Laversab 6150 User manual

MODEL 6150

USER'S MANUAL

LAVERSAB INC.,

505 GILLINGHAM LN.

SUGAR LAND, TEXAS 77478.

PHONE: (281) 325-8300

FAX: (281) 325-8399

Email: customerservice@laversab.com

Document Number: 9052

Date: Mar.11, 2011.

i

WARRANTY

Laversab Inc., warrants its products to conform to or exceed the specifications as set

forth in its catalogs in use at the time of sale and reserves the right, at its own discretion,

without notice and without making similar changes in articles previously manufactured,

to make changes in materials, designs, finish, or specifications. Laversab Inc. warrants

products of its own factory against defects of material or workmanship for a period of one

year from date of sale.

Liability of Laversab Inc. under this warranty shall be limited to replacing, free of

charge (FOB Houston, Texas), any such parts proving defective within the period of this

warranty, but Laversab Inc. will not be responsible for transportation charges,

consequential or incidental damages. No liability is assumed by Laversab for damages

that are caused by misuse or abuse of the product.

The warranty of Laversab Inc. is not made for products manufactured by others

which are illustrated and described in Laversab catalogs or incorporated in Laversab

products in essentially the same form as supplied by the original manufacturer.

Warranties of the original manufacturers supplant the warranty of Laversab Inc., but, in

applicable instances, the latter agrees to use its best efforts to have original suppliers make

good their warranties.

ii

COPYRIGHT NOTICE

Copyright (c) 2008 onward by Laversab Inc. All rights reserved. The content of this

manual may not be reproduced in any form by any means, in part or in whole, without

the prior written permission of Laversab Inc.

DISCLAIMER

No representations or warranties are made with respect to the contents of this user's

manual. Further, Laversab Inc. reserves the right to revise this manual and to make

changes from time to time in the content hereof without obligation to notify any person of

such revision.

iii

REVISION HISTORY

Document No. Release Date Description

9052

10/10/2008

Model 6150 User’s Manual

9052

03/11/2011

Model 6150 Rev B1 User’s Manual

iv

WARNING

THE 6150 USES LINE VOLTAGES FOR ITS OPERATION WHICH ARE POTENTIALLY

DANGEROUS. IMPROPER OPERATION OF THIS EQUIPMENT MAY RESULT IN

PERSONAL INJURY OR LOSS OF LIFE. HENCE THE EQUIPMENT DESCRIBED IN

THIS MANUAL SHOULD BE OPERATED ONLY BY PERSONNEL TRAINED IN

PROCEDURES THAT WILL ASSURE SAFETY TO THEMSELVES, TO OTHERS AND TO

THE EQUIPMENT.

BEFORE PERFORMING ANY MAINTENANCE, TURN THE POWER OFF AND

DISCONNECT THE POWER CORD FROM THE POWER SOURCE.

ALWAYS USE A 3-PIN GROUNDED OUTLET AS YOUR AC POWER SOURCE

v

TABLE OF CONTENTS

Warranty ............................................................................................................................. i

Copyright notice, disclaimer ............................................................................................... ii

Revision History ................................................................................................................... iii

Warning ............................................................................................................................. iv

Section 1: Introduction .................................................................................................. 1

Section 2: Functional Details ........................................................................................ 5

2.1 Power On .................................................................................................................. 5

2.2 Limits and Leak-times ............................................................................................. 5

2.3 Main Screen .............................................................................................................. 7

2.4 Leak Check Mode ..................................................................................................... 12

2.5 Functions ................................................................................................................... 14

Section 3: Typical Use .................................................................................................... 18

3.1 Setup .......................................................................................................................... 18

3.2 Low-level leak checks ............................................................................................. 18

3.3 High-Altitude leak check ..................................................................................... 19

3.4 Airspeed accuracy check ........................................................................................ 19

3.5 Altimeter accuracy check ....................................................................................... 20

Section 4: Calibration .................................................................................................... 22

4.1 Equipment ................................................................................................................ 22

4.2 Calibration Procedure ............................................................................................. 22

4.3 Calibration Report ................................................................................................. 26

Section 5: Maintenance ..................................................................................................... 28

Appendix A: Specifications ................................................................................................ 29

Appendix B: Repair and Return Policies ......................................................................... 30

1

SECTION 1

INTRODUCTION

The 6150 Digital Air Data and Leak Tester is a high accuracy Pitot Static Tester which can

be used for performing leak checks on the Pitot and Static systems of all aircraft. It can

also be used to perform accuracy checks on altimeters, airspeed indicators, air data

computers and other air data related equipment on-board aircraft. However, such

accuracy checks must be limited only to aircraft that are not RVSM compliant. The 6150 is

NOT RVSM compliant. However, the relatively high accuracy (see specifications) of the

6150 makes it suitable for use to perform only leak-checks even on RVSM compliant

aircraft.

The 6150 has powerful built-in pumps for vacuum and pressure. Altitudes and Airspeeds

can be simulated on the Static and Pitot outputs by using the metering valves provide on

the unit. There is no maintenance required on the 6150, other than the annual calibration.

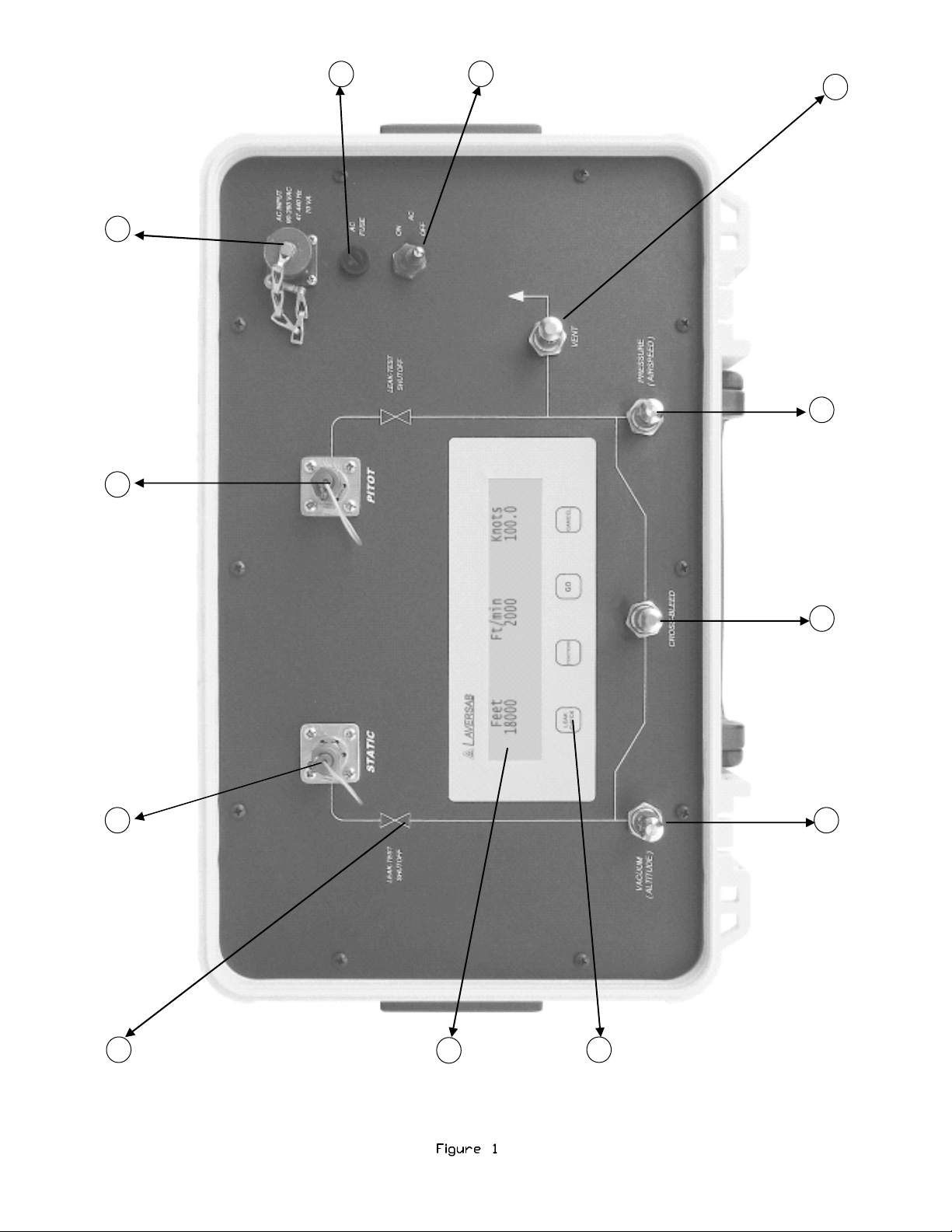

The top panel of the 6150 is shown in Figure 1. The different components on the top

panel, indicated by numbers in Figure 1, are explained below.

1. Static output port

This #4-AN port is normally connected to the Static port of the aircraft. As an option, this

port can also be fitted with a #6-AN fitting.

2. Pitot output port

This #4-AN port is normally connected to the Pitot port of the aircraft.

3. AC input connector

This 3-pin circular connector accepts AC input power for the unit. AC power between 90-

260 VAC and 47-440 Hz is suitable for the unit. Nominal power consumption is 70 VA.

4. AC Fuse

The AC input power is fused with a 1 amp slow-blow, 20 mm fuse.

5. ON /OFF switch

This is used to turn power to the unit, ON or OFF.

2

2

1 2 3

4

5

6

7

8

9

12

11

10

3

6. VENT metering valve

This valve is used to vent-to-ambient, pressure or vacuum from the Pitot output. With the

Cross-bleed valve open, the Vent valve can also vent-to-ambient, pressure or vacuum

from the Static system.

CAUTION : This metering valve seals before it reaches its STOP. Do Not tighten at all

past this STOP. Not even finger-tight. Any tightening past the STOP may cause

permanent damage to the valve and it will constantly leak.

7. PRESSURE or AIRSPEED metering valve

This valve is used for increasing airspeed or pressure at the Pitot output. With the Cross-

bleed valve open, it can also be used to create pressure on the Static port for altitudes

below field elevation (like -1000 feet) .

CAUTION : This metering valve seals before it reaches its STOP. Do Not tighten at all

past this STOP. Not even finger-tight. Any tightening past the STOP may cause

permanent damage to the valve and it will constantly leak.

8. CROSS-BLEED valve

When this valve is open it equalizes pressure between the Pitot and Static outputs and

provides Zero airspeed.. When this valve is closed it isolates the Pitot and Static outputs

and allows the user to create a specific airspeed, either by opening the Vent valve or the

Pressure valve.

CAUTION : This metering valve seals before it reaches its STOP. Do Not tighten at all

past this STOP. Not even finger-tight. Any tightening past the STOP may cause

permanent damage to the valve and it will constantly leak.

9. VACUUM or ALTITUDE valve

Opening this valve increases altitude or vacuum on the Static output. If the Cross-bleed

valve is closed while altitude (vacuum) is increased on the Static output, this will cause

airspeed to increase automatically on the Pitot output, even if the Vent valve is open, since

the difference between Pitot pressure and Static pressure increases. If the Cross-bleed

valve is open and the Vent valve and Pressure valve are closed, opening the Vacuum

valve will increase altitude on the Static output but maintain close to Zero airspeed on the

Pitot output.

CAUTION : This metering valve seals before it reaches its STOP. Do Not tighten at all

past this STOP. Not even finger-tight. Any tightening past the STOP may cause

permanent damage to the valve and it will constantly leak.

4

10. Keypad

There are four keys:

The LEAK CHECK key is used to enter the Leak-test mode, and also for some other

functions.

The FUNCTIONS key is used to scroll through several functions (detailed later). It is also

used for some other actions.

The GO key is used to execute certain commands or options.

The CANCEL key is used to cancel certain commands or functions. This key is also used

to return to the Main Screen on the display.

11. Display

All indicators and readings are shown on this 40-character by 4-line LCD display. The

display is backlit for easy viewing in all lighting conditions. The various screens shown on

the display are explained in detailed in Section 2.

12. LEAK-TEST SHUTOFF solenoid-valves

There are two valves, one on the Static output and one on the Pitot output. During the

Leak-test mode, both of these solenoid-valves are automatically closed to isolate the

aircraft from the metering valves of the 6150. The 6150 can still monitor the altitude and

airspeed on the Static and Pitot ports. However, once the solenoid-valves are closed, none

of the metering valves will have any effect on the pressure (or vacuum) on the Static or

Pitot outputs.

5

SECTION 2

FUNCTIONAL DETAILS

This section explains all the different screens and functions of the 6150.

2.1 Power On.

When power is turned ON to the 6150, the display shows the sign-on screen for 3 seconds.

The pumps remain OFF. After the sign-on screen, the display shows the Limits and

Leak-times screen.

2.2 Limits and Leak-times

The Limits and Leak-times screen shows the current setting of the user-programmable

value for the maximum altitude limit and maximum airspeed limit. It also shows the

current setting for the three programmable leak time periods. This screen is displayed

only after power-up.

The minimum altitude limit is always set at -1200 feet and cannot be changed. The

minimum airspeed limit is set to -20 knots and cannot be changed.

The leak time periods are used in the leak test mode where the 6150 displays the altitude

and airspeed at the end of the specified time period and also the accumulated leak in

altitude and airspeed over that time period. For example, if the leak timers are set for 3, 5

and 10 minutes and the leak check was started at 10000 feet, then at the end of 3 minutes if

the altitude was at 9500 feet then the accumulated leak over 3 minutes is 500 feet. So the

6150 would display the values 9500 and 500. The airspeed leak at the end of 3 minutes

would be shown in the same manner. The process is repeated at the end of 5 minutes and

10 minutes also.

Please refer to the details on “Leak Check Screen”, later in this section.

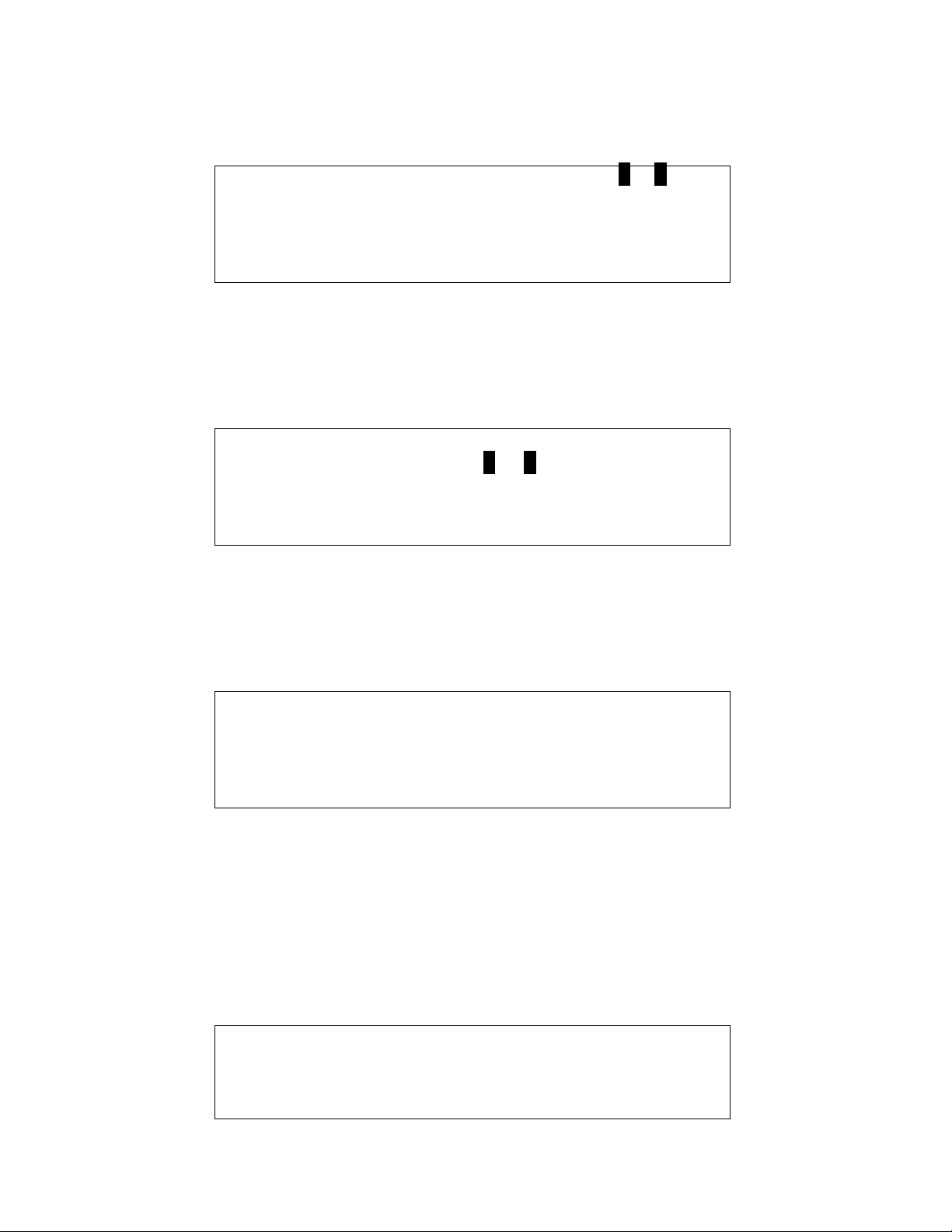

The Limits and Leak-times screen appears as below.

Max Alt.= 31000 ft. Max Airsp.= 310 kts

Leak timers: 3, 5, 10 minutes

FUNCTIONS: Change GO: Accept

6

The screen shows that the maximum altitude limit is set to 31000 feet and the maximum

airspeed limit is set to 310 knots. The leak timers are set for 3, 5 and 10 minute intervals.

To make changes to values, press the FUNCTIONS key. To accept the values as they

appear, press GO. If the FUNCTIONS key is pressed to make a change, the next screen

that appears is shown below.

Max Altitude = 31000 ft.

LEAK CHECK: Incr.

FUNCTIONS: Decr. GO: Accept

This screen allows the max altitude limit to be changed. Pressing LEAK CHECK increases

the limit by 1000 feet.. Pressing FUNCTIONS decreases the value by 1000 feet. The

maximum altitude limit can be changed in steps of 1000 feet, between a minimum value of

10,000 ft. and a maximum of 60,000 ft. It is recommended that the limit be set to a value

that is at least 1000 feet higher than the maximum altitude that will normally be generated

with the 6150 for the user’s typical aircraft. For example, if the user will normally perform

tests up to 30,000 ft. then the limit should be set at 31,000 ft..

Once the value of the limit is acceptable, pressing GO will accept the selected value and

move to next screen shown below.

Max Airspeed = 310 knots

LEAK CHECK: Incr.

FUNCTIONS: Decr. GO: Accept

This screen allows the max airspeed limit to be changed, using the LEAK CHECK and

FUNCTIONS keys, in increments of 10 knots. The limit can be changed between 100 knots

and 500 knots. The limit should be set at least 10 knots above “normal-usage” airspeed, i.e.

if the tester will normally be used up to 300 knots then the limit should be set to 310 knots.

Press GO to accept the value for max. airspeed. This will bring up the next screen shown

below

Leak-time 1= 3 min. Leak-time 2= 5 min.

Leak-time 3= 10 min.

LEAK CHECK: Incr.

FUNCTIONS: Decr. GO: Accept

This screen allows the user to select the value for leak-time 1. The value will increment or

7

decrement in steps of 1 minute. The minimum value for leak-time 1 is 1 minute and the

maximum is 18 minutes. When GO is pressed, the displayed value is accepted and the

screen changes as shown below:

Leak-time 1= 3 min. Leak-time 2= 5 min.

Leak-time 3= 10 min.

LEAK CHECK: Incr.

FUNCTIONS: Decr. GO: Accept

This screen allows the user to select the value for leak-time 2. The value will increment or

decrement in steps of 1 minute. The minimum value for leak-time 2 is one minute higher

than leak-time 1 and the maximum is 19 minutes. When GO is pressed, the displayed

value is accepted and the screen changes as shown below:

Leak-time 1= 3 min. Leak-time 2= 5 min.

Leak-time 3= 10 min.

LEAK CHECK: Incr.

FUNCTIONS: Decr. GO: Accept

This screen allows the user to select the value for leak-time 3. The value will increment or

decrement in steps of 1 minute. The minimum value for leak-time 3 is one minute higher

than leak-time 2 and the maximum is 20 minutes. When GO is pressed, the displayed

value is accepted and the screen changes as shown below:

Max Alt.= 31000 ft. Max Airsp.= 310 kts

Leak timers: 3, 5, 10 minutes

FUNCTIONS: Change GO: Accept

Press GO to accept the changes. You will now exit the Limits and Leak-times screen and

the next screen will appear as shown below.

2.3 Main Screen

Most of the operations to control and achieve specific altitudes and airspeeds will be done

while in this screen, shown below:

Feet Ft/min. knots

425 0 6.5

Press GO to start pumps

8

In this screen, (the values displayed on your screen will likely be different), 425 feet is the

altitude being measured at the Static output of the 6150 and 6.5 knots is the airspeed being

measured at the Pitot output. There is no change of altitude so the VSI is indicated as 0

ft/min.

Please note that any VSI values below 20 ft/min will be shown as 0 ft/min.

Pumps are normally off and can be started by pressing GO.

Under certain conditions the pumps will be turned OFF automatically (see section 2.3.7)

Before starting the pumps, please ensure that all 4 metering valves are closed.

Before starting the pumps, please connect the Pitot and Static outputs to the aircraft.

While in the Main Screen, the metering valves can be used to change the altitude at an

appropriate VSI (Ft/min), and also the airspeed. The recommended method for using

these metering valves is shown below. This method is the simplest way to achieve desired

altitudes and airspeeds, without having to operate more than one metering valve at a

time.

2.3.1 Changing airspeed while maintaining altitude at ambient (Ground).

Increase airspeed: Close all valves. Slowly open the Pressure (Airspeed) valve while

watching the knots value increase. When the desired knots value is achieved, close the

Pressure (Airspeed) valve.

Decrease airspeed: Close all valves. Slowly open the Vent valve until the desired airspeed

is achieved, then close the Vent valve.. An airspeed between -15 knots and +15 knots is

essentially equal to zero airspeed.

2.3.2 Changing Altitude while maintaining zero airspeed.

Keeping airspeed near zero while changing altitude is the ideal way to move from one

altitude to another. Please note that keeping airspeed near zero will NOT damage the

airspeed indicator on the aircraft.

Close all valves. Slowly open the Cross-bleed valve until airspeed is close to zero. Then

open the Cross-bleed valve all the way and leave it open. This ensures that airspeed will

always stay close to zero while altitude is increased or decreased.

Increase altitude: Slowly open the Vacuum valve while watching the VSI (Ft/min).

The displayed VSI value is heavily damped. Please allow a few seconds for the VSI

value to stabilize after making any changes to the Vacuum valve.

Once a desired VSI is achieved, it will reduce very slowly, and it may not be necessary to

9

constantly make changes to the Vacuum valve. Slowly close the Vacuum valve as you

approach the desired altitude.

Decrease altitude: Close the Vacuum valve completely, then slowly open the Vent valve

while watching the VSI. This will allow you to achieve altitudes all the way down to

Ground. If an altitude below Ground is desired (like -1000 ft.) then close the Vent valve

and slowly open the Pressure valve while watching the VSI. To return to Ground altitude,

close the Pressure valve and slowly open the Vent valve.

Note that during all these operations, the Cross-bleed valve is completely open and

therefore, airspeed will be close to zero.

2.3.3 Changing Airspeed while maintaining an Altitude other than Ground

Increase airspeed: Close the Cross-bleed valve. Slowly open the Pressure valve (or the

Vent valve) until the desired airspeed is achieved. The Vent valve will work only for

airspeeds below ambient pressure.

Decrease airspeed: Close the Pressure valve (and Vent valve). Then slowly open the

Cross-bleed valve until the desired airspeed is achieved. Notice that as the Cross-bleed

valve is opened, the Altitude will also decrease. Watch the VSI as the Cross-bleed valve is

opened.

2.3.4 Maintaining a positive Airspeed while changing Altitude.

This requires making constant changes to two valves simultaneously and is therefore

NOT a recommended method. However if it is absolutely necessary to follow this

method, please follow the steps below.

Increase altitude: First achieve the desired positive airspeed using the Pressure valve

while keeping the other valves closed. Close the Pressure valve. Open the Vacuum valve

slowly. As the altitude increases, the airspeed will also increase. Reduce the airspeed to

the desired value by opening the Cross-bleed valve. You will need to constantly adjust the

Vacuum and Cross-bleed valves to maintain the desired VSI and the desired positive

airspeed. When the desired altitude is achieved, close both the Vacuum and Cross-bleed

valves. The Cross-bleed valve should be closed before the Vacuum valve to maintain the

desired positive airspeed.

Decrease altitude: First achieve the desired positive airspeed using the Pressure valve

while keeping the other valves closed. Close the Pressure valve. Slowly open the Cross-

bleed valve. This will cause the airspeed to decrease and the altitude also to decrease.

Increase the airspeed to the desired value by opening the Pressure valve. You will need to

constantly adjust the Pressure and Cross-bleed valves to maintain the desired VSI and the

desired positive airspeed. When the desired altitude is achieved, close both the Pressure

and Cross-bleed valves. The Cross-bleed valve should be closed before the Pressure valve

to maintain the desired positive airspeed.

10

2.3.5 Checking for leaks in the Main Screen

When an altitude and airspeed have been achieved, it is possible to check for leaks

without going into the Leak Test screen.

If the Cross-bleed valve is open and the other three valves are closed, the altitude value

shown on the display will indicate the leak of both the Static and Pitot system combined.

Do NOT pinch-off either hose to the aircraft to try and isolate the leak between Pitot

and Static sides. This could cause a large negative airspeed on the aircraft.

To isolate the Pitot and Static systems, close the Cross-bleed valve and open the Pressure

(or Vent) valve to increase the airspeed to about 100 knots. Then, with all valves closed,

the true Static leak will be shown on the displayed altitude value. However, it will still not

be possible to determine the true Pitot leak since the displayed airspeed value will change

depending on both the Static and Pitot leaks.

To determine the true Pitot leak while at an altitude other than Ground, keep all valves

closed and a positive airspeed of approximately 100 knots. Then open the Vacuum valve

slowly to hold the altitude steady at a fixed value. By doing this you are compensating for

the Static leak. Now the displayed airspeed value will indicate the true Pitot leak.

Please note that if altitude is more than 500 feet above Ground and airspeed is around

100 knots, a Pitot leak will cause airspeed to INCREASE.

The ideal way to perform a Pitot leak check is while holding Static at Ground, as follows.

Close all valves. Ensure that both Pitot and Static are at Ground by opening the Cross-

bleed valve and then the Vent valve. Once Ground is achieved, close Cross-bleed and

Vent valves. Slowly open the Pressure valve to achieve 100 knots. Close the Pressure

valve. The true Pitot leak can be observed on the displayed airspeed value. In this

situation, any leak Pitot leak will always cause airspeed to decrease.

2.3.6 Protection against Negative Airspeed

The 6150 has built-in protection against excessive negative airspeed. An internal relief-

valve prevents the airspeed from going more negative than about -30 knots.

This relief-valve is active even when the 6150 is powered-off.

There are two conditions during the operation of the 6150 when the internal relief-valve

will NOT protect against negative airspeed.

a. During Leak-Check Mode, the Leak Test Shutoff solenoids are closed. This prevents

the relief-valve from providing the negative airspeed protection to the aircraft. Therefore,

in Leak-Check Mode, if the 6150 detects negative airspeed, it automatically trips out of

Leak-Test Mode and opens the Leak Test Shutoff solenoids, thereby allowing the

relief-valve to provide protection against excessive negative airspeed.

11

b. During Calibration Mode, the Leak Test Shutoff solenoids are closed. This prevents the

relief-valve from providing the negative airspeed protection. However, this protection is

normally not required during Calibration Mode.

2.3.7 Warnings

While in the Main Screen, several warning messages are displayed to alert the user to

existing or potential error conditions. These messages are automatically cleared when the

error condition no longer exists. Warning messages are displayed for the following

conditions.

a. Airspeed close to limit : Indicates that at the rate at which airspeed is being changed, it

will exceed the limit within 10 seconds. Usually, slowing down the rate of change of

airspeed will clear the message.

b. Airspeed is negative : Indicates that airspeed is more negative than -20 knots. Opening

the Cross-bleed valve or the Pressure valve will usually make airspeed more positive.

c. Airspeed over limit : Indicates that airspeed is over the programmed limit.

Under this condition, the pumps will automatically be turned OFF.

If altitude is at Ground, reduce airspeed by opening the Vent valve. If altitude is above

Ground, reduce airspeed by opening the Cross-bleed valve. After the airspeed is below

the limit, close all valves and then turn ON the pumps

d. Altitude close to limit : Indicates that at the rate at which altitude is being changed, it

will exceed the limit within 10 seconds. Usually, reducing the VSI will clear the message.

e. Altitude over limit : Indicates that altitude is either over the programmed max. limit or

below -1200 feet.

Under this condition, the pumps will automatically be turned OFF.

To decrease altitude from a high value, open the Cross-bleed valve and then the Vent

valve. To increase altitude from a negative value, open the Vent valve. If the airspeed

starts going negative, open the Cross-bleed valve also. After the altitude is within limits,

close all valves and then turn ON the pumps.

f. Any combination of the above 5 conditions will generate other warning messages.

A list of all the warning messages is shown below:

** Airspeed close to limit **

** Airspeed over limit **

** Airspeed is negative **

12

** Altitude close to limit **

** Altitude over limit **

** Alt and A/S close to limits **

** Alt and A/S over limits **

** A/S negative, Alt over limit **

** A/S negative, Alt close to limit **

** A/S over limit, Alt close to limit **

** Alt over limit, A/S close to limit **

2.4 Leak Check Mode

The Leak Check mode is used to perform an accurate timed leak-check of the Pitot and

Static systems of the aircraft. During the Leak Check mode, both Pitot and Static systems

are leak-checked simultaneously. Before entering the Leak Check mode, you must achieve

the desired altitude and airspeed at which the leak check is to be performed. This is done

using the metering valves while in the Main Screen (section 3 above).

Once the desired altitude and airspeed have been achieved, enter the Leak Check mode by

pressing the LEAK CHECK key. The Leak Test Shutoff solenoids will close. This will

isolate the Pitot and Static outputs from the pumps and the metering valves.

In Leak Check mode the aircraft is not protected against negative airspeed. If a negative

airspeed condition exists, the 6150 will automatically trip out of Leak Check mode to

prevent excessive negative airspeed. See section 2.3.6 above.

Within 10 seconds of entering the Leak Check mode, the pumps will automatically turn

OFF. At that point, all four metering valves should be closed.

You may exit out of Leak Check mode, back to the Main Screen, at any time by pressing

the CANCEL key.

In Leak Check mode the display appears as below (actual values may be different)

5000 feet 0 ft/min. 100.0 kts

1m: / /

2m: / /

3m: / 00:02 /

The top line shows the actual measured values at the Static and Pitot outputs. These are

updated every 0.25 seconds. Please note that any VSI values below 20 ft/min will be

shown as 0 ft/min.

The center of the 4th line shows the elapsed time in minutes and seconds (mm:ss).

13

The start of the second, third and fourth lines show “1m:”, “2m:” and “3m:” which

indicates that the leak times have been programmed for 1, 2 and 3 minutes. For changing

leak-time values please see Section 2.2.

At the end of 1 minute of elapsed time, the display appears as below:

4995 feet 0 ft/min. 99.8 kts

1m: 4995 / 5 99.8 / 0.2

2m: / /

3m: / 01:00 /

Line 2 now shows that at the end of 1 minute, the altitude was 4995 ft. and the amount of

altitude leak over 1 minute was 5 feet. Also, the airspeed was 99.8 knots and the amount

of airspeed leak over 1 minute was 0.2 knots.

Although line 1 will continue to update, line 2 will remain as shown.

At the end of 2 minutes of elapsed time, the display appears as below:

4991 feet 0 ft/min. 99.6 kts

1m: 4995 / 5 99.8 / 0.2

2m: 4991 / 9 99.6 / 0.4

3m: / 02:00 /

Line 3 now shows that at the end of 2 minutes, the altitude was 4991 ft. and the total

amount of altitude leak over 2 minutes was 9 feet. Also, the airspeed was 99.6 knots and

the total amount of airspeed leak over 2 minutes was 0.4 knots.

Although line 1 will continue to update, lines 2 and 3 will remain as shown.

At the end of 3 minutes of elapsed time, the display appears as below:

4988 feet 0 ft/min. 99.5 kts

1m: 4995 / 5 99.8 / 0.2

2m: 4991 / 9 99.6 / 0.4

3m: 4988 / 12 03:00 99.5 / 0.5

Line 4 now shows that at the end of 3 minutes, the altitude was 4988 ft. and the total

amount of altitude leak over 3 minutes was 12 feet. Also, the airspeed was 99.5 knots and

the total amount of airspeed leak over 3 minutes was 0.5 knots.

Although line 1 and the timer will continue to update, lines 2, 3 and 4 will remain as

14

shown.

Once the timed leak has completed you should record all the displayed values before

returning to the Main Screen by pressing CANCEL. The values shown on the display for

the timed leaks are automatically recorded internally in the 6150 and may be retrieved

later. Please see section 5.1 for more details.

When CANCEL is pressed to exit out of the Leak Check mode, the Leak Test Shutoff

solenoids are opened and the Main Screen is displayed.

2.4.1 Warnings in Leak Check mode

While in the Leak Screen, several warning messages are displayed to alert the user to

existing or potential error conditions. These messages are automatically cleared when the

error condition no longer exists. Warning messages are similar to those displayed in the

Main Screen. Please see Section 2.3.7 above.

There is one exception.

If airspeed goes more negative than -20 knots while in the Leak Check mode, the 6150

will automatically trip out of Leak Check mode and return to the Main Screen. The

Leak Test Shutoff solenoids will be opened to allow the internal relief-valve to protect

the aircraft against excessive negative airspeed. See section 2.3.6

When the 6150 trips out of Leak Check mode due to negative airspeed, the following

message will appear on the Main Screen:

Leak-check cancelled due to negative A/S

Press GO to continue

When the GO key is pressed, normal operation in the Main Screen will continue.

2.5 Functions

From the Main Screen, pressing the FUNCTIONS key allows you to scroll through several

functions. These are described below.

2.5.1 RECORDED Leak values

The first function shows the Leak values that were recorded during the last-executed Leak

Check. The leak values are stored even through a power-down. If the last Leak Check

that was performed was started at 5000 feet and 100.0 knots, and the leak values were

exactly as shown in section 2.4 above, then the screen displayed will appear as shown

below:

5000 feet ** RECORDED ** 100.0 kts

Table of contents

Other Laversab Test Equipment manuals