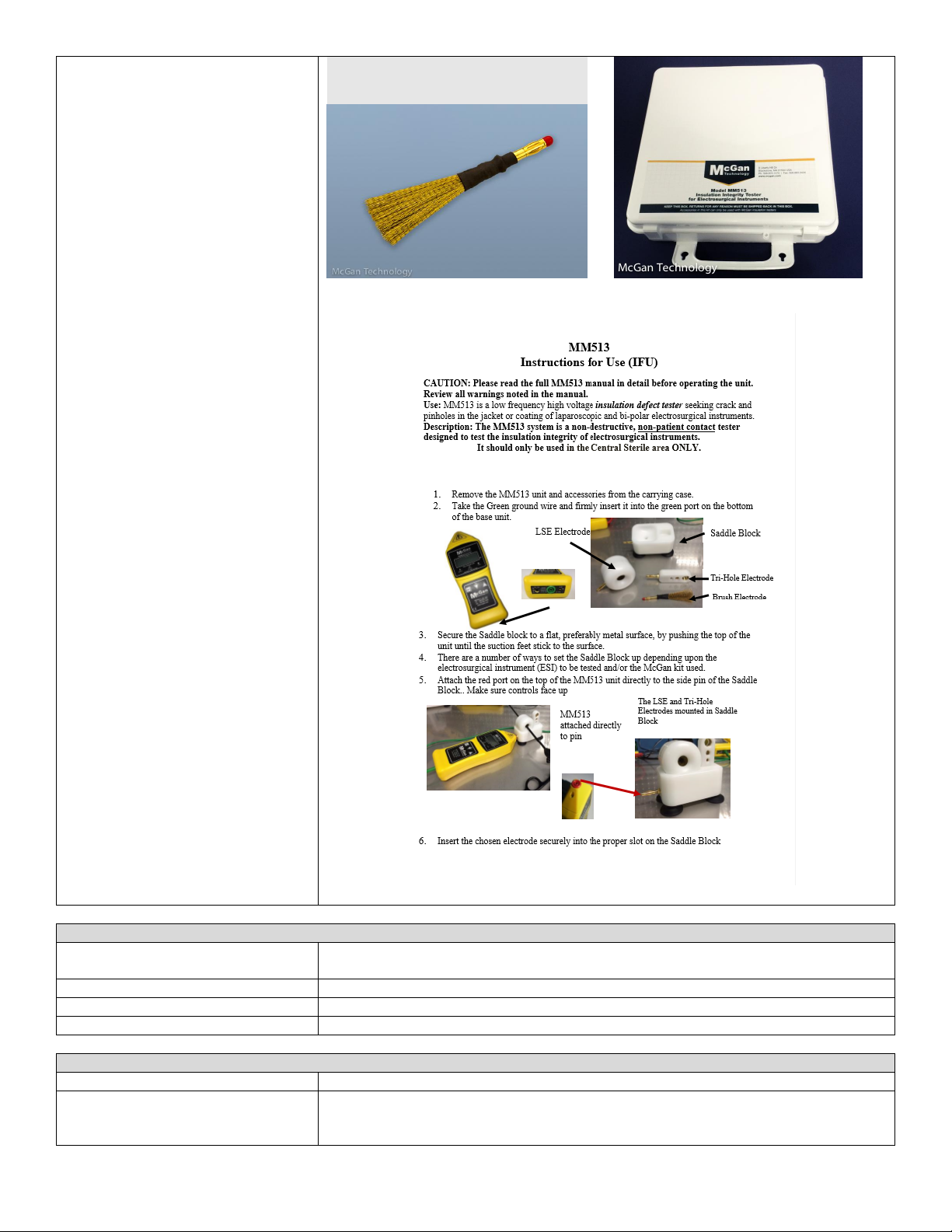

●DO NOT operate unit if you are not in good health. People with a cardiac

condition should not operate this unit.

●DO NOT operate this unit if you have a pacemaker. This unit should only be

used for checking porosity (or electrical breakdown) of dielectric or insulating

materials (e.g., Jacketing material, powder coatings).

●DO NOT use this unit around other machinery. An electrical shock may cause

the operator to fall and injure themselves.

●DO NOT operate this unit around people who not directly involved in the testing

procedure.

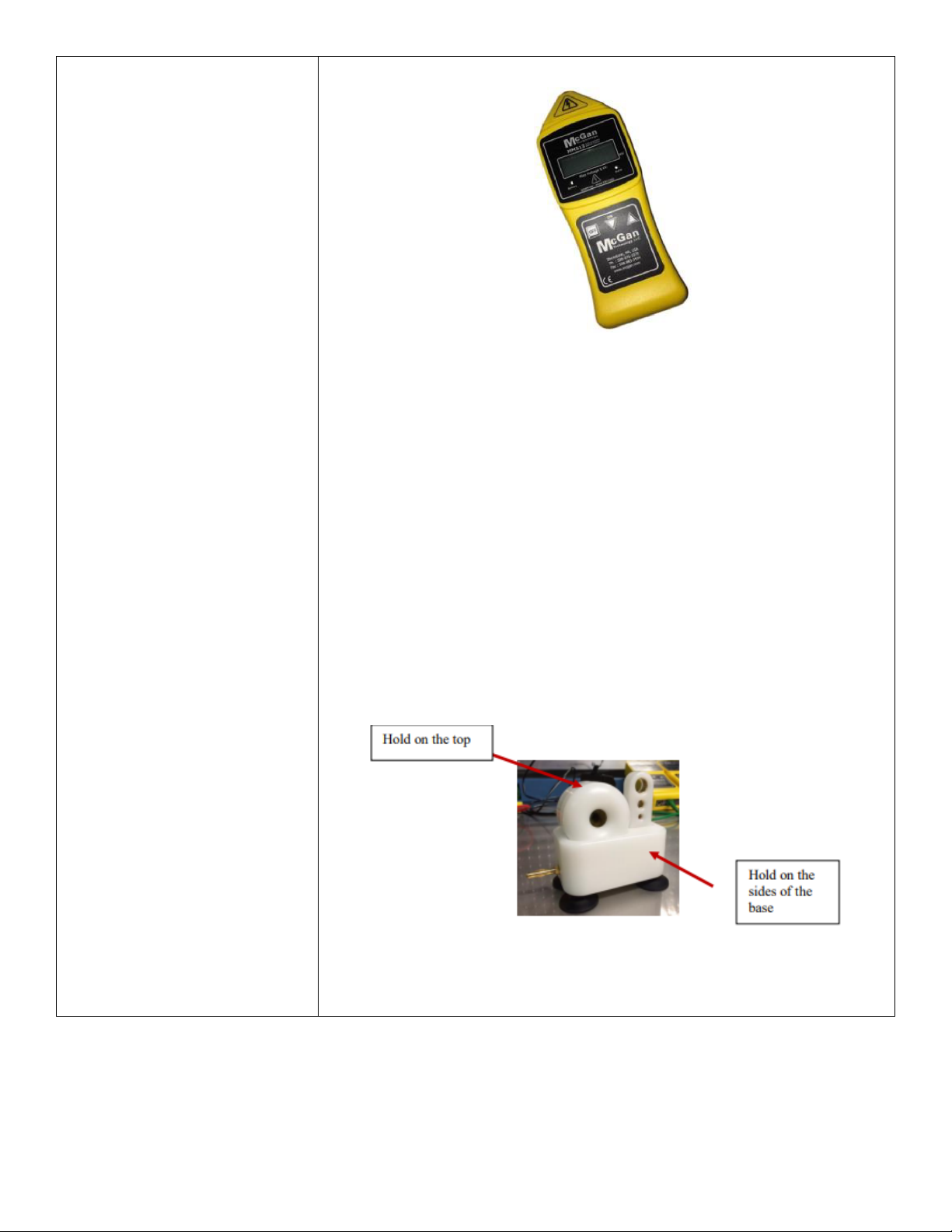

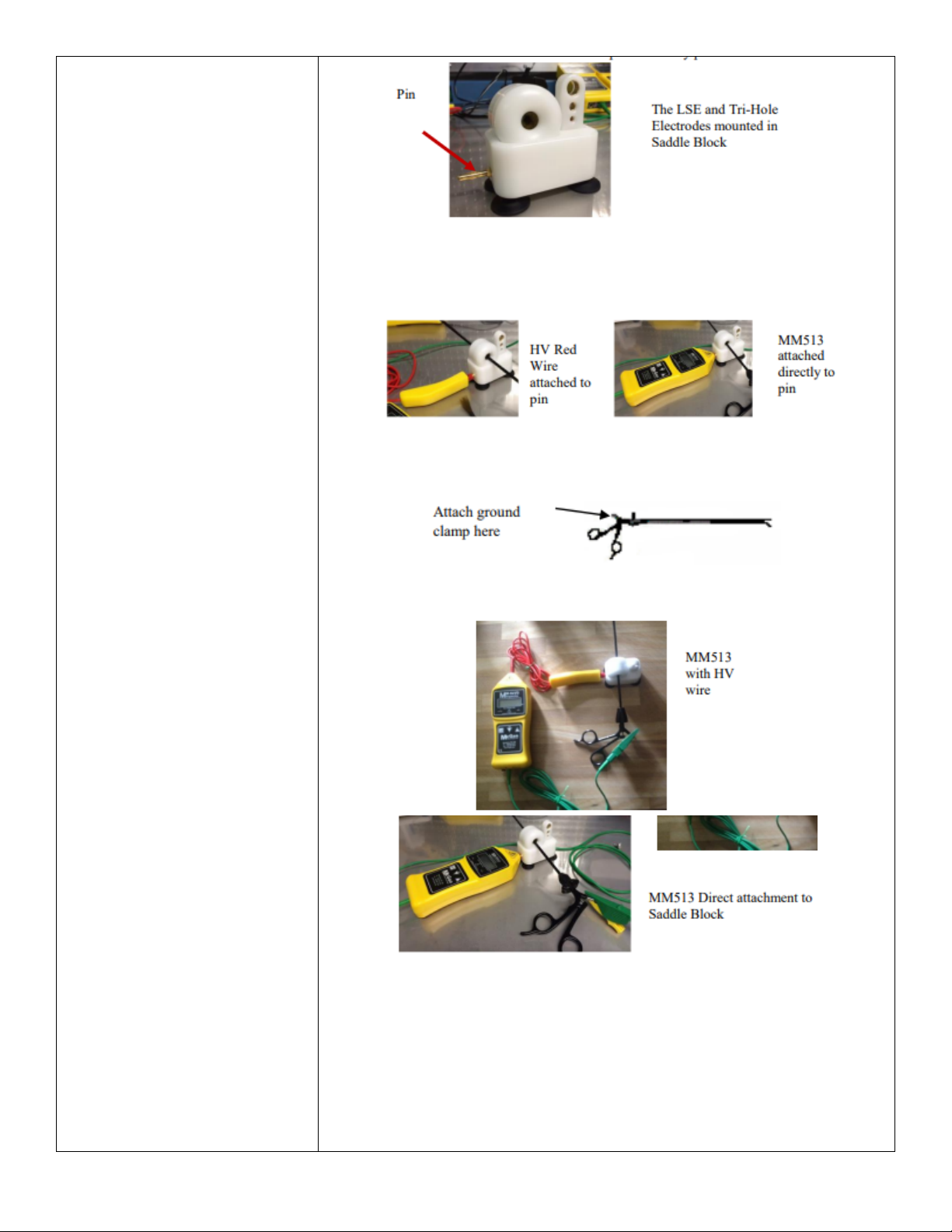

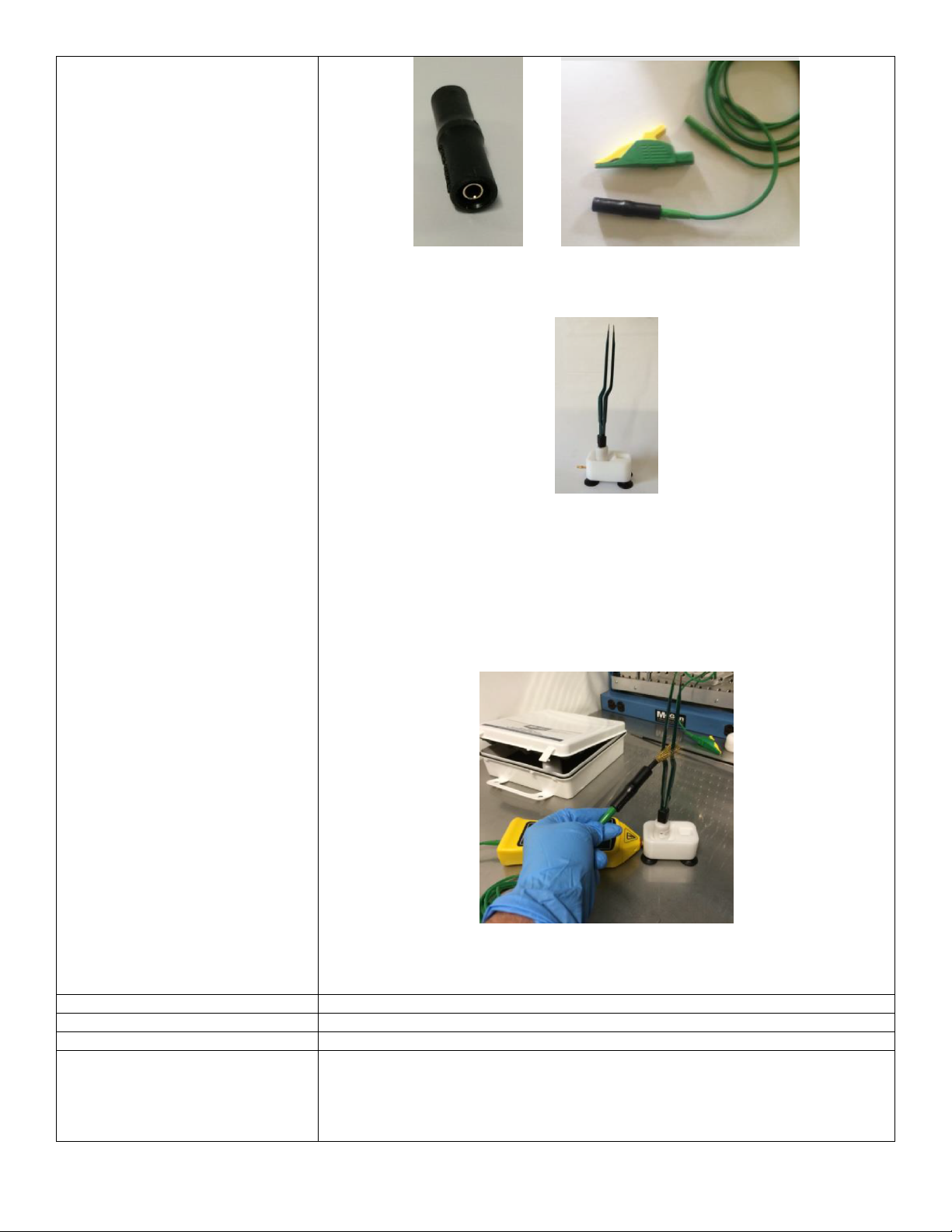

●DO NOT operate this unit other than McGan Technology Probes. McGan

Probes CAN ONLY be used with the appropriate McGan Insulation Tester(s).

●DO NOT simultaneously handle the brush electrode and ground clamp, as it will

cause a mild “tingle”. Use surgical gloves as a precaution against “tingle”.

●You cannot operate the MM513 unit with the AC adaptor plugged into the

rechargeable battery port on the bottom of the base unit.

●ONLY USE Lithium Polymer (LiPo) battery and the associated AC power

adapter (PN/5VQACP-0015) provided with the M513 system.

●LED battery indicator light will illuminate when the unit is low on power.

oIf the power from the battery is too low the LED will not illuminate.

oIf the MM513 fails to operate due to battery failure, contact Customer

Service.

●Always keep the working end of any of the probe electrodes away from your

body

●Do not touch probe electrodes when the instrument is activated.

●After the instrument has been turned off, always ground the probe before

disassembling the unit to ensure that any residual charge has dissipated.

⚠

DANGER ⚠

●DO NOT use wet. After cleaning, thoroughly DRY all areas before using the

components, and inspect for any defects in the electrodes.

●DO NOT use the test equipment in any combustible or flammable

atmosphere (i.e., flammable anesthetics),as a test voltage can cause an arc or

spark to be generated and an explosion could result.

Troubleshooting