RCDTesting 6

RCD testing

1. ON/OFF - Pressing and releasing this button turns the DRC 430 on

and off (intelligent auto Power Off is also incorporated).

2. When the DRC 430 is first connected to a live socket it will automatically

test the socket wiring to establish that the circuit wires have been

connected to the correct terminals on the back of the socket. If all three

LED’s light GREEN and no sound is emitted the wiring status is correct and

you can proceed to the incoming supply polarity test (step 3).

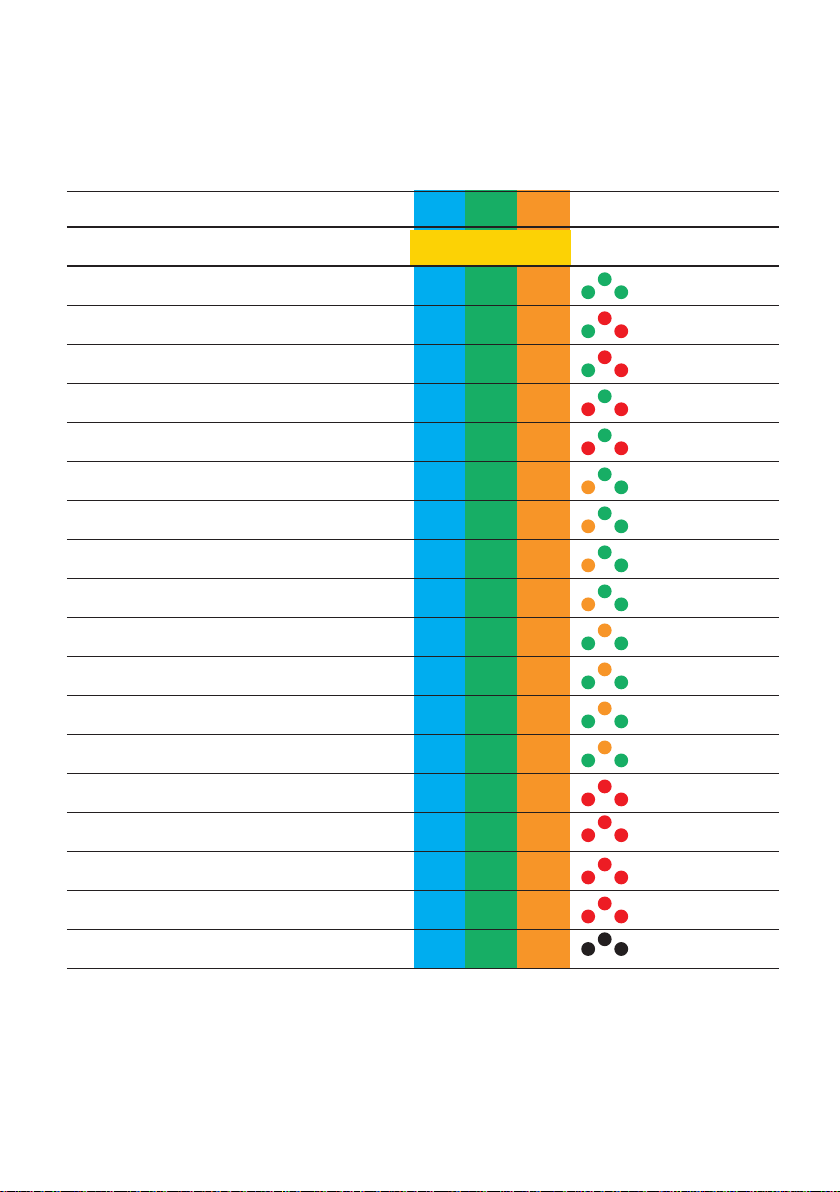

A fault with the socket wiring will be indicated by an audible alternating

tone and the LED’s, at least one of which will be Red or Orange, will flash.

If a fault indication is given – DO NOT PROCEED -investigation and

remedial action is required before you can conduct anRCD test.

If this happens placing your thumb on the polarity test pad will now activate

the ‘fault location’ function. With your thumb on the pad check the indication

given by the LED’s against the chart on the back cover to identify where the

main problem lies. Note: The colour of the LED’s may change when the pad

is touched.

3. Check that the mains voltage is in the correct range 207-253VAC.

Note: All tests are inhibited until the mains voltage appears in the display

4. Incoming supply Polarity Test - this important test is discussed in full

on page three of this manual, please read.

To conduct the test - with all three LED’s lit GREEN place your thumb on the

polarity test pad area. If the supply polarity is correct the LED's will start to

flash Green and you can proceed to step 4. If the supply polarity has been

reversed the three LED’s will turn Red and flash.

If this happens stop testing and notify the supply company immediately.

5. RCD TYPE SELECTION BUTTON

This selects the type and rating of RCD to be tested. 30mA, 100mA, 300mA

or 500mA rated type AC ( general purpose RCD's) and 100A or 300mA rated

type ACS (Selective)

6. SELECT TEST BUTTON

6a. CURRENT MULTIPLIER

This button is used to select the test current multiplier that is applied to the

selected rating of RCD type (chosen in step 5) for the test to be carried out.

For example if the 30mA rating was selected in step 5, choosing x1/2 here

would apply a test current current of 15mA (1/2 x 30mA) when the test is

conducted.

Choosing x5 here would apply a test current of 150mA (5x 30mA)