Hekatron LRS 01 User manual

Ventilation-Duct

Smoke Switch System

LRS 01 Basic

Installation Instructions

Installation Instructions LRS 01

2

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

3

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

Installation Instructions LRS 01

2

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

3

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

Table of contents

Introduction ....................................................................4

1. Project planning ........................................................5

2 Technical data............................................................6

3 General information .................................................7

3.1 Operation of the LRS 01 ......................................... 7

3.2 Transport, storage and unpacking......................... 7

3.3 Scope of supply ...................................................... 7

4 Rules and regulations................................................8

5 Installation instructions.............................................9

5.1 Mounting the LKS 02.............................................. 9

5.2 Electrical connection of the ORS 210................... 12

6 Commissioning ........................................................14

6.1 Functional testing ................................................ 14

6.2 Display of operating status of the ORS 210 ........ 14

7 Maintenance instructions........................................15

8 Ordering data..........................................................16

Installation Instructions LRS 01

4

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

5

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

Introduction

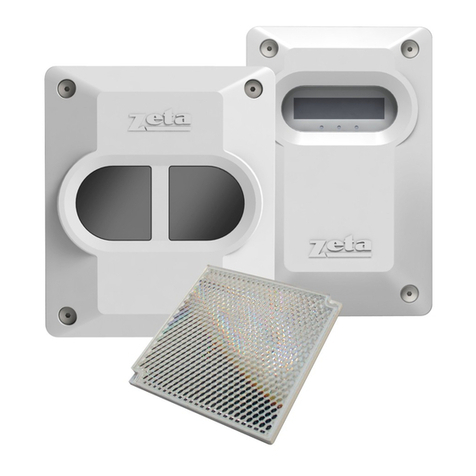

Figure 01

The LRS 01 consists of a ventilation duct socket LKS 02 and an ORS 210

optical Smoke Switch with alarm latching. It is used for monitoring smoke

in ventilation ducts.

The LKS 02 provides a mounting for Smoke Switch ORS 210 and is fitted on the

outside of a ventilation duct. The LRS 01 is intended for use inside buildings.

Installation Instructions LRS 01

4

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

5

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

1. Project planning

The socket LKS 02 is designed for use on rectangular ventilation ducts with

dimension “a” from 0.15 m to 1.0 m. It can also be used on circular ducts from

0.2 m to 1.0 m in diameter. The lateral reach of the inlet tube into a duct is ca.

500 mm. The ventilation duct socket must be placed so that reliable smoke detec-

tion can be assumed. Disruptive factors, which could affect reliable operation of

the LRS 01 must be eliminated.

A2

A2

B

B

A1

A1

min. 3 x a

A1: Ideale Betriebsumgebung

A2: Erhöhte Staubbelastung

B: Bereich für Rauchfrüherkennung ungeeignet.

a: Kanalmaß

a

a

Luftstromrichtung

Figure 02

Figure 02 provides recommendations for project planning.

To ensure reliable

smoke detection, in large ducts several LRS 01 Smoke Switches should be instal-

led. The airflow parameters must be taken into account when determining

their positions.

Zentrum

Figure 03

Direction of Airflow

A1: ideal operating environment

A2: higher dust loadings

B: zone unsuitable for early detection of smoke

a: duct dimension

Centre

Installation Instructions LRS 01

6

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

7

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

2 Technical data

Housing LKS 02

Field of application ventilation ducts

Min. air speed 1 m/s

Max. air speed 20 m/s

Temperature range see Smoke Switch ORS 210

Degree of protection IP 54 (on duct surface)

Colour blue / transparent

Material PC / aluminium tube

Installation

Openings

on a ventilation duct

2 x Ø 28-30 mm at 150 mm pitch centres

for mounting in housing

2 x max. 6 dia. at 206 mm pitch centres

Cable entries 4 x Ø6-10 mm

Dimensions without tube L 25 cm x B 13.5 cm x H 10 cm

Weight without tube ca. 350 g

The temperature range of the socket LKS 02 and Smoke Switch ORS 210 combi-

nation is determined by the technical data of the Smoke Switch.

Temperature range: - 20 °C to + 75 °C

Permissible rel. humidity: up to 95 % RH

(dewing and steam condensation

can cause false alarms)

Smoke Switch ORS 210

Operating principle light-scattering

Reaction thresholds to construction and testing rules for

smoke-triggered installations (12/76)

Operating voltage 18 to 28 V DC

Current draw at 28 V DC

quiescent

in alarm

in fault

22 mA

11 mA

16 mA

Relay contacts with latching alarms

switchable voltage, max.

switchable current, max.

switchable power, max.

30 V DC

1 A

30 W

Degree of protection IP 40

Operating ambient temperature -20°C to +75 °C

Weight 120 g

The ORS 210 has latching alarm functions. Following an alarm , the

relay (contacts 4 and 5) remains open until the supply voltage is briefly

interrupted.

Installation Instructions LRS 01

6

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

7

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

3 General information

3.1 Operation of the LRS 01

When it is in operation, the Smoke Switch ORS 210 (in conjunction with socket

LKS 02) is continuously exposed to the flow of air in the ventilation duct being

monitored. When it detects smoke particles, an alarm is triggered and held. The

safety equipment is activated. Resetting is carried out by briefly interrupting the

power supply when the duct is free of smoke.

3.2 Transport, storage and unpacking

The LRS 01 is supplied in a suitable carton package. This package can be recy-

cled.

Please note the properties of the package!

The carton in which the LRS 01 is packed complies with minimal package

requirements, and can support up to 10-times its own weight when stacked.

The package is only to a limited extent suitable for transport by post or rail. For

transport in tropical zones, transport by sea etc., special packages are available.

For further information, please contact the manufacturer.

Do not open the package until the Smoke Switch is to be installed. Keep the

installation instructions for future reference.

3.3 Scope of supply

- Housing with transparent cover

- Inlet tube: 415 mm long - total length of standard version

length in duct = 345 mm

- Flow adapter for ORS 210

- Plugs and gaskets

- Installation instructions

- Packaging and markings

- M 16 x 1.5 duct connection

- M 16 x 1.5 locknut

- Mounting screws

- Optical Smoke Switch ORS 210

Installation Instructions LRS 01

8

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

9

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

4 Rules and regulations

The requirements of § 3 and § 17 of the MBO (Musterbauordnung = Specimen

Construction Code) apply to fire protection in ventilation equipment. These

paragraphs are incorporated into the local regulations issued by the States of

the German Federal Republic. Rules and regulations of the country in which the

equipment is installed must be observed.

Extract:

„Buildings and their equipment must be constructed so that measures are

incorporated to prevent outbreaks of fire and restrict the spread of fire and

smoke, and so that, in the event of a fire, the rescue of people and animals and

effective fire-extinguishing operations are possible.“

As a matter of principle, if a product simultaneously falls within the scope of

other directives, all directives will be applied in parallel so that the special

requirements of all directives can be fulfilled.

Installation Instructions LRS 01

8

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

9

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

5 Installation instructions

5.1 Mounting the LKS 02

If the inside diameter of the ventilation duct is less than 350 mm, the inlet

tube must be shortened to suit. The inlet tube can be sawn off to the required

length.

To ensure reliable smoke detection, at least five of the holes in the tube

must be inside the ventilation duct (see Figure 04).

Figure 04

The tube must not be bent and it must be cut cleanly at right-angles.

When choosing a place to mount the LKS 02, take care that there is enough

space to change the inlet tube. If the inlet tube has not been shortened, a space

of at least 470 mm is required outside the duct.

The LKS 02 must be mounted on the duct using suitable fasteners, aligned with

the direction of flow, and sealed with rubber gaskets.

Ensure that the place where the socket LKS 02 is installed is, as far as possible,

free of vibration.

247 135

150

min. 140

345 95

100

Installation Instructions LRS 01

10

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

11

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

Make sure that the direction in which the socket LKS 02 is installed corresponds

to the direction of airflow in the duct. To help with this, the LKS 02 has arrows

on its base showing the direction of flow (see Figure 05).

Figure 05

Warning!

When mounting the LKS 02 socket, it is important to ensure that the

airflow direction is correct, and that the socket is properly sealed.

206

150

Flow direction

Flow direction

Installation Instructions LRS 01

10

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

11

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

If the self-drilling screws (4.8 x 22) supplied are not suitable for fastening the

socket to the ventilation duct, use other more suitable fasteners. There are two

holes 6 mm diameter spaced at 206 mm in the base of the LKS 02 for mounting

it.

Two larger holes for the inlet and outlet tubes must also be drilled in the venti-

lation duct (see Figure 06).

Figure 06

Opening the LKS 02 cover

For servicing, the LKS 02 has quick-action clips. By pressing gently on the hous-

ing cover, it is easier to open or close the clips. If the LKS 02 socket is mounted

inverted, take care, when opening the transparent cover, that parts do not fall

on the floor (cover, suction tube etc.).

Handling

The connection lead for the Smoke Switch ORS 210 must be passed through the

plug supplied into the housing and connected.

The Smoke Switch ORS 210 is screwed into the socket LKS 02.

Then the inlet tube with flow adapter is fitted.

After a positive functional check with test gas, the cover of the LKS 02 can be

fitted by pressing gently on it and closing the clips.

Display of Smoke Switch ORS 210

The display of Smoke Switch ORS 210 is visible through the transparent cover of

the LKS 02 housing.

Application limits

This Smoke Switch should not be used where quantities of dust, smoke,

moisture or steam are to be expected from plant operations. Make sure that the

Smoke Switch will not be subject to dew formation. TheLRS 01 must not be used

out of doors. These instructions must be taken into account when planning the

installation.

Installation Instructions LRS 01

12

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

13

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

3

1

2 4

5

6

–

+

Communication interface

Relay

contactso

Supply

voltage

5.2 Electrical connection of the ORS 210

At the cable gland and fastening, there must be no leakage to the ventilation

duct. When connecting or changing the socket, ensure that it is correctly ori-

entated to the direction of flow. In the LKS 02, the LED of the ORS 210 and the

arrow in the socket point towards the outlet tube. The LRS 01 can only operate

correctly when the cover is properly closed.

For cable entry, 4 x M16 plugs are fitted. When properly used, they comply with

the requirements of IP 54 within their 6 – 10 mm sealing range.

The sealing plugs can be replaced/supplemented by 16 x 1.5 cable glands with

M16 x 1.5 locknuts.

Terminal assignment in socket of LKS 02

Terminal 1 24 V DC

Terminal 2 0 V DC

Terminal 3 Option (communication/RS BUS)

Terminal 4 and 5 Potential-free NC

Terminal 6 free

Electrical installation

The electrical installation must comply with VDE regulations.

Safety instruction

Electrical connection is only to be carried out by a qualified electrician or

by a person suitably instructed in electrotechnical matters.

Operating positions of relay contacts

4

5

Operating status

- slight contamination

4

5

- heavy contamination

- no power

- fault

- alarm

Installation Instructions LRS 01

12

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

13

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

Mains connection

The power supply must be switched off before carrying out any work on the

mains unit!

The power supplies recommended for the Smoke Switch are NG 519 and NAG

03.

The installation can be operated by hand using the manual triggering unit DKT

02. At the same time, there is a permanent display of the operating status of the

installation.

Replacement/fault correction

Before fitting the Smoke Switch, before replacing a warning device, and before

trying to correct a fault (broken wire and/or short circuit), the mains power

supply must be switched off.

Cable installation

For low voltages, all normal, commercially-available telecommunications cable,

with or without screening, can be used. The conductor cross-sections must be

chosen to suit the current required by connected equipment and the installed

lengths:

Conductor diameter: min. 0.6 mm to max. 1.4 mm

Cable diameter: max. 9 mm

Recommended cable type: IY(ST)Y 4 x 2 x 0.6 mm

Only conductors with the same diameter may be connected at a terminal.

Cables must be installed so that they have adequate strain relief.

Contact loading

The electrical limits for loads on the relay contacts (30 V DC/1 A) must not be

exceeded - not even for short periods. Appropriate measures must be adopted

to protect the contacts.

Warning!

Safety-relevant switching-off and control of the installation must be carried

out using the relay contacts of Smoke Switch ORS 210. Status information,

transmitted via the communication interface (terminal 3), is purely for ease

of operation and information

Installation Instructions LRS 01

14

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

15

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

6 Commissioning

Before commissioning the Smoke Switch in a ventilation system, the air ducts

and the LKS 02 must be cleaned carefully. Only then should the Smoke Switch

be removed from its packing and fitted to the LKS 02 socket.

6.1 Functional testing

Testing must comprise at least the following points:

The interaction of all items of equipment and their technical condition must be

checked. A check must be carried out to ensure that the detection parameter

(smoke) to which the optical Smoke Switch should react, can reach it. For func-

tional testing of the Smoke Switch ORS 210, test aerosol 918/5 must be used.

Test aerosol 918/5 is free of halogenated hydrocarbons (CFCs etc.). If a Smoke

Switch does not react when so tested, then it must be replaced. The inlet tube

must be free of any obstructions.

Warning!

The warnings and safety instructions on the aerosol can must be observed

without fail.

These tests and maintenance must only be carried out by a specialist or a person

trained to do so. The tests and their results are to be recorded in a logbook.

6.2 Display of operating status of the

ORS 210

Signal, frequency Colour of LED Meaning

green Operating status

green/yellow Slight contamination

green/yellow Heavy contamination

yellow Fault

red Alarm

„Off“ No power

Installation Instructions LRS 01

14

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

15

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

7 Maintenance instructions

Hekatron Smoke Switches are to be maintained in accordance with VDE 0833

Part 1 taking into account special ambient operating conditions. We recom-

mend that Smoke Switches are serviced in our works when they have been in

operation for 8 years. Under special ambient operating conditions (e.g. excessive

exposure, external influences, contamination etc.), servicing in our works may

be needed after a shorter period

By observing basic maintenance measures according to DIN 31051 in conjunction

with DIN EN 13306, the LRS 01 system should be kept permanently ready for

operation; it should be serviced annually as specified by the manufacturer.

Test aerosol 918/5 from HEKATRON is to be used for functional testing of Smoke

Switch ORS 210.

The interaction of all items of equipment and their technical condition must be

checked.

The inlet tube must be inspected visually at regular intervals. Any deposits

found must be removed. For visual inspection, the inlet tube must be removed

from the LKS 02 socket. After visual inspection and cleaning, the inlet tube must

be correctly replaced.

The Smoke Switch must not be opened!

Installation Instructions LRS 01

16

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

17

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

8 Ordering data

Description Order No.

LRS 01 5000605

Replacement Smoke Switch ORS 210 5000614.0201

Cable gland, M16 x 1.5 3610370

Locknut M16 x 1.5 3610371

Replacement socket 143 A 5000350

Mains unit NG 519 5400080

Mains unit NAG 03 5400081

Signal, display and operating unit SAB 04 4400043

NG 519 with SAB 04 5400083

NAG 03 with SAB 04 5400084

Push-button DKT 02, grey 6200118

Push-button DKT 02, yellow 6200107

Test aerosol 918/5 6900331

HEKATRON Vertriebs GmbH

PO Box 1040 · D-79296 Sulzburg

Tel. +49 76 34 5 00-2 64

FAX +49 76 34 5 00-3 23

www.hekatron.com

Installation Instructions LRS 01

16

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

17

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

Installation Instructions LRS 01

18

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

19

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

Installation Instructions LRS 01

18

HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg 7002428 100206.VDA Ausgabe 10.02.2006

Installation Instructions LRS 01

19

7002428 100206.VDA Ausgabe 10.02.2006 HEKATRON Vertriebs GmbH · Brühlmatten 9 · D-79295 Sulzburg

HEKATRON Vertriebs GmbH

Brühlmatten 9

D-79295 Sulzburg

Tel. (0 76 34) 5 00-264

Telefax (0 76 34) 5 00-323

www.hekatron.de

A member of the

Swiss Securitas Group

This manual suits for next models

2

Table of contents

Other Hekatron Smoke Alarm manuals