Series TY-B – 5.6 K-factor

Horizontal and Vertical Sidewall Sprinklers

Standard Response, Standard Coverage

Page 1 of 6 NOVEMBER 2014 TFP161

IMPORTANT

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and in-

stallation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Worldwide

Contacts

www.tyco-fire.com

plicable approval agencies, the test-

ing is not representative of all possible

corrosive atmospheres. Consequently,

it is recommended that the end user

be consulted with respect to the suit-

ability of these coatings for any given

corrosive environment. The effects of

ambient temperature, concentration of

chemicals, and gas/chemical velocity,

should be considered, as a minimum,

along with the corrosive nature of the

chemical to which the sprinklers will be

exposed.

NOTICE

The Series TY-B Sprinklers described

herein must be installed and maintained

in compliance with this document, as

well as with the applicable standards of

the National Fire Protection Association,

in addition to the standards of any oth-

er authorities having jurisdiction. Failure

to do so may impair the performance of

these devices.

The owner is responsible for maintaining

their fire protection system and devices

in proper operating condition. Contact

the installing contractor or product man-

ufacturer with any questions.

Sprinkler

Identification

Numbers

TY3351 – Horizontal Sidewall

TY3451 – Vertical Sidewall

Technical

Data

Approvals

UL and C-UL Listed

FM Approved

LPCB Approved

VdS Approved

NYC Approved

(Refer to Table A for complete approval

information, including corrosion-resis-

tant status.)

Maximum Working Pressure

Refer to Table B.

Discharge Coefficient

K=5.6 gpm/psi1/2 (80,6 lpm/bar1/2)

Temperature Ratings

Refer to Table A.

Finishes

Sprinkler: Refer to Table C.

Recessed Escutcheon: Signal or Pure

White, Jet Black, Chrome Plated, or

Natural Brass

Physical Characteristics

Frame ................... Bronze

Button..............Brass/Copper

Sealing Assembly...Beryllium Nickel

w/TEFLON

Bulb ......................Glass

Compression Screw. . . . . . . . Bronze

HSW Deector . . . . . . . . . . . . Bronze

VSW Deector . . . . . . . . . . . . Copper

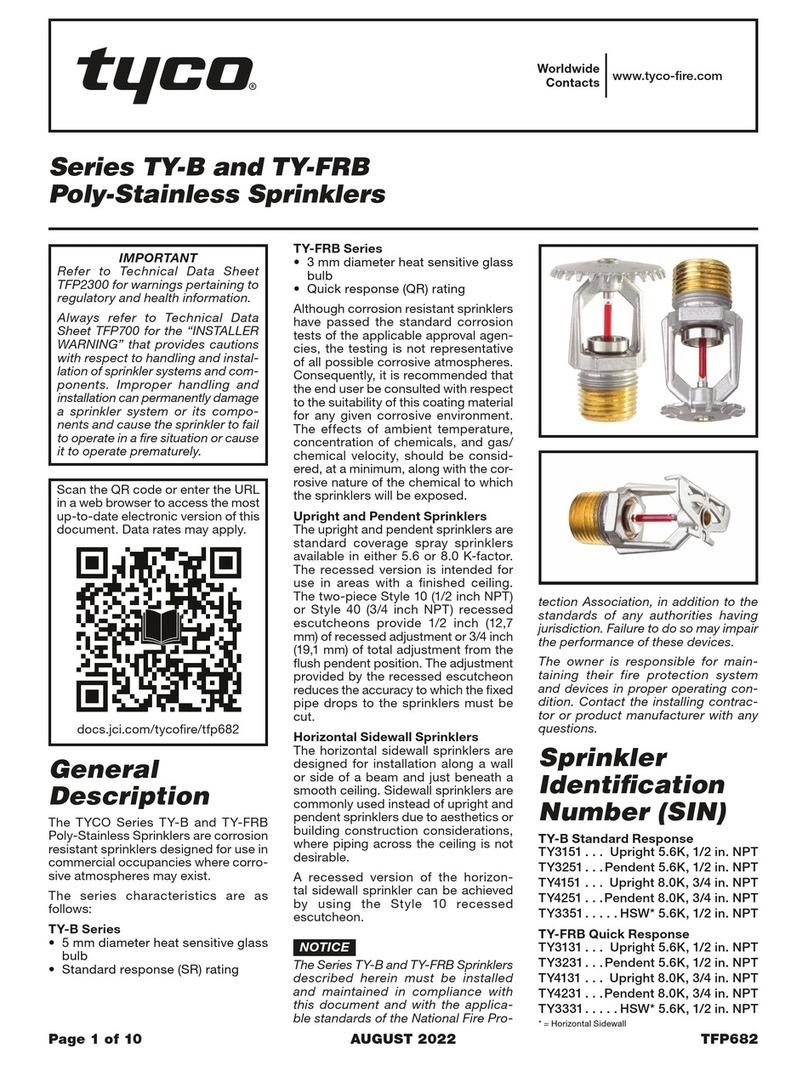

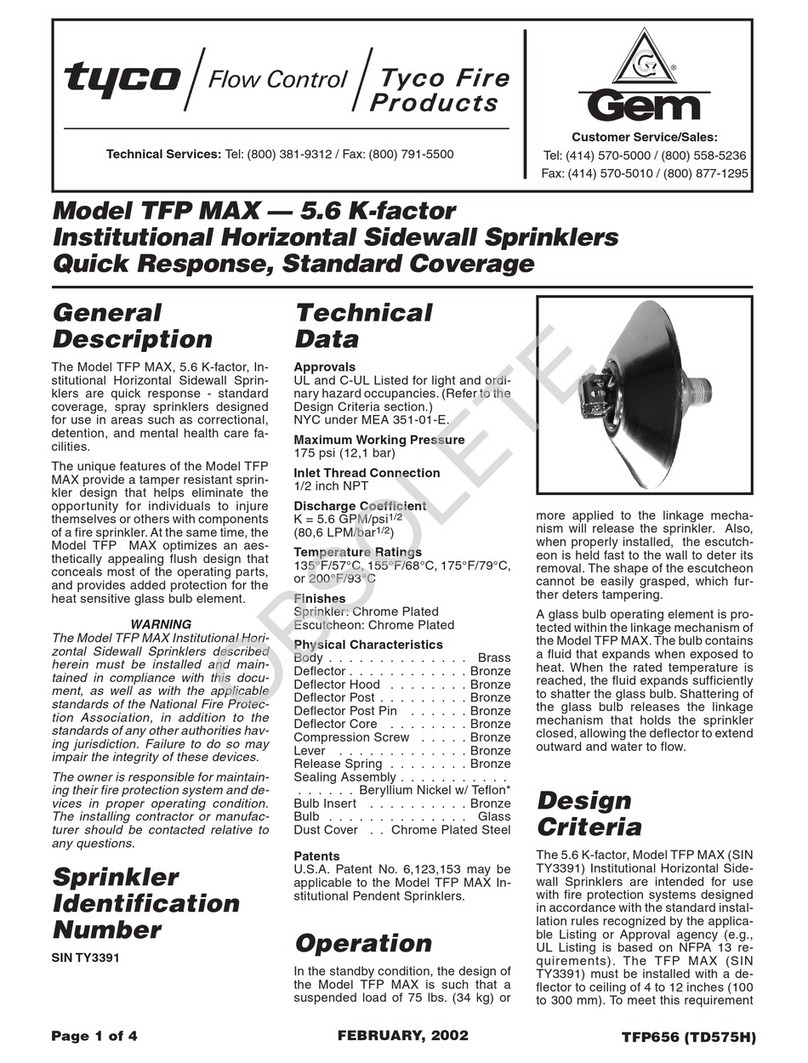

General

Description

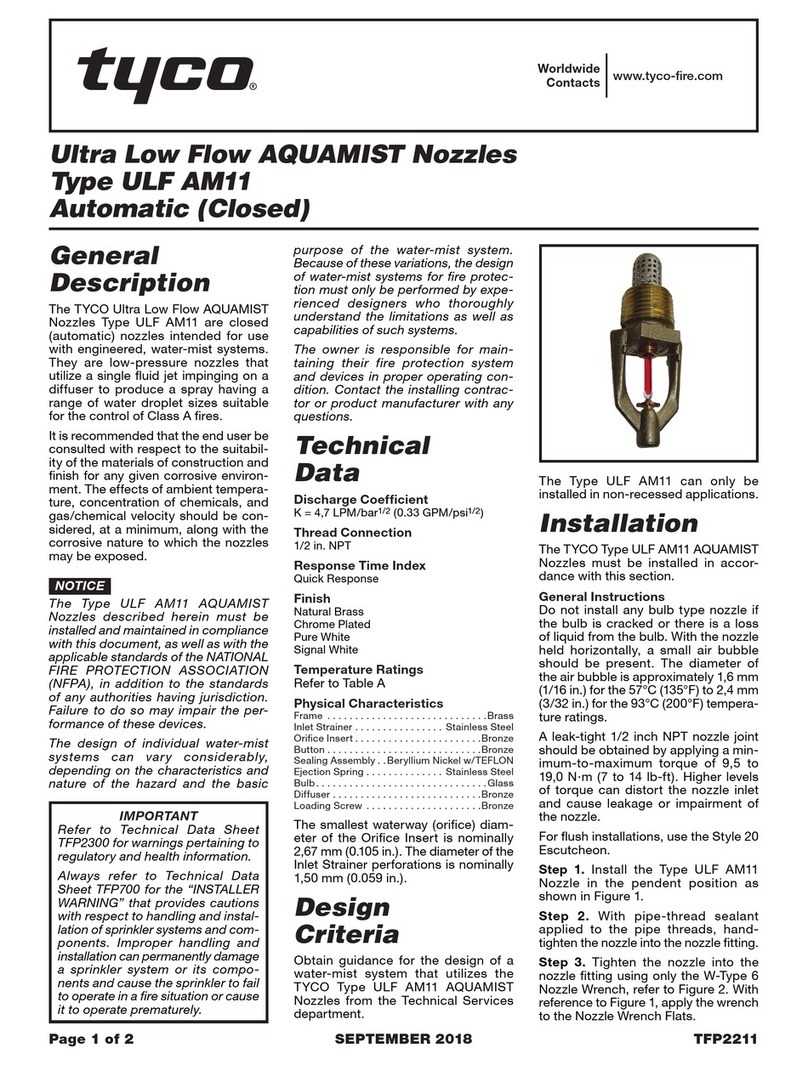

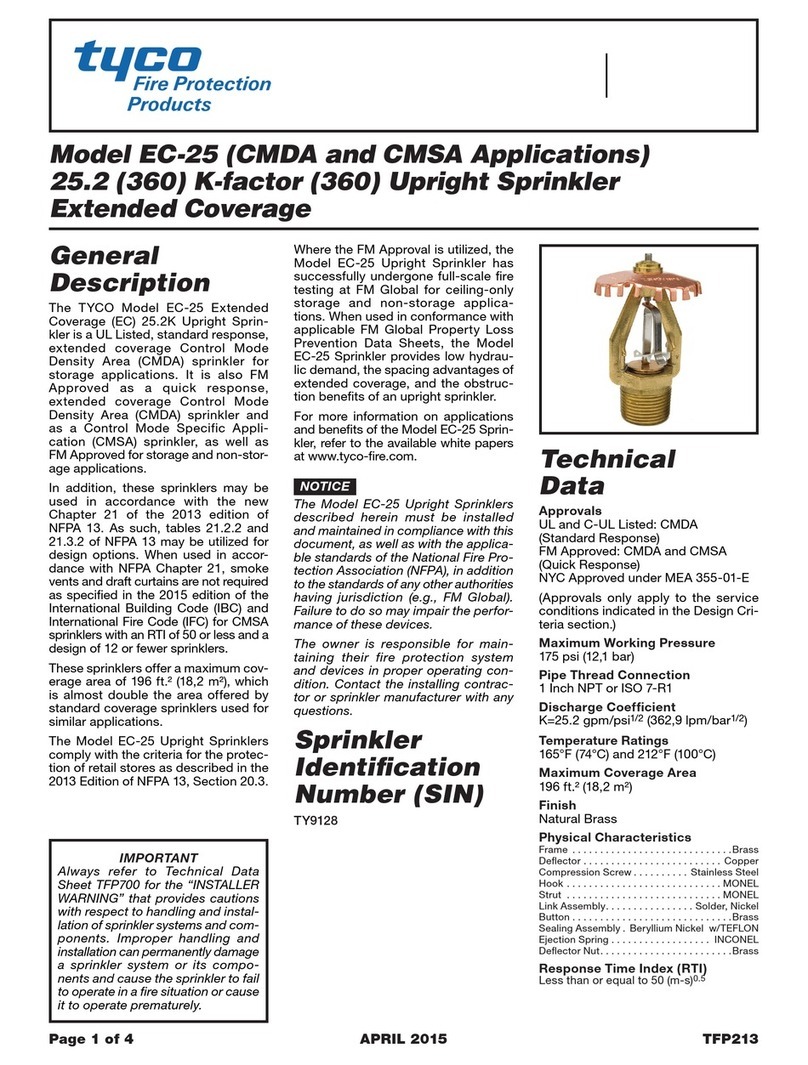

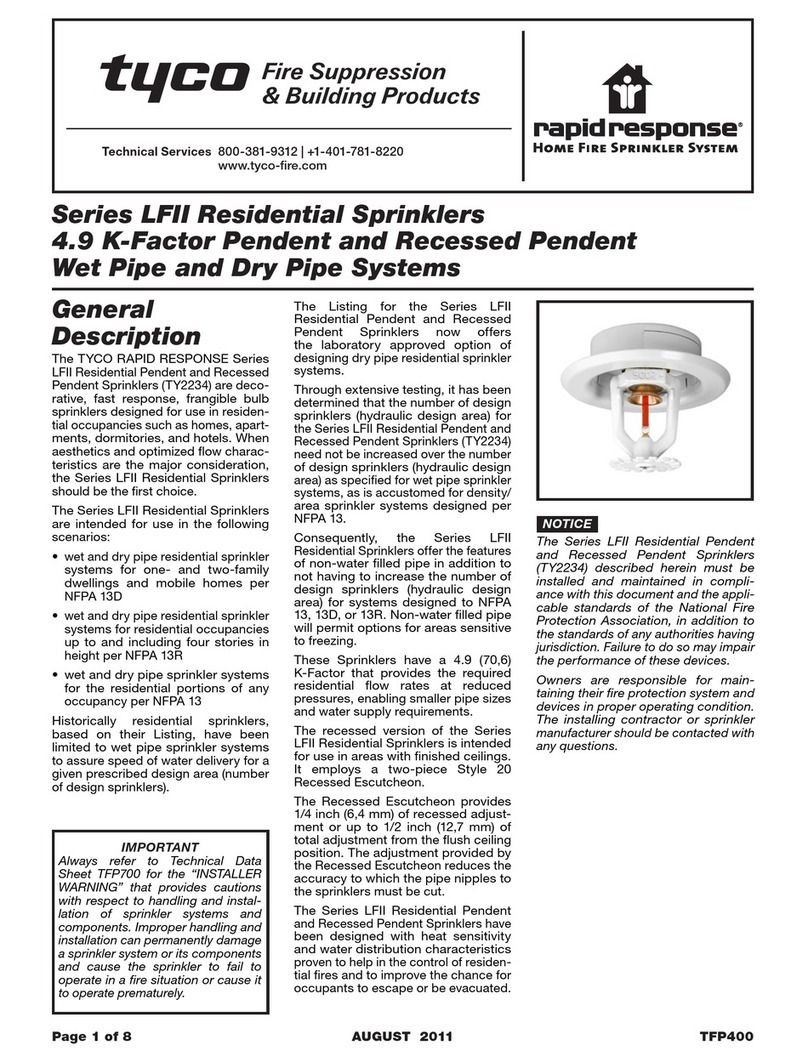

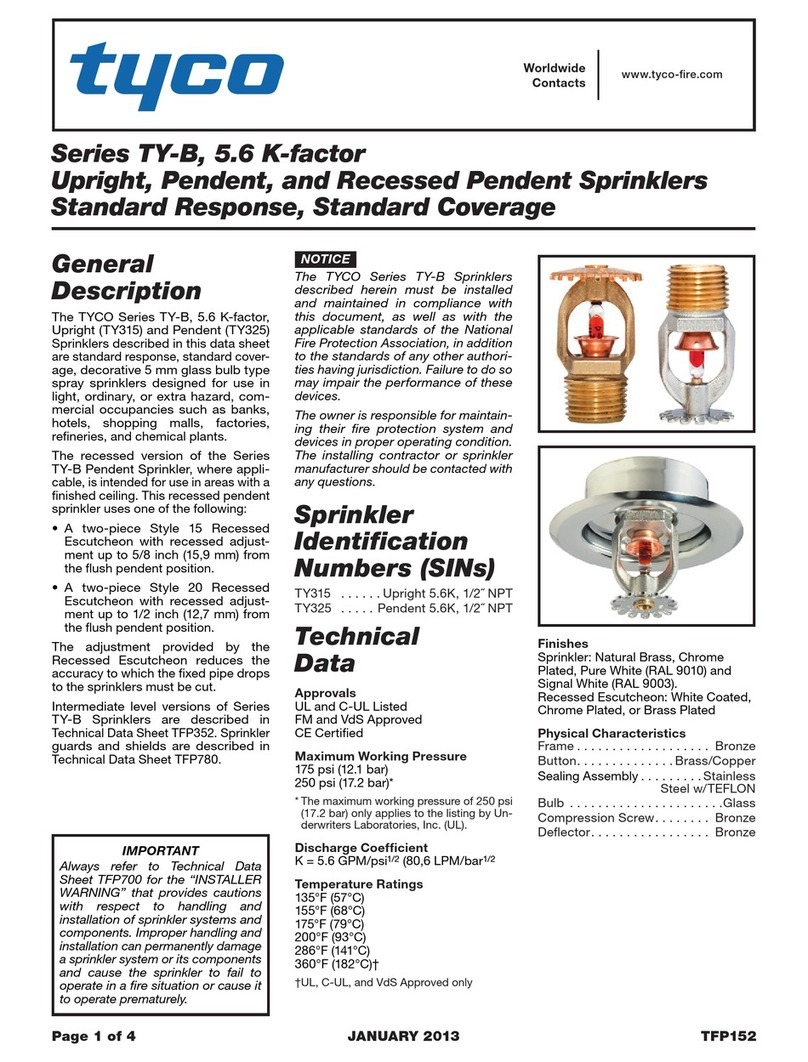

The TYCO Series TY-B, 5.6 K-factor,

Horizontal and Vertical Sidewall Sprin-

klers described in this technical data

sheet are standard response, standard

coverage decorative 5 mm glass bulb

type spray sprinklers designed for use

in light and ordinary hazard, commercial

occupancies such as banks, hotels, and

shopping malls.

They are designed for installation along

a wall or the side of a beam and just

beneath a smooth ceiling. Sidewall

sprinklers are commonly used instead

of pendent or upright sprinklers due to

aesthetics or building construction con-

siderations, where piping across the

ceiling is not desirable.

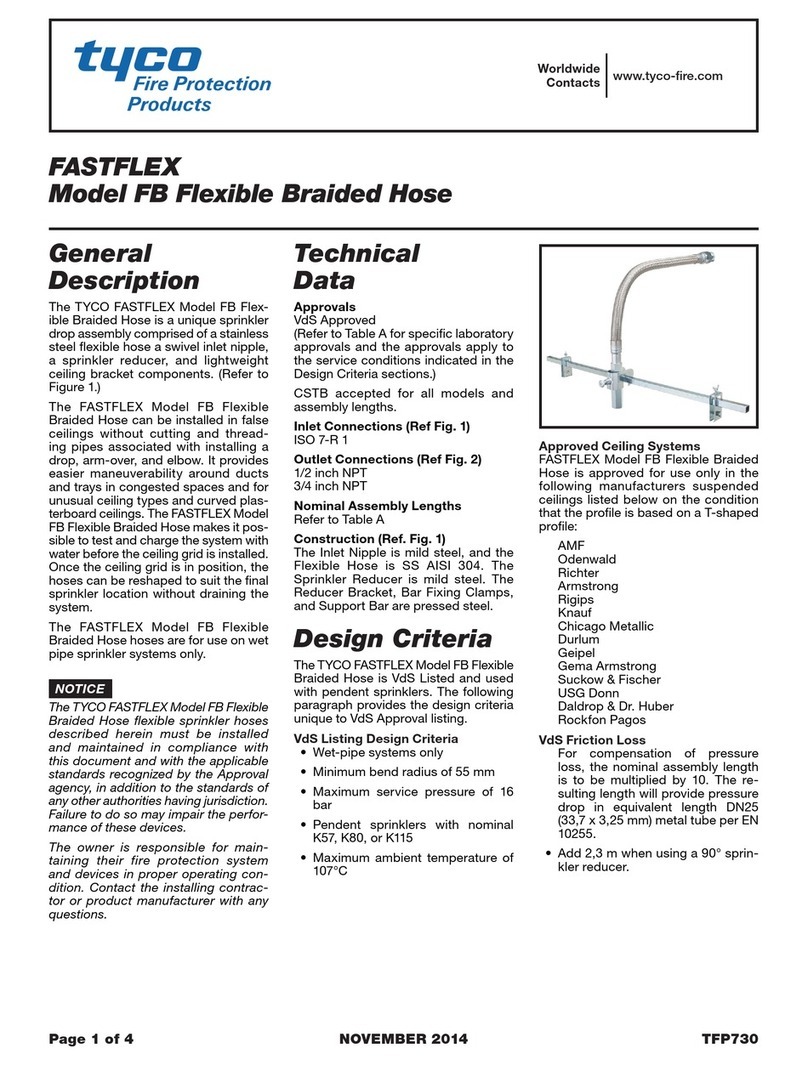

The recessed version of the Series TY-B

Horizontal Sidewall Sprinkler is intend-

ed for use in areas with a nished wall.

It uses a two-piece Style 10 Recessed

Escutcheon. The Recessed Escutcheon

provides 1/2 inch (12,7 mm) of recessed

adjustment or up to 3/4 inch (19,1 mm)

of total adjustment from the ush side-

wall position. The adjustment provided

by the Recessed Escutcheon reduces

the accuracy to which the xed pipe

nipples to the sprinklers must be cut.

Corrosion-resistant coatings, where

applicable, are utilized to extend

the life of copper alloy sprinklers

beyond that which would otherwise be

obtained when exposed to corrosive

atmospheres. Although corrosion re-

sistant coated sprinklers have passed

the standard corrosion tests of the ap-