Model

Signal

period [µm]

Reference

marks

P43

Display step

(unit: P01)

mm inches

Subdi-

vision

P32

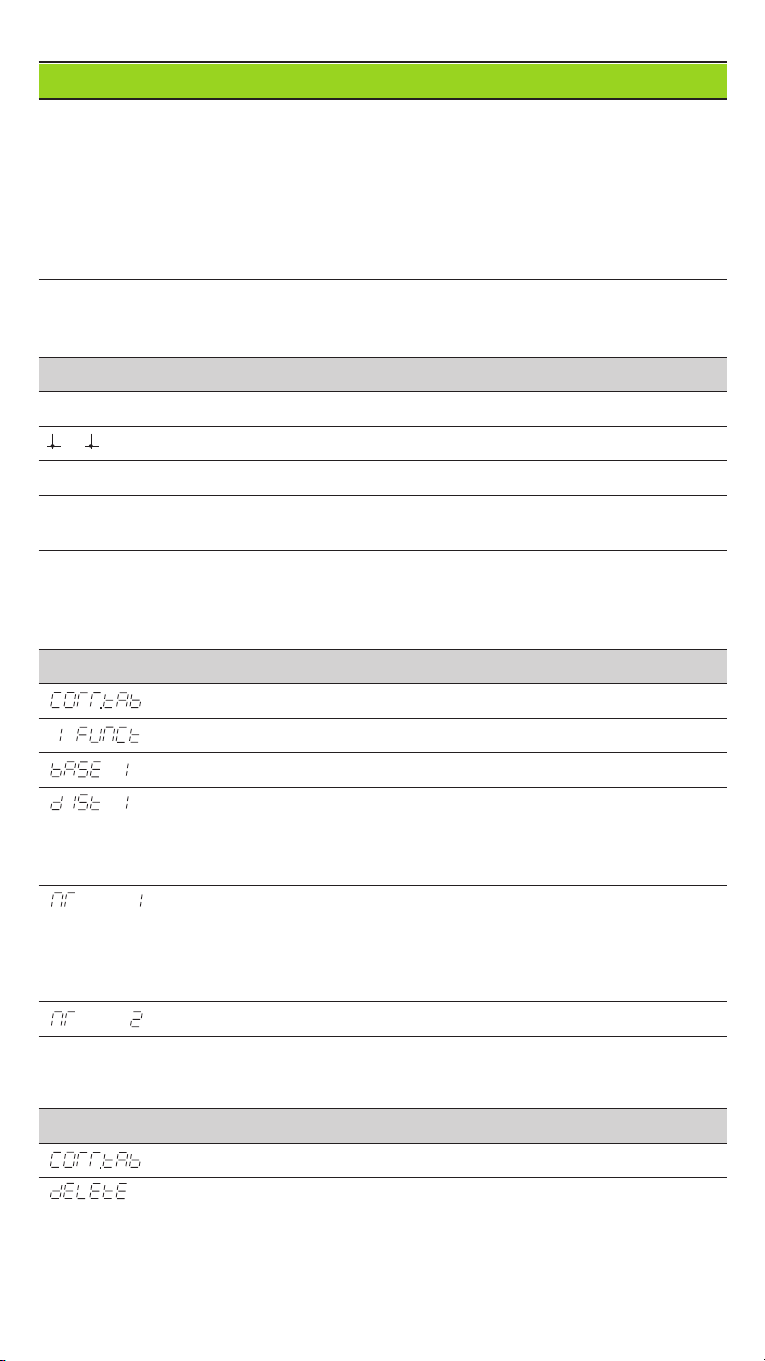

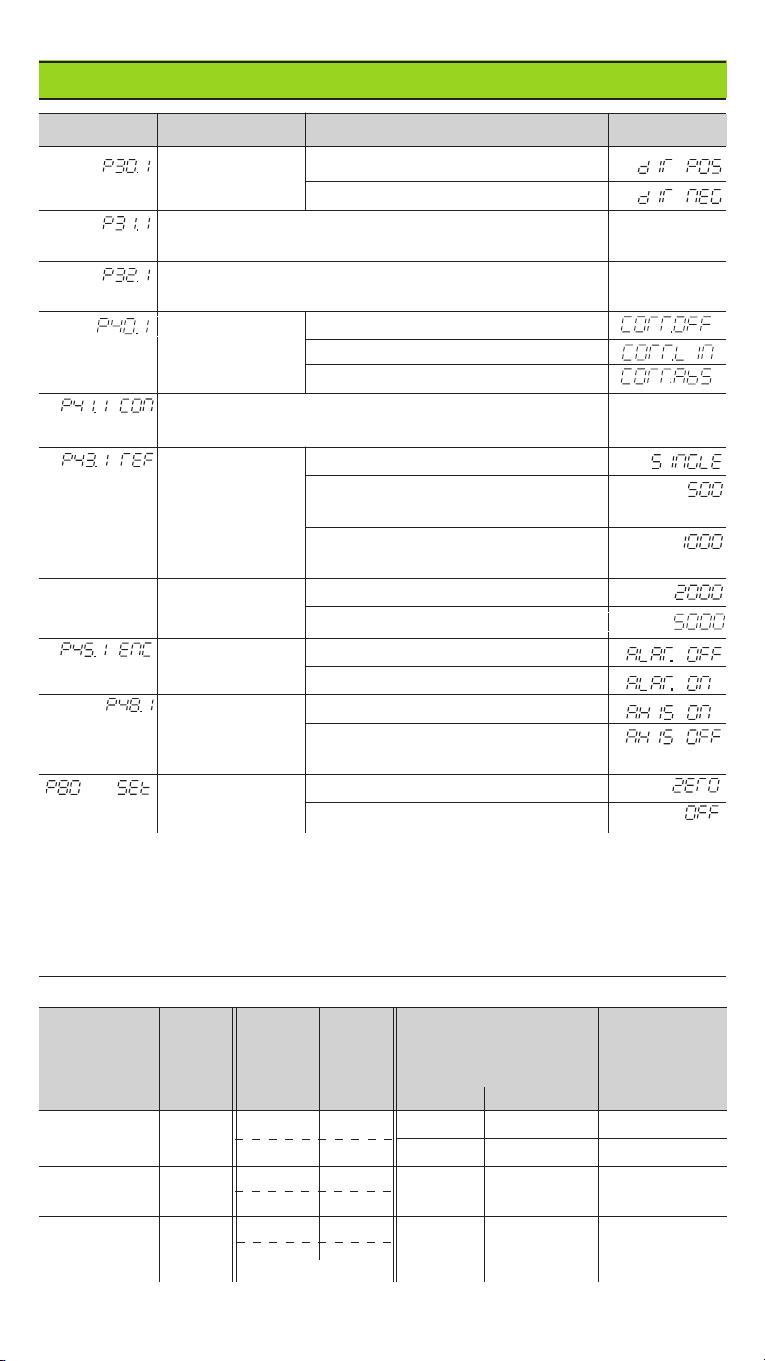

Operating Parameter List – cont'd.

Parameter Meaning Function / Effect Setting

Counting Normal

(Direction: Positive)

direction AInverse

(Direction: Negative)

Signal period of encoder A

(

Period

:) 2, 4, 10, 20, 40, 100, 200

Subdivision of the encoder signals A

(

Subdivision

:) 4, 2, 1, 0.8, 0.5, 0.4, 0.2, 0.1

Select Error compensation not active

error Linear error compensation active

compensation Non-linear error compensation active

Linear error compensation1) A

Compensation

–99 999 < P41 < + 99 999 [µm/m]

Reference One reference mark

marks ADistance-coded with 500 •SP

(SP = signal period)

Distance-coded with 1000 •GP

(e.g. for LS 303 C / LS 603 C)

Distance-coded with 2000 •SP

Distance-coded with 5000 •SP

Encoder Monitoring off

(Alarm Off)

Encoder

monitoring AMonitoring on

(Alarm On)

Axis display ADisplay measured position

(

Axis

) Do not display measured position /

no encoder

Function of Resets display to zero

CL key Does not reset display to zero

1) Calculate the entry value for P41

Example: Displayed measuring length La= 620.000 mm

Actual length (determined with, for example, the VM 101 comparator

system from HEIDENHAIN) Lt= 619.876 mm

Length difference ∆L = Lt–La= –124 µm

Compens. factor k: k = ∆L / La= –124 µm / 0.62 m = –200 [µm/m]

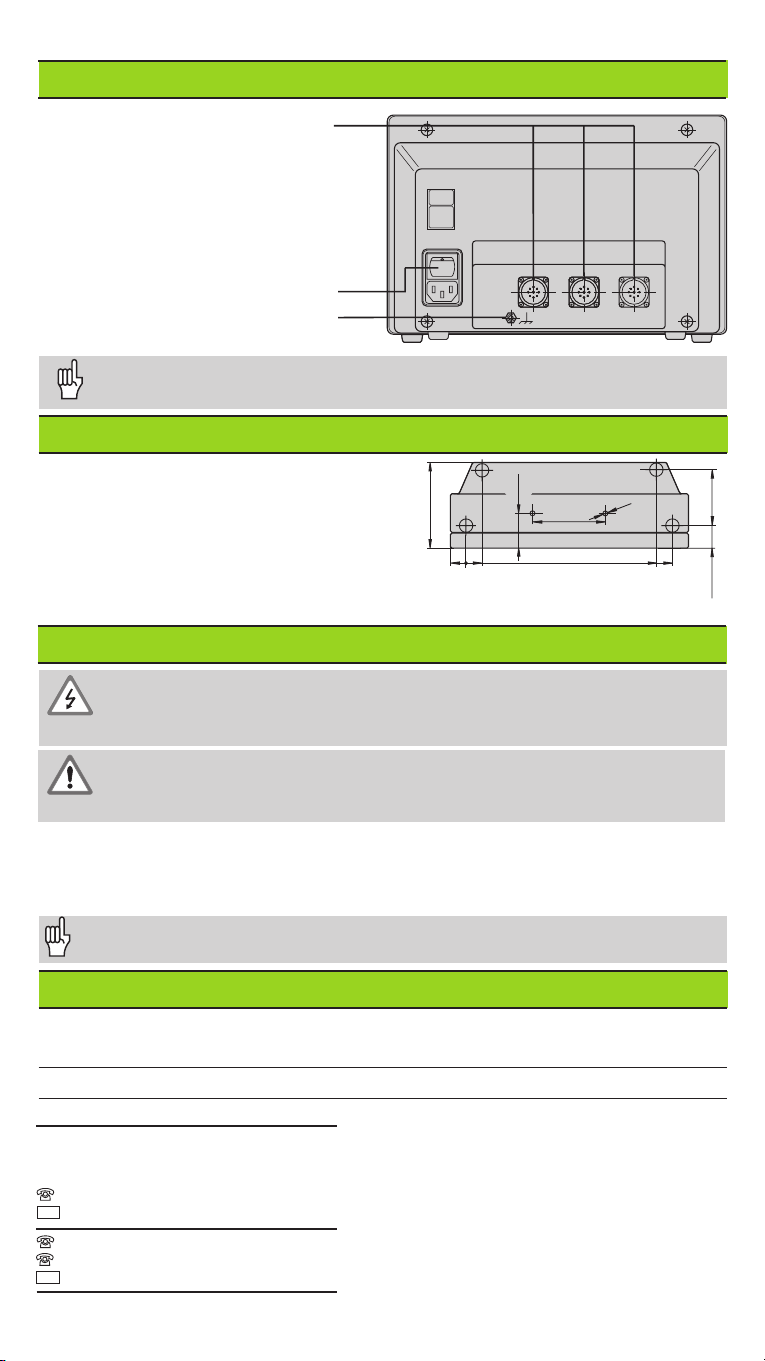

Parameter Settings for HEIDENHAIN Linear Encoders

LS 303 20 one single 0.005 0.000 2 4

LS 603 dist.c. 1 000 0.01 0.000 5 2

LB 302 40 one single 0.01 0.000 5 4

LIDA 10x dist.c. 2 000

LB 3xx 100 one single 0.025 0.001 4

dist.c. 1 000 0.05 0.002 2

0.1 0.005 1

Example: Linear encoder with signal period s = 20 µm

Desired display step a = 0.005 mm

Subdivision P32 ==

==

= 0.001 ••

••

•s / a = 4