYS keep children and bystanders away.

USE fluids with a flashpoint above 40 degrees C.

4

FOR SAFE OPERATIONS:

1. Keep work area clean

Cluttered or dark areas and benches invite accidents.

2. Consider work area environment

Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, rain, gases or dust. Keep work area well lit. Avoid working with power tools in damp

or wet areas or when perspiring. Store tools away from moisture. Do not use power tools

where there is risk to cause fire or explosion. Power tools create sparks which may ignite

the dust or fumes.

3. Guard against electric shock

Avoid body contact with earthed or grounded surfaces (e.g. pipes, radiators, ranges,

refrigerators).

4. Store idle tools

When not in use, tools should be stored in a dry, high or locked up place, out of reach of

children.

5. Do not force the tool

It will do the job better and safer at the rate for which it was intended.

6. Dress properly

Rubber gloves and non-skid footwear are recommended when working outdoors.

7. Do not abuse the cord

Never carry the tool by the cord or yank it to disconnect it from the socket.

Keep the cord away from heat, oil and sharp edges.

8. Do not overreach

Keep proper footing and balance at all times.

9. Disconnect tools

When not in use, before servicing and when changing accessories such as spray tip, etc.

10. Use outdoor extension leads

When use the tool outdoors, use only extension cords intended for outdoor use.

11. Stay alert

Watch what you are doing. Use common sense. Do not operate tool when you are tired or

under the influence of drugs, alcohol or medication.

12. Have your tool repaired by a qualified person

This electric tool is in accordance with the relevant safety requirement. Repairs should only

be carried out by qualified persons using original spare parts, otherwise this may result in

considerable danger to the user.

13. Do not use guns for spraying flammable materials.

5

14. Do not clean guns with flammable solvents.

15. If operating a power tool in a damp location is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces the risk of electric shock.

16. Prevent unintentional starting. Ensure the switch is in the off-position before connecting to

power source and/or battery pack, picking up or carrying the tool.

17. Remove any adjusting key or wrench before turning the power tool.

18. If devices are provided for the connection of dust extraction and collection facilities, ensure

these are connected and properly used.

19. Maintain power tools.

Check for misalignment or binding of moving parts, breakage of parts and any other

condition that may affect the power tools operation. If damaged, have the power tool

repaired before use.

20. Use the power tool, accessories and tool etc. in accordance with these instructions, taking

into account the working conditions and the work to be performed.

21. A-weighted sound pressure level:87.4 dB(A).

22. A-weighted sound power level:96.3 dB(A).

23. Hand-arm vibration emission value: 0.582 m/s2.

CAUTION:

HAZARD: Solvent and paint fumes can explode or ignite, causing property damage and

severe injury. Avoid all ignition sources such as static electricity sparks,

open flames, pilot lights, cigarettes, etc.

HAZARD: Paints, solvents, insecticides and other materials may be harmful if inhaled

causing severe nausea, fainting or poisoning.

HAZARD: Do not hold cord at plug connections to support cord. Failure to observe may

result in an electric shock.

TREATMENT: See a physician immediately.

Notes:

Practice before painting. Practice spraying water on cardboard, and adjust the paint

flow and turn the wings of the tip to get the desired spray pattern. (see Page 8 & 9.)

Keep spray tip and needle clean.

Check spray tip and needle for dried paint before each use.

Make sure paint tube is inserted tightly into the intake port.

Always clean the sprayer after each use. (see Clean Up, page 11.)

6

SERVICING OF A DOUBLE-INSULATED PRODUCT:

In a double-insulated product, two systems of insulation are provided instead of

grounding. No grounding means is provided on a double-insulated product, nor should a

means for grounding be added to the product. Servicing of a double-insulated product

requires extreme care and knowledge of the system, and should be done only by qualified

service personnel. Replacement parts for a double-insulated product must be identical to

those parts in the product.

The double-insulated product shall be marked with « DOUBLE INSULATION » or «DOUBLE

INSULATED » and « ».

PAINT PREPARATION:

Most oil-based paint should be thinned with thinner before

spraying. (Figure A) It might include dry paint particles which

could block the spray tip. Strain the paint after thinning. Strain

the paint through a fine metal sieve or nylon stocking to remove

particles or fibers which could block the spray gun. (Figure B)

When spraying lumps, no spray or thick spray pattern, it might be

necessary to thin paint to achieve optimum spray pattern.

THE IDEAL CONSISTENCY FOR VARIOUS PAINTS:

Water based paint 20-35 sec.

Oil-based paint 20-30 sec.

Coating 20-30 sec.

Enamel paint 20-25 sec.

Wood stain 20-30 sec.

Metallic Paint 20-30 sec.

Clear Sealer No thinning required

Polyurethane No thinning required

Primer 30-45 sec.

Stain No thinning required

Varnish 20-45 sec.

* This guide can offer only general information.

Thinning should be followed according to the stain or paint manufacturer’s guideline.

A

B

C

7

OPERATING:

Adjust the Air-Cap

Slacken off the air-cap nut, turn the air-cap

to the required position to produce a

horizontal or vertical or round spray pattern.

The horizontal spray is generally used when

painting up and down, and vertical spray when

painting across, and round spray when painting

on the strip.

Adjust the paint flow

The knob adjusts the amount of paint released through

the nozzle. Turn the paint control knob clockwise,

the released flow becomes larger; turn it counterclockwise

for less flow. Adjust it until you get a desired spray pattern.

Air Blowing Nozzle

It is a breeze dusting device, suitable

for the use of dusting computer mainframe

heat sinks, keyboards, air conditioner

filter meshes, and all kinds of

precision instruments.

However, it is not suitable

for liquid spraying.

VERTICAL

SPRAY

HORZONTAL

SPRAY

HORZONTAL

OR

VERTICAL SPRAY

8

HOW TO OPERATE YOUR SPRAY GUN PROPERLY?

1. Practice before painting- Test your sprayer on cardboard or

scrap wood especially when you operate the sprayer first

time. 15 – 20 cm (6 – 8 inches) is about the best distance for

spraying. (Figure A)

2. Always hold spray gun upright and spray parallel to the

painting surface. (Figure B)

3. When spraying overhead (e.g. ceilings) or floors, be sure to

adjust the angle of suction tube; or the sprayer may fail to

get the paints from the container due to tilting. The vertical

inclination should be not more than 70° to avoid paints

running up into the head of the gun through the air-cap.

(Figure C)

4. The warm air from sprayer might cause the paint dried on

the spray tip and needle tip easily, so always keep the brass

needle clean with wet tissue or cloth to enable it to

work longer. (See Figure D)

5. If the motor doesn’t stop running or the needle is not

flexible, pull and release trigger quickly (2-3 times) to make

the needle back in the proper place. And use lubricant oil on

these 2 positions. (See Figure E & F)

6. If the paint could not be sprayed out, clean holes on each

side of pickup tube and the spray tip.

(See Figure G & H)

INCORRECT

CORRECT

A

B

C

D

E

F

G

H

9

CLEANING UP

After the project has been completed or when you are going to take a longer rest, it is all

necessary to clean up the gun to prevent the paint from dried out and causing damage to

the gun.

Cleaning steps

1. Unplug sprayer from electrical outlet and empty the remaining material in the

container. (Figure A)

2. Fill container with some solvent (for oil-based paints) or soapy water (for water-

based paints).

3. Plug sprayer into an electrical outlet then spraying towards the recycling bucket for

about one minute (can’t spray towards the flammable area) till the paint inside the

circuit is fully cleaned. (Figure B)

4. Unplug sprayer and discard the remaining cleaning solution.

5. Disassemble nut, air-cap, suction tube, cup, etc. Clean up them with the above

cleaning solution thoroughly and then reassemble all parts to the gun. (Figure C)

6. Put a small amount of light oil such as WD-40 or 3-in-one etc. into the below position

(See page 8. Figure E & F) and trigger sprayer briefly. Always clean and lubricate

piston and cylinder after spraying your sprayer with water or paint for avoiding rust.

(See page 8. Figure E & F)

7. Clean the unit not enough and lubricate it with no lubricating oil which will cause

cylinder rusted to seize, failure to follow the above steps will void your guarantee.

Clean Air Filter

Clean or replace air filter periodically. An excessively dirty

filter might cause damage to the sprayer, and ensure

adequate ventilation at all time while using the unit.

A

B

C

10

TROUBLE SHOOTING

TROUBLE CAUSE REMEDY

Sags or runs

Too much paint.

Gun moved too slowly.

Paint too thin.

Gun held at incorrect angle or too close to

painting surface.

Spray overlaps too much.

Turn the adjust nut counterclockwise.

Move gun faster.

Add

unthinned paint to achieve correct time

through viscosity test cup.

Hold gun at right angle to surface and at a

distance of 15-20 cm.

Overlap spray about 1/3 width of spray

pattern

.

Dry spray

Insufficient paint coming from the spray

gun.

Gun held too far from surface.

Overspray from a preceding section when

gun is not held at right angle to painting

surface.

Spray patterns not well overlapped.

Air cap holes partially blocked.

Turn the adjust nut clockwise.

Hold gun at a distance of 15-20 cm surface or

closer for small objects.

Hold gun at right angle to the painting

surface.

Pay attention to the gun movement path.

Determine if obstruction is on air cap or paint

tip by

making a test pattern, rotating air cap half

turn, and spraying another test pattern. If the

de

fect is inverted, obstruction is on air cap.

Spitting or

spraying lumps

Solid particles in paint.

Downward spraying angle more than 90°.

Strain paint.

Do not downward the angle too much.

Motor is

running but no

spray

Paint not thin enough.

Air partition cap missing/dirty.

Loose paint container.

Lid washer missing/dirty.

Motor is running but the trigger

does

not pull the needle.

Loose needle.

Low volume of paint from spray gun.

The needle tip drops from the needle,

so needle tip is jammed tight in spray

tip.

Obstruction on paint tip or dirt on air cap

seat or paint tip seat.

Add the appropriate amount of solvent to the

paint. Add only a small amount of solvent to

the paint at one time.

Replace/clean air partition cap.

Tighten paint container.

Replace/clean lid washer.

Increase pressure on the trigger to pull

needle to shoot paint out.

Tighten needle.

Turn the adjust nut clockwise

,

the release

amount becomes bigger or Clean spray tip &

needle to restart the trigger.

Take out needle tip and install needle tip in

the needle.

Clean air cap with non-metallic instrument. If

obstruction is on paint tip, check for fine

burring which can be removed with 600 wet

or dry sandpaper. For dried paint inside, open

and wash.

Fluttering spray

Jamming needle.

Needle nut not seated properly.

Blocked paint passages or Slide pipe not

seated properly.

Loose slide pipe & switch spring.

Pull and then release trigger quickly

(2

-

3

times) to make sure needle is seated

properly.

Tighten needle nut.

Clean paint passages or Lubricate slide pipe to

make

sure slide pipe is seated properly.

Ensure slide pipe has to clasp

spring

properly.

Paint leaking

from the paint

container

Loose paint container.

Loose lid washer or worn lid washer.

Tighten paint container .

Tighten lid washer or replace lid washer .

Paint leaking

from the nozzle

Loose nozzle.

Needle nut is too tight, so the needle not

seated properly.

Tighten nozzle.

Loosen needle nut.

11

PARTS LIST

ITEM

DESCRIPTION

1. RETAINING NUT

2. AIR CAP

3. AIR PARTITION CAP

4. SPRAY TIP

5. GUN BODY

6. MOTOR LID

7. FILTER

8. MOTOR

9. MOTOR PARTITION

10. GUIDE NUT

ITEM

DESCRIPTION

11. NEEDLE

12. NEEDLE SPRING

13. SLIDE PIPE

14. SPRING FOR SLIDE PIPE

15. TRIGGER

16. SPRING FOR ADJUST NUT

17. PAINT CONTROL NUT

18. HANDLE HOUSING

19. HANDLE SCREW

20. SWITCH

ITEM

DESCRIPTION

21. SCREW FOR WIRE FIXING

22. WIRE FIXING

23. LID WASHER

24. PAINT TUBE

25. LID SCREW NUT

26. PAINT CONTAINER

27. AIR BLOWING NOZZLE

12

The Choice of Spray Tip Set Size (Optional)

* Ø 2.0mm is Included with TM-663A+

Large spray tip sets are for water-based paint (latex paint); small spray tip sets are for oil-based paint.

Website

YouTube

Tsung Mao Ind. Co., Ltd

tsungmao@haupon.com.tw

MADE IN TAIWAN

Rev B 20190322

Installing / Replacing Nozzle & Spray Tip (For TM

-

663A+ Only)

1.

Use one of the included wrenches to loosen the tip and nozzle. (Figure A)

2. Disassemble the spray tip with two wrenches. (Figure B)

3. Use two wrenches to replace with desired tip and nozzle. (Figure B)

(Be caution do not overtighten to prevent needle from breaking)

4. Tighten the nozzle with the included wrench. (Figure C)

Spray Tip Size Recommended Material Air Cap Nozzle

Ø 1.0mm

Ø

1.3mm

Coating, Photocatalyst, Sealer, Lacquer, Adhesive,

Wood paint, Enamel paint

Black

Ø1.5mm Sealer, Lacquer, Red Lead Primer, oil-based paint,

Paint with hardener

Black

Ø2.0mm* Solvent based Waterproof paint, Oil-based paint, Red Lead

Primer, Anti-rust primer, PU paint

Black

Ø2.5mm Latex Paint, Waterproof paint, PU paint, Super Glue, Paint with

hardener, Ready-mixed paint, Wood paint

Blue

Ø3.0mm

Ø

3.5mm

Recycle paint, Faux stone paint, High viscosity paint Blue

Ø

4.0mm

Recycle paint

,

Faux stone paint

,

High viscosity paint

B

lue

This manual suits for next models

1

Table of contents

Other Haupon Paint Sprayer manuals