HD FIRE PROTECT K FACTOR-8 User manual

MAY, 2018 HD 287PAGE 1 OF 4

HD FIRE PROTECT

PVT. LTD.

SPRINKLER - UPRIGHT, PENDENT AND

RECESSED PENDENT (K FACTOR - 8)

TECHNICAL DATA

Style Upright, Pendent and

Recessed Pendent

Temperature Standard Response - 5mm

Response glass bulb

Quick Response - 3mm glass bulb

Coverage Standard Coverage

K-Factor 8.0 US (115 metric)

Nominal Thread Size 3/4” NPT

Max. Working 175 PSI (12 Bar)

Pressure

Factory Hydrostatic 500 PSI (35 Bar)

Test Pressure

Min. Operating 7 PSI (0.5 Bar)

Pressure

Temp. Rating 57°C (135° F), 68°C (155° F),

79°C (175° F), 93°C (200° F)

Approvals UL Listed

Finish Brass, Chrome Plated,

White Painted

. White shade is RAL9010.

For other shades, contact

HD Sales.

Ordering Style, Temperature Rating &

Information Response, Finish

SIN Number HD171 - SR, Pendent &

Recessed Pendent

HD172 - SR, Upright

HD271 - QR, Pendent &

Recessed Pendent

HD272 - QR, Upright

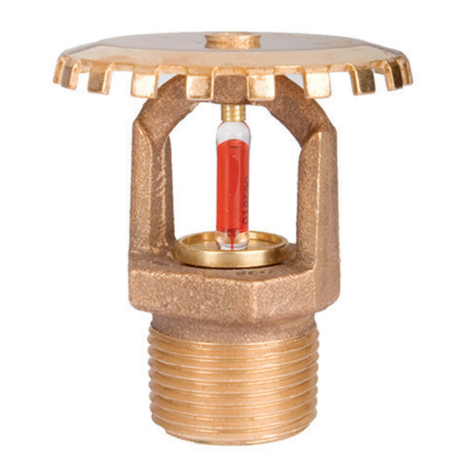

DESCRIPTION

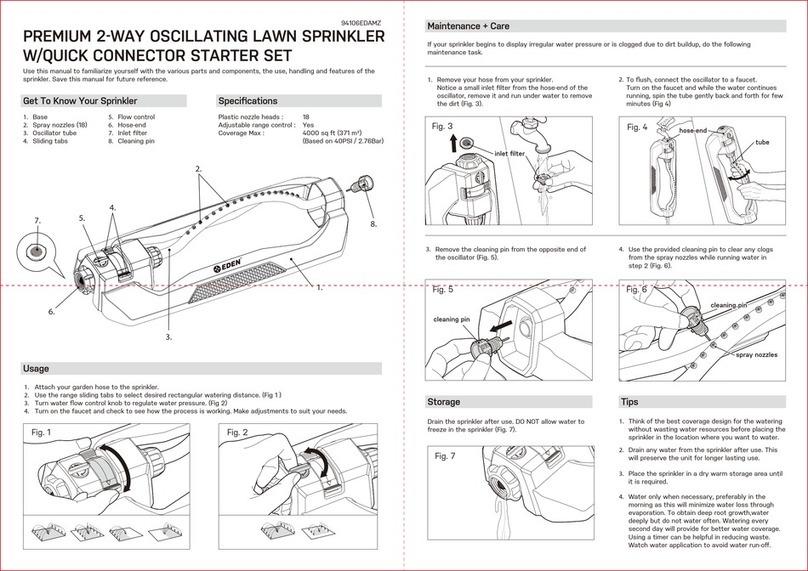

Pendent & Upright Sprinklers

HD Pendent and Upright sprinklers are designed for

use in light and ordinary hazards. The temperature

response is standard response (5mm glass bulb)

and quick response (3mm glass bulb). The sprinklers

come with compact design, glass bulb type, available

in several different finishes and temperature ratings.

The pendent sprinklers must be installed in pendent

position, and upright sprinklers are to be installed in

the upright position.

Pendent Recessed Sprinklers are installed with

adjustable or non-adjustable Escutcheon plates (also

termed as Rosette plates). These are intended to

be installed with finished ceilings. Escutcheon plate

adjustment provides convenience in Pendent Sprinkler

installation in case of areas with finished ceilings or

walls.

Sprinkler Operation

The Sprinkler operating device is state of the art heat

responsive frangible glass bulb supplied by a world

leader in this innovative technology. The glass bulb

contains fluid which expands when exposed to heat.

When rated temperature is reached, the bulb shatters

and water flows through the sprinkler and strikes

deflector, forming a uniform water spray pattern to

control or extinguish fire.

Care and Handling

Sprinklers must be handled with due care, they must

be stored at ambient temprature for best results.

Storage as well as any onward shipment is to be made

in original packing only. Sprinklers must be visually

inspected carefully before installation. Sprinklers

visibly damaged, dropped or exposed to temperature

in excess of the maximum ambient temperature

permitted, should never be installed. Never install

any glass blub sprinkler if the bulb is cracked or if

there is a loss of liquid from the bulb. Sprinkler must

be installed after the piping is in place to prevent

mechanical damage.

Use Teflon Tape or soft thread sealent on male thread

of the Sprinkler for the leak tight Sprinkler joint. Use

proper wrench and appropriate torque. Excessive

tightening torque may distort the Sprinkler inlet

and cause leakage. Sprinkler must never be painted,

plated or coated after they leave factory.

The HD Sprinkler described herein must be installed

and maintained in accordance with the latest edition

of HD technical data, the latest standard of National

Fire protection Association (NFPA) and Factory Mutual

(FM) or to the standard of any other authorities

having jurisdiction. The owner is solely responsible for

maintaining their fire protection system and device in

proper operating condition.

MAY, 2018 HD 287PAGE 2 OF 4

HD FIRE PROTECT

PVT. LTD.

Inspection Testing and Maintenance

Refer to NFPA 25 for inspection testing and maintenance

requirement or to the authority having jurisdiction.

For details of warranty, refer HD’s current price list,

conditions of sale or contact HD directly. Exposure to

ultraviolet or direct sunlight for extended period may

cause the liquid dye in glass bulb to fade or lose colour.

Colourless or faded coloured bulbs are not a problem, as

long as the fluid level has not been affected. The loss of

colour in the liquid will not effect sprinkler performance,

as long as the bulb is intact and not damaged. The loss of

colour may be an issue in identifying sprinkler temperature

rating, but the temperature rating is still stamped on the

sprinkler deflector.

SPRINKLER RATINGS

SPRINKLER

TEMP.

CLASSIFICATION

NORMAL

SPRINKLER TEMP.

RATING

NFPA MAX.

CEILING TEMP.

ALLOWED

GLASS BULB

COLOUR

Ordinary 57° C (135° F) 38° C (100° F) Orange

Ordinary 68° C (155° F) 38° C (100° F) Red

Intermediate 79° C (175° F) 66° C (150° F) Yellow

Intermediate 93° C (200° F) 66° C (150° F) Green

Material Specification

Deflector Brass

Bulb Glass

Load Screw Brass

Cap Copper

Frame Brass

Seal Belleville Washer coated on both

sides with Teflon Tape

Bulb Nominal

Diameter

Standard Response 5.0mm

Quick Response 3.0mm

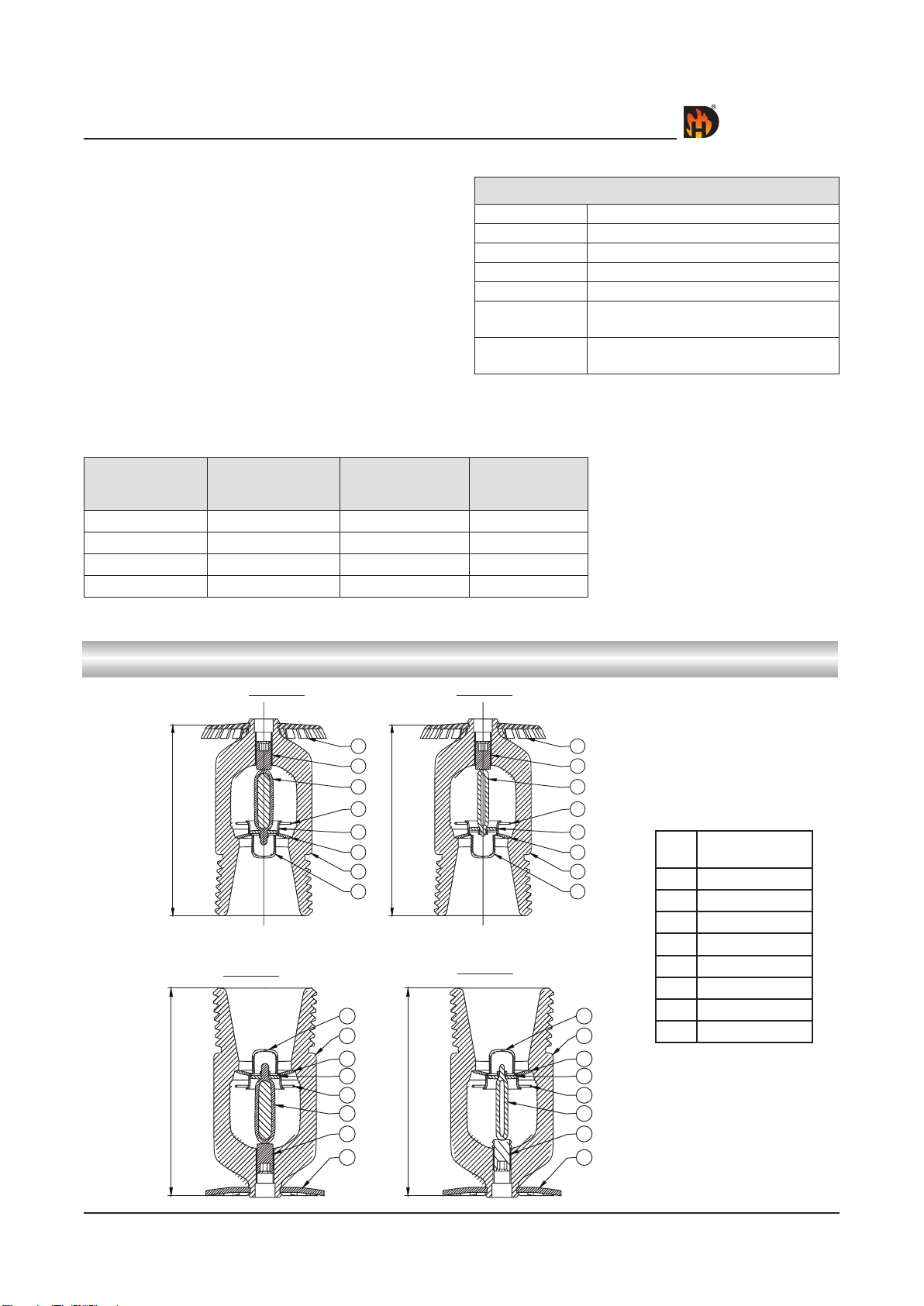

As per Table 6.2.5.1 NFPA 13

2

5

7

8

4

6

1

3

51.6 ±0.5

51.6 ±0.5

2

5

7

8

4

6

1

3

DIMENSIONS (FRAME & DEFLECTOR FINISH)

3

1

6

4

8

7

5

2

52.4 ±0.5

52.4 ±0.5

3

1

6

4

8

7

5

2

SL.

NO PART NAME

1 FRAME

2 DEFLECTOR

3CAP

4 CAP SEAT

5 LOAD SCREW

6 SEAL

7 BULB

8 SPRING

HD 172 HD 272

HD 171 HD 271

MAY, 2018 HD 287PAGE 3 OF 4

HD FIRE PROTECT

PVT. LTD.

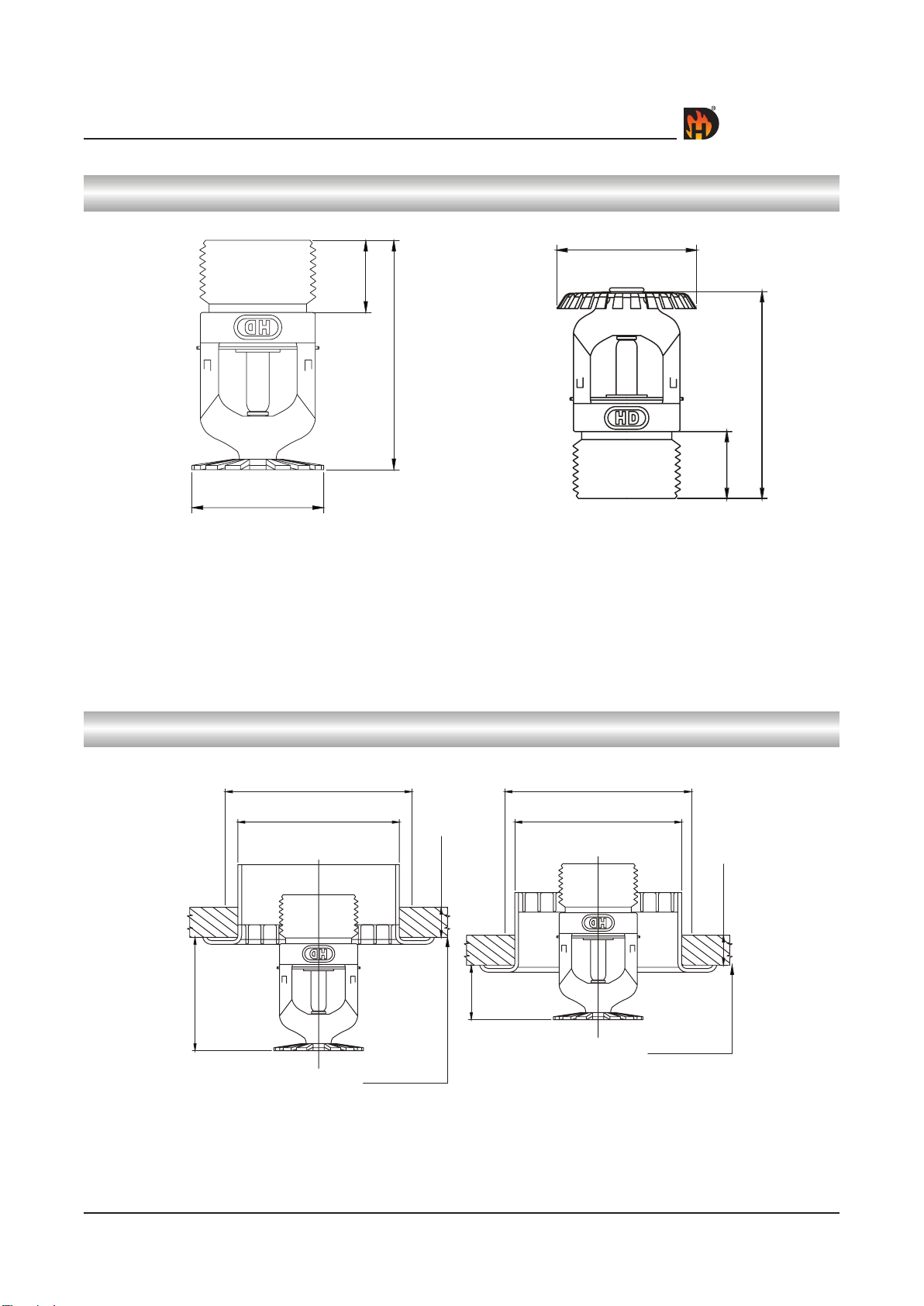

RECESSED PENDENT

PENDENT & UPRIGHT SPRINKLER

30.32 mm

16.5 mm

52.4 mm

34.35 mm

16.5 mm

51.6 mm

TYPICAL WALL

FINISHED SURFACE

38.08mm

18.58mm

FINISHED SURFACE

TYPICAL WALL

MAXIMUM EXTENSION

MAXIMUM RECESS

MAX.HOLE 0 60mm MAX.HOLE 0 60mm

MIN..HOLE 0 54mm MIN..HOLE 0 54mm

PENDENT UPRIGHT

Tolerance for all dimensions ± 0.5 mm

MAY, 2018 HD 287PAGE 4 OF 4

HD FIRE PROTECT

PVT. LTD.

DISTRIBUTION PATTERNS

275

Distribute the water distance (cm)

Mounting height (cm)

2151 65 105 45

305 245 185 1357 5

45 1051 65 215 275

30524518513575

50

100

150

200

250

300

120

230

K8.0 PENDENT SPRINKLER

DISTRIBUTION PATTERNS - TRAJECTORY

175 psi

50 psi

100 psi

20 psi

275

Distribute the water distance (cm)

Mounting height (cm)

215 165 1054 5

3052 45 185 135 75

45 105 1652 15 275

30524518513575

50

100

150

200

250

300

120

230

100 psi

175 psi

20 psi

50 psi

K8.0 UPRIGHT SPRINKLER

DISTRIBUTION PATTERNS - TRAJECTORY

MAY, 2018 HD 287PAGE 5 OF 4

HD FIRE PROTECT

PVT. LTD.

DISCHARGE CURVE

12345 6

80

PRESSURE IN Kg./Sq.Cm.

DISCHARGE IN LPM

PRESSURE IN PSI

0.51 .5 2.53 .5 4.55 .5 6.5 77.5 88.5 9

71 52 03 03 54 55 05 56 57 08 08 59 5 100 105 115 120

100

120

140

160

180

200

220

240

260

280

300

320

340

360

380

400

60

21

26

16

31

37

42

48

53

58

63

69

74

79

85

90

95

100

106

DISCHARGE IN GPM

NOMINAL K=8.0

NOMINAL K=114

TOOLS

SPRINKLER WRENCH SPRINKLER KEY

MAY, 2018 HD 287PAGE 6 OF 4

HD FIRE PROTECT

PVT. LTD.

LIMITED WARRANTY

HD FIRE PROTECT PVT. LTD. hereby referred to as HD FIRE warrants to the original purchaser of the fire protection products manufactured by HD FIRE and to any other person

to whom such equipment is transferred, that such products will be free from defect in material and workmanship under normal use and care, for two (2) years from the date of

shipment by HD FIRE. Products or Components supplied or used by HD FIRE, but manufactured by others, are warranted only to the extent of the manufacturer’s warranty.

No warranty is given for product or components which have been subject to misuse, improper installation, corrosion, unauthorized repair, alteration or un-maintained.

HD FIRE shall not be responsible for system design errors or improper installation or inaccurate or incomplete information supplied by buyer or buyer’s representatives.

HD FIRE will repair or replace defective material free of charge, which is returned to our factory, transportation charge prepaid, provided after our inspection the material is

found to have been defective at the time of initial shipment from our works. HD FIRE shall not be liable for any incidental or consequential loss, damage or expense arising directly

or indirectly from the use of the product including damages for injury to person, damages to property and penalties resulting from any products and components manufactured

by HD FIRE. HD FIRE shall not be liable for any damages or labour charges or expense in making repair or adjustment to the product. HD FIRE shall not be liable for any

damages or charges sustained in the adaptation or use of its engineering data & services. In no event shall HD Fire’s product liability exceed an amount equal to the sale price.

The foregoing warranty is exclusive and in lieu of all other warranties and representation whether expressed, implied, oral or written, including but not limited

to, any implied warranties or merchantability or fitness for a particular purpose. All such other warranties and representations are hereby cancelled.

NOTICE :

The equipment presented in this bulletin is to be installed in accordance with the latest publication standards of NFPA or other similar organisations and also with the

provision of government codes or ordinances wherever applicable.

The information provided by us is to the best of our knowledge and belief, and consist of general guidelines only. Site handling and installation control is not in our scope.

Hence we give no guarantee for result and take no liability for damages, loss or penalties whatsoever, resulting from our suggestion, information, recommendation or

damages due to our product.

Product development is a continuous programme of HD FIRE PROTECT PVT. LTD. and hence the right to modify any specification without prior notice is reserved with

the company.

D-6/2, ROAD NO. 34, WAGLE INDUSTRIAL ESTATE, THANE 400 604, INDIA.

• TEL: + (91) 22 2158 2600 • FAX: +(91) 22 2158 2602

HD FIRE PROTECT PVT. LTD.

Protecting What Matters Most to You

Table of contents

Other HD FIRE PROTECT Irrigation System manuals