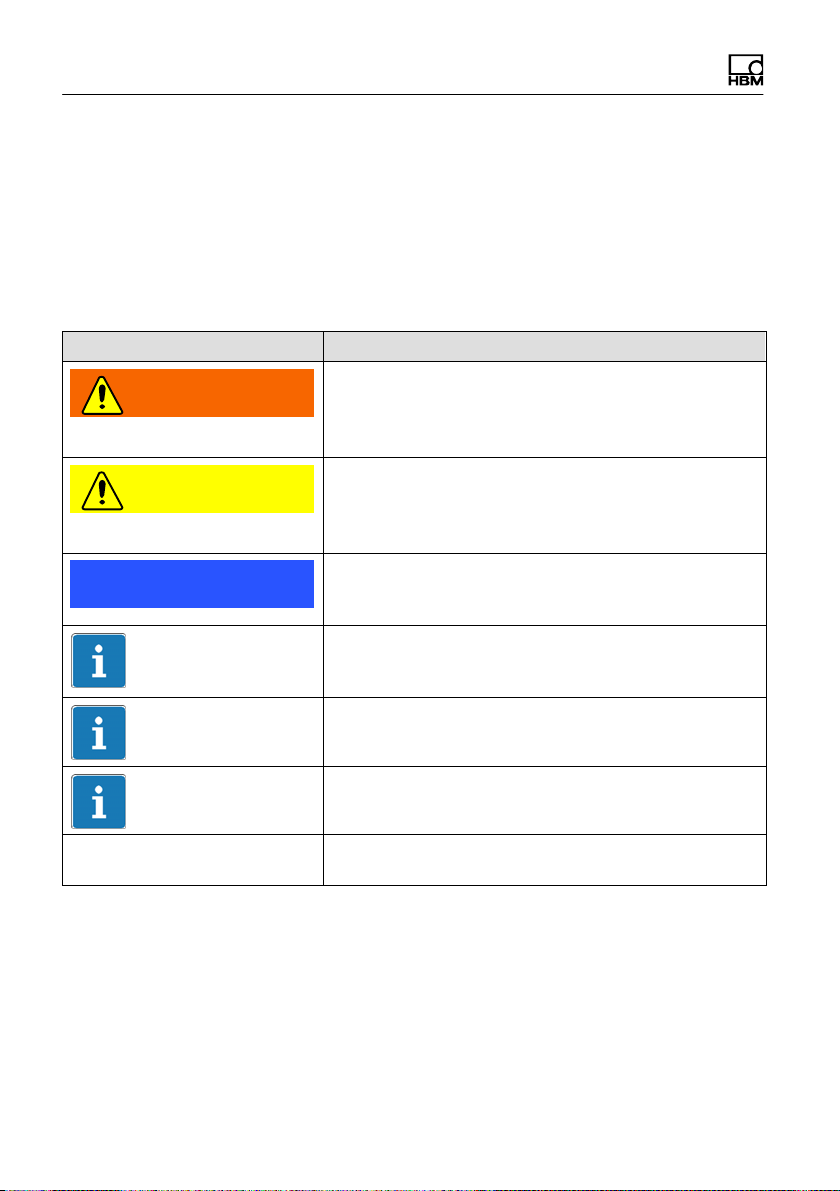

Safety instructions

ME50S6 A00260_04_Y00_01 HBM: public 5

Maintenance and cleaning

The Clip Electronic are maintenance‐free. Please note the following points

when cleaning the front panel:

SRemove the mains plug from the socket before cleaning.

SClean the front panel with a soft, slightly damp (not wet!) cloth. Never use

solvents, since they may damage the labelling on the front panel.

SWhen cleaning, please ensure that no liquid finds its way into the device or

onto the contacts.

Residual dangers

The ME50S6 scope of performance and supply covers part of the measuring‐

technology, only. The plant designer/constructor/operator must in addition de

sign, realise and take responsibility for the measuring‐system's safety such

that potential residual dangers are minimized. The respective regulations must

in any case be observed. Residual dangers regarding the measuring system

must be specified explicitly.

Reconstruction and modifications

HBM's express consent is required for modifications regarding the ME10

construction and safety. HBM does not take responsibility for damage resulting

from unauthorized modifications.

In particular, repair and soldering works on the boards are prohibited. If com

plete componentry is replaced use original HBM components, only.

Qualified personnel

The device may be used by qualified personnel, only; the technical data and

the special safety regulations must in any case be observed. When using the

device, the legal and safety regulations for the respective application must also

be observed. The same applies if accessories are used.

Qualified personnel means: personnel familiar with the installation, mounting,

start‐up and operation of the product, and trained according to their job.

Maintenance and repair work on an open device with the power on should only

be undertaken by trained personnel who are aware of the above‐mentioned

dangers.