HBK Z30A User manual

Z30A

ENGLISH DEUTSCH

Mounting Instructions

Montageanleitung

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-0111.0007

DVS: A02076 01 X00 03

05.2022

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Z30A

ENGLISH DEUTSCH

Mounting Instructions

Z30A

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 3................................................

2 Markings used 5....................................................

2.1 The markings used in this document 5.................................

2.2 Symbols on the product 5............................................

3 Scope of supply 6...................................................

4 Application notes 7.................................................

5 Structure and mode of operation 8....................................

5.1 Measuring body 8...................................................

5.2 Housing 8.........................................................

5.3 Disturbance variables 8..............................................

6 Conditions on site 9.................................................

6.1 Ambient temperature 9..............................................

6.2 Moisture 9.........................................................

6.3 Air pressure 9......................................................

6.4 Chemical effects 9..................................................

7 Mechanical installation 10............................................

7.1 Important precautions during installation 10..............................

7.2 General installation guidelines 10.......................................

7.3 Mounting accessories for tensile/compressive loading 10..................

7.3.1 Installation drawing for compressive loading 14..........................

8 Electrical connection 15..............................................

8.1 Instructions for cabling 15.............................................

8.2 Pin assignment 15...................................................

8.3 TEDS transducer identification 16......................................

9 Specifications 17....................................................

10 Dimensions Z30A 20.................................................

3

Z30A

SAFETY INSTRUCTIONS

1 SAFETY INSTRUCTIONS

Use in accordance with the regulations

Z30A type force transducers are used for high‐precision force measurements and for

force reference measurements (transfer standard). Use for any additional purpose shall

be deemed to be not in accordance with the regulations.

In the interests of safety, the transducer should only be operated as described in the

Mounting Instructions. It is also essential to observe the appropriate legal and safety

regulations for the application concerned during use. The same applies to the use of

accessories.

The transducer is not a safety element within the meaning of its use as intended. Proper

and safe operation of this transducer requires proper transportation, correct storage,

assembly and mounting and careful operation and maintenance.

General dangers of failing to follow the safety instructions

The Z30A force transducer corresponds to the state of the art and is fail‐safe. The

transducers can give rise to remaining dangers if they are inappropriately installed and

operated by untrained personnel.

Everyone involved with the installation, commissioning, maintenance or repair of a force

transducer must have read and understood the Mounting Instructions and in particular

the technical safety instructions.

Remaining dangers

The scope of supply and performance of the transducer covers only a small area of force

measurement technique. In addition, equipment planners, installers and operators should

plan, implement and respond to the safety engineering considerations of force

measurement technique in such a way as to minimise remaining dangers. Prevailing

regulations must be complied with at all times. There must be reference to the remaining

dangers connected with force measurement technique.

Prohibition of own conversions and modifications

The transducer must not be modified from the design or safety engineering point of view

except with our express agreement. Any modification shall exclude all liability on our part

for any damage resulting therefrom.

Qualified personnel

These transducers are only to be installed by qualified personnel strictly in accordance

with the technical data and with the safety rules and regulations which follow. It is also

essential to observe the appropriate legal and safety regulations for the application

concerned. The same applies to the use of accessories.

Z30A

SAFETY INSTRUCTIONS

4

Qualified personnel means persons entrusted with the installation, fitting, commissioning

and operation of the product who possess the appropriate qualifications for their

function.

Conditions on site

Protect the transducer from damp and weather influences such as rain, snow, etc.

Maintenance

The Z30A force transducer is maintenance free.

Accident prevention

Although the specified nominal force in the destructive range is several times the full

scale value, the relevant accident prevention regulations from the trade associations

must be taken into consideration.

5

Z30A

MARKINGS USED

2 MARKINGS USED

2.1 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

WARNING This marking warns of a potentially dangerous situ

ation in which failure to comply with safety require

ments can result in death or serious physical injury.

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important

This marking draws your attention to important in

formation about the product or about handling the

product.

Tip

This marking indicates application tips or other

information that is useful to you.

Information

This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

2.2 Symbols on the product

CE mark

The CE mark enables the manufacturer to guarantee that the

product complies with the requirements of the relevant EU direc

tives (the declaration of conformity is available at

http://www.hbm.com/HBMdoc

).

Z30A

SCOPE OF SUPPLY

6

3 SCOPE OF SUPPLY

SForce transducer Z30A

SOperating Manual Z30A

Accessories (not included in the scope of supply)

SDKD calibration certificate according to ISO 376

Order no. K-CAL-FD

(Class 00 according to DIN EN10002-3 resp. ISO376 guaranteed

SKnuckle eyes ZGW/ZGOW

for 50 N to 1000 N: Order no. 1-U1R/200kg/ZGW

for 2 kN to 10 kN: Order no. 1-U2A/1t/ZGUW

SThrust piece

(recommended for precision measurements, for example ISO 376-Calibrations)

for 50 N to 1000 N Order no. 1-EDO3/1kN

for 2 kN to 10 kN Order no. 1-EDO4/50kN

SLoad button for compressive load

for 50 N to 1000 N: Order no. 1-U1R/200kg/ZL

for 2 kN to 10 kN: Order no. 3-9202.0140

SCable/plug

Order number Description

1-KAB139A-6 Kab 139A-6 connection cable , 6m, with Binder cable socket

and free ends

K-CAB-F Connection cable, freely configurable (cable length, plug at

amplifier end, etc.)

STransport case

for four Z30A force transducers and accessories

Order no. 1-Z30/Box

7

Z30A

APPLICATION NOTES

4 APPLICATION NOTES

Force transducer Z30A

Series Z30A precision force transducers measure tensile and compressive forces.

They measure static and quasi‐static forces with great accuracy and reproducibility and

therefore require judicious handling. You must be particularly vigilant when transporting

and installing the devices. If the transducers are dropped or jolted, permanent damage

could be caused.

Z30A force transducers complete with DKD certificate from HBM

Force transducer calibrated to guaranteed class 00 according to ISO 376.

As standard these transducers are calibrated in the tensile direction. On request they can

also be calibrated in the compressive direction to DKD standards.

The limits for permissible mechanical, thermal and electrical stresses are stated in the

specifications. Be sure to allow for them when planning, installing and operating the

measurement configuration .

Z30A

STRUCTURE AND MODE OF OPERATION

8

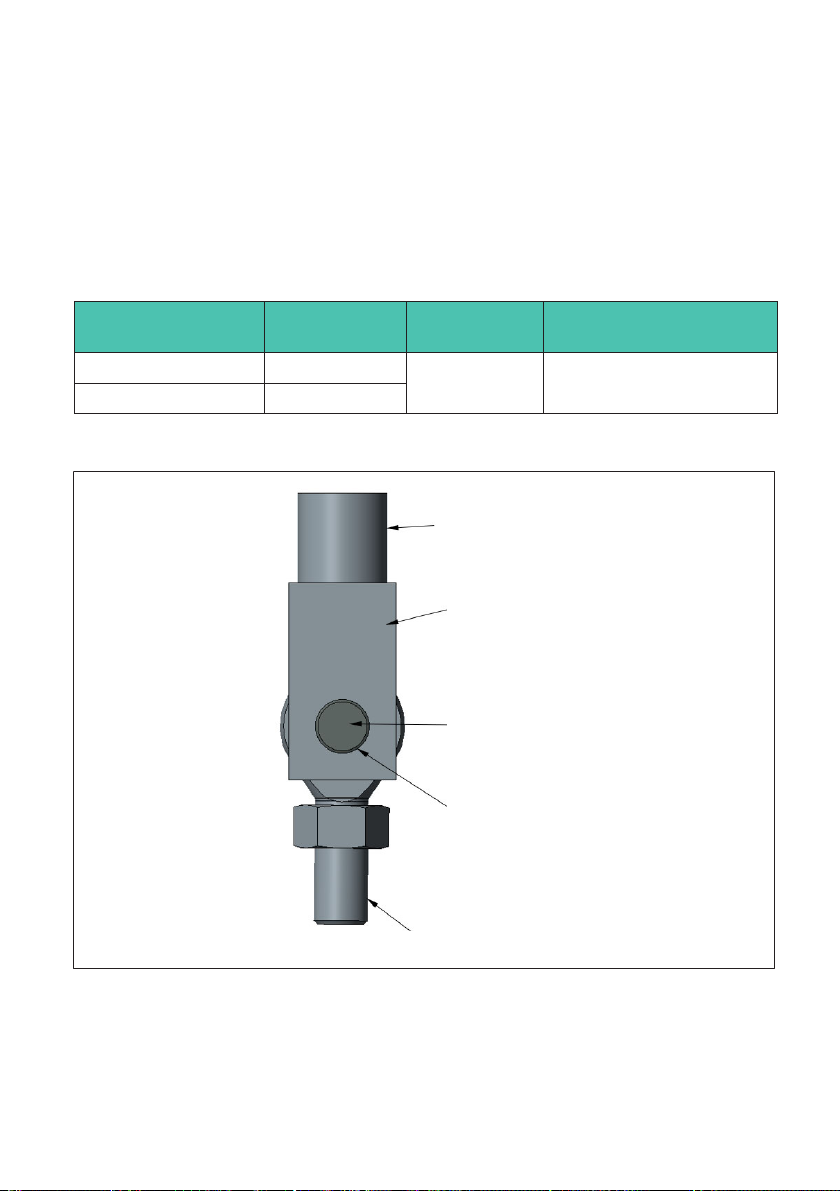

5 STRUCTURE AND MODE OF OPERATION

5.1 Measuring body

The measuring body comprises a system of measuring body with strain gages (double

bending beam principle).

5.2 Housing

The enclosure provides protection against splashes and minor impacts (IP50 degree or

protection per DIN EN60529).

5.3 Disturbance variables

Torsion, bending and transverse loads are disturbance variables and are therefore to be

avoided. If necessary they can be remedied with HBM mounting accessories (see

chapter 7.3 ).

9

Z30A

CONDITIONS ON SITE

6 CONDITIONS ON SITE

6.1 Ambient temperature

The effects of temperature on the zero signal and on the sensitivity are compensated. To

achieve optimal measurement results the nominal temperature range must be

maintained. Temperature‐induced measurement errors can be caused by uneven cooling

or heating (for example by radiant heat). A radiation shield and all‐round heat insulation

bring about marked improvements. They must not form a force shunt.

6.2 Moisture

Extreme humidity or a tropical climate should be avoided if this means that the classified

limit values are exceeded (degree of protection IP50 under DIN EN 60529).

6.3 Air pressure

Changes in air pressure have no effect on the force transducer since it is not hermetically

sealed.

6.4 Chemical effects

The aluminium enclosure of the transducer is protected by a powder coating. If used in

difficult environmental conditions (direct weather effects, contact with media which

encourage corrosion) additional protective measures should be employed by the user.

Z30A

MECHANICAL INSTALLATION

10

7 MECHANICAL INSTALLATION

7.1 Important precautions during installation

Streat the transducer gently

Sif measuring compressive forces, make sure there is a solid support structure

Sthe force‐introduction surfaces must be scrupulously clean and fully load‐bearing

Skeep to the depths of engagement for threaded rods or knuckle eyes

Sdo not overload the transducer.

WARNING

If there is a risk of breakage through overload on the transducer and thus a risk to persons,

additional safety measures are to be taken.

7.2 General installation guidelines

The measurement direction in which forces act on the transducer must be as precise as

possible.

WARNING

Torsion and bending moments, eccentric loading and transverse forces result in measure

ment errors and if limit values are exceeded, could destroy the transducer.

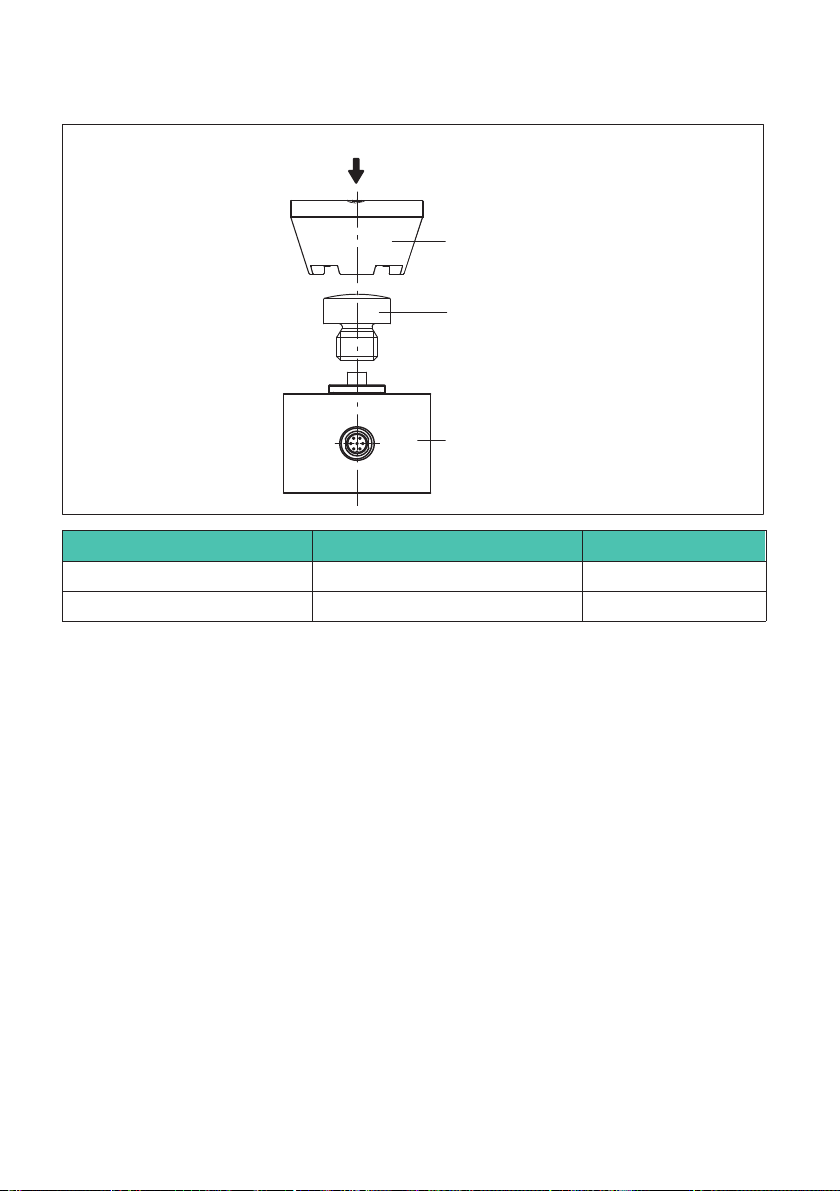

7.3 Mounting accessories for tensile/compressive loading

Knuckle eyes are available for installing with the Z30A (see page 24). These mounting

accessories prevent the introduction of torsional moments into the transducer. Using two

knuckle eyes will also exclude bending moments, shear loading and eccentric loading.

Knuckle eyes are mainly provided to deal with static tensile loading on the transducer.

For dynamic loading, Z30A transducers must be installed free from play. Knuckle eyes

have only limited application in the case of dynamic loading, since alternating dynamic

stress increases the play in the universal joints and falsifies the measured value. It also

produces a self‐amplifying load cycle which can destroy the knuckle eyes. The breaking

force is only 150% Fnom.

Thrust pieces EDO3/1kN or EDO4/50kN (see page 26) and two load buttons (see page

25) are available for introducing compressive forces.

11

Z30A

MECHANICAL INSTALLATION

Notes on mounting with knuckle eyes

1. Shaft diameter

When using a sensor with knuckle eyes mounted on one or both sides, make sure that the

shaft is the right size.

You will find the diameters of the knuckle eyes, suitable shafts and their recommended

tolerances in the table below

Knuckle eye Z30A

Knuckle eyes Nominal

diameter

Hole fitting

size

Recommended shaft

fitting size

1-U1R/200kg/ZGW 8 H7 g6

1-U2A/1t/ZGUW 12

Tab. 7.1 Recommended fitting sizes/tolerances for shaft and hole

Customer's construction

Customer's shaft holder

Shaft

Play based on recommended fitting

size, see Tab. 7.1 page 11

Threaded connector for mounting

on force transducers

Fig. 7.1 Example diagram of installation with knuckle eye

Z30A

MECHANICAL INSTALLATION

12

CAUTION

If a shaft with an overly small diameter is used, the bearing of the knuckle eye will be

subjected to linear load. This subjects the inner bearing shell to excessive load, which can

lead to damage and, if forces are high, can cause the knuckle eye bearing to break.

Select the shaft as recommended in the mounting instructions.

2. Distance between knuckle eye and shaft bearing

The shaft support must allow for suitable play between the knuckle eye and the shaft

bearing.

CAUTION

If there is too much distance between the knuckle eye and the shaft bearing, this generates

bending moments in the shaft, causing it to deform.

This deformation puts strain on points of the edges of the inner bearing shell, which can

cause the knuckle eye or shaft to suffer damage or break.

Select the play as recommended in the mounting instructions.

To determine the play between the knuckle eye and the shaft bearing, you can apply the

following rule of thumb:

Shaft diameter Play between knuckle eye and bearing

<30 mm 1/10 of the nominal diameter

Tab. 7.2 Rule of thumb for determining play between knuckle eye and shaft bearing

Based on this, recommendations for the play between the knuckle eye and shaft bearing

are as follows:

Knuckle eye Play between knuckle eye and shaft bearing

1-U1R/200kg/ZGW 0.8mm

1-U2a/1t/ZGUW 1.2mm

Tab. 7.3 Recommendations for play between knuckle eye and shaft bearing

13

Z30A

MECHANICAL INSTALLATION

Customer's construction

Customer's shaft holder

Recommended play,

see Tab. 7.3, page 12

Threaded connector for mounting

on force transducers

Shaft

Fig. 7.2 Example diagram of installation with knuckle eye

3. Shaft surface quality and hardness

The recommended surface roughness is ≤10 μm.

The shaft must have a minimum hardness of 50 HRC.

Z30A

MECHANICAL INSTALLATION

14

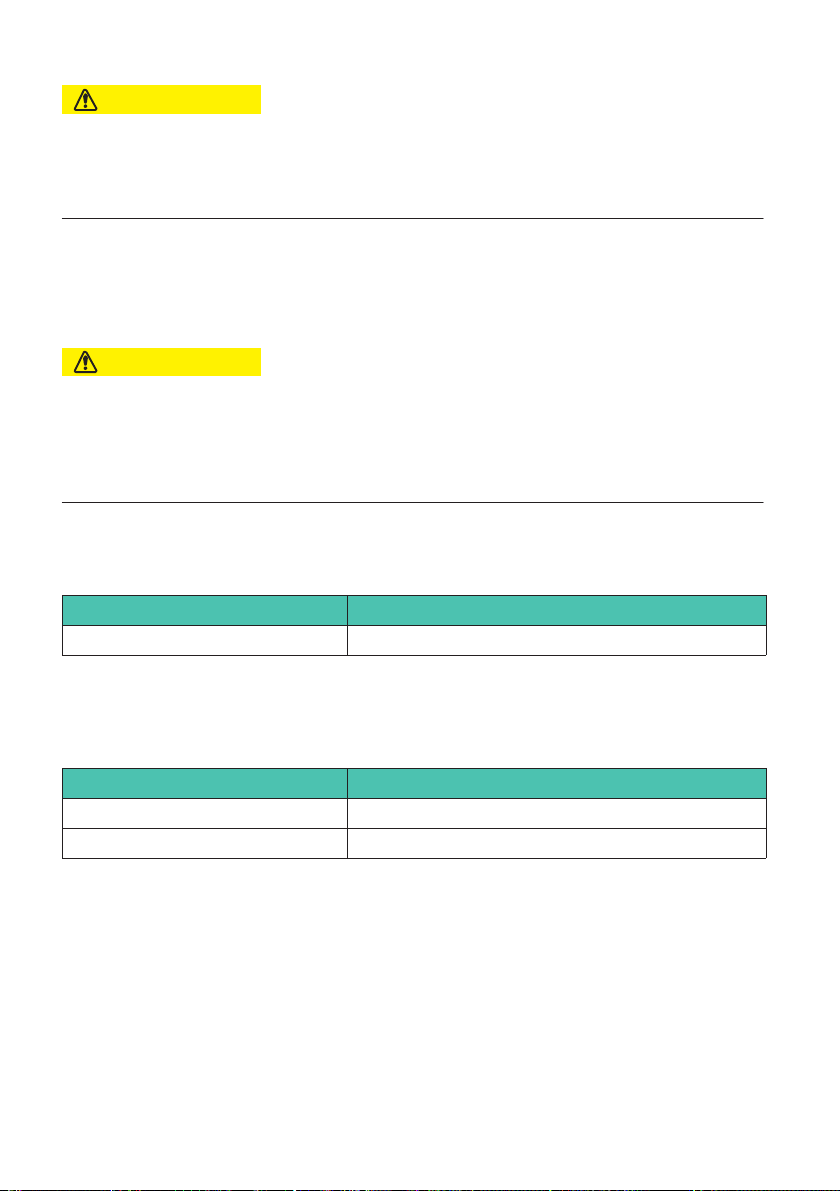

7.3.1 Installation drawing for compressive loading

F

Thrust piece

Load button

Transducer

Type Load button Thrust piece

Z30A/50N - 1000N 1-U1R/200kg/ZL 1-EDO3/1kN

Z30A/2kN - 10kN 3-9202.0140 1-EDO4/50kN

15

Z30A

ELECTRICAL CONNECTION

8 ELECTRICAL CONNECTION

8.1 Instructions for cabling

SAlways use shielded, low‐capacity measurement cable (HBM cables meet these

requirements).

SDo not lay measurement cable parallel to high‐voltage power lines or control circuits.

If this is not possible (e.g. in cable ducts) protect the measurement cable, e.g. with

armoured steel tube and maintain a minimum distance of 50 cm from the other

cables. High‐voltage power lines and control lines should be twisted (15 turns per

meter).

SAvoid stray fields of transformers, motors and contactors.

SDo not earth transducer, amplifier and display device more than once. All the devices

in the measurement chain are to be connected to the same earthed conductor.

SThe screen of the connection cable is connected to the transducer housing.

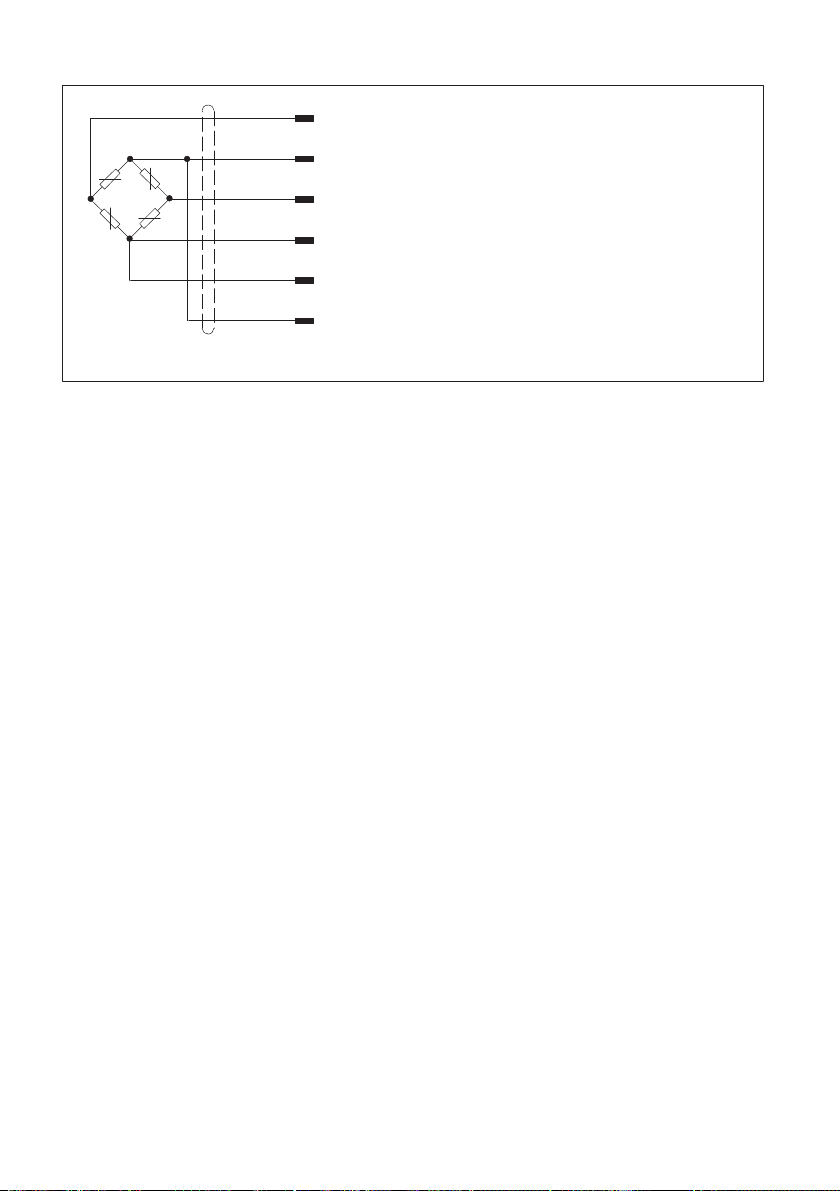

8.2 Pin assignment

Two 7‐pin male device connectors are located on the enclosure (male connectors, Series

723). To avoid creating force bypasses through the cable, you can use either the lower or

the lateral connector, depending on the configuration.

If the transducer is connected according to the following connection diagram then when

the transducer has compressive loading the output voltage at the measuring amplifier is

positive.

Pin on

Binder plug

Assignment

61

572

43

Binder series 723

Top view 1Measurement signal (+)

2Excitation voltage (-) (TEDS)

3Excitation voltage (+)

4Measurement signal (-)

5No function

6Sensor circuit (+)

7Sensor circuit (-) (TEDS)

Fig. 8.1 Male connector, series 723 (screwed)

Z30A

ELECTRICAL CONNECTION

16

WH (white)

BK (black)

RD (red)

BU (blue)

GN (green)

GY (grey)

Measurement signal (+) UA

Excitation voltage (+) UB

Sensor circuit (-) (TEDS)

Sensor circuit (+)

Excitation voltage (-) UB(TEDS)

Measurement signal (-) UA

Cable shield, connected to housing

Fig. 8.2 Pin assignment of plug and KAB139A-6 connection cable

8.3 TEDS transducer identification

TEDS stands for ”Transducer Electronic Data Sheet”.

An electronic data sheet is stored in the transducer as defined in the IEEE 1451.4

standard, making it possible for the measuring amplifier to be set up automatically. A

suitably equipped amplifier imports the transducer characteristics (electronic data

sheet), translates them into its own settings and measurement can start.

At connection PIN 7 (to ground at PIN 2), there is a digital identification system available.

The basis for this is a 1‐wire EEPROM DS2433, from Maxim/Dallas.

HBM provides you with the TEDS Editor for storing your data. This is included in the

software for the MGCplus Setup Assistant (see TEDS operating manual “TEDS-module in

transducer” on our website at ww.hbm.com/TEDS).

The Editor also makes it possible to manage the different user rights, to protect the

fundamental transducer data from being inadvertently overwritten.

17

Z30A

SPECIFICATIONS

9 SPECIFICATIONS

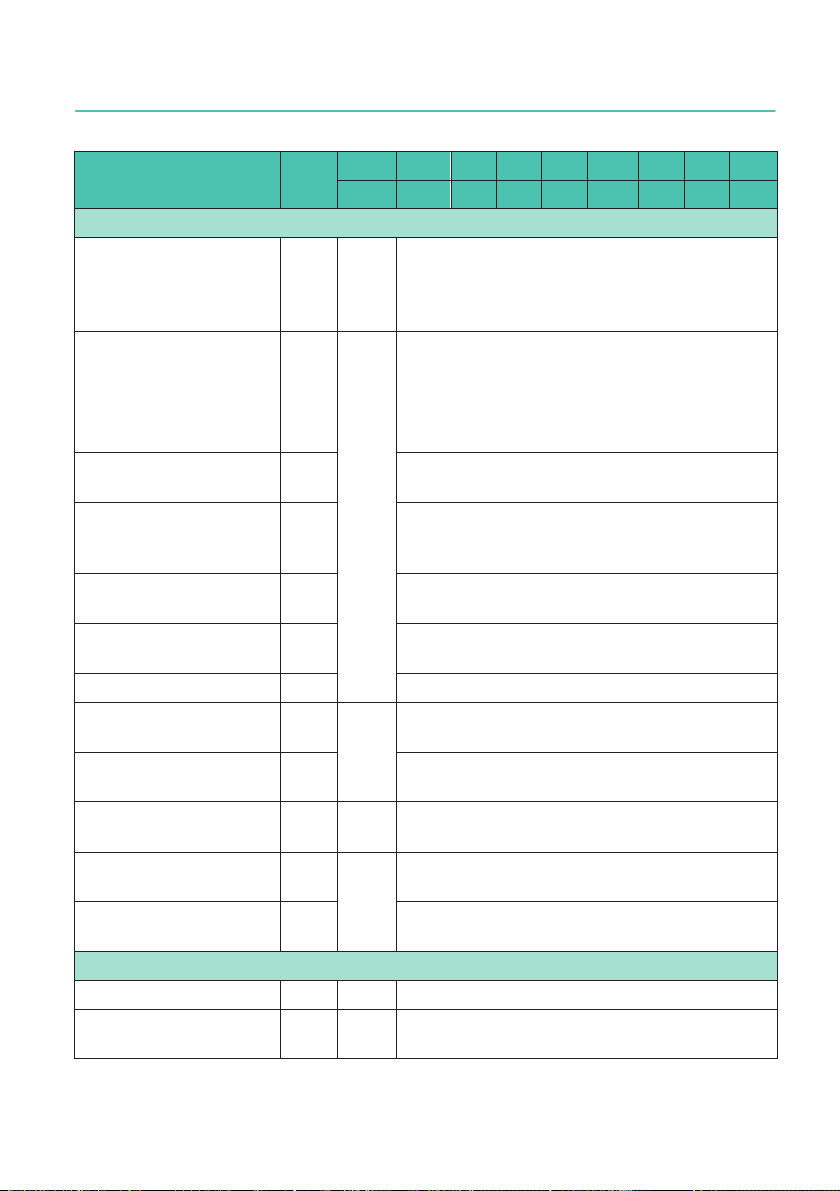

Nominal (rated) force Fnom

N50 100 200 500 1000

kN 2 5 10

Accuracy values per ISO376

Accuracy information

in accordance with

ISO376 in the force

range of 20 % to 100 %

001)

Rel. reproducibility and

repeatability errors

(0.2Fnom to Fnom)

For a constant mount

ing position

b'

%

<±0.02

For varying mounting

positions b <±0.04

Rel. deviation from the

fitting curve (0.2Fnom

to Fnom)

fc<±0.02

Rel. zero error (zero

signal return) fo<±0.008

Rel. reversibility error

(0.2Fnom to Fnom)v <±0.06

Rel. non-linearity dlin <±0.03

Temperature coeffi

cient of sensitivity TCS%/

10K

<±0.02

Temperature coeffi

cient of zero signal TC0<±0.02

Rel. creep over 30

mins.

dcrF+

E% <±0.03

Effect of lateral forces

(lateral force 10% Fnom)dQ

%

<±0.03

Effect of eccentricity

per mm dE<0.03

Rated electrical output

Nominal (rated) output Cnom mV/V 2

Rel. sensitivity error

(pressure) dc% <±0.1

Z30A

SPECIFICATIONS

18

100050020010050N

Fnom

Nominal (rated) force

1052kN

Fnom

Nominal (rated) force

Rel. rated output varia

tion (tension/compres

sion)

dzd % <±0.1

Rel. zero signal

deviation ds,o mV/V <±0.2 <±0.1

Input resistance Re

Ω

>345 >690

Output resistance Ra300 … 500 600 … 800

Insulation resistance Ris >5·109

Reference excitation

voltage Uref

V

5

Operating range of the

excitation voltage BU,G 0.5 … 12

Temperature

Reference temperature tref

°C

+22

Nominal (rated)

temperature range

Bt,no

m+10 … +40

Operating temperature

range Bt,G -10 … +70

Storage temperature

range Bt,S -25 … +85

Characteristic mechanical quantities

Max. operating force FG

%

120 150

Force limit FL150

Breaking force FB250

Static lateral force limit FQ100 75 35 100 90 40

Torque limit MGN·m 1.5 3 5 5 5 80

Nominal (rated)

displacement Snom mm < 0.4 approx. 0.2

Fundamental frequency fGkHz 0.2 0.3 0.5 0.9 1.1 1.1 1.1 1.25

Rel. permissible oscil

lation stress Frb % 70

General information

Degree of protection in

accordance with

EN 60529

IP50

Other manuals for Z30A

1

Table of contents

Languages:

Other HBK Test Equipment manuals