Heat Wave HW150 User manual

WARM IT UP WITH AFREE SOURCE OF HEAT!

Siebring Manufacturing, Inc.

303 S. Main St. PO Box 658

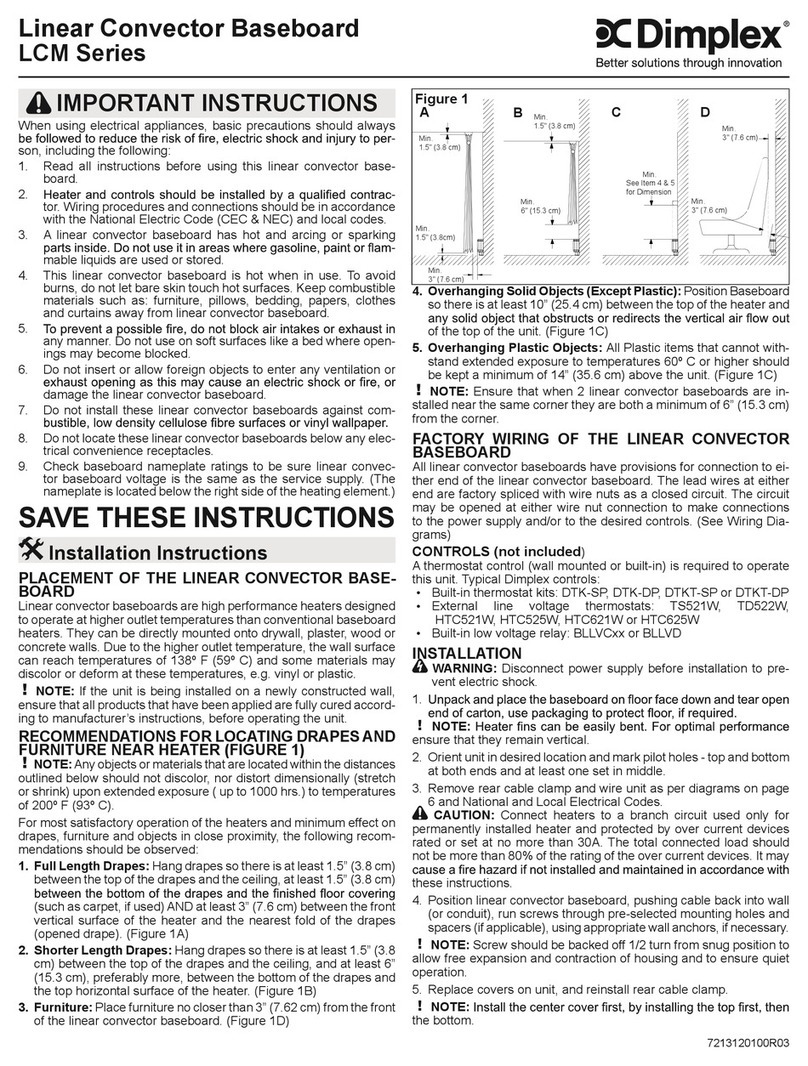

George, IA. 51237

Ph. 712-475-3317

Fax 712-475-3490

www.siebringmfg.com

1

TABLE OF CONTENTS

IMPORTANT NOTES –PLEASE READ

1

Warranty Policy and Conditions that Void the Warranty

1

Preface

1

TABLE OF CONTENTS

1-5

1.00

WARNINGS & WARRANTY

6-9

Letter from Kagi Heating & Supply

10

2.00

GENERAL OPERATION: How a HEATWAVE Furnace Works

11

3.00

OVERVIEW: Furnace Controls and Operation

12

3.01

Thermostat

13

3.02

Oil Primary Control

13

3.03

Fan Control

14

3.04

Hi-Limit Control

14

3.05

Barometric Draft Control

14

3.06

Atomizing Air Regulator

15

3.07

Oil Preheater

15

3.08

Oil Preheater Thermostat

15

3.09

Air and Oil Solenoid Valve

16

3.10

Cad Cell

16

3.11

Oil Regulator

17

3.12

Air Pressure Switch

17

3.13

Combustion Air, Blast Tube, Air Turret Band Adjuster

17

3.14

Igniter Electrodes

17

3.15

Nozzle

18

3.16

Neon Indicating Lamps

18

3.17

Preheater On / Off Switch

18

3.18

Soft Start Tank (Standard on all KAGI Burners)

19

4.00

INSTALLATION

19

4.01

Consideration for Proper Installation

19

4.02

Required Reference Materials

19

4.03

Introduction

20

4.04

Site Selection Requirements

20

4.05

Installation of Furnace on a Combustible Floor

21

4.06

Installation: Ceiling Requirements

21

4.07

Installing Heater Too High

21

4.08

Ventilation and Combustion Air Requirements

21

4.09

Ventilation and Combustion Air Groupings

21

4.10

Location of Furnace Considering Ventilation & Combustion Air

21

4.11

Air Circulation / Heat Distribution

22

4.12

Minimum Clearances from Combustible

23

4.13

Blower Installation

23

2

4.14

Burner Installation

23

4.15

Chimney Requirements

24

4.16

Ceramic or Masonry Chimney

25

4.17

Chimney Connector

26

4.18

Chimney Clearance Outdoors

27

4.19

Special Chimney Caps for Down Drafts

27

4.20

Barometric Damper / Barometric Draft Control

27

4.21

Oil Tank Installation / Pump / Piping Section

28

4.22

Furnace and Storage Tank Clearance

28

4.23

Tank Size Selection

28

4.24

Oil Tank Temperatures

29

4.25

Underground Tanks (Use Of)

29

4.26

Vent Pipe for the Storage Tank

29

4.27

Fill Pipe

30

4.28

Tank Venting / Filling Gauge

30

4.29

Tank Agitator (For Mixing Different Viscosity Oils)

30

4.30

Floating Pick-Up Oil Sump (For Dirty Underground Tanks)

30

4.31

Pump Installation and General Pump Information

31

4.32

Optimum Pump Location

32

4.33

Fuel Filter and Location

32

4.34

Piping and Fuel Lines

33

4.35

Pipe Diameter

34

4.36

Pipe Material

34

4.37

Compressed Air Supply

34

4.38

Compressed Air Piping

35

4.39

No Compressed Air Available

36

4.40

Electrical Supply

36

4.41

Electrical Conduit

37

4.42

Electrical Supply: Pump

37

4.43

Pump Connections Form Wiring Schematic

37

4.44

Electrical Wall Thermostat

37

4.45

Ducted Installation

37

4.46

Ducting Pressure and Changes

38

4.47

Louvers (Non Ducted Installations)

38

4.48

Comment on Installation Diagram

38

4.49

Comment on Installation Wiring Diagram

39

4.50

Summary: Installation Instructions

39

5.00

START-UP PROCEDURE

40

5.01

Pump Priming and Additional Start-Up Information

41

5.02

Furnace Smells When First Fired Up

44

6.00

FURNACE ADJUSTMENT AND GENERAL OPERATION

GUIDLINE

44

6.01

Furnace Controls Requiring Adjustment

44

3

6.02

Adjusting the Secondary Air Without a Smoke Spot Tester

45

6.02a

Adjusting the Flame Using the Cad Cell on Furnaces Where There is

No Flame Observation Port

45

6.03

Adjusting the Oil Pressure Regulator

45

6.04

Fan Speed

46

6.05

Draft Readings

46

6.06

Power Draft Boosters

47

6.07

Venting all Combustion Air from Outdoors to Overcome Negative

Building Pressures

47

6.08

Viewing the Flame from Observation Port

47

6.09

Optimum Flame Length

48

6.10

Flame Length Will Increase On Its Own

48

6.11

Optimum Flame Color

49

6.12

Dark Red / Orange Flame

49

6.13

Over Firing Your Furnace

49

6.14

Adjustable Flow Rate

49

6.15

Filter Waste Oil

49

6.16

Filter Waste Oil Through a Magnet

50

6.17

Adding Thin Fuels to Waste Oil Supply

50

6.18

Burning Rear End Grease

50

6.19

Burning Synthetic, Cooking, and Other Oils

50

7.00

CHECKS AND MAINTENANCE

51

7.01

Maintenance and Service

51

7.02

Stack Temperature for Determining When Dust Clean-out is Needed

51

7.03

Protective Clothing

52

7.04

Dust Removal From 2nd Clean-out door (CAUTION)

52

7.05

Maintenance Schedule

53

7.06

Seasonal Cleaning

54

7.07

Burner Cleaning

57

7.08

Cleaning Strainer in Waste Oil Transfer Pump

58

7.09

Cleaning the Suction Strainer in the Storage Tank

58

7.10

Cleaning the Oil Filters

59

7.11

Cleaning the Nozzle

59

7.12

DELETED

7.13

Cleaning Lines, Solenoids, and Preheater Block

60

7.14

Cleaning the Cad Cell

61

7.15

Checking the Cad Cell

61

7.16

Oil Primary Relay Test

62

7.17

Cad Cell Sensor Test

62

7.18

Checking the Blower Pulley

63

7.19

Blower Belt Tension

63

7.20

Removal of Accumulated Excess Oil

63

7.21

Checking the Oil Primary Control

64

7.22

Bleeding the Pump

64

7.23

Checking the Oil Pump Properly

65

4

7.24

Checking Regulators

66

7.25

Checking Transformer

66

7.26

Checking for Water in Nozzle Discharge Spray

67

7.27

Checking for Water in Oil Supply

67

7.28

Checking for Water in Air Supply

68

7.29

Checking Neon Indicator Lights

68

7.30

Jumping Switches to Check Components

68

8.00

TROUBLE SHOOTING

69

8.01

Seven Common Reasons Why Burner Will Not Ignite

69

8.02

Flooded Furnace

70

8.03

Burner Trouble Shooting

71

8.04

Furnace Fails to Start

72

8.05

Furnace Starts, Burns a Short Time, Then Shuts Down

73

8.06

Furnace Burns With Smoky Flame

74

8.07

Furnace Burns With Long Narrow Flame

74

8.08

Furnace Burns, Flame Has Sparks and “Fireflies”

75

8.09

Flame Impingement

75

8.10

Furnace Burns With Short Flame

76

8.11

Flame Pulsates

76

8.12

Flame Pulsates Now and Then, Especially When It’s Windy and

Sometimes Goes Out

76

8.13

Furnace Burns, But Puts Out Low Heat

77

8.14

Flame is Too Short and Gets Shorter When Increasing the Air

Pressure, and Then Goes Out

78

8.15

Flame is Hard to Adjust, a Little Turn and It Is Too Much, A Touch

Backwards and It’s Too Small

78

8.16

Flame Will Continue When the Inspection Door Is Opened, But

Goes Out When It Is Closed

78

8.17

Furnace Burns Too Hot

78

8.18

Furnace Does Not Shut Off

79

8.19

Furnace Runs Well, Then Burner Stops and Blower Blows Cold Air

79

8.20

Furnace Burns, But Rumbles

79

8.21

Furnace Operates, But Smells

80

8.22

Furnace Drips Oil

80

8.23

Furnace Set At Night Is Off By Morning

80

8.24

Furnace Has Excessive Ash Buildup

81

8.25

Furnace Has Black Clinkers In Chamber

82

8.26

Furnace Chamber Flaking Metal

82

8.27

Flame Is Not Burning in the Center of the Baffle Target (See 8.27)

82

8.28

Furnace Baffle Has Burnout Hole or is Loose and Not in the Right

Position

82

8.29

Oil Primary Control Trouble Shooting

83

8.30

Oil or Air Solenoids Chatter

83

8.31

Oil Regulator is Noisy

83

8.32

Pump Does Not Work When Burner Comes On

84

5

8.33

Pump Works, But Runs Hot

84

8.34

Pump Works, But Is Noisy

85

8.35

Pump By-Pass Pressure Too High

85

8.36

Pump Turns, But No Pressure

85

8.37

Pump Has Too High Vacuum Or No Vacuum

86

8.38

Pump Was Working Till the Oil Filters / Screen in the Pump Was

Cleaned

86

8.39

No Spark At Electrodes

87

8.40

No Oil Discharge At Nozzles

87

8.41

Deleted

8.42

No Oil Spray From Nozzle: Due to a Malfunctioning Air Pressure

Switch

87

8.43

Burner Has Spark and Oil Spray, Will Not Ignite

88

8.44

Blower Runs Continuously

88

8.45

Furnace Fan Cycles Too Often, Room Is Cold

89

8.46

Continuous Air Flow Out of Nozzle

89

8.47

Continuous Oil Flow Out of Nozzle

90

8.48

Faulty Wall Thermostat

90

8.49

Green Light Comes On and Then Goes Out, After Waiting, Comes

Back On

90

8.50

Oil Pressure Gauge on the Burner Starts to Climb When the Burner

Shuts Off and Gets So High It Ruins the Gauge

91

9.00

MISCELLANEOUS

92

9.01

Furnace Shut Down for Extended Periods

92

9.02

Operating Furnace On Warm Day To Rid Waste Oil

92

SUNTEC FACTORY PUMP INFORMATION

DELTA FACTORY SERVICE / MAINTENANCE

CAUTION DECALS AND NOTES

MAINTENANCE SCHEDULE AND DECALS

BURNER PARTS LIST (In rear of book, illustrated drawings)

10.0 Index of Drawings 93

Note: Letter drawings A-F, F(ICM), F-1 & F-2 (figures 33-41) apply to the Kagi

S-250 & S-500 burners and are broken down by component to make viewing &

wiring easier and less confusing.

6

IMPORTANT NOTES: PLEASE READ

When the furnace is delivered to you, BE SURE THAT THE FURNACE CABINET

AND OTHER BOXES THAT ACCOMPANY IT ARE OPENED AND CHECKED

FOR FREIGHT DAMAGES BEFORE THE DRIVER LEAVES as it is easier to file a

claim if the driver signs the bill of lading and acknowledges that the furnace is damaged.

If there is no time to inspect the shipment, observe outside carton damages and make note

of this on the delivery bill of lading. If you do not, you may NOT get full compensation

on damages as some freight companies will pay you on “hidden damages” which may be

only a partial payment on your loss. Siebring Manufacturing, Inc. carefully inspects and

packages furnaces for shipment, and has NOT sent you a damaged one.

Open the boxes and remove the contents and check that you have one of each of the

following items:

A. OWNERS MANUAL

B. SQUIRREL CAGE CIRCULATION BLOWER

C. ELECTRIC MOTOR FOR (B)

D. FAN BELT FOR (B)

E. SMALL PARTS PACKAGE FOR (B), (B, C AND E MAYBE

PREASSEMBLED)

F. ALUMINUM WASHABLE FILTER & FITTINGS

G. CHECK VALVE

H. SUCTION STRAINER

I. WASTE OIL TRANSFER PUMP

J. WALL THERMOSTAT

K. 8 INCH BAROMETRIC DAMPER

IMMEDIATELY NOTIFY YOUR HEATWAVE DEALER OR SIEBRING

MANUFACTURING OF ANY SHORTAGES

Siebring Manufacturing, Inc. and our insurance carrier need to know the location of all

units sold to assist in handling warranty claims and to disseminate important service

bulletins directly to owners.

WARRANTY POLICY

MULTI-OIL FUELED HEATER (LIMITED WARRANTY)

7

If you are in need of service support and your local dealer or Heatwave representative is

not available or cannot help you, contact the Kagi Customer Service Department (888-

866-5244) during normal business hours (Pacific Time). Read and check your Heatwave

Owner’s Manual under “Trouble Shooting” first as your problem may be very simple to

solve. As an owner, you can perform a number of checks and maintenance procedures

with the assistance of you manual. Before a part is considered defective, a Kagi service

technician can help you determine if it just needs cleaning and/or adjustment.

HEATWAVE Warrants to the purchaser of this Multi-Oil Fueled Heater Unit that it will

repair or replace any part which in normal use proves to be defective in material or

workmanship within a period of ONE (1) YEAR from the date of purchase, provided

same is returned for factory inspection and warranty determination. The combustion

chamber (Limited Warranty) is warranted for a period of TEN (10) YEARS at a pro-rated

schedule, provided the heater is properly installed and maintained.

HEATWAVE does not warrant the paint finish as this is subject to abrasion, scratching,

and discoloration during installation and operation. The warranty does NOT cover any

labor charges involved with parts replacement or service unless preauthorized by

Siebring Mfg., Inc. in writing.

NOTICE: The Heatwave Multi-Oil Fueled Burners, Model HW150, HW250, and

HW350 are tested, designed, and listed to burn the following:

A. USED CRANKCASE OILS UP TO 50 SAE WEIGHT

B. #2 FURNACE FUEL OILS

C. USED AUTOMATIC TRANSMISSION FLUID

WARNING: CONDITIONS THAT WILL VOID THE WARRANTY

A. Using in the heater or adding to the storage tank substances, including, but not

limited to the following: paint, thinner, gasoline, other volatile liquids, or

solvents, transformer oils, or gear lubes. Some of these substances have a high

chloride content which can oxidize HEATWAVE stainless steel targets and

chambers. It is illegal to mix any of these substances with waste oil and doing so

can cause a hazardous condition.

B. Tampering with the internal components of the safety switches, air/oil, aluminum

preheater, or any parts in general.

C. Not installing the heater properly as per instruction in this manual and/or

according to local and state codes.

D. Not maintaining the heater according to instructions in this manual.

E. Abusing or altering any part.

F. Using parts other than those supplied by Siebring Mfg., Inc. to operate this heater.

G. Over-firing the heater.

NOTE: Siebring Mfg., Inc. and our insurance carrier need to know the location of all

heaters sold in order to distribute service bulletins directly to the owner.

8

For warranty service, simply contact the dealer from whom the heater was purchased. If

the unit was purchased directly from Siebring Mfg., Inc., notify Siebring Mfg., Inc. in

writing of any defects. No parts will be accepted for warranty inspection unless Siebring

Mfg., Inc. has issued an RGA (Returned Goods Authorization) number. Before this

number is given, the part or parts will have been determined by phone to be defective and

the model, serial number, replacement part number, purchase date, and nature of defect

will be recorded.

This warranty gives you specific legal rights and you may have other rights which may

vary from state to state.

PREFACE

All installations must be made in accordance with state and local codes, which vary from

state to state, and may differ from this manual.

Heater must be installed and / or inspected by a licensed heating contractor before

operation.

IMPORTANT NOTES AND CAUTIONS:

RULES AND REGULATIONS PROMULGATED BY STATE AND LOCAL

AUTHORITIES TAKE PRECEDENCE OVER THE GENERAL INSTRUCTION

PROVIDED IN THIS MANUAL.

THE INSTALLATION OF THE EQUIPMENT SHALL BE IN ACCORDANCE WITH

NFPA (NATIONAL FIRE PROTECTION AGENCY) REGULATIONS OF

AUTHORITIES HAVING JURISDICTION OVER ENVIRONMENTAL MATTERS,

AND FUEL, FIRE, AND ELECTRICAL SAFETY.

Installation, operation, and maintenance permits from each of the above authorities

may be required, as well as municipal permits.

The three Heatwave furnaces Models HW150, HW250, and HW350 are listed with ETL

Laboratories, which have tested the U.L. Standards for waste oil burning furnaces.

Models HW150, HW250, and HW350 are listed to use #2 furnace fuels, automatic

transmission oils, and used crankcase oils up to 50 SAE.

CAUTION: NOT FOR RESIDENTIAL USE!

CAUTION: DO NOT BURN GASOLIN OR ADD GASOLING TO THE FUEL

SUPPLY!

CAUTION: DO NOT TRY TO BURN CLEANING FLUIDS, PAINT THINNERS,

OR OIL ADDITIVES IN THIS APPLIANCE!

9

CAUTION: DO NOT PUSH THE RESET BUTTON ON A FLAMEOUT IF THE

FURNACE IS HOT TO THE TOUCH AND FILLED WITH OIL

VAPORS OR FUMES!

CAUTION: DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

LIQUIDS NEAR THIS FURNACE!

CAUTION: KEEP THE FUEL VALVE NEAREST THE SUPPLY TANK SHUT

OFF WHEN THE BURNER IS SHUT DOWN FOR EXTENDED

PERIODS!

CAUTION: DO NOT INSTALL THE FURNACE OR BURNER ON OR NEAR

COMBUSTABLE MATERIALS! (See instructions for minimum

distances.)

CAUTION: IF YOU TURN OFF THE POWER TO THE BURNER, FOR ADDED

SAFETY, TURN TO “OFF” OR OPEN THE CIRCUIT TO THE

WALL THERMOSTAT.

CAUTION: DO NOT TAMPER WITH THE CONTROLS; CALL YOUR

TECHNICIAN!

CAUTION: THE EXHAUST STACK MUST BE CLEANED ANNUALLY!

CAUTION: WASTE OILS CAN CONTAIN POISONOUS HEAVY METALS

AND OTHER FOREIGN MATERIALS. WHEN BURNED, THESE

COMPOUNDS ARE DEPOSITED WITHIN OR EMITTED FROM

THIS HEATING APPLIANCE AND THEREFORE CARE SHOULD

BE TAKEN WHEN USING, CLEANING, AND MAINTAINING

THIS EQUIPMENT!

CAUTION: WHENEVER ANY CLEANING, INCLUDING THAT OF THE FLUE

AND EXHAUST STACK IS DONE, PROTECTIVE CLOTHING,

INCLUDING GLOVES AND A FACE MASK OR RESPIRATOR,

MUST BE WORN!

10

.From Kagi Heating & Supplies:

THANK YOU for selecting a HEATWAVE MULTI-FUELED FURNACE. Your

furnace may come to you unassembled to reduce shipping damage. This furnace will be

simple to assemble –just follow the instructions in this manual. It will be operational in

a short time. NOTE: The Heatwave furnace maybe shipped to you already assembled.

Proper installation is extremely important for safe, reliable operation of the Heatwave

furnace. Simple maintenance on the furnace must be performed periodically or the

furnace will not start properly and components of the furnace will fail, leading to

premature replacement of parts. MOST COMPLAINTS about waste oil furnaces,

regardless of the manufacturer, are due to improper installation and maintenance.

HEATWAVE furnaces all have standard UL-listed safety devices that are used in

residential oil furnaces and all models Siebring Mfg., Inc. manufactures are engineered to

operate on a negative draft. Should the chamber leak, all obnoxious gases will be vented

up the chimney, not into the room. An UL-listed electric eye monitors flame, and should

a flameout occur the burner will shut down immediately. Should the circulation blower

fail, a hi-limit switch set at 200° F. will immediately shut off the burner which will not

start again on its own, but must be reset.

I have installed, investigated, and field-checked hundreds of waste oil furnaces and I urge

reading this manual very carefully before installing and operating your HEATWAVE

furnace. Your reward will be a furnace that eliminates your waste oil problems, and

saves you up to hundreds of dollars each month during the heating season.

Tom Kagi Sr.

Sales / Engineer

11

2.00 HOW A HEATWAVE FURNACE WORKS:

When the HEATWAVE furnace is energized from an electrical service panel, the current

goes directly to the High-Limit micro switch in the High-Limit fan switch. This is a

normally closed switch, and from there it goes to the burner. Inside the burner is an

aluminum heat sink block, which begins to heat. This aluminum heat sink houses two

electrical heating elements. The larger wattage heater (250 watts) is always on and

preheats the air for atomization and helps heat the waste oil contained in this aluminum

block. The lower wattage heater (50 –100 watts) is the oil pre-heater and is installed in

the oil passage within the aluminum block. This heater is energized only when the burner

is operating and heats the oil prior to entering the nozzle. This aluminum block is kept at

approximately 160° F. by a thermostat contacting the aluminum block.

There is normally open snap thermo-disc, which closes on temperature rise. When this

thermo sensor closes, it energizes a green neon indicator light on the burner which signals

the burner has preheated the oil to ignition temperature, and the burner is ready to fire.

When the wall thermostat is turned up above ambient temperature, and the points in the

thermostat are closed, calling for heat, a jump connection is created between the two TT

terminals on the oil primary control and the primary control load wire is activated

sending power to all of the burner components. The combustion blower now comes on,

air pressure is sensed on the air pressure switch sends power to the fuel pump. The air

and oil solenoid valve is normally closed and when it receives current, it opens; allowing

air to be pushed out from the nozzle with compressed air and through venture action, oil

is allowed to flow and sprayed into the firing chamber.

A 14,000-volt transformer is energized, always sparking while the burner is on,

producing a hot, constant, electrical spark. The combustion air in the blast tube blows

into this blue spark, lengthening it, and moves this arc into the oil spray igniting it.

The waste oil is sucked out, from the aluminum block by a special nozzle using

compressed shop air or an optional remote air compressor. This nozzle has a large

discharge orifice to allow large colloidal matter suspended in waste oil to pass through.

Inside this special nozzle is an oil distributor which spins the oil and air out into

microscopic droplets to allow a complete burn. When the oil primary control is

energized, a normally closed oil solenoid is energized open, and oil flows into the block

from a remote gear-driven pump. The pump receives current from an air pressure switch,

which closes at approximately at 9 PSI, which delivers oil from the oil storage tank

through a 100-micron filter directly to the burner. This pump is always working when

the burner is firing and stops when the burner cycles off. The smaller wattage element

12

heater in the aluminum heat sink block is connected to the oil primary circuit and when

energized, starts to heat the oil. This oil heater turns on and off when the burner is

cycling. This unique feature is the reason KAGI burners are so reliable. Others on the

market keep a constant high temperature on the oil, and when these heaters are left on for

extended periods of time, the oil will carbon and coke up in the pre-heater.

The KAGI burner has a variable oil regulator, which allows a variety of different-

viscosity oils to be burnt hence the variable BTU output. It can burn from ONE HALF of

a gallon to FOUR gallons per hour, depending on the size of the nozzle used and the

adjustment set on the burner.

When ignition is established, important adjustments to the blast tube air (combustion air)

oil pressure, oil flow, and air for atomization must be made for a clean burn.

When the proper adjustments are made, the oil burns with a clean, extremely hot,

yellowish-orange flame. The retention-head theory is utilized in the KAGI burner by

spinning the heavier droplets of waste oil together, making a complete burn. When the

burner is operating for a while and the cabinet air reaches a preset temperature, a fan

switch automatically turns the circulation blower on, forcing heated air into the room. A

UL-listed cadmium sulfide cell, or “electric eye”, monitors the flame and should a flame-

out occur, this safety switch turns the burner off immediately.

Should circulation blower fail, an UL-listed safety cabinet switch will automatically turn

off the burner when it reaches 200° F.

The heated air from the burner passes to the end of the combustion chamber, and is

directed to the opposite end of the chamber, making a total of three passes before it exits

out the chimney stack. This reduces the stack temperature, and makes your

HEATWAVE furnace one of the most thermo-efficient furnaces on the market.

3.00 OVERVIEW: FURNACE CONTROLS AND OPERATION

The following is a list of furnace controls:

1. THERMOSTAT

2. OIL PRIMARY CONTROL

3. FAN CONTROL

4. HI-LIMIT CONTROL

5. BAROMETRIC DRAFT CONTROL

6. AIR REGULATOR

7. OIL PREHEATER

8. PREHEATER THERMOSTAT

9. OIL SOLENOID

10. AIR SOLENOID

11. CAD CELL

12. OIL REGULATOR

13

13. AIR PRESSURE SWITCH

14. PREHEATER THERMOSTAT (snap disc)

15. PREHEATER ON/OFF SWITCH

16. AIR TURRET BAND ADJUSTER

17. IGNITOR ELECTRODES

18. NOZZLE

3.01 THERMOSTAT

The wall thermostat controls the operation of the automatic furnace to keep room

temperature within a desired range. The thermostat should be located approximately five

feet above the floor, in a central location with good natural air circulation. Avoid placing

the thermostat near opening doors or other sources of draft (including duct flow). The

thermostat will not operate properly unless it is mounted level.

The thermostat has a heat anticipator that artificially supplies heat to the sensing element

while the burner is operating. The anticipator prevents the room temperature from

exceeding the desired setting.

Follow the manufacturer’s instructions for installation and adjustment. An anticipator

setting of 0.2 should be used for the Carlin 48245S primary. The wall thermostat should

not be installed where it may be affected by drafts or flow from air ducts.

3.02 OIL PRIMARY CONTROL

The oil primary control is the gray or black rectangular box sitting on the top right side of

the burner. It has a red reset button on the top of the control (see figure 11).

When the wall thermostat is set for a temperature above the ambient temperature of the

room, the oil primary control starts the burner by switching on various components. A

cadmium sulfide cell, “electric eye” monitors the light level in the combustion chamber

to ensure there is fire. After 45 seconds, if there is no fire, the primary control shuts the

burner down. The burner will not restart unless the control is reset. Should the fire go

out at any time during operation, the oil primary control will automatically stop the

burner.

If fuel is not being ignited, this control precludes the burner from operating thereby,

preventing fuel from being sprayed into the combustion chamber.

CAUTION!! If a jumper wire is placed across the FF terminals on the oil primary

control, once the oil burner is started, the oil burner will continue to run, with or without

flame ignition. The cad cell switch is normally open, which means at room temperature

and without outside influence, it has no current continuity. The cad cell functions as a

jumper wire across the FF terminals. If the burner does not function without the jump

cable, stop and determine what the problem is. (See index of drawings for illustration).

14

CAUTION!! OPERATING THE BURNER WITH THE JUMPER WIRES ATTACHED TO

THE FF TERMINALS IS NOT RECOMMENDED AS THIS RESULTS IN BY-PASSING

THE OIL PRIMARY CONTROL, AN IMPORTANT SAFETY DEVICE THAT IS

DESIGNED FOR YOUR PROTECTION!

NOTE: The burner must be started first before the jump cable is attached, as attaching

the jump cable first will make the burner unable to start!

CAUTION!! DO NOT PRESS THE RESET BUTTON IF THE FURNACE IS HOT TO

THE TOUCH. ALLOW THE FURNACE TO COOL AND DO NOT PRESS THE RESET

BUTTON MORE THAN TWICE. (If the burner fails, check the “TROUBLE

SHOOTING” section and /or call your service attendant or service organization or

KAGI’S Customer Service Department.

3.03 FAN CONTROL

The fan control is a silver-colored rectangular box with a plastic push-and-pull button

that monitors the temperature of the air moving over the heat exchanger. When this

temperature reaches 120° F.*, the blower fan activates, distributing heat to the building.

After the burner shuts down, the blower operates until the temperature reaches

approximately 90° F.*. These temperatures are factory set and may require field

adjustments. To turn the fan on sooner, adjust the “ON” tab of the fan control to a lower

temperature. To run the fan longer after the burner shuts off, adjust the “OFF” tab of the

fan control to a lower temperature. (See figure 29 for illustration)

The plastic “Auto” or “Manual” button on the fan control is usually left in a pulled-out

position, which is “automatic”. When this button is pushed in to the “Manual” position,

the blower fan will come on immediately and stay on. This is the “summer fan” position

for air circulation during the warmer months. Figure 30-31.

*THESE TEMPERATURE SETTINGS MAY BE ADJUSTED UP OR DOWN.

3.04 HI –LIMIT CONTROL

The Hi-Limit control resides in the same unit as the fan control. It is a separate micro-

switch with its own circuitry. Normally set at 170°F, the limit will shut the burner down

when the temp setting is met. An additional safety control shuts down the burner if the

outlet air temperature exceeds a factory setting of 200° F., thereby, monitoring such

problems as overheating caused by a blower motor failure, loose or broken fan belt,

blockage of the ductwork, or other circulation related problems.

3.05 BAROMETRIC DRAFT CONTROL

The barometric draft control automatically prevents the draft in the combustion chamber

from exceeding a pre-set level by killing or reducing the draft in the event the weather

conditions cause a drop in the barometric pressure outside, WITHOUT this control a

15

fluttering flame or a serious flameout could occur. By building code, this control must be

installed!

A barometric draft control designed for oil burners must be installed in the flue pipe close

to the furnace, preferably in the first section of pipe. CAUTION: DO NOT USE A

WOOD BURNING DRAFT CONTROL as they are different from models used for oil

furnaces. The opening in the flue must be the full sized of the collar of the draft control.

Use a spirit level to ensure that the control does not lean backward or forward and that

the hinge is level. Be sure that it does not stick and is able to swing freely. Operate the

furnace at least 30 minutes before adjusting the draft control with a draft gauge. Be sure

it is adjusted to obtain top performance from your furnace. Excessive draft could cause

low carbon dioxide readings and excessive heat to leave through the chimney. (See

section 6.05 on Draft Readings)

3.06 ATOMIZING AIR REGULATOR (see figure 14)

The air regulator is located on the left side of the burner and controls the pressure of the

atomizing air reaching the nozzle. This air is necessary for operation of the special, low-

pressure nozzle; it sucks the oil out and breaks it into microscopic droplets. Too much air

pressure will prevent ignition and cause flameout, and too little air pressure will cause an

oxygen-starved, smoky flame. The adjustments will vary depending on the viscosity of

the oil, burning rate, altitude and location of the furnace. Set air pressure to 12 PSI or

above. The air regulator has a water separator and water drain on the filter bowl.

3.07 OIL/AIR PREHEATER WITH ON/OFF SWITCH (see figure 6)

Waste oil is preheated within this aluminum block at a thermostatically set temperature

when the on/off switch is activated. It can be turned OFF when furnace fuels that DO

NOT NEED HEATING are to be burned. The air for atomization is also heated in this

block for ignition. The temperature can be raised or lowered for different viscosity oils

by adjusting the preheater thermostat. The thermo-sensor contacts the aluminum block

on the outside and regulates the temperature at its setting. Aluminum transfers heat very

quickly and uniformly through this block. There are less than two ounces of oil in the oil

cavity that is heated, and the oil passages in the block are engineered to move the oil

quickly at a speed preventing the oil from jelling inside the block. The aluminum block

in the KAGI burner very seldom requires cleaning.

3.08 PREHEATER THERMOSTAT (see figure 36 drawing D)

Used crankcase and automotive transmission oil require preheating. The thermostat

controls the temperature of the aluminum block which preheats the oil, approximately

140°F. The oil heater comes on when the burner is called to heat and further raises the

temperature of the oil. The oil temperature should not be set higher than what is required

for ignition. The higher the oil preheat temperature, the more coking and sludging will

occur. If the temperature is set higher than factory recommendations to burn thick oils,

the preheater should be turned down or off when the burner is not being used to minimize

16

coking and sludging. KAGI preheaters can be disassembled and cleaned if necessary.

(See “Cleaning the Preheater Block”). # 1 & # 2 furnace fuels do not require preheating.

The thermostat should be deactivated by turning the preheater switch off! (Located to the

left side of front panel of the burner).

3.09 AIR AND OIL SOLENOIDS (see figure 17)

The air and oil solenoid valves on the KAGI burners are actually the same parts. Both

solenoids are energized by the load wire from the primary control. They are magnetically

normally closed switches, which open when current flows to them. There is an internal

piston with rubber disk on the end of the piston that seals an orifice; it is actuated by a

spring on the opposite end of the piston. There is an arrow stamped in the casting

pointing to the flow direction and this pressure ensures no leakage by helping push on the

piston. The current energizes a coil surrounding the metal piston, snapping it up with the

magnetic field it creates. The solenoid stops the airflow when the burner stops. On the

oil pressure side, this valve stops the oil flow from feeding the fire and eliminates nozzle

dripping from residual oil in the delivery system.

CAUTION!! DO NOT TURN BURNER ON WITH THE ELECTRICAL SPOOLS(coils)

OFF THE VALVE BODY OF THE SOLENOIDS WHEN YOU ARE CHECKING, AS IN A

FEW SECONDS THEY CAN BURN UP. REASON: THE SPOOLS (coils) ARE A DEAD

SHORT AND METAL CONDUCTING CORE MUST BE PLACED IN THE MIDDLE TO

ABSORB THE ELECTRICAL ENERGY.

3.10 CAD CELL (see figure 38 Drawing F)

The cad cell is located underneath the ignition transformer, with its lens pointed toward

the combustion chamber. It has two distinct yellow wires extending from it to the FF

terminals on the oil primary control. The cad cell is a safety switch, which is normally

open. Light causes continuity between the two yellow wires. When light is directed to

this switch through the lens, it acts as a closed jumper between the FF terminals.

The cad cell has a light-sensitive “electric eye” that detects the presence of a flame in the

combustion chamber. It is a safety device that ensures the furnace will shut down if the

flame goes out. If there is burning in the combustion chamber prior to ignition, the cad

cell will not allow the primary control to start the burner. If the burner is bench-tested

and light is allowed into the cad cell, the burner will not start unless the cad cell is

momentarily shaded.

The cad cell is a resistor that varies its electrical resistance according to the amount of

color and light it senses. It acts as a switch when it sees the light of an oil flame. When

the cad cell senses light, it has a very low resistance and conducts electricity. When it

conducts electricity, the energy pulls in a sensitive relay, which closes a set of points in

the oil primary control. When exposed to darkness, the cad cell has a very high

17

resistance and current will not pass through it, thereby permitting the safety switch to trip

open.

The cad cell is sensitive to white, orange, and yellow flames, but not to a blue flame.

While a stack-mounted control relies upon the heat from the fuel used for operation, a cad

cell control depends upon the light from the oil flame.

The main requirements for efficient operation are:

1. Sufficient direct light sensed by the cell.

2. Location where temperatures do not exceed 140° F.

3.11 OIL REGULATOR (see figure 15)

The oil regulator is located on the right side of the burner in the center of the front control

panel. The oil regulator differs in appearance from the air regulator as it does not have

the filter bowl/water separator. The oil regulator controls the pressure and the flow rate

of the oil that is being burned. The burning rate can be increased or decreased by simply

turning the screw on the regulator. The pressure will vary depending on the viscosity of

the oil, even if the flame length is the same. It is IMPORTANT that the flame is not

increased to a point where the target and chamber becomes red hot. With extremely light

fuel oil, such as #1 and #2 furnace fuels, under warm ambient conditions, a reading may

hardly exist. This is normal and nothing to worry about. The oil regulator may be

disassembled and cleaned if necessary. (See figure 15)

3.12 AIR PRESSURE SWITCH (see figure 33 Drawing A)

This is a small micro-switch plumbed to the right side of the aluminum pre-heater block.

The electrical box lid (under primary control) must be hinged open to gain access to the

switch. It is a normally open switch that closes when the air pressure exceeds 9 PSI.

When closed, the switch energizes the remote fuel pump.

3.13 COMBUSTION AIR, BLAST TUBE, AIR TURRET BAND ADJUSTER

This adjusting band is located opposite the burner motor on the round part of the burner

housing. It consists of a thin metal band with a bolt and screw to friction lock it on the

housing. Moving and aligning the holes with the opening in the burner housing admits

more air into the blast tube. Closing the openings will admit less air into the blast tube to

the point no air is allowed to enter. This band covers the air entering the squirrel cage fan

for combustion and can be adjusted to provide maximum heat and carbon dioxide

readings, as well as, lower stack temperature. (See Figure #6)

3.14 IGNITOR ELECTRODES (see figure 13)

A 14,000-volt constant duty transformer is always arcing when the burner is operating.

The electrodes and porcelain insulators must be cleaned and free of cracks that will cause

18

grounding of the spark. The gap between the electrodes must be less than the air gap

between each electrode and the ground, otherwise electricity will be routed towards the

ground, preventing ignition. If the spark is shorting to the nozzle or retention head, it can

burn and ruin them. (See figure #13)

3.15 NOZZLES (see figure 12)

The siphon nozzles on the KAGI burners are of a special low-pressure design and consist

of a head/cap, oil distributor, stem, and “O” ring. Compressed air enters the fluted stem

and by Venturi design, sucks oil out of the center of the stem where the oil flows. The

distributor spins the air and oil into a fine mist to create an efficient complete burn. (See

figure #12). Typical nozzles: HW150 = 609.5, HW250 = 609-7/8, HW350 = 609-9

NOTE: The nozzle should be inspected annually and replaced as necessary for best

performance as the colloidal abrasive material in waste oil could wear the orifice into an

oblong shape, resulting in flame impingement and hard ignition.

3.16 NEON INDICATING LAMPS (see figures 33A & figure 35C)

The neon lamps are on the burner face to indicate which electrical functions are

operating.

Red Lamp On: The burner is energized and caution must be taken when servicing

anything on the burner.

Green Lamp On: Indicates the pre-heater is on and at the right preset temperature. The

green light will not come on when the burner is first turned on as a temperature sensor

interrupts its continuity, which is normally open. At approximately 120° F., it closes and

the green lamp will come on. When burning waste oil and the burner is first turned on, it

is necessary to wait at least 15 minutes and allow the preheater to reach its preset

temperature. Do not attempt to start the burner until the green lamp is on.

Amber Lamp On: The remote pump is energized. The amber light will illuminate and go

out anytime the pump is energized manually or automatically.

White Lamp On: The oil pre-heaters are turned off and you cannot burn cold waste oil.

The multi-fueled Kagi burner will burn waste and furnace fuels; however, it is important

to turn the pre-heater off when burning furnace oils. Furnace oils should not be

preheated.

3.17 PREHEATER ON/OFF SWITCH

This toggle switch placed to the left of the neon indicating lamps turns the preheater on to

heat the waste oil and of (center position of the toggle switch) when burning furnace fuels

19

that require no preheating. Waste oil must be heated to a certain temperature to ignite.

This switch will manually turn the pre-heater on and off. If this switch is mistakenly left

off when waste oil is introduced into the burner, the burner will not ignite. The very

downward position of this triple position switch is to manually turn the pump on to bleed

air out of the fuel lines.

CAUTION!! DO NOT OPERATE YOUR FURNACE WITH THIN FURNACE FUELS

WITH THE PREHEATER ON!

The KAGI burner has not been designed to burn anything lighter in viscosity than furnace

fuels; therefore, it is NOT necessary that this switch be left on to preheat the oil when

burning #1 and #2 furnace fuels as the lessened viscosity from heating will greatly

increase the fuel flow.

3.18 SOFT START TANK (standard on all KAGI burners)

The soft start tank illustrated in drawing figure #6 is a miniature air tank placed between

the air shut-off solenoid and the discharge nozzle on the KAGI burners. The purpose of

this tank is to interrupt the air pressure flow to the nozzle. The air enters this tank and

tries to pressurize this small tank, allowing the air discharging from the nozzle to come

out gradually, enriching the oil-to-air mixture. A higher fuel to air mixture ignites better,

resulting in a reliable burner that ignites every time, wherever the air pressure may be set.

Generally, if a waste oil burner doesn’t have this tank, and the burner is adjusted to a

leaner mixture; it will burn clean and hot, but will usually not re-ignite when it cycles off.

There is a small stainless steel drain screw on the bottom of the tank that should be

periodically drained to keep its volume from being decreased by any water or fluids that

could leak into the tank. The soft start tank and kit can be purchased separately from

KAGI manufacturing and installed on any waste oil burner to improve its performance.

4.00 INSTALLATION

4.01 CONSIDERATIONS FOR PROPER INSTALLATION

The considerations for proper installation include:

1. Mounting burner

2. Mounting circulation blower (may come already installed)

3. Oil tank and fuel line piping

4. Chimney

5. Clearances

6. Compressed air supply

7. Electrical supply

8. Air circulation

9. Wall thermostat location

This manual suits for next models

2

Table of contents

Other Heat Wave Heater manuals