HyQuest Solutions Pty Ltd

TBRG Calibrator TB340A © Copyright Page - 4 Issue 7 : 28 Apr, 2017

TABLE OF FIGURES

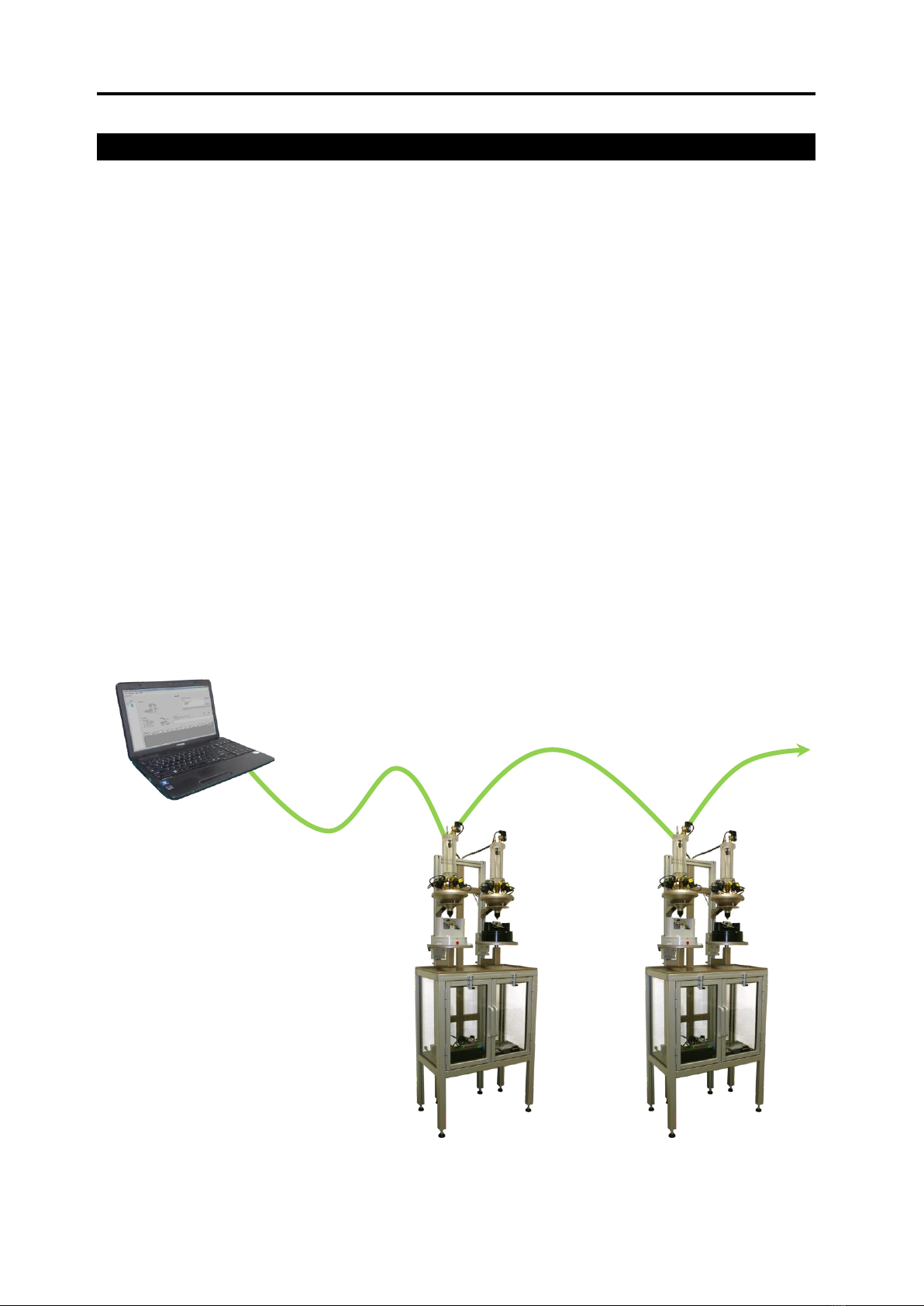

Figure 1-1 TBRG Calibrator overview...................................................................5

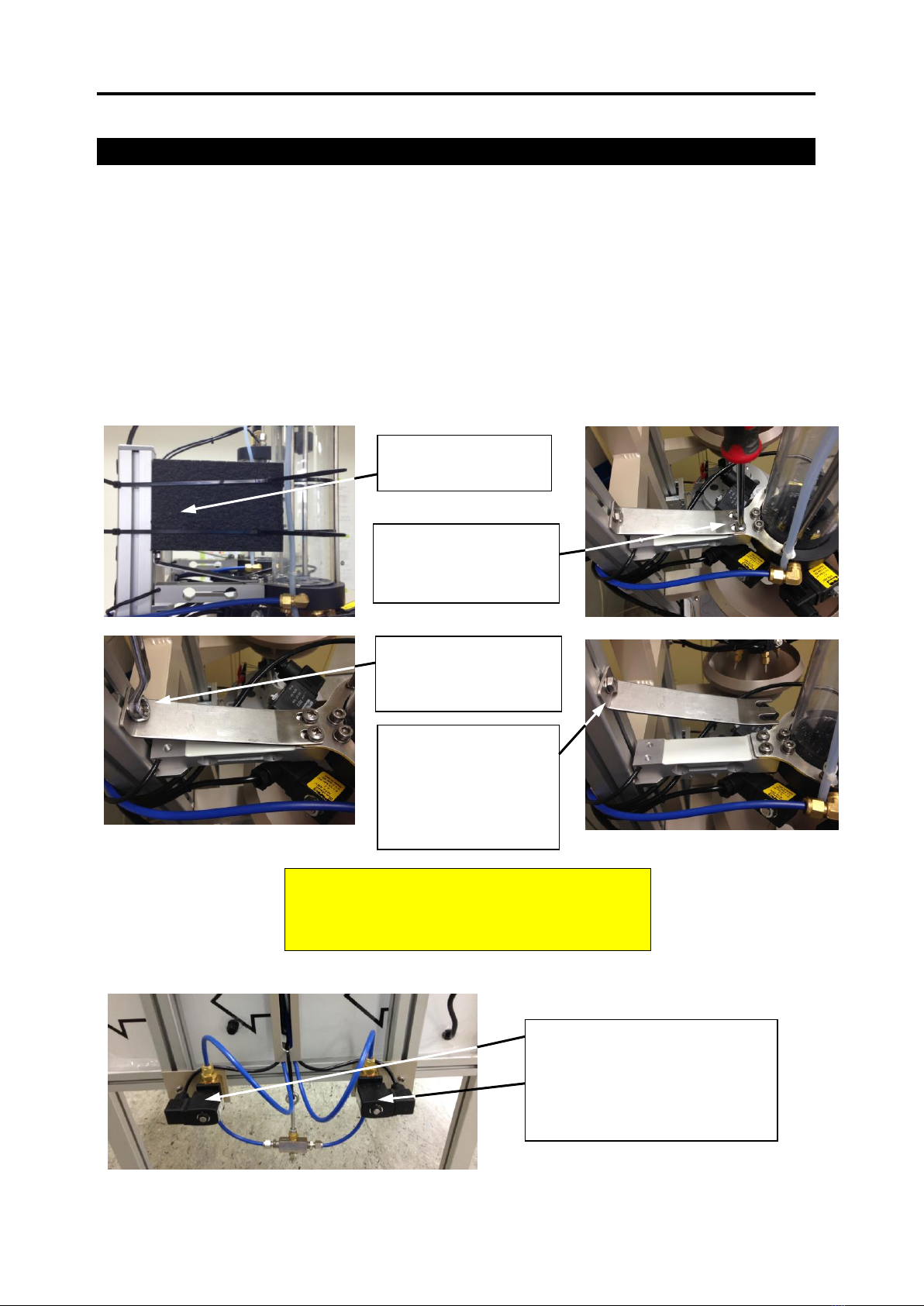

Figure 3-1 Power switch in cabinet of TBRG Calibrator ........................................... 10

Figure 3-2 Device Manager in Control Panel (Windows 7) ......................................... 11

Figure 3-3 USB to RS-485 adapter in Device Manger ............................................... 12

Figure 4-1 Reed switch connections .................................................................. 14

Figure 4-2 Test setup selection........................................................................ 15

Figure 4-3 Tipping bucket rain gauge options in test setup ....................................... 16

Figure 4-4 Test options in test setup ................................................................. 17

Figure 4-5 Nozzle setup in test setup ................................................................ 18

Figure 4-6 Test process setup in test setup ......................................................... 19

Figure 4-7 Main testing screen ........................................................................ 21

Figure 4-8 Unit list in main testing screen........................................................... 22

Figure 4-9 Unit details in main testing screen ...................................................... 23

Figure 4-10 Test overview and control in main testing screen ................................... 24

Figure 4-11 Current test in main testing screen .................................................... 25

Figure 4-12 Test history in main testing screen..................................................... 26

Figure 4-13 Reporting screen .......................................................................... 27

Figure 4-14 Unit list in reporting...................................................................... 28

Figure 4-15 Filter for unit list in reporting .......................................................... 28

Figure 4-16 Test data table in reporting ............................................................. 29

Figure 4-17 Staged test data in reporting............................................................ 30

Figure 4-18 Test details in reporting ................................................................. 32

Figure 4-19 Program options dialog................................................................... 33

Figure 4-20 Report plain text header in program options ......................................... 34

Figure 4-21 Report image header in program options.............................................. 34

Figure 4-22 Communications in program options ................................................... 35

Figure 4-23 Print and auto-print in program options............................................... 36

Figure 4-24 PDF and auto-PDF in program options ................................................. 36

Figure 4-25 Configure PLC in program Options...................................................... 37

Figure 4-26 Model management dialog ............................................................... 38

Figure 4-27 Model list in model management ....................................................... 39

Figure 4-28 Bucket list in model management ...................................................... 40

Figure 4-29 Catch size in model management ...................................................... 41

Figure 4-30 Theoretical and practical values in model management............................ 41

Figure 4-31 Tolerances in model management...................................................... 42

Figure 4-32 Adding a new tolerance in model management ...................................... 43

Figure 4-33 Editing a tolerance in model management............................................ 44

Figure 4-34 Load cell calibration dialog.............................................................. 45

Figure 4-35 Load cell calibration dialog 2 and 3 –Selecting Station and Nozzle............... 46

Figure 4-36 Load cell calibration dialog 4 and 5 –Nozzle Rate ................................... 46

Figure 4-37 Load cell calibration dialog 6 - Taring container..................................... 46

Figure 4-38 Load cell calibration dialog 7 - Container to collect water......................... 47

Figure 4-39 Load cell calibration dialog 8 and 9 - Filling and Draining .......................... 47

Figure 4-40 Load cell calibration dialog 10 –Weigh the water collected ....................... 48

Figure 4-41 Load cell calibration dialog 11 –Repeated process 5 times –then test........... 48

Figure 5-1 Switches on the relay module ............................................................ 49