Read this installation manual completely to ensure proper installation, then file it with the owner or

maintenance department. Compliance and conformity to drain requirements and other local codes

and ordinances is the responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for before discarding any

packaging material. If any parts are missing, do not begin installation until missing parts are

obtained.

This unit must be fastened to the floor. It is recommended that this unit be installed in an area that

has a hard surface that can accommodate floor fasteners.

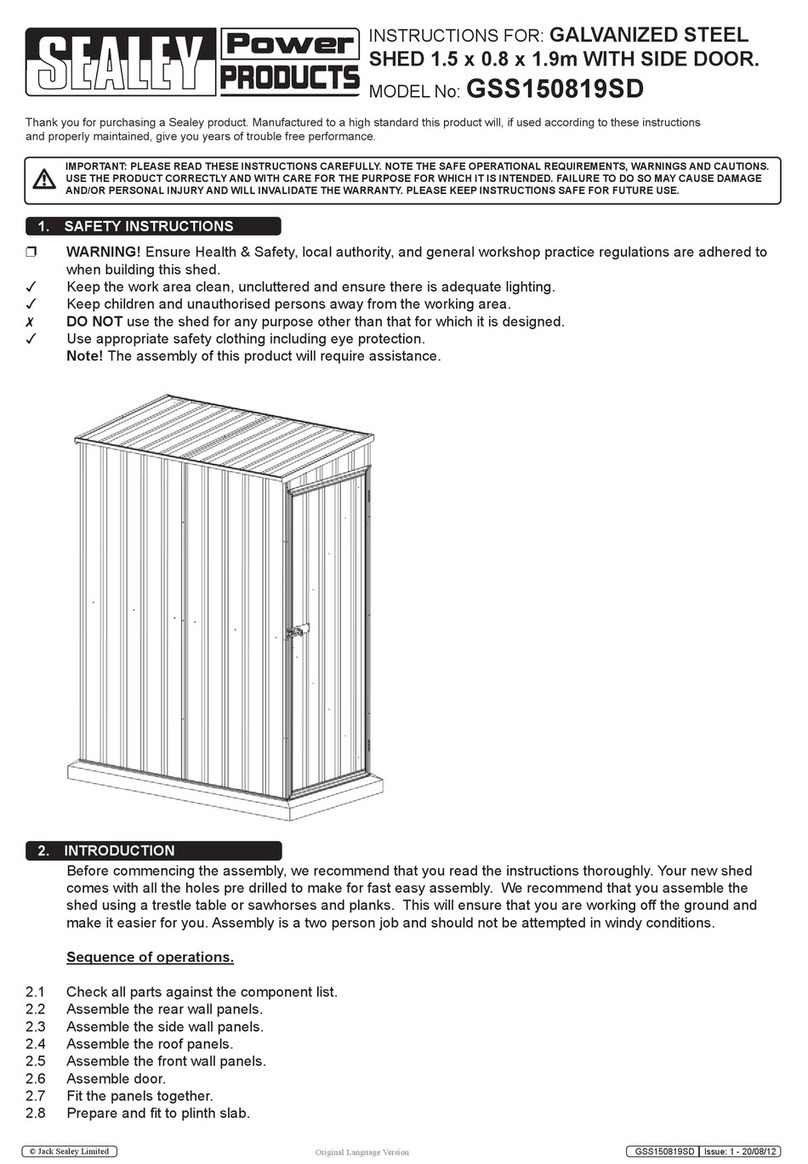

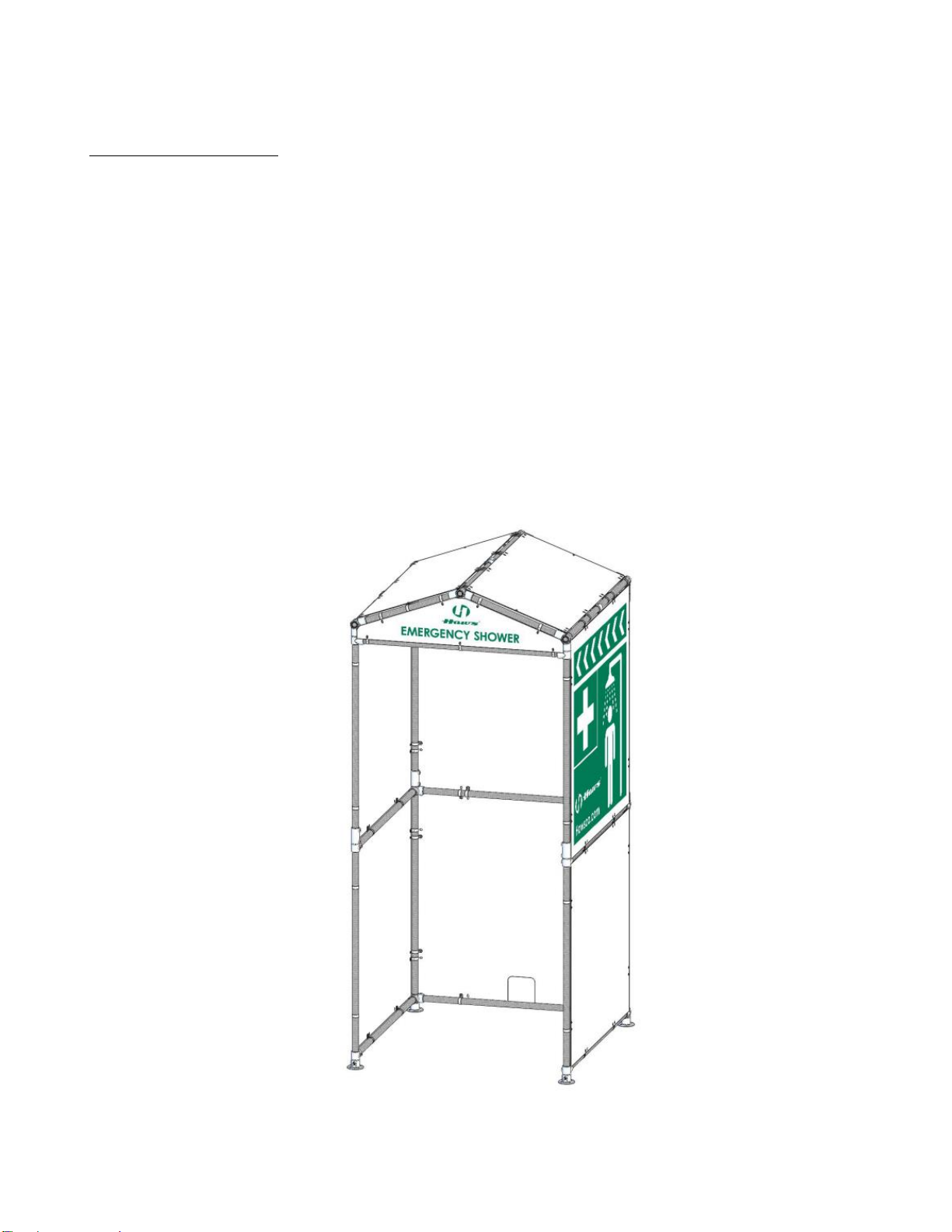

DESCRIPTION OF PRODUCT

Haws Corporation Model 9035 Shower Shelter (with Privacy Curtain option).

Not part of any Certified model. Not Certified on its own.

Haws Model 9035 can be installed indoors or outdoors. Its usage intention is weather and privacy

protection.

SHIPPING, HANDLING AND STORAGE

Recommended Equipment, Materials, and Supplies to be provided by Installer:

•Existing slab on grade. The installer shall verify that the following minimum requirements of the

existing slab-on-grade are satisfied.

oAllowable Soil Bearing Pressure: 1500 psf

oSlab-on-grade minimum thickness: 6 inches

oCompressive Strength of slab, f’c: 3000 psi

oAdequate footprint area (minimum 6’ x 6’ recommended)

oAdequate vertical space (minimum 14.5 ft. recommended, 13 ft. required)

•Recommended anchors (Not Included, customer to determine anchor suitability):

High strength adhesive anchors (ICC-ES Report ESR-3187): Hilti HIT-HY 200 Safe Set epoxy

adhesive anchorage system and Hilti hollow drill bit system with 5/8” diameter Hilti HIT-Z Rod,

2 ASTM F844 flat washers, and ASTM A563 Grade A nuts. Floor Flanges have four (4) 5/16”

diameter clearance holes (16 total).

Hilti specifies 3-3/4” minimum embedment depth per HIT-Z specifications. A forklift capable of

safely lifting and maneuvering this product should be utilized to transport the unit from truck to

site.