Printed in Japan

Mitutoyo Corporation 1-20-1 Sakado, Takatsu-ku, Kawasaki City, Kanagawa 213-8533

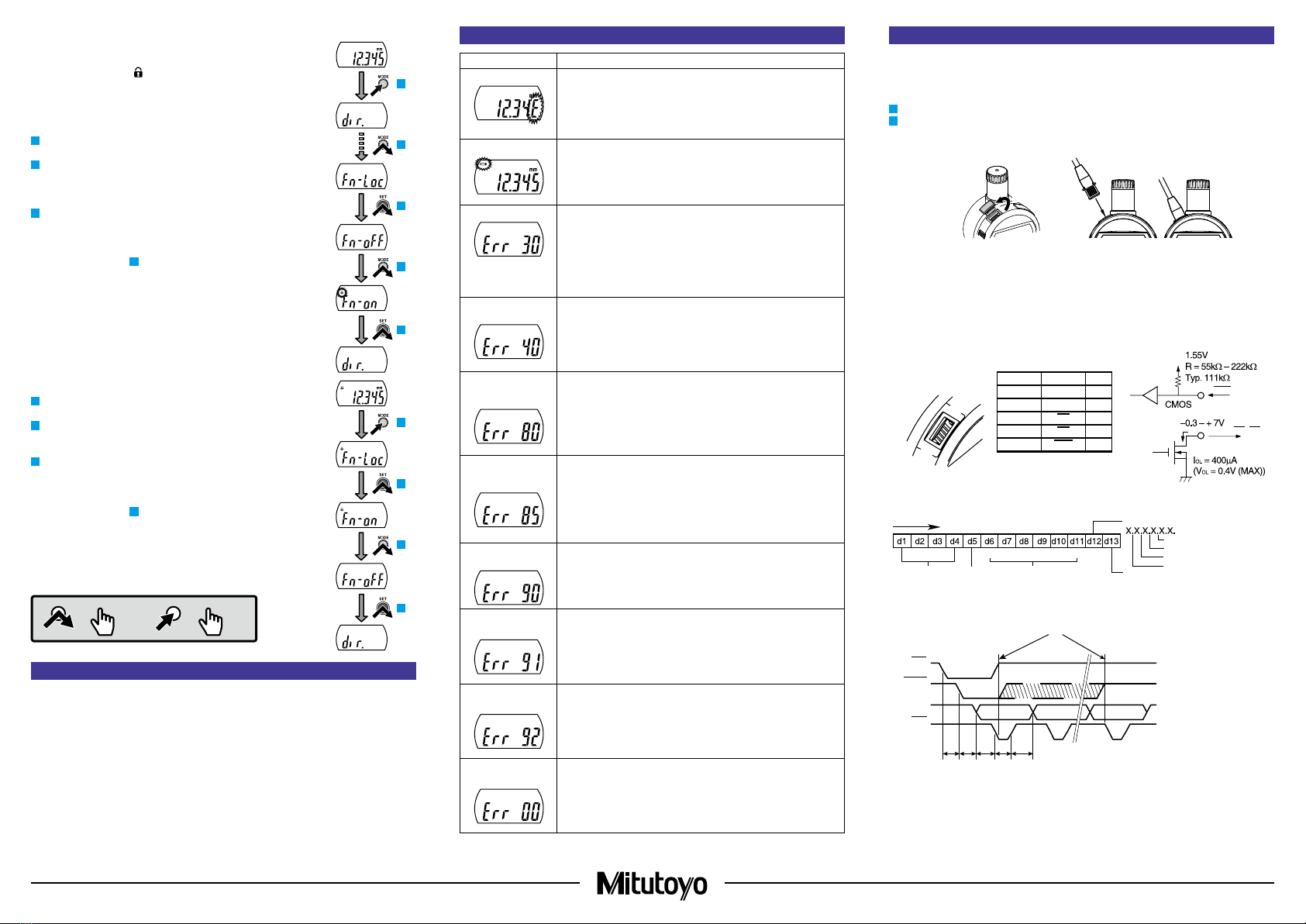

5) Executing/canceling Function Lock function

This product has a Function Lock function which ignores origin

operation in order to avoid accidentally changing the origin. When

function lock is executed, [ ] will appear on the display and operations

other than turning the power on/off, holding/releasing the displayed

value, outputting the displayed value, and canceling the Function Lock

function will be disabled.

●Executing Function Lock function

1Press and hold the [MODE] key to enter parameter setting mode.

⇨Shifts to parameter setting mode.

2Selecting the parameter item to set

1 Press the [MODE] key until [Fn-Loc] is displayed.

2 Press the [SET] key.

⇨Function Lock function can be set.

3Setting the function lock function

1 Press the [MODE] key and select execute (on).

2 Press the [SET] key.

⇨Settings are confirmed; shifts to next parameter item.

(Proceed to step 2in "1) Setting counting direction".)

Tips

• The Function Lock function is executed as soon as parameter

setting is confirmed and the product returns to measurement mode.

•

To set an item for which the function has been locked, first cancel

the Function Lock function

.

●Canceling Function Lock function

1Press and hold the [MODE] key to enter parameter setting mode.

⇨Shifts to parameter setting mode [Fn-Loc].

2Press the [SET] key to confirm the parameter item (function lock)

to set.

⇨Function Lock function can be set.

3Setting the function lock function

1 Press the [MODE] key and select cancel (oFF).

2 Press the [SET] key.

⇨Settings are confirmed; shifts to next parameter item.

(Proceed to step 2in "1) Setting counting direction".)

Key icon operation

=

> 2 s

=

< 1 s

11. Precautions After Use

• When cleaning, wipe this product with a soft cloth moistened with diluted neutral detergent. Do not

use an organic solvent such as thinner, which may cause the product to deform or malfunction.

•

Dirt on the spindle may lead to malfunction. Clean with a cloth moistened with alcohol, etc. before use.

• Do not lubricate the spindle with lubricating oil, etc.

• If the product is to be out of use for 3 months or more, remove the battery before storage. Liquid

leakage from the battery may damage the product.

• Do not store the product in a place with a high temperature or humidity, or a lot of dust or oil mist.

1

3

2

2

3

1

2

3

3

12. Error Displays and Countermeasures

Error Display Causes and Countermeasures

ABS Synthesis Error Although this may be momentarily displayed while the spindle is

moving, it is a normal artifact of internal processing. If it occurs while

the spindle is not moving, the internal sensor has failed.

In this case, repair is required: contact your dealer or agent or our

sales office.

Low Battery Voltage

Battery is depleted.

Replace with a new battery.

Display Overflow

The measured value exceeds the number of digits that can be displayed.

• In ABS, press the [SET] key to enter the origin setting and reset (re-

preset) the origin.

•

I

n INC, press the [SET] key at the appropriate position and set to zero.

• Press and hold the [MODE] key to enter parameter setting mode

and change the resolution to an appropriate value. (0.001 mm or

0.00005 in models only)

Sensor Contamination

Detection Error A sudden change in temperature may create condensation on the

detector, or it may be contaminated by other sources.

• Turn the power off and allow the product to adapt to the temperature

for about 2 hours.

• If it does not recover after adapting to the temperature, repair is

required: contact your dealer or agent or our sales office.

Preset Value Setting

Error (Normal

Measurement)

The preset value set for normal measurement exceeds the number of

digits that can be displayed.

• Press and hold the [SET] key to return to preset value settings, and

then reset to an appropriate value.

• Press the [SET] key to return to measurement mode, and then

switch to an appropriate resolution in parameter setting mode.

(0.001 mm or 0.00005 in models only)

Preset Value Setting

Error (Calculation

Measurement)

The preset value set for calculation measurement exceeds the

number of digits that can be displayed.

• Press and hold the [SET] key to return to preset value settings, and

then reset to an appropriate value.

• Press the [SET] key to return to measurement mode, and then

switch to an appropriate resolution in parameter setting mode.

(0.001 mm or 0.00005 in models only)

Tolerance Limit Value

Setting Error The upper limit is set below the lower limit.

• Press the [SET] key to return to the tolerance limit value settings,

and then reset so that the upper limit is above the lower limit.

Upper Limit Setting

Error The upper limit exceeds the number of digits that can be displayed.

• Press and hold the [SET] key to return to upper limit settings, and

then reset to an appropriate value.

• Press the [SET] key twice to enter resolution settings, and then switch

to an appropriate resolution. (0.001 mm or 0.00005 in models only)

Lower Limit Setting

Error The lower limit exceeds the number of digits that can be displayed.

• Press and hold the [SET] key to return to lower limit settings, and

then reset to an appropriate value.

• Press the [SET] key to enter resolution settings, and then switch to

an appropriate resolution. (0.001 mm or 0.00005 in models only)

Calculation Coefficient

Setting Error The calculation coefficient is set to 0.0000.

• Press and hold the [SET] key to return to calculation coefficient

settings, and then reset the calculation coefficient to a value other

than 0.0000.

13. Output Function

1) Externally outputting the displayed value

The product can be connected to an optional external display, external printer, PC, etc. The

displayed value can be output to a device supporting Digimatic output format by connecting the

product and the external device with a connection cable (optional).

1Press the [ON/OFF] key to turn off the product.

2Connecting the product and the external device

1. Remove the cap of the output connector of the product.

2. Connect the product and the external device with a connection cable.

12

Cap

Connection

cable

Tips

• Two types of connection cables (optional), part No. 905338 (1 m) and part No. 905409 (2 m),

are available for this product.

• When connecting a connection cable, pay attention to the connector direction as you insert it.

• Store the removed cap to prevent loss.

• Always install the cap if a connection cable is not used.

2) Output connector

3) Output data format

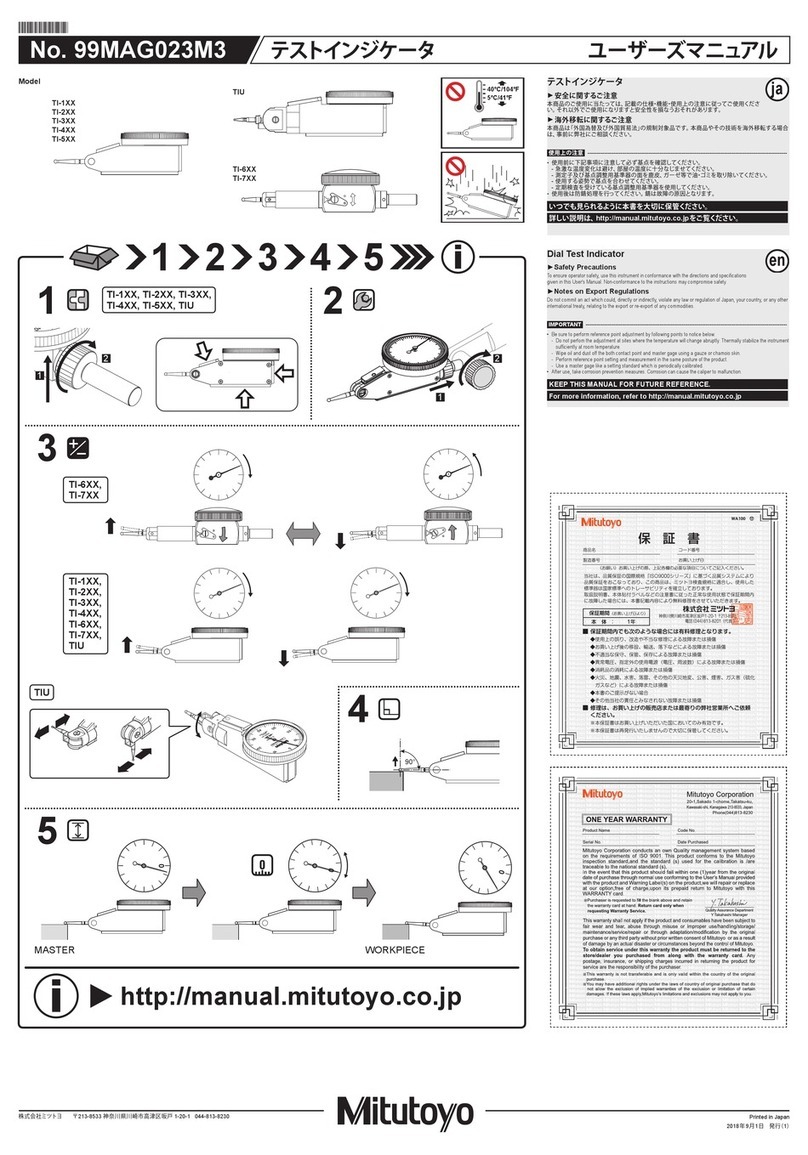

(1) Output order

(2) All "F"

(3) Sign

(4)

Measured value

(5)

Decimal point

(6) Unit

4) Timing chart

10 ms ≤ t1 < 150 ms

0.1 ms ≤ t2 < 0.2 ms

0.1 ms ≤ t3 < 0.2 ms

0.05 ms ≤ t4 < 0.2 ms

t5 depends on the device

being used.

*1 Keep REQ at Low until CK is output.

Return it to High before the final CK output is completed (52nd bit).

REQ

DATA, CK, RD

(1)

(5)

Pin No. Signal I/O

(1) GND -

(2) DATA O

(3) CK O

(4) RD O

(5) REQ I

・Input

・Output

MSD LSD

(2) (4)

(3)

+: 0(0000)

2(0100

3(1100)

4(0010

5(1010

(6)

mm:0(0000)

RD

REQ

CK

t5 t1 t2 t3 t4

1bit 2bit 52bit