EMUGE Speedsynchro Modular/NFC User manual

Speedsynchro®Modular/NFC/IKZ

Speedsynchro®Modular/NFC/MQL

Speedsynchro®Modular/NFC

Operating instruction

Speedsynchro®Modular/NFC

2 Operating instruction edition: 01.09.2022

Contents:

1Application range, safety instructions and technical data............................. 4

1.1 Application range, determined use............................................................................................. 4

1.2 Specifications ............................................................................................................................. 5

1.3 Safety instructions and hints ...................................................................................................... 6

1.4 Proprietary rights ........................................................................................................................ 6

1.5 Dimensions and technical data .................................................................................................. 7

2Putting the Speedsynchro®Modular/NFC into operation............................... 8

2.1 Unpacking................................................................................................................................... 8

2.2 First putting into operation / preparation..................................................................................... 8

Setting the angular position of the stop block.................................................................. 8

Assembly of the coolant-lubricant tube depending on shank type................................ 10

Using the Speedsynchro®Modular/NFC with adjustment screw................................... 11

2.3 Programming notes.................................................................................................................. 13

2.4 Re-putting into operation.......................................................................................................... 14

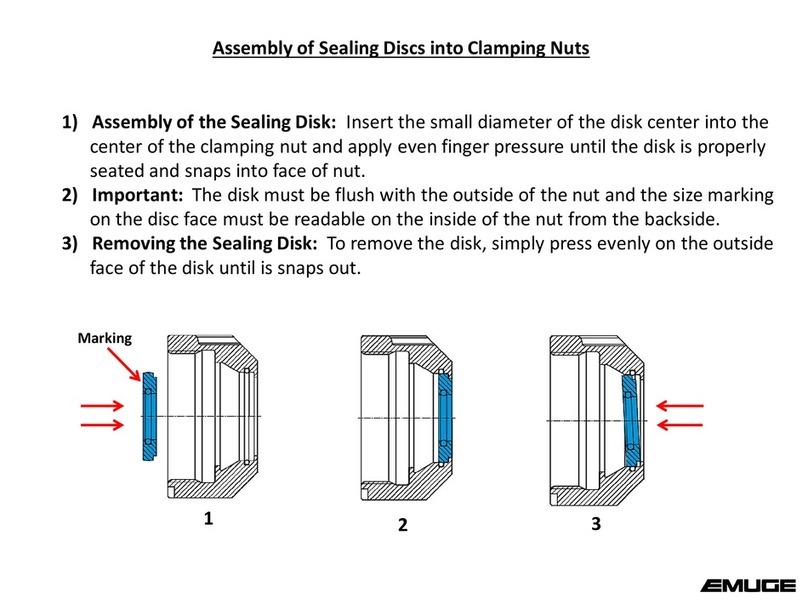

2.5 Sealing disk .............................................................................................................................. 15

Application ..................................................................................................................... 15

Assembly of the sealing disk......................................................................................... 15

2.6 Collet......................................................................................................................................... 16

Application ..................................................................................................................... 16

Assembly of the collet.................................................................................................... 16

2.7 Assembly of the tap/cold-forming tap....................................................................................... 17

2.8 Remove of the tap/cold-forming tap, clamping nut and sealing disk........................................ 18

3Readout operating data via NFC interface..................................................... 19

3.1 Speedsynchro- Electronics................................................................................................... 19

3.2 Readout operating data............................................................................................................ 19

3.3 Display in the app..................................................................................................................... 20

4Maintenance / Servicing .................................................................................. 22

4.1 Maintenance schedule.............................................................................................................. 22

4.2 External cleaning...................................................................................................................... 22

4.3 Maintenance............................................................................................................................. 22

5Storage when not in use.................................................................................. 23

6Disposal instructions....................................................................................... 23

7EU-Declaration of Conformity......................................................................... 24

8UK Conformity Assessed................................................................................ 25

9FCC-Rules......................................................................................................... 26

Speedsynchro®Modular/NFC

Operating instruction edition: 01.09.2022 3

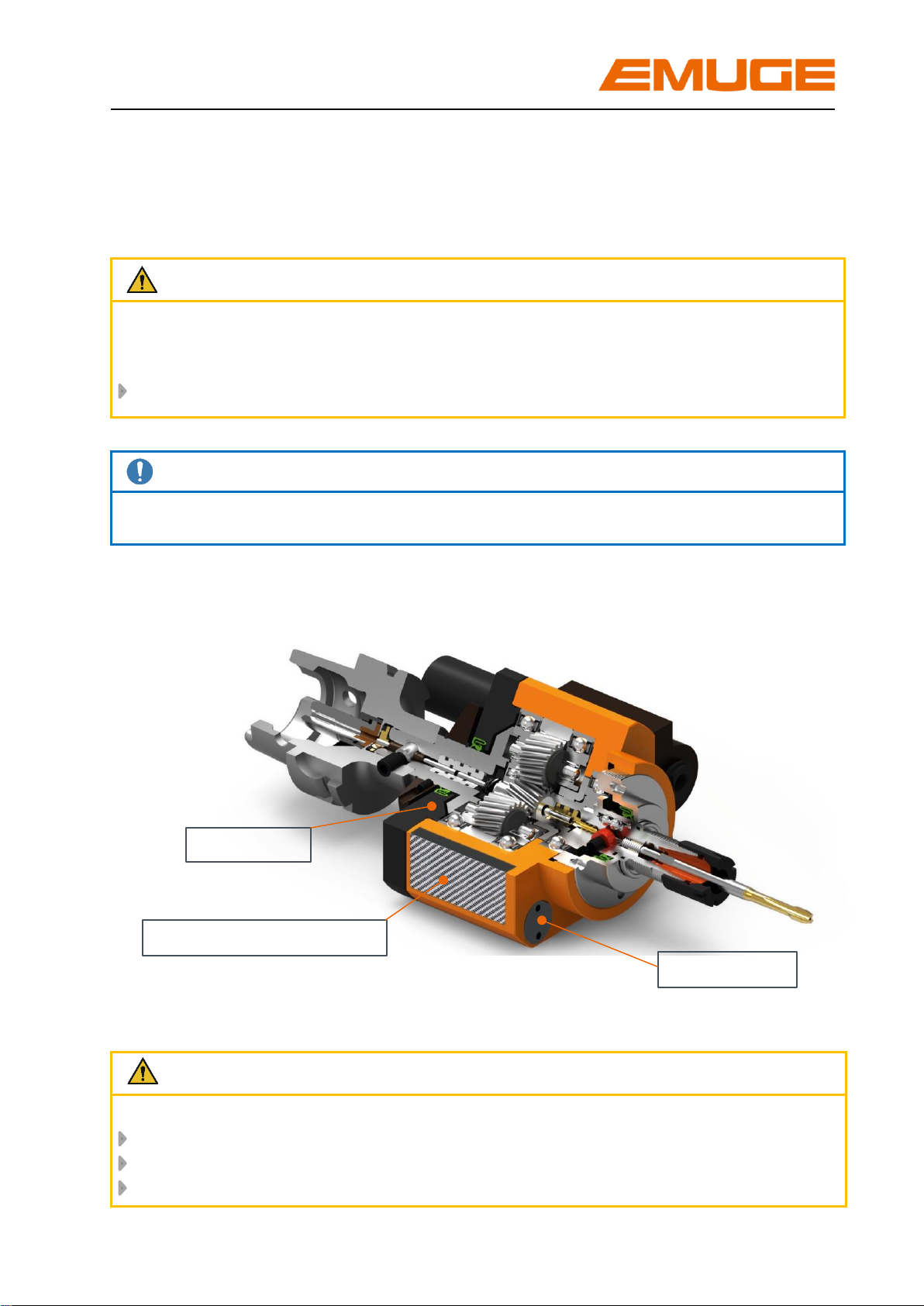

Electronics and NFC Antenna

Sensors

Battery

Warnings, symbols

In this operating instruction the following symbols are used:

Attention

Marks special instructions, rules and prohibitions, which are important in order to avoid

any damage.

Please observe these instructions!

Note

Marks application instructions and other useful information.

Sectional view:

Speedsynchro® Modular/NFC

Attention

Battery:

Not rechargeable

Do not incinerate

Dispose of as prescribed. Please refer to chapter 6, page 23

Speedsynchro®Modular/NFC

4 Operating instruction edition: 01.09.2022

1 Application range, safety instructions and technical data

1.1 Application range, determined use

The collet holders type Speedsynchro®Modular/NFC are used on CNC-machining

centers with synchronous control. They are intended for clamping of taps/cold-forming

taps for thread production.

Normally the Speedsynchro®Modular/NFC are equipped with one of the following

shanks:

Cylinder shank according to DIN 1835 B+E

ABS-clutch

Applicable for cutting range M1 –M8, please refer to Table 1, page 7

The tap/cold-forming tap is locked via the collets according to DIN ISO 15488.

The collets must be chosen depending on the used type and used tap/cold-forming

tap, for more information please refer to chapter 2.6, page 16.

The collet holders type Speedsynchro®Modular/NFC are available as:

IKZ for coolant-lubricant pressures up to 50 bar

MQL for 1-channel or 2-channel - MQL systems, up to 10 bar

For correct use, the Speedsynchro Modular/NFC must be secured against twisting in

the machine spindle. This requires a stop fixture adapted to the machine-side stop

block. For further details, please refer to chapter 2.2 page 8

The non-determined use exempts the manufacturer from any liability.

Speedsynchro®Modular/NFC

Operating instruction edition: 01.09.2022 5

1.2 Specifications

Further characteristics of the Speedsynchro®Modular/NFC:

The Speedsynchro®Modular/NFC uses an integrated gear ratio of 1:4,412. (This

enables the machine spindle to be operated in a lower speed range, thus saving

energy up to 90%)

The integrated minimal length compensation on tension and compression

compensates arising minimal pitch differences between synchronous spindle and

tap/cold forming tap possibly leading to high thread flank friction forces. A possible

increase of axial force during the thread producing cycle is reduced to a minimum.

The resulting advantages are:

- no mis-cutting of the threads

- optimized tool life of tap/cold-forming tap

The Speedsynchro®Modular/NFC has an NFC-Modul (NFC = Near Field

Communication) with integrated electronics. This takes and stores the operating

data. An NFC-enabled smartphone is required to read out the data (not included in

the delivery). For further details please refer to chapter 3, page 19.

Simple programming as synchronous cycle with feed programme adapted to the

transmission ratio.

The reversal of the tap/cold-forming tap is done by the machine spindle:

- no switching components in the Speedsynchro®Modular/NFC

- low wear and longer maintenance intervals

Due to the modular design, the adjustment screw matched to the tool can be

mounted if required, please refer to chapter 2.2.3 , page 11.

This manual suits for next models

2

Table of contents

Other EMUGE Industrial Equipment manuals