HEIDENHAIN ND 780 User manual

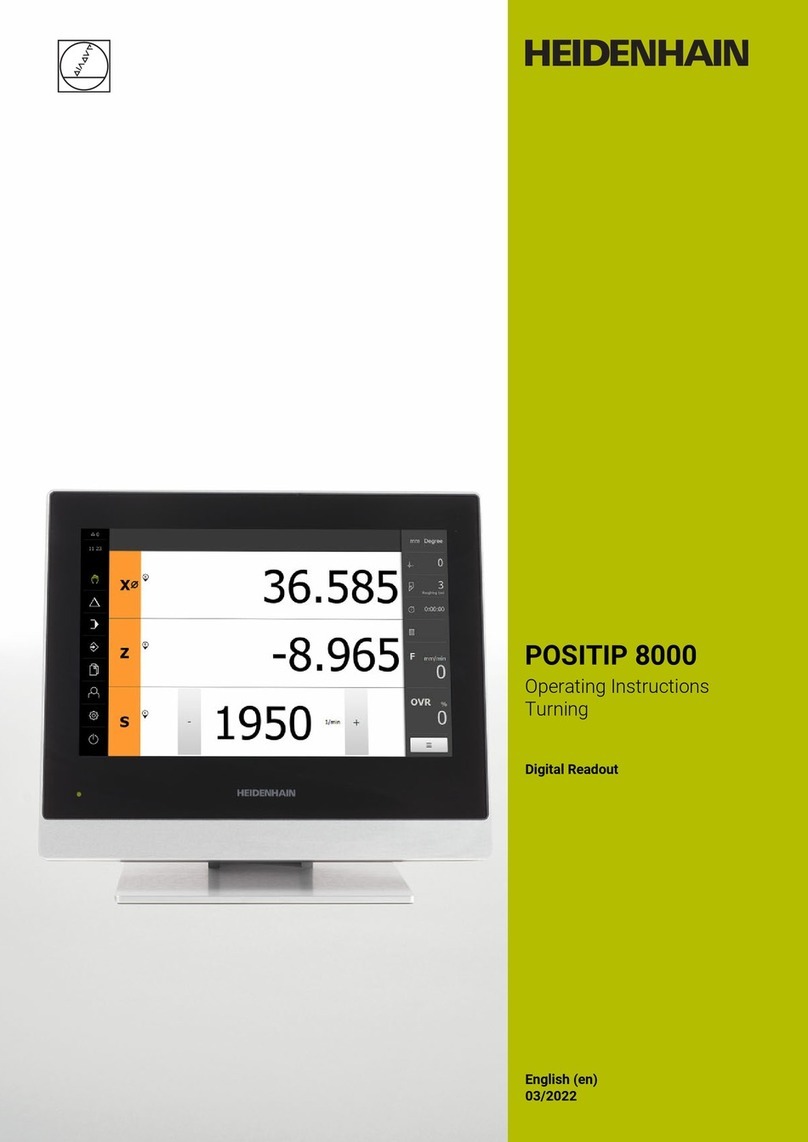

ND 780 Screen

Status Bar Symbols

Datum Tool Feed Rate Stopwatch Unit of

Measure Actual Value Distance-To-

Go Page

Indicator Set/Zero

Axis Label

Display Area

Ref symbol

Graphic

Positioning

Aid

Soft Key

Functions

Numeric input keys

3 axis keys to select between X, Y and Z axes

Soft keys - Row of keys under the screen of

the ND 780 whose functions vary according

to associated fields that appear above them

on the screen

Clear key Confirm entry and

select entry field

Up/Down arrow keys -

are also used to adjust

screen contrast

ND 780 5

Introduction

Software Version

The software version is shown on the initial power up screen.

Symbols within notes

Every note is marked with a symbol on the left indicating to the

operator the type and/or potential severity of the note.

ND 780 Fonts

The chart below shows how the different variables (soft keys, hard

keys, forms and form fields) are represented within the text of this

manual:

Soft keys - SETUP soft key

Hard keys - ENTER hard key

Forms - ANGULAR forms

Form Fields - RADIUS

Data in fields - ON, OFF

This User’s Manual covers the functions of the ND 780 for

both milling and turning applications. Operational

information is arranged in three sections: General

Operations, Mill Specific Operations and Turn Specific

Operations.

General Information

e.g. on the behavior of the ND 780.

Warning – Refer to accompanying documents

e.g. when a special tool is required for a function.

Caution - Risk of electric shock

e.g. when opening a housing.

The ND 780 and the machine tool must be prepared by the

machine tool builder to perform this function.

ND 780 7

I – 1 Fundamentals of Positioning ..... 12

Datums ..... 12

Actual Position, Nominal Position and Distance-To-Go ..... 12

Absolute Workpiece Positions ..... 13

Incremental Workpiece Positions ..... 13

Zero Angle Reference Axis ..... 14

Position Encoders ..... 14

Encoder Reference Marks ..... 15

I – 2 General Operations for ND 780 ..... 16

Layout of Screen ..... 16

General Navigation ..... 17

Operating Modes ..... 17

Graphic Positioning Aid ..... 18

Help Screen ..... 18

Data Input Forms ..... 18

Error Messages ..... 19

Power Up ..... 20

Reference Mark Evaluation ..... 20

ENABLE/DISABLE REF function ..... 21

Setup ..... 22

Job Setup Parameters ..... 22

Units ..... 22

Scale Factor ..... 23

Mirror ..... 23

Edge Finder (milling applications only) ..... 23

Diameter Axes ..... 24

Measured Value Output ..... 24

Graphic Positioning Aid ..... 25

Status Bar Settings ..... 25

Stopwatch ..... 26

Remote Switch ..... 26

Console Adjustment ..... 27

Language ..... 27

Import/Export ..... 27

General Operation’s Soft Key Function Overview ..... 28

General Operation’s Soft Key Functions Detailed ..... 29

Set Zero Soft Key ..... 29

Calc Soft Key ..... 30

I Operating Instructions ..... 11

8

I – 3 Milling Specific Operations ..... 33

Soft Key Functions Detailed ..... 33

Tool Soft Key ..... 33

Tool Radius Compensation feature ..... 33

Tool Table ..... 33

Tool Table Usage ..... 35

Calling the Tool Table ..... 37

Tool call ..... 37

Datum Soft Key ..... 38

Probing Functions for Datum Setting ..... 40

Datum setting with the edge finder ..... 40

Probing with a Tool ..... 44

Preset Soft Key ..... 46

1/2 Soft Key ..... 52

Patterns Soft Key (Milling) ..... 53

Functions for milling patterns ..... 53

Circle Pattern Soft Key ..... 53

Linear Pattern ..... 56

I – 4 Turning Specific Operations ..... 59

Soft Keys Functions Detailed ..... 59

Tool Soft Key ..... 59

To access the Tool Table menu: ..... 59

Tool Table Usage ..... 60

Setting tool offsets using TOOL/SET ..... 60

Setting Tool Offset using NOTE/SET Function ..... 61

Datum Soft Key ..... 62

Preparation: ..... 62

Setting Datums using NOTE/SET Function ..... 64

Preset Soft Key ..... 65

RX(Radius/Diameter) Soft Key ..... 65

ND 780 9

II – 1 Installation and Electrical Connection ..... 68

Items Supplied ..... 68

Accessories ..... 68

ND 780 Display Unit ..... 68

Mounting Location ..... 68

Installation ..... 68

Electrical connection ..... 68

Electrical requirements ..... 69

Environmental ..... 69

Wiring the power connector, see Fig. II.1 ..... 69

Preventative maintenance ..... 69

Connecting the Encoders ..... 70

Pin layout for encoder inputs. ..... 70

Connecting Edge Finder Output and Input Signals ..... 72

Pin layout for Edge Finder and Measured Value Output input (see Fig. II.5 for pinout) ..... 72

II – 2 Installation Setup ..... 73

Installation Setup Parameters ..... 73

Encoder Setup ..... 74

Display Configuration ..... 74

Coupling ..... 74

Z Coupling (turning applications only) ..... 75

Enabling Z Coupling ..... 75

Disabling Z Coupling ..... 75

Error Compensation ..... 76

Linear Error Compensation ..... 76

Non-Linear Error Compensation ..... 77

Backlash Compensation ..... 78

Serial Port (X31) ..... 79

Counter Settings ..... 80

Diagnostics ..... 81

Keypad Test ..... 81

Encoder signal plot ..... 81

II – 3 Encoder Parameters ..... 82

Example settings for HEIDENHAIN linear encoders with 11-µAPP signals ..... 82

Example settings for HEIDENHAIN linear encoders with 1-VPP signals ..... 82

II – 4 Data Interface ..... 84

Serial port ..... 85

Wiring the connecting cable ..... 86

Signal ..... 86

External Operations via RS-232 Data Interface ..... 87

II Technical Information ..... 67

10

II – 5 Measured Value Output ..... 88

Data output using external signals ..... 88

Data output using Edge Finder ..... 90

II – 6 Specifications for Milling ..... 93

II – 7 Specifications for Turning ..... 95

II – 8 Dimensions ..... 96

II – 9 Accessories ..... 97

Accessory ID Numbers ..... 97

ND 780 Handle

Id. Nr. 520 012-01 ..... 97

ND 780 Mounting Instructions

Universal Mounting Arm

ld. Nr. 382 929-01 ..... 98

ND 780 Mounting Instructions

Tilting Base

ld. Nr. 281 619-01 ..... 99

ND 780 Mounting Instructions

Tilting Bracket

ld. Nr. 520011-01 ..... 100

ND 780 Mounting Instructions

Mounting Frame

ld. Nr. 532811-01 ..... 101

Other manuals for ND 780

3

Table of contents

Other HEIDENHAIN Digital Readout manuals