-

2

-

■

Safety precautions

1. Spark and open flames are strictly prohibited.

Flammable liquids can cause fire.

Avoid any ignition sources such as smoking,

open flames, electrical goods, etc.

Use grounded gun stay.

Ground resistance

:

Less than

1

M

Ω

Check the earth stability periodically.

If not, insufficient grounding can cause fire and

explosion due to static electric sparking.

1. Never point gun toward people or animals.

If done, it can cause inflammation of eyes and

skin or bodily injury.

2. Never exceed maximum operating pressure

and maximum operating Temperature.

3. Be sure to release both air and liquid pressures before cleaning,

disassembling, servicing or job interruption.

If not, remaining pressure can cause bodily injury due to improper

operation or scattering of cleaning liquid.

In order to release pressure, first stop sup compressed air to pressure feed

tank, operate piston of gun to release pressure in liquid hose and stop

compressed air to gun.

4. Tip of fluid needle set has a sharp point.

Do not touch the tip of fluid needle during maintenance for the protection of

the human body.

Protection of human body

1

.

Use in a well-ventilated site by using spray booth.

If not, poor ventilation can cause organic solvent poisoning and start a fire.

2

.

Always wear protective gear

(

safety glasses, mask, gloves

)

.

If not, cleaning liquid, etc., can cause inflammation of eyes and skin.

If you feel something wrong with eyes or skin, immediately see a doctor.

3

.

Wear earplugs if necessary.

Noise level can exceed

85dB

(A), depending on operating conditions and coating site.

Other precautions

1

.

Never alter this spray gun.

If done, it can cause insufficient performance or failure.

2

.

Enter working areas of other equipment (robots, reciprocators, etc.)

after machines are turned off.

If not, contact with them can cause

injury.

3

.

Do not use corrosive liquid (acid and alkali, etc.).

Please confirm adaptability before you use such corrosive liquid (acid,

alkali, and chemicals, etc.). We will submit the material list for such

adaptability examination upon request.

4. Never spray food or chemicals through this gun.

It is not possible to use this gun for food, products absorbed orally such as

medicine, and facilities manufacturing these products.

If done, it can cause accidents due to corrosion inside liquid passages

and health problems by drawing foreign matter.

5. Do not spray liquid which has a direct influence on the health and

growth of human beings, animals and plants due to corrosion and

reaction inside liquid passages.

6

.

If something goes wrong, immediately stop operation and determine the

cause. Do not use again until you have resolved the problem.

■

How to connect

This gun should be operated by adequately trained operators only.

Ensure that the gun has not been damaged during transportation.

-

Use clean air filtered through air dryer and air filter.

・・・

If not, dirty air can cause coating failure.

-

If you use this gun for the first time after purchasing, clean liquid passages and remove rust preventive oil by spraying cleaning liquid.

If not, remaining preventive oil can cause coating failure such as fish eyes.

-

Use three-way solenoid valve with effective cross section of more than

φ

4mm inner dia. area and air hose of over

φ

4mm inner dia. with less than 10m

length. When operate multiple guns, use larger size of solenoid valve cross section and hose inner dia. accordingly.

If not, small dia. of solenoid valve and longer air hose between three-way solenoid valve and gun can cause delay in operation.

Firmly fix hose to spray gun and supply equipment .

・・・

If not, disconnection of hose and falling of container can cause bodily injury

.

Fit the gun to fitting stay, aim at sprayi

ng direction and fix it with fixing bolts

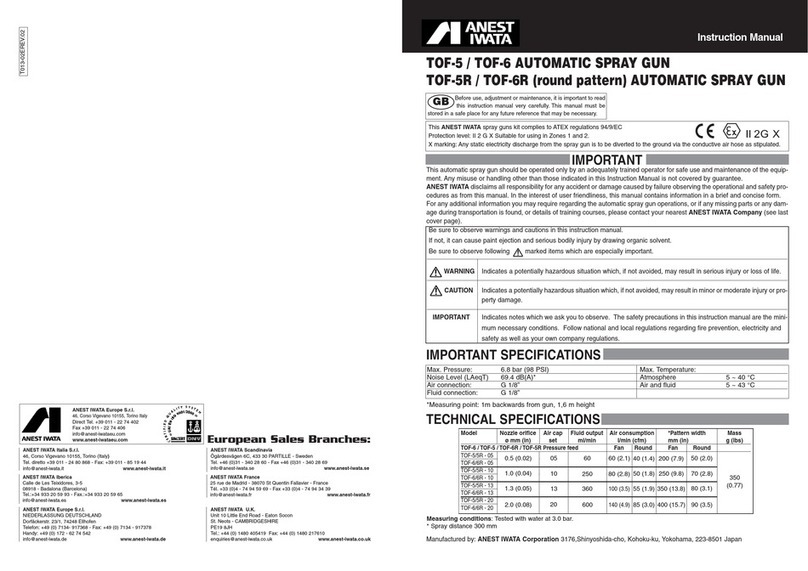

Job 2. Connect atomizing air hose to atomizing air side (AIR marked side) and operating

air hose to operating air side (CYL marked side) tightly.

(As for the TOF-5 type, the piston operates only by connection on the AIR side.)

Connect liquid hose to liquid inlet (LIQUID marked side) tightly.

Job 4. Pour comparable cleaning liquid into container, spray and clean liquid passage.

Job 5. Supply liquid to container, test spray and adjust liquid output, air volume and pattern

width.

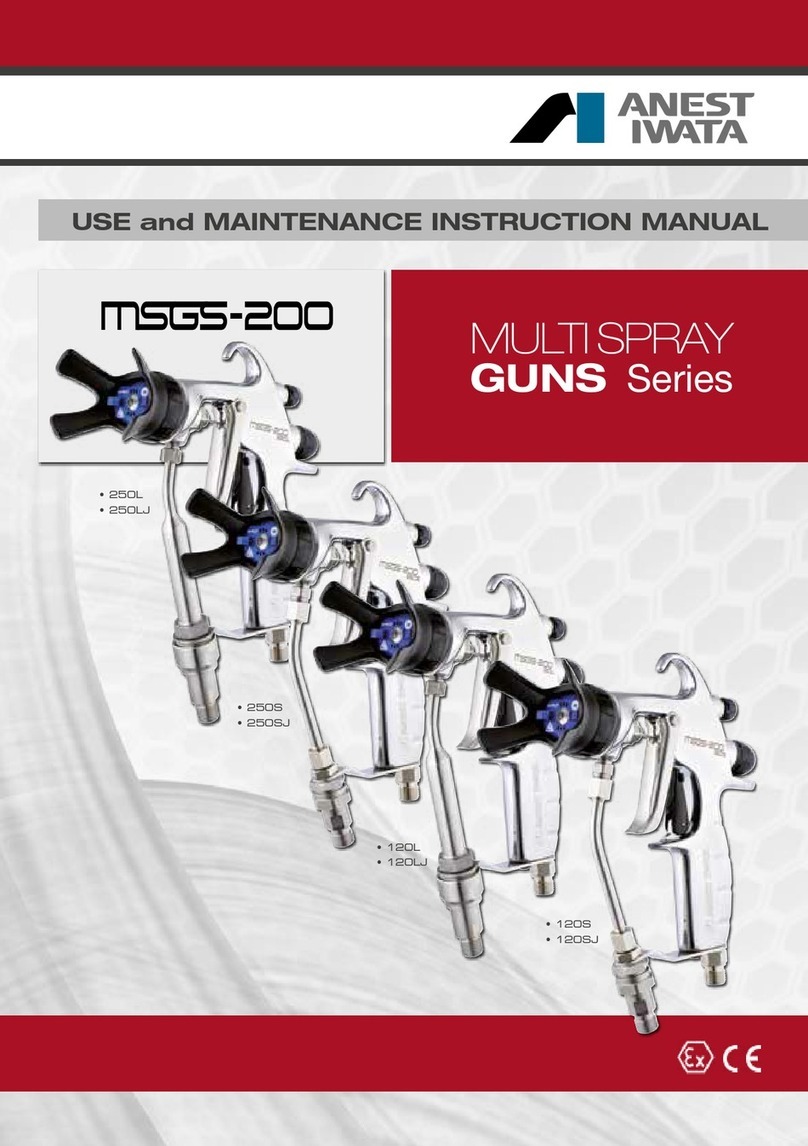

Fire and explosion

Improper use of

equipment

of air hose and liquid hose]

TOF-5B/ 5RB

When you operate three-way valve, both

atomizing air and piston operating air will flow

and spray will start.