6PW20i

HBM A1269-2.0 en/de/fr

1 Application

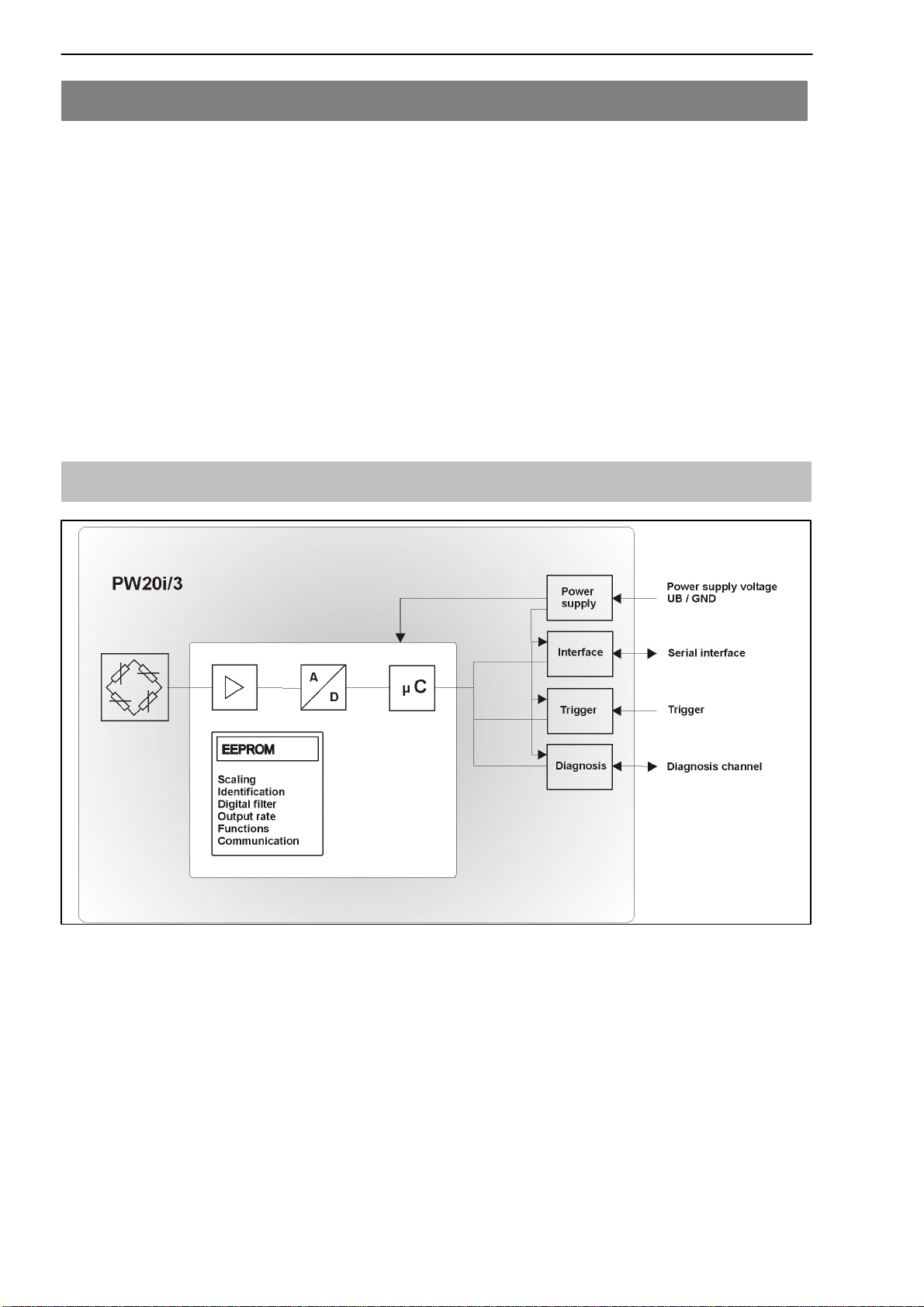

The PW20i load cells belong to the digital load cells and measurement chain

family specially developed by HBM for high-speed dynamic weighing

processes. They acquire measurement signals from strain gages, condition

them digitally, output them and can network them for buses on request.

They supply a fully-filtered, scaled and digitalized output signal for direct

connection to a bus system or a PC. They operate with high sampling rates of

up to 1200 measurements per second and can be easily and rapidly adapted

to the actual weighing system by means of adjustable parameters.

The integrated trigger function allows event-driven weight determination which

significantly reduces the external software requirements for checkweigher

applications, for example.

The PW20i includes dosing control. As this load cell does not have any digital

outputs, the external Master control must make digital I/Os available. The

PW20i generates the information to control these digital outputs in the

respective measurement statuses (MSV - measurement status). The Master

control then only needs to forward these control bits to its digital outputs, in

order to drive the dosing control valves.

The load cell can be delivered with RS-485, RS-232, CANopen or DeviceNet

interface options.

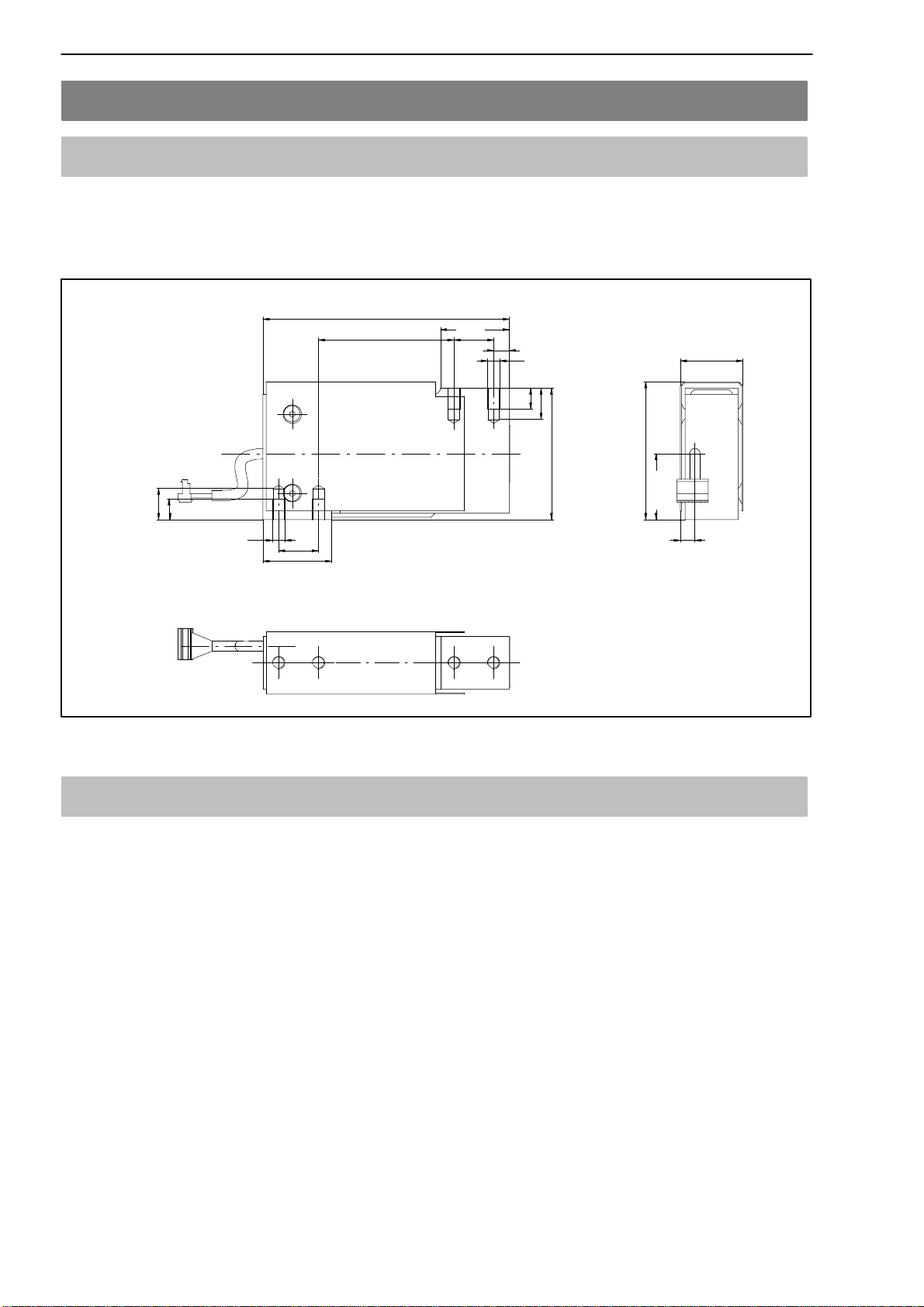

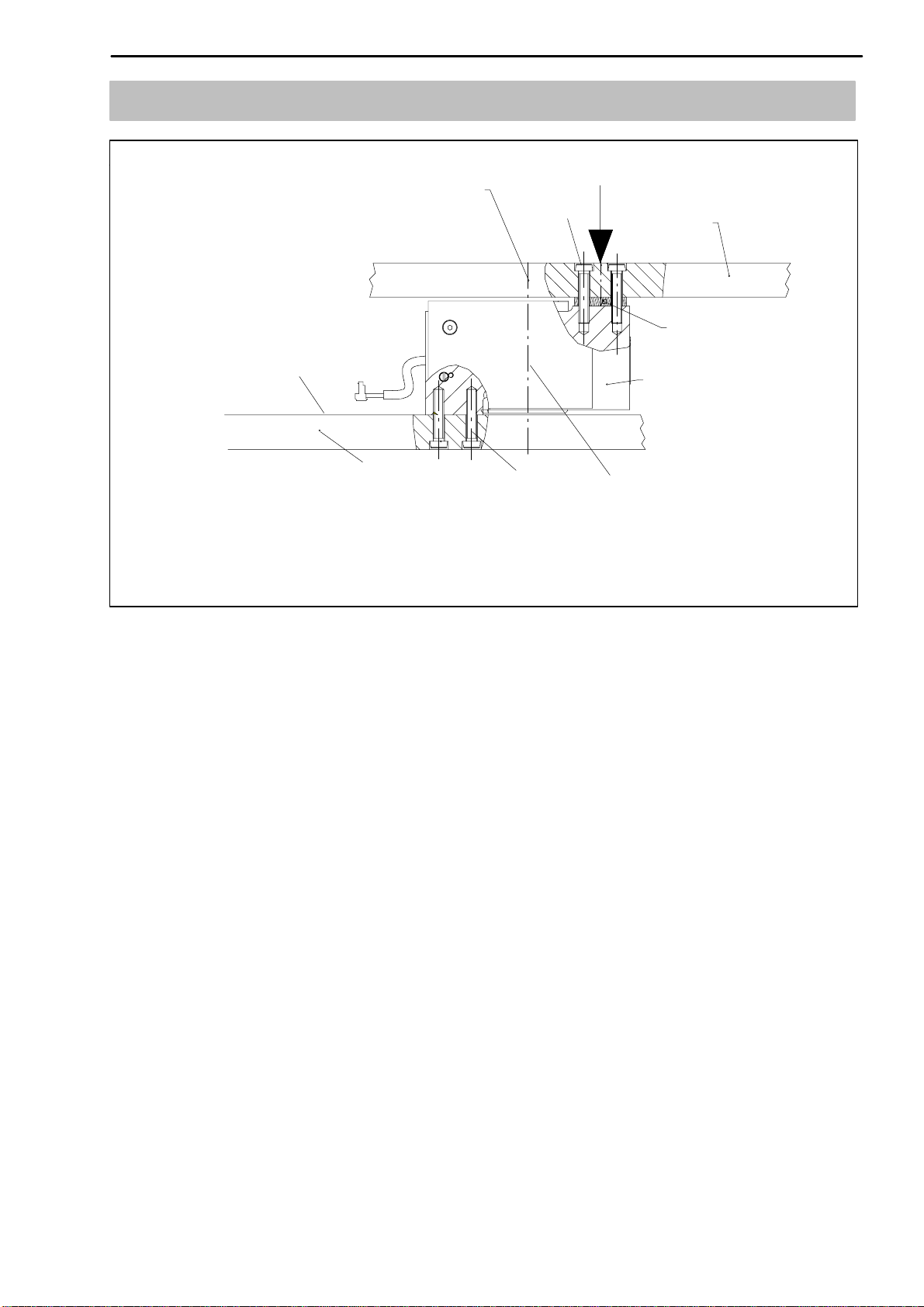

PW20i load cells are space-saving in use and are protected against spray

water and contamination by a stainless steel casing (IP 65).

The PC software AED_Panel32 is available to facilitate parameter settings, to

display dynamic measurement signals and for comprehensive frequency

analysis of the dynamic system.

This part of the operating instructions describes the hardware and the functions

of the PW20i digital load cells. In the help file “AED_help_e” you will find the

commands for serial communication.